TROUBLESHOOTING

REPLACEMENT PART NUMBERS

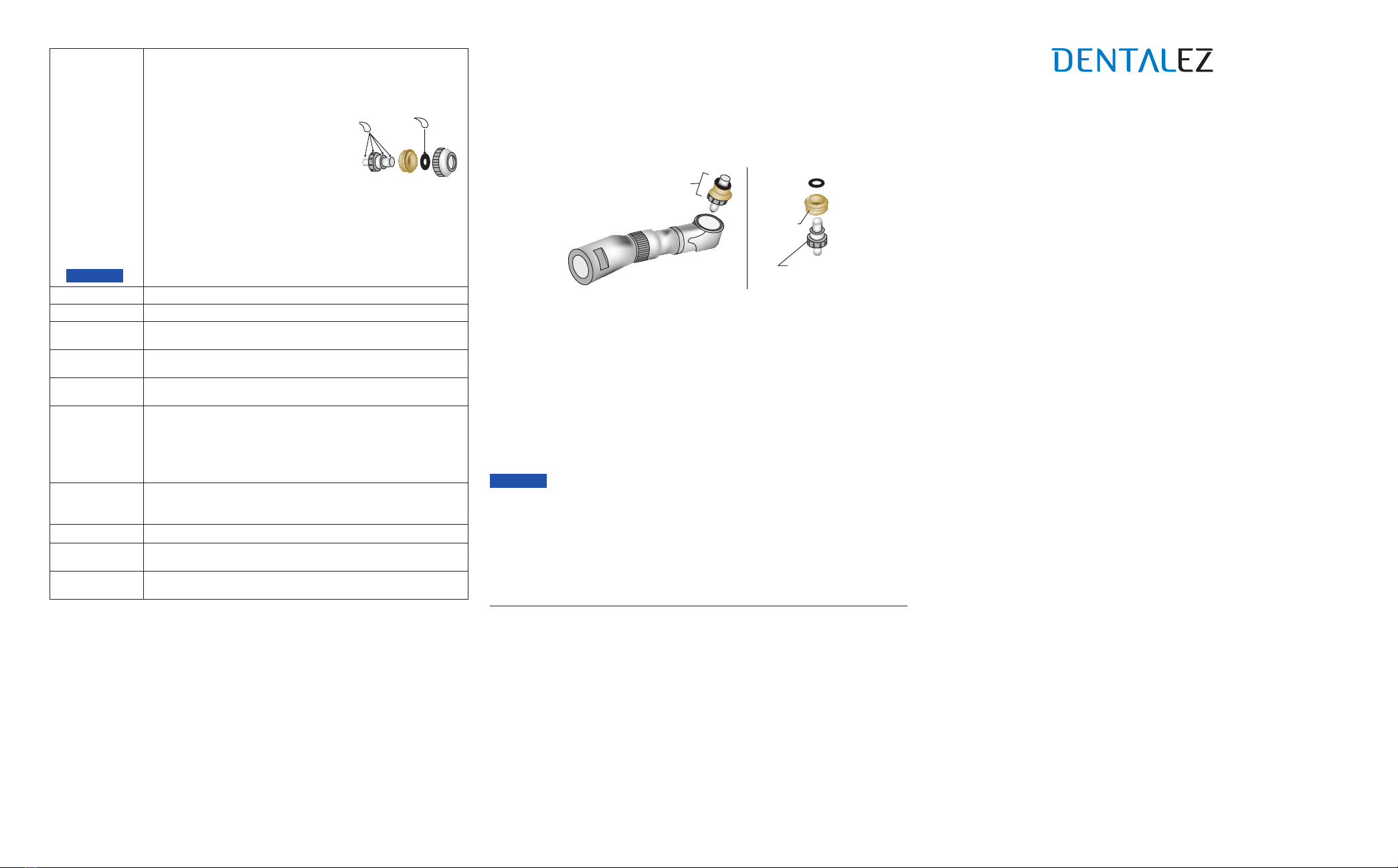

Titan 3 Five Star Prophy Angle Cartridge Lubricated ........................................... 258948

(Includes cartridge and bronze bushing with O-ring)

Transmission Gear Assembly Lubricated.............................................................. 259008

Prophy Angle End Caps (Package of 2) Lubricated .............................................. 265805

Screw-to-Button Adapter ....................................................................................... 258950

Angle Disconnect Wrench..................................................................................... 203048

O-Rings (Package of 3) ........................................................................................ 258951

DentaLube II ......................................................................................................... 262539

Titan 3 Motor-to-Angle Adapter ............................................................................. 264073

Titan T Motor-to-Angle Adapter ............................................................................. 263970

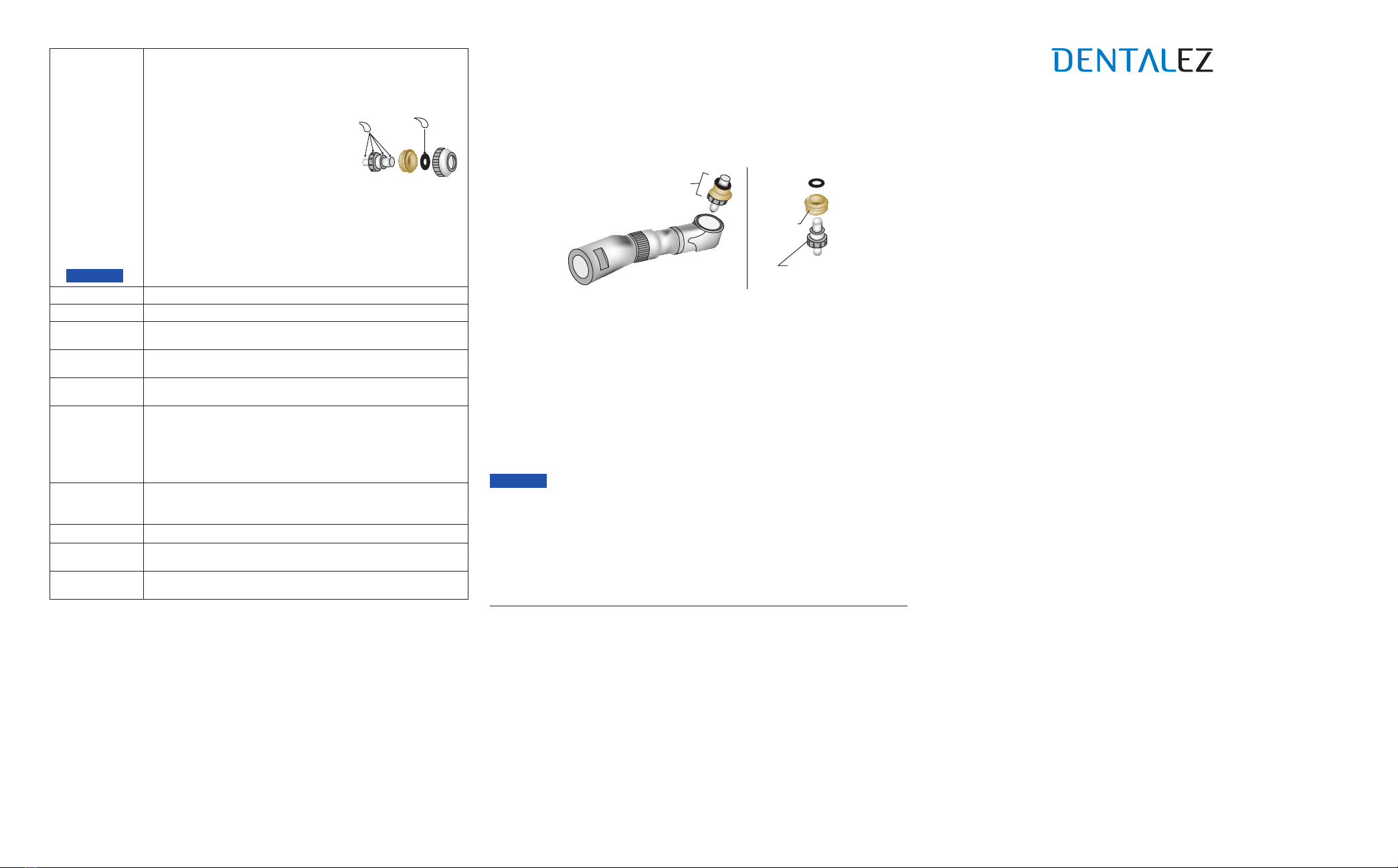

CARTRIDGE REPLACEMENT

CARTRIDGE

GEAR

ASSEMBLY

BRONZE

BUSHING

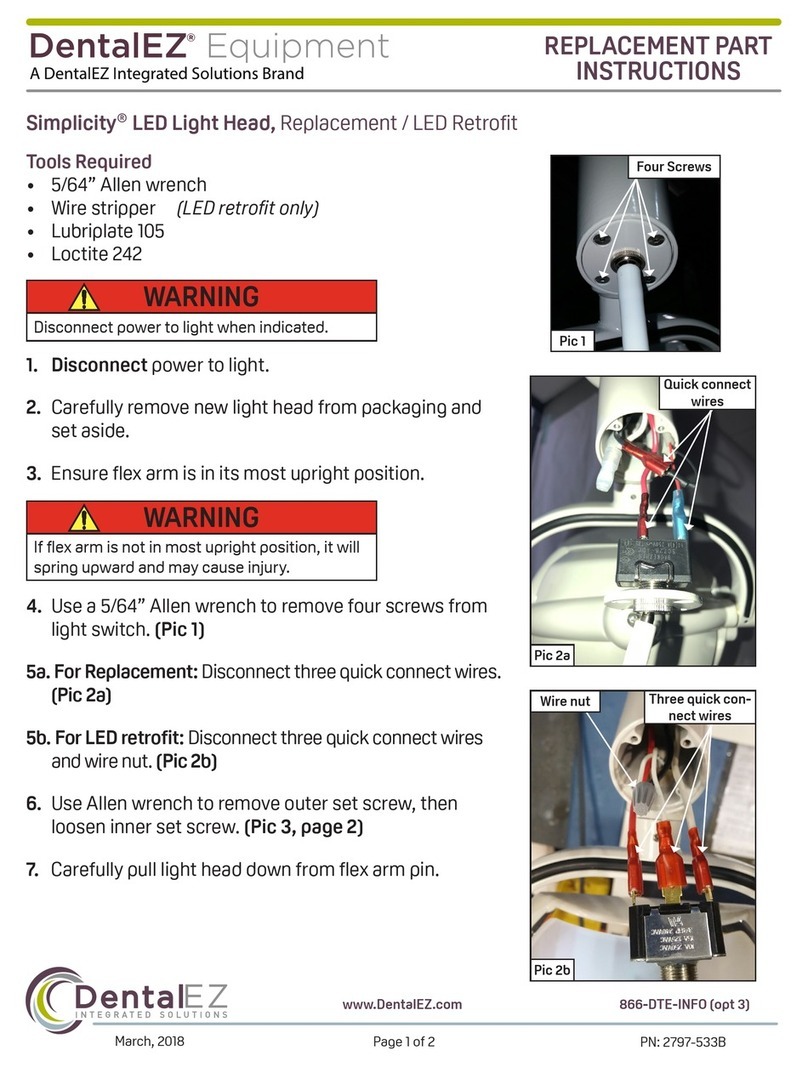

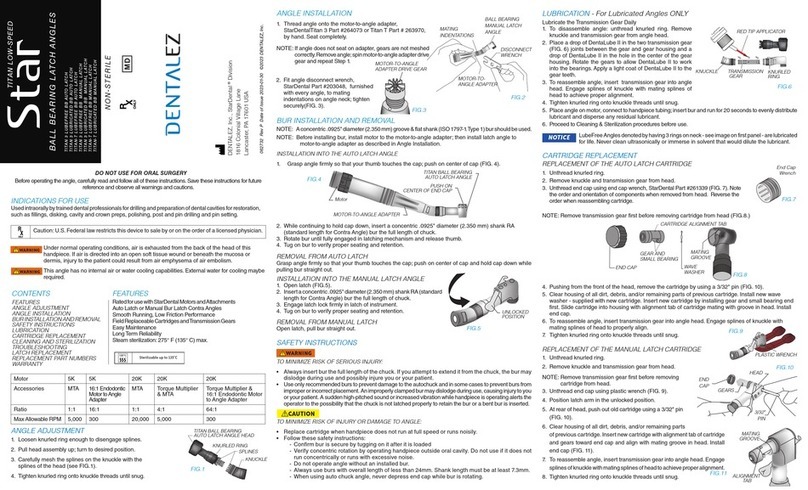

1. Remove the end cap using the plastic wrench to turn it clockwise. (See illustration

under Cleaning and Lubricating.)

Note: Do not use pliers on the bronze bushing.

2. Pull bronze bushing to remove cartridge from prophy head as shown below in (FIG.

10). If cartridge is not removable by hand, thread a prophy cup or a screw-to-button

adapter in the cartridge and tug on it.

3. Separate gear assembly from the bronze bushing by pulling apart as shown above.

4. If gears are worn, replace cartridge, Star Part #258948. If not, simply wipe clean

with a lint free cloth.

5. Wipe the inside of the housing with a lint free cloth or cotton swab, barely

dampened with solvent.

Note: Do not immerse head in solvent.

6. Guide the shaft of the gear assembly through the center of the bronze bushing.

Install the assembled cartridge into the angle housing.

7. Position end cap and turn counterclockwise. Hand tighten to secure. Use wrench to

fully seat – 30° maximum.

Do not overtighten as poor performance and damage to angle may result.

PROBLEM: LOW POWER

Cause: Air leak at motor

Correction: Replace gasket;

refer to Titan Motor Instruction Manual.

Cause: Debris build-up

Correction: Refer to Cleaning and Lubricating section.

Cause: Faulty angle

Correction: Replace cartridge.

Note: If a problem persists, contact dealer for further assistance;

or, contact Star technical service at: 1-866-DTE-INFO (1-866-383-4636)

ALWAYS INSIST ON STAR PARTS FOR BEST PERFORMANCE.

DESCRIPTION ITEM NUMBER

NOTICE

NOTICE

CLEANING

MANUAL

CONTINUED:

7. When prophy paste is consistently found in the cartridge, install a new

bronze bushing, or a new cartridge, Star Part #258948, which includes

the bronze bushing. Replacing the bronze bushing renews the seal and

protects the gear and bearing from abrasive paste.

8. Wipe the inside of the housing with a lint-free cloth or cotton swab.

Note: Do not immerse head in solvent.

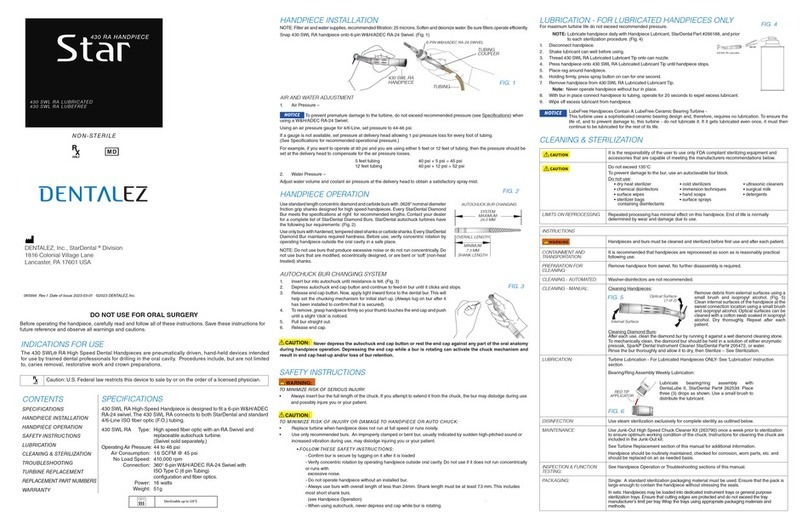

9. After cleaning, apply one drop of DentaLube II,

Star Part #262539, to the inside

diameter of the O-ring and to the gear as

shown. (See FIG. 9)

10. To reassemble, insert gear assembly into bronze bushing and guide

shaft through the hole in O-ring. Install cartridge into prophy head

angle.

11. Turn end cap counterclockwise and hand tighten to secure. Use

wrench to fully seat – 30° rotation maximum.

Do not overtighten as poor performance and damage to angle may result

LUBRICATION: Lubricate - See ‘Lubrication’ instruction section.

DISINFECTION: Use steam sterilization exclusively for complete sterility as outlined below.

MAINTENANCE: Angle should be routinely maintained, checked for corrosion, worn parts,

etc. and should be replaced on an as needed basis.

INSPECTION &

FUNCTION TESTING:

See Installation, Operating Recommendations, and/or Troubleshooting

sections of this manual.

PACKAGING: Single: A standard sterilization packaging material must be used. Ensure

that the pack is large enough to contain the item without stressing the seals.

WRAPPED

INSTRUMENT

STERILIZATION:

Gravity Type Autoclave: Pre-Vacuum

Autoclave:

• Minimum of 15 minutes at 132° C • Minimum of 4

minutes at 132° C

• Minimum of 30 minutes at 121° C

Do not exceed 135° C

DRYING: Dry the prophy angle for 30 minutes minimum using the sterilization dry

cycle and allow the prophy angle to cool to room temperature in bag prior to

use. If moisture is present, increase your sterilizer dry cycle appropriately.

STORAGE: Store in bag after sterilization until ready to use.

ADDITIONAL

INFORMATION:

Do not exceed the sterilizer manufacturer’s guidelines for load capacity. Use

only paper or paper/plastic bags.

MANUFACTURER

CONTACT:

See first or last panels of this manual.

FIG. 9 FIG. 10

LIMITED WARRANTY

O-Rings and Seals are specifically excluded from this warranty.

DENTALEZ warrants the Titan Lubricated Five Star Prophy Angle to be free of defects in material and

workmanship, under normal usage, under the following terms:

Star Products: Warranty Period*:

Lubricated Five Star Prophy Angle 3 Months from date of purchase

Please note the following additional terms of our warranty and return policy:

• Warranty covers manufacturing defects only and does not cover defects resulting from abuse,

accidents, misuse, improper handling, cleaning, care or maintenance or the failure to follow or

observe our operating/use, maintenance and/or installation instructions. Damage resulting from

the use of chemicals, cleaners, disinfectants or sterilization is not covered under this warranty

nor is normal wear and tear. Failure to use authorized parts or an authorized repair facility voids

this warranty.

• Liability is limited to repair or replacement of the defective part(s) or products at our sole discretion.

All other liabilities, in particular liability for damages, including, without limitation, special, exemplary,

consequential or incidental damages are excluded

• THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED,

INCLUDING ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. NO EMPLOYEE, REPRESENTATIVE OR DEALER IS AUTHORIZED

TO CHANGE THIS WARRANTY IN ANY WAY OR TO GRANT ANY OTHER WARRANTY.

*Provided conditions in warranty are met.

WARRANTY REGISTRATION

Please visit the website below to register your Star product.This will ensure proper registration and prompt

and accurate service should any of your purchases need evaluation or repair during the warranty period.

Star Products: WWW.DENTALEZ.com/warranty

FOR NEW PRODUCTS, MANUALS AND TECHNICAL INFORMATION, CALL

1-866-DTE-INFO OR VISIT OUR WEB SITE @ WWW.DENTALEZ.COM

IMPORTANT NOTICE ABOUT RETURNING PRODUCT TO DENTALEZ INC.

Anyone wishing to return any DENTALEZ Inc. product to a DENTALEZ facility MUST obtain the proper

RETURN AUTHORIZATION NUMBER from the Customer Service Department. The RA Number must

appear clearly marked on both the outside and inside of the returned product carton. When calling for

a return authorization number you will be asked to provide the following information:

To Obtain A

Return Authorization

Number Call

1-866-DTE-INFO

1. Product Name, Model Number or Part Number

2. Serial Number of Product

3. Dealer Return Purchase Order Number

4. Reason For Return

5. Copy of Invoice Showing Purchase

Items will be evaluated. Return Authorization Number is not a guarantee for credit. Your cooperation

with this procedure will help us expedite processing of any returns.