D+H KA 34-ACB User manual

KA 34-ACB / KA 54-ACB

99.828.64 1.3/05/20

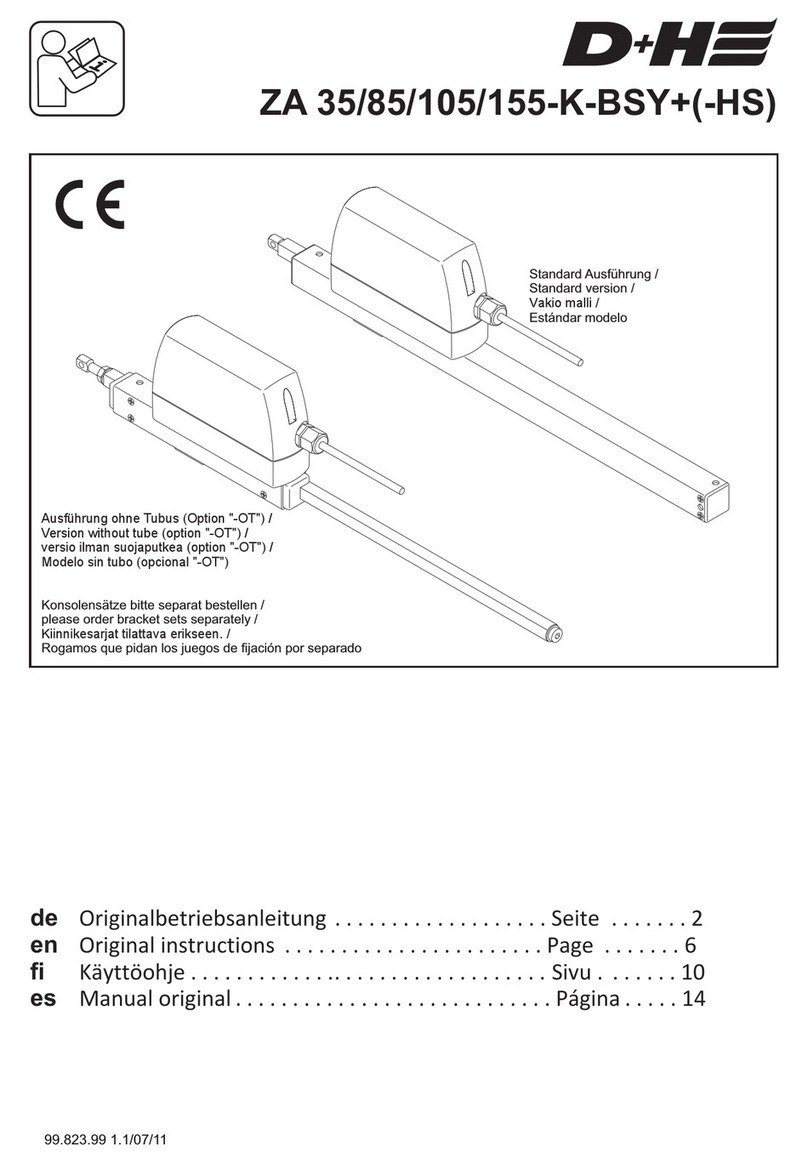

Standard version

Mirrored version (Option "-L")

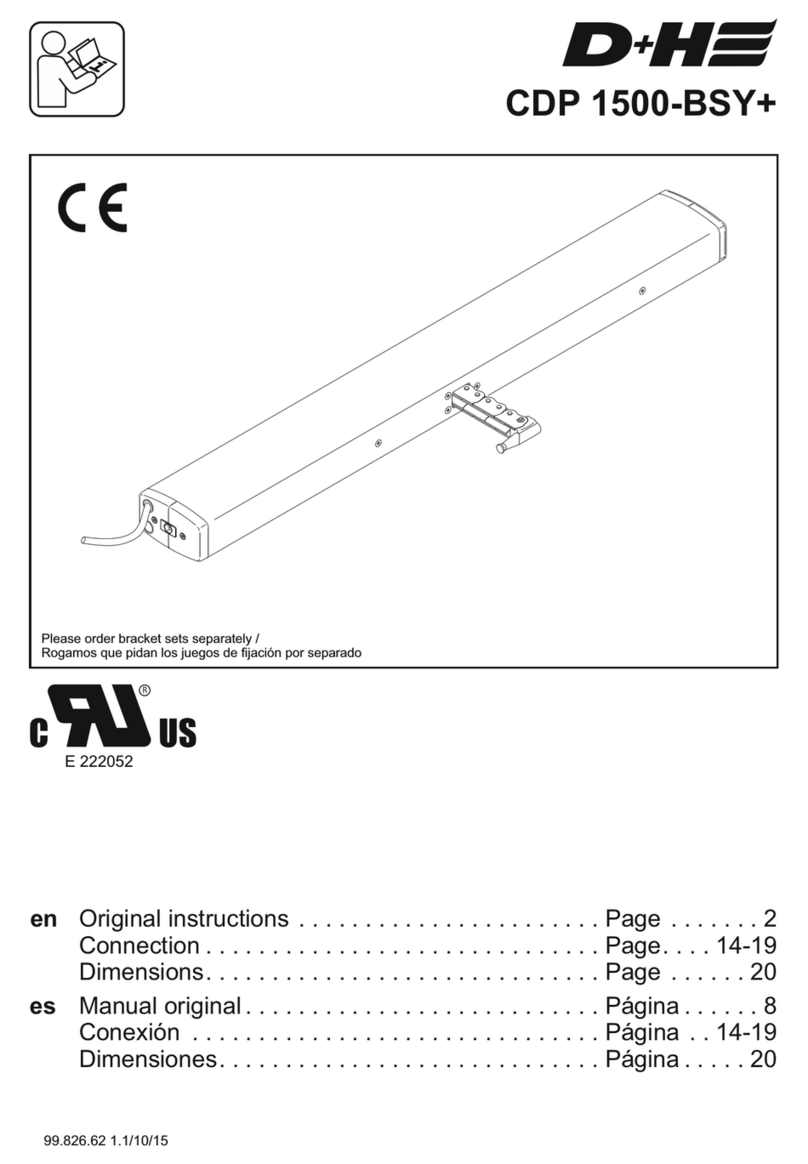

en Original instructions . . . . . . . . . . . . . . . . . . . . . . . Page . . . . . . . 2

Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page . . . . . . . 8

Please order bracket sets separately

Technical Data

2/12 KA 34-ACB / KA 54-ACB English English

Observe maximum pressure load of the chain!

Maximum pressure load of the chain is not

automatically identical with maximum pressure force

of the drive!

Pressure load diagram

KA 54-BSY+ KA 34-BSY+

100

200

300

400

500

600

700

800

500

400

300

200

100

0

max. Load (N)

Stroke / (mm)

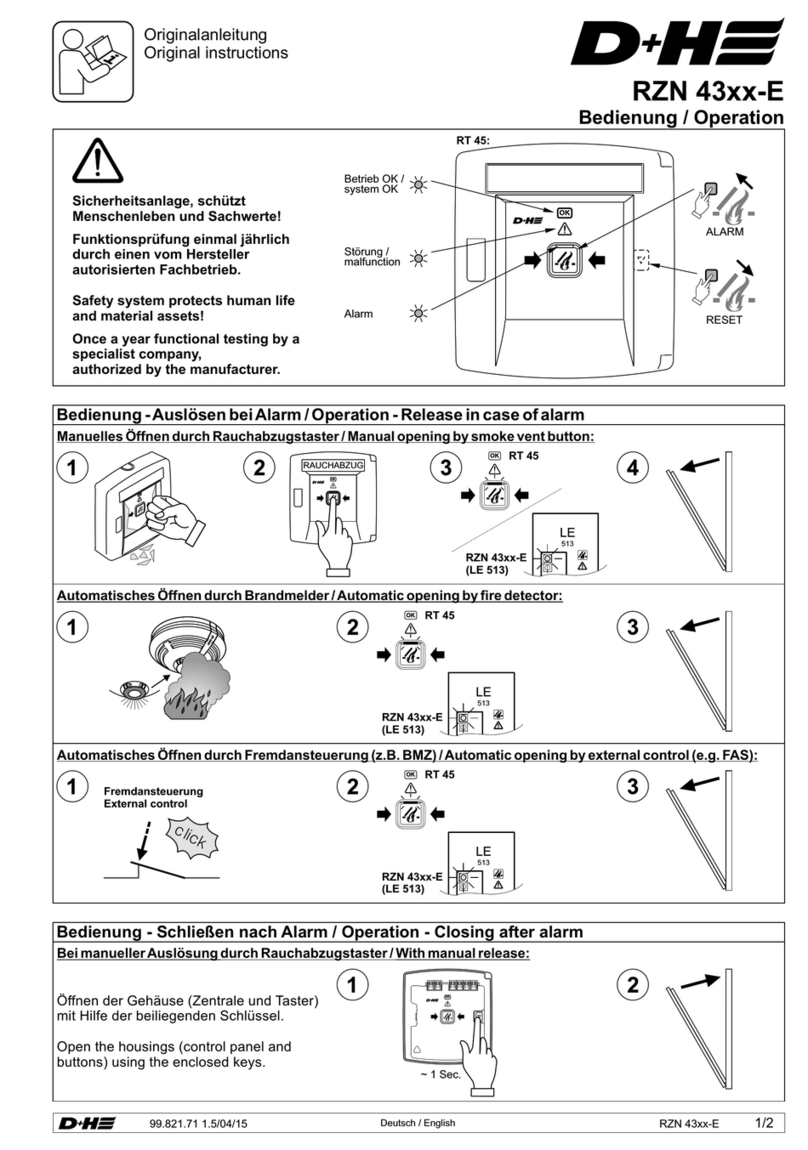

Safety notes

Safety extra low voltage 24 V DC!

Do not connect directly to the mains supply!

- Connection has to be carried out only by an

authorized electrical specialist

- Danger of violent pressure in handaccessible area

- Keep away people from the operating area of the

drive

- Keep away children from the control

- Observe pressure load diagram of the chain!

- Use only in dry rooms

- Only for inside mounting.

Use rain detector with danger of rain

(e.g. at domelights or roof windows)

- This product may not be operated without the

covering stoppers, which are delivered with

bracket sets

- Just use unchanged original D+H parts

- Observe mounting instructions of bracket set!

Observe enclosed r ed safety slip!

Performance features

- ACB (Advanced Communication Bus) bus interface

with ModBus protocol for the connection to

compatible D+H control panels or direct integration

into building management systems, for example

- Microprocessor controlled synchro electronics

BSY + for a precise synchronous run of up to

8 drives

- Individually programmable (via software SCS)

- SHEV-high speed function (fast-running

feature in OPEN-direction)

- Protection system for the main closing edge

- Locking relief after closing

Drive unit with 2,5 m silicone cable. Dependent on

the type of window, different bracket sets are

available separately.

Extent of supply

Intended use

- Chain drive for electric opening and closing of

windows and flaps in the facade and roof area

- Operating voltage 24 V DC stabilized

- Useable for smoke ventilation as well as daily

natural ventilation

- Only for inside mounting

WARNING

Read all safety warnings, instructions, illustrations

and specifications provided with this product.

Failure to follow all instructions listed below may

result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future

reference.

* Programmable with software SCS

Opening and Closing Ranges

Type

KA 34-ACB

Nominal current

1 A

Nominal stroke length*

600 mm, 800 mm

Nominal locking force

Service life

Duty cycle

Housing

Ingress protection

Temp. range

Fire stability

Ambient humidity

Emission sound pressure level

Additional functions*

approx. 2000 N

>20.000 double strokes

30 % (With cycle time 10 minutes)

Aluminium powdercoated (~ RAL 9006)

IP 32 th bracket sets)(With covering stoppers delivered wi

-5 ... +75 °C

30 min / 300 °C

≤ 90 %, not condensing

LpA 70 dB(A)≤

Closing edge protection = activated (3 repetitions of stroke);

Locking relief = activated (retraction lift max. 0,2 mm)

C3*

Nominal stroke -100 mm

300 N

7 mm/s

(16,1 mm/s)

O1*

C1* C2*

O2* O3*

23 mm

150 N

5 mm/s

(5 mm/s)

77 mm

150 N

5 mm/s

(5 mm/s)

23 mm

500 N

7 mm/s

(16,1 mm/s)

15 mm

500 N

7 mm/s

(16,1 mm/s)

Nominal stroke -38 mm

500 N

7 mm/s

(16,1 mm/s)

Range

Force

Speed

(SHEV high-speed)

KA 34-ACB / KA 54-ACB 3/12

99.828.64 1.3/05/2099.828.64 1.3/05/20

ACB bus interface

ACB is used for secure communication between the

drive and compatible D+H control systems. It

enables activation, diagnostics and configuration

with perfect position, directly from the control panel.

In this process, all status messages, such as the

OPEN and CLOSED signals, opening stroke and

drive errors, are transmitted to the control panel.

BSY+ synchronised electronics:

A synchronous group can contain up to 8 drives,

which communicate via bus. Each drive has its own

address, configurable with SCS.

The last drive of a synchronous group is the master,

which controls the other drives, the slaves.

Differences in forces between the drives of a group

are balanced by means of intelligent force and

position control. In the event that a drive

malfunctions, all the drives are automatically cut off.

Functional description

Technical Data

2/12 KA 34-ACB / KA 54-ACB English English

Observe maximum pressure load of the chain!

Maximum pressure load of the chain is not

automatically identical with maximum pressure force

of the drive!

Pressure load diagram

KA 54-BSY+ KA 34-BSY+

100

200

300

400

500

600

700

800

500

400

300

200

100

0

max. Load (N)

Stroke / (mm)

Safety notes

Safety extra low voltage 24 V DC!

Do not connect directly to the mains supply!

- Connection has to be carried out only by an

authorized electrical specialist

- Danger of violent pressure in handaccessible area

- Keep away people from the operating area of the

drive

- Keep away children from the control

- Observe pressure load diagram of the chain!

- Use only in dry rooms

- Only for inside mounting.

Use rain detector with danger of rain

(e.g. at domelights or roof windows)

- This product may not be operated without the

covering stoppers, which are delivered with

bracket sets

- Just use unchanged original D+H parts

- Observe mounting instructions of bracket set!

Observe enclosed r ed safety slip!

Performance features

- ACB (Advanced Communication Bus) bus interface

with ModBus protocol for the connection to

compatible D+H control panels or direct integration

into building management systems, for example

- Microprocessor controlled synchro electronics

BSY + for a precise synchronous run of up to

8 drives

- Individually programmable (via software SCS)

- SHEV-high speed function (fast-running

feature in OPEN-direction)

- Protection system for the main closing edge

- Locking relief after closing

Drive unit with 2,5 m silicone cable. Dependent on

the type of window, different bracket sets are

available separately.

Extent of supply

Intended use

- Chain drive for electric opening and closing of

windows and flaps in the facade and roof area

- Operating voltage 24 V DC stabilized

- Useable for smoke ventilation as well as daily

natural ventilation

- Only for inside mounting

WARNING

Read all safety warnings, instructions, illustrations

and specifications provided with this product.

Failure to follow all instructions listed below may

result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future

reference.

* Programmable with software SCS

Opening and Closing Ranges

Type

KA 34-ACB

Nominal current

1 A

Nominal stroke length*

600 mm, 800 mm

Nominal locking force

Service life

Duty cycle

Housing

Ingress protection

Temp. range

Fire stability

Ambient humidity

Emission sound pressure level

Additional functions*

approx. 2000 N

>20.000 double strokes

30 % (With cycle time 10 minutes)

Aluminium powdercoated (~ RAL 9006)

IP 32 th bracket sets)(With covering stoppers delivered wi

-5 ... +75 °C

30 min / 300 °C

≤ 90 %, not condensing

LpA 70 dB(A)≤

Closing edge protection = activated (3 repetitions of stroke);

Locking relief = activated (retraction lift max. 0,2 mm)

C3*

Nominal stroke -100 mm

300 N

7 mm/s

(16,1 mm/s)

O1*

C1* C2*

O2* O3*

23 mm

150 N

5 mm/s

(5 mm/s)

77 mm

150 N

5 mm/s

(5 mm/s)

23 mm

500 N

7 mm/s

(16,1 mm/s)

15 mm

500 N

7 mm/s

(16,1 mm/s)

Nominal stroke -38 mm

500 N

7 mm/s

(16,1 mm/s)

Range

Force

Speed

(SHEV high-speed)

KA 34-ACB / KA 54-ACB 3/12

99.828.64 1.3/05/2099.828.64 1.3/05/20

ACB bus interface

ACB is used for secure communication between the

drive and compatible D+H control systems. It

enables activation, diagnostics and configuration

with perfect position, directly from the control panel.

In this process, all status messages, such as the

OPEN and CLOSED signals, opening stroke and

drive errors, are transmitted to the control panel.

BSY+ synchronised electronics:

A synchronous group can contain up to 8 drives,

which communicate via bus. Each drive has its own

address, configurable with SCS.

The last drive of a synchronous group is the master,

which controls the other drives, the slaves.

Differences in forces between the drives of a group

are balanced by means of intelligent force and

position control. In the event that a drive

malfunctions, all the drives are automatically cut off.

Functional description

4/12

5/12

English English

Technical Data

* Programmable with software SCS

Opening and Closing Ranges

Type

KA 54-ACB HP800 / SB III

Nominal current

1,8 A

Nominal stroke length*

1200 mm

Nominal locking force

Service life

Duty cycle

Housing

Ingress protection

Temp. range

Fire stability

Ambient humidity

Emission sound pressure level

Additional functions*

approx. 2000 N

>10.000 double strokes

30 % (With cycle time 10 minutes)

Aluminium powdercoated (~ RAL 9006)

IP 32 (With covering stoppers delivered with bracket sets)

-5 ... +75 °C

30 min / 300 °C

≤ 90 %, not condensing

LpA 70 dB(A)≤

Closing edge protection = activated (3 repetitions of stroke);

Locking relief = activated (retraction lift max. 0,2 mm)

C3*

Nominal stroke -100 mm

800 N

7 mm/s

(17,2 mm/s)

O1*

C1* C2*

O2* O3*

23 mm

150 N

5 mm/s

(5 mm/s)

77 mm

150 N

5 mm/s

(5 mm/s)

23 mm

500 N

7 mm/s

(17,2 mm/s)

15 mm

500 N

7 mm/s

(17,2 mm/s)

Nominal stroke -38 mm

500 N

7 mm/s

(17,2 mm/s)

Range

Force

Speed

(SHEV high-speed)

Technical Data

* Programmable with software SCS

Opening and Closing Ranges

Type

KA 54-ACB

Nominal current

1,4 A

Nominal stroke length*

800 mm, 1100 mm, 1200 mm

Nominal locking force

Service life

Duty cycle

Housing

Ingress protection

Temp. range

Fire stability

Ambient humidity

Emission sound pressure level

Additional functions*

approx. 2000 N

>20.000 double strokes

30 % me 10 minutes)(With cycle ti

Aluminium powdercoated (~ RAL 9006)

IP 32 (With covering stoppers delivered with bracket sets)

-5 ... +75 °C

30 min / 300 °C

≤ 90 %, not condensing

LpA 70 dB(A)≤

Closing edge protection = activated (3 repetitions of stroke);

Locking relief = activated (retraction lift max. 0,2 mm)

C3*

Nominal stroke -100 mm

500 N

7 mm/s

(17,2 mm/s)

O1*

C1* C2*

O2* O3*

23 mm

150 N

5 mm/s

(5 mm/s)

77 mm

150 N

5 mm/s

(5 mm/s)

23 mm

500 N

7 mm/s

(17,2 mm/s)

15 mm

500 N

7 mm/s

(17,2 mm/s)

Nominal stroke -38 mm

500 N

7 mm/s

(17,2 mm/s)

Range

Force

Speed

(SHEV high-speed)

KA 34-ACB / KA 54-ACB KA 34-ACB / KA 54-ACB

99.828.64 1.3/05/2099.828.64 1.3/05/20

4/12

5/12

English English

Technical Data

* Programmable with software SCS

Opening and Closing Ranges

Type

KA 54-ACB HP800 / SB III

Nominal current

1,8 A

Nominal stroke length*

1200 mm

Nominal locking force

Service life

Duty cycle

Housing

Ingress protection

Temp. range

Fire stability

Ambient humidity

Emission sound pressure level

Additional functions*

approx. 2000 N

>10.000 double strokes

30 % (With cycle time 10 minutes)

Aluminium powdercoated (~ RAL 9006)

IP 32 (With covering stoppers delivered with bracket sets)

-5 ... +75 °C

30 min / 300 °C

≤ 90 %, not condensing

LpA 70 dB(A)≤

Closing edge protection = activated (3 repetitions of stroke);

Locking relief = activated (retraction lift max. 0,2 mm)

C3*

Nominal stroke -100 mm

800 N

7 mm/s

(17,2 mm/s)

O1*

C1* C2*

O2* O3*

23 mm

150 N

5 mm/s

(5 mm/s)

77 mm

150 N

5 mm/s

(5 mm/s)

23 mm

500 N

7 mm/s

(17,2 mm/s)

15 mm

500 N

7 mm/s

(17,2 mm/s)

Nominal stroke -38 mm

500 N

7 mm/s

(17,2 mm/s)

Range

Force

Speed

(SHEV high-speed)

Technical Data

* Programmable with software SCS

Opening and Closing Ranges

Type

KA 54-ACB

Nominal current

1,4 A

Nominal stroke length*

800 mm, 1100 mm, 1200 mm

Nominal locking force

Service life

Duty cycle

Housing

Ingress protection

Temp. range

Fire stability

Ambient humidity

Emission sound pressure level

Additional functions*

approx. 2000 N

>20.000 double strokes

30 % me 10 minutes)(With cycle ti

Aluminium powdercoated (~ RAL 9006)

IP 32 (With covering stoppers delivered with bracket sets)

-5 ... +75 °C

30 min / 300 °C

≤ 90 %, not condensing

LpA 70 dB(A)≤

Closing edge protection = activated (3 repetitions of stroke);

Locking relief = activated (retraction lift max. 0,2 mm)

C3*

Nominal stroke -100 mm

500 N

7 mm/s

(17,2 mm/s)

O1*

C1* C2*

O2* O3*

23 mm

150 N

5 mm/s

(5 mm/s)

77 mm

150 N

5 mm/s

(5 mm/s)

23 mm

500 N

7 mm/s

(17,2 mm/s)

15 mm

500 N

7 mm/s

(17,2 mm/s)

Nominal stroke -38 mm

500 N

7 mm/s

(17,2 mm/s)

Range

Force

Speed

(SHEV high-speed)

KA 34-ACB / KA 54-ACB KA 34-ACB / KA 54-ACB

99.828.64 1.3/05/2099.828.64 1.3/05/20

6/12 English

Shift of drive cable

The drive will be full configured by factory.

The drives must be reconfigured in case of

alterations (e.g. removing of drives

from existing set or integrating

a new drive) with SCS.

If after mounting the measure x is as bigger as

23 mm, null balance with software SCS is neccesary.

Closure Ranges will shift in relation to new zero

point.

Mount the drives mechanical stress-free.

With that, a better load distribution

is ensured on all the drives.

At vertical active pulling application (e.g. for a

skylight) the forces must be rearranged by software

SCS

Slave 1

Mounting informations

≥ 23 mm ?

X

Main closing edge

Beside closing edge

Beside

closing edge

Closing edge protection

In the "CLOSE" direction the drive has an active

protection for the main closing edge. If there is an

overload in the closing range 3 and 2, the drive runs

"OPEN" for 10 seconds, then "CLOSE" again. If after

three attempts closing is not possible, the drive

remains in this position.

In addition, the drive is equipped with passive

protection. The closing speed in closing range 2 and

1 is reduced to 5 mm/s.

Significantly greater forces can be

exerted at the secondary closing

edges. Danger of crushing hands and

fingers!

7/12

English

99.828.64 1.3/05/2099.828.64 1.3/05/20

Electrical devices, accessories, batteries and packa-

ging should be sorted for environmental-friendly

recycling. Do not dispose electrical devices and

batteries into household waste!

Only for EC countries:

According the European Guideline 2012/19/EU for

waste electrical and electronic equipment and its

implementation into national right, electrcal devices

that are no longer usable must be collected separa-

tely and disposed of in an environmentally correct

manner.

DisposalDeclaration of Conformity

We declare under our sole responsibility that the

product described under “Technical Data” is in

conformity with the following directives:

2014/30/EU, 2014/35/EU

Technical file at:

D+H Mechatronic AG, D-22949 Ammersbek

Dirk Dingfelder Maik Schmees

Member of the Board Authorized signatory, Technical Director

18.05.2020

Maintenance and cleaning

Maintenance work is only allowed when the device is in

a de-energized condition! Inspection and maintenance

has to be carried out according to D+H maintenance

notes. Only original D+H spare parts may be used.

Repair is to be carried out exclusively by D+H.

Wipe away debris or contamination with a dry, soft

cloth.

Do not use cleaning agents or solvents.

Guarantee

You will get 2 years guarantee for all D+H products

from date of verified handing over of the system up to

maximal 3 years after date of delivery, when

mounting and starting has been carried out by an

authorized D+H-distributor.

D+H guarantee is expired, with connection of D+H

components with external systems or with mixing of

D+H products with parts of other manufacturers.

Visual inspection:

Only one master drive is allowed.

The master always has the last address of all the

drives; this can be found on a sticker attached to

the drive. Slaves are numbered downwards from

the master, so that in a group of three drives, for

example, the master is no. 3, with a slave 2 and

slave 1 drive. Please note that this only applies in

the ex-factory configuration. As soon as the drives

are reconfigured with SCS, the ex-factory

addressing no longer applies.

Wiring:

Is the drive or drive group wired properly?

See connection plans.

Diagnostics with SCS software:

The SCS software and a BSY+ interface is

required for further troubleshooting or

configuration.

Troubleshooting

KA 34-ACB / KA 54-ACB KA 34-ACB / KA 54-ACB

6/12 English

Shift of drive cable

The drive will be full configured by factory.

The drives must be reconfigured in case of

alterations (e.g. removing of drives

from existing set or integrating

a new drive) with SCS.

If after mounting the measure x is as bigger as

23 mm, null balance with software SCS is neccesary.

Closure Ranges will shift in relation to new zero

point.

Mount the drives mechanical stress-free.

With that, a better load distribution

is ensured on all the drives.

At vertical active pulling application (e.g. for a

skylight) the forces must be rearranged by software

SCS

Slave 1

Mounting informations

≥ 23 mm ?

X

Main closing edge

Beside closing edge

Beside

closing edge

Closing edge protection

In the "CLOSE" direction the drive has an active

protection for the main closing edge. If there is an

overload in the closing range 3 and 2, the drive runs

"OPEN" for 10 seconds, then "CLOSE" again. If after

three attempts closing is not possible, the drive

remains in this position.

In addition, the drive is equipped with passive

protection. The closing speed in closing range 2 and

1 is reduced to 5 mm/s.

Significantly greater forces can be

exerted at the secondary closing

edges. Danger of crushing hands and

fingers!

7/12

English

99.828.64 1.3/05/2099.828.64 1.3/05/20

Electrical devices, accessories, batteries and packa-

ging should be sorted for environmental-friendly

recycling. Do not dispose electrical devices and

batteries into household waste!

Only for EC countries:

According the European Guideline 2012/19/EU for

waste electrical and electronic equipment and its

implementation into national right, electrcal devices

that are no longer usable must be collected separa-

tely and disposed of in an environmentally correct

manner.

DisposalDeclaration of Conformity

We declare under our sole responsibility that the

product described under “Technical Data” is in

conformity with the following directives:

2014/30/EU, 2014/35/EU

Technical file at:

D+H Mechatronic AG, D-22949 Ammersbek

Dirk Dingfelder Maik Schmees

Member of the Board Authorized signatory, Technical Director

18.05.2020

Maintenance and cleaning

Maintenance work is only allowed when the device is in

a de-energized condition! Inspection and maintenance

has to be carried out according to D+H maintenance

notes. Only original D+H spare parts may be used.

Repair is to be carried out exclusively by D+H.

Wipe away debris or contamination with a dry, soft

cloth.

Do not use cleaning agents or solvents.

Guarantee

You will get 2 years guarantee for all D+H products

from date of verified handing over of the system up to

maximal 3 years after date of delivery, when

mounting and starting has been carried out by an

authorized D+H-distributor.

D+H guarantee is expired, with connection of D+H

components with external systems or with mixing of

D+H products with parts of other manufacturers.

Visual inspection:

Only one master drive is allowed.

The master always has the last address of all the

drives; this can be found on a sticker attached to

the drive. Slaves are numbered downwards from

the master, so that in a group of three drives, for

example, the master is no. 3, with a slave 2 and

slave 1 drive. Please note that this only applies in

the ex-factory configuration. As soon as the drives

are reconfigured with SCS, the ex-factory

addressing no longer applies.

Wiring:

Is the drive or drive group wired properly?

See connection plans.

Diagnostics with SCS software:

The SCS software and a BSY+ interface is

required for further troubleshooting or

configuration.

Troubleshooting

KA 34-ACB / KA 54-ACB KA 34-ACB / KA 54-ACB

8/12 English 9/12

English

(4)

Abzweigdose / Junction box /

Boîte de dérivation / Caja de conexión

BSY+

Master BSY+

Slave (s)

(1)

110 Ω

2 or 3 drives star-shaped

Group

Mot.a

ACB.a

Mot.b

ACB.b

CPS-M (AM)

(1)/(2)

110 Ω

(GN)

BSY+.b

(YE)

BSY+.a

(GY)

ACB.b

(OG)

ACB.a

(BN)Mot. b

(WH)Mot. a

KA-ACB

(GN)

BSY+.b

(YE)

BSY+.a

(GY)

ACB.b

(OG)

ACB.a

(BN)Mot. b

(WH)Mot. a

KA-ACB

(GN)

BSY+.b

(YE)

BSY+.a

ACB.b

ACB.a

(BN)Mot. b

(WH)Mot. a

KA-ACB

(GN)

BSY+.b

(YE)

BSY+.a

(GY)

ACB.b

(OG)

ACB.a

(BN)Mot. b

(WH)Mot. a

KA-ACB

BSY+

Slave 1

(4)

Abzweigdose / Junction box /

Boîte de dérivation / Caja de conexión

BSY+

Master 2

(1)

110 Ω

(3)

Group

Mot.a

ACB.a

Mot.b

ACB.b

CPS-M (AM)

(1)/(2)

110 Ω

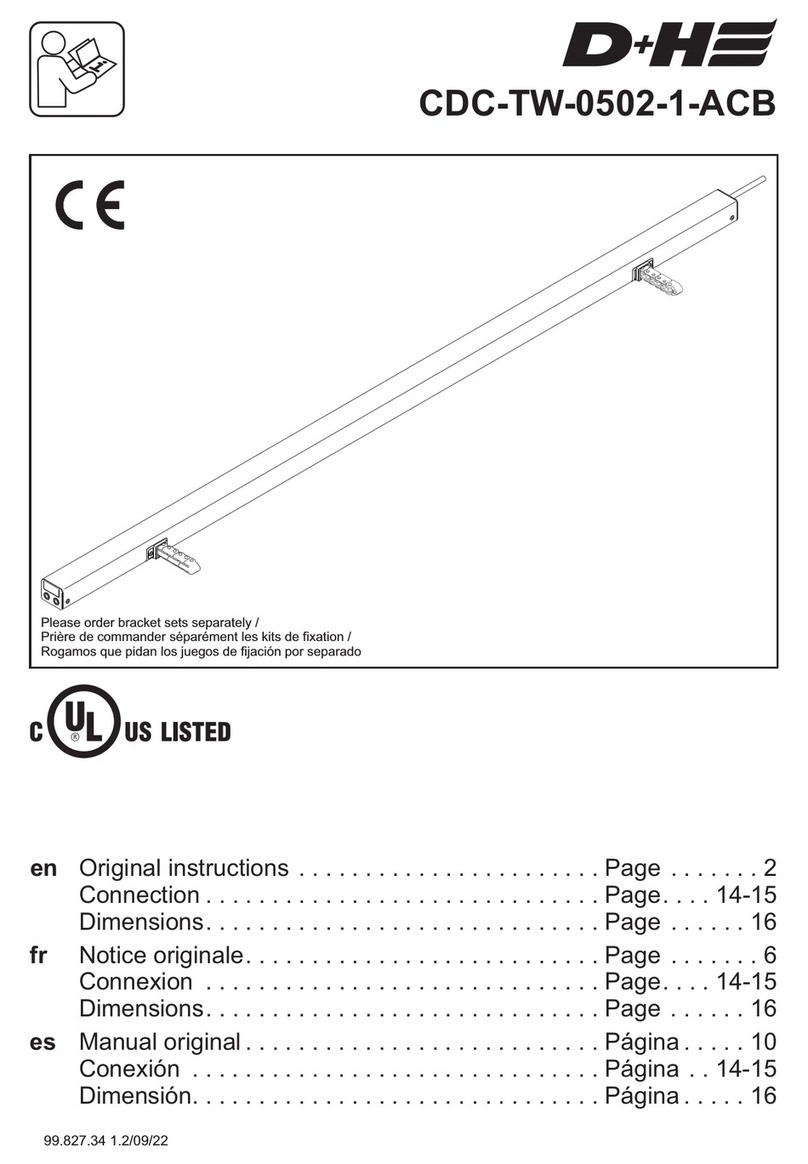

Connection

Pin Assignment

Connection

BN (Mot. b)

OG (ACB.a)

GY (ACB.b)

GN (BSY+.b)

YE (BSY+.a)

WH (Mot. a)

Notes

(1) Termination:

The ACB segment must be terminated with 2 resistors (110 Ω).

The resistors must in each case be connected at the end of the cable.

(2) Integrated resistor

(3) Protect wire against short circuit

(4) Cable according to D+H table for layout of cables (See instructions for use of control panel)

(WH) weiss / white / blanc / blanco

(BN) braun / brown / brun / marrón

(OG) orange / orange / orange / naranja

(YE) gelb / yellow / jaune / amarillo

(GN) grün / green / vert / verde

(PK) rosa / pink / rose / rosa

(GY) grau / grey / gris / gris

2 up to max. 3 drives looped through

KA 34-ACB / KA 54-ACB KA 34-ACB / KA 54-ACB

99.828.64 1.3/05/2099.828.64 1.3/05/20

8/12 English 9/12

English

(4)

Abzweigdose / Junction box /

Boîte de dérivation / Caja de conexión

BSY+

Master BSY+

Slave (s)

(1)

110 Ω

2 or 3 drives star-shaped

Group

Mot.a

ACB.a

Mot.b

ACB.b

CPS-M (AM)

(1)/(2)

110 Ω

(GN)

BSY+.b

(YE)

BSY+.a

(GY)

ACB.b

(OG)

ACB.a

(BN)Mot. b

(WH)Mot. a

KA-ACB

(GN)

BSY+.b

(YE)

BSY+.a

(GY)

ACB.b

(OG)

ACB.a

(BN)Mot. b

(WH)Mot. a

KA-ACB

(GN)

BSY+.b

(YE)

BSY+.a

ACB.b

ACB.a

(BN)Mot. b

(WH)Mot. a

KA-ACB

(GN)

BSY+.b

(YE)

BSY+.a

(GY)

ACB.b

(OG)

ACB.a

(BN)Mot. b

(WH)Mot. a

KA-ACB

BSY+

Slave 1

(4)

Abzweigdose / Junction box /

Boîte de dérivation / Caja de conexión

BSY+

Master 2

(1)

110 Ω

(3)

Group

Mot.a

ACB.a

Mot.b

ACB.b

CPS-M (AM)

(1)/(2)

110 Ω

Connection

Pin Assignment

Connection

BN (Mot. b)

OG (ACB.a)

GY (ACB.b)

GN (BSY+.b)

YE (BSY+.a)

WH (Mot. a)

Notes

(1) Termination:

The ACB segment must be terminated with 2 resistors (110 Ω).

The resistors must in each case be connected at the end of the cable.

(2) Integrated resistor

(3) Protect wire against short circuit

(4) Cable according to D+H table for layout of cables (See instructions for use of control panel)

(WH) weiss / white / blanc / blanco

(BN) braun / brown / brun / marrón

(OG) orange / orange / orange / naranja

(YE) gelb / yellow / jaune / amarillo

(GN) grün / green / vert / verde

(PK) rosa / pink / rose / rosa

(GY) grau / grey / gris / gris

2 up to max. 3 drives looped through

KA 34-ACB / KA 54-ACB KA 34-ACB / KA 54-ACB

99.828.64 1.3/05/2099.828.64 1.3/05/20

10/12 English 11/12

English

KA 34-ACB / KA 54-ACB KA 34-ACB / KA 54-ACB

99.828.64 1.3/05/2099.828.64 1.3/05/20

Connection

Master

Master

Slave

5 cm 1,5 cm

Master Slave

2 3

4

1

8

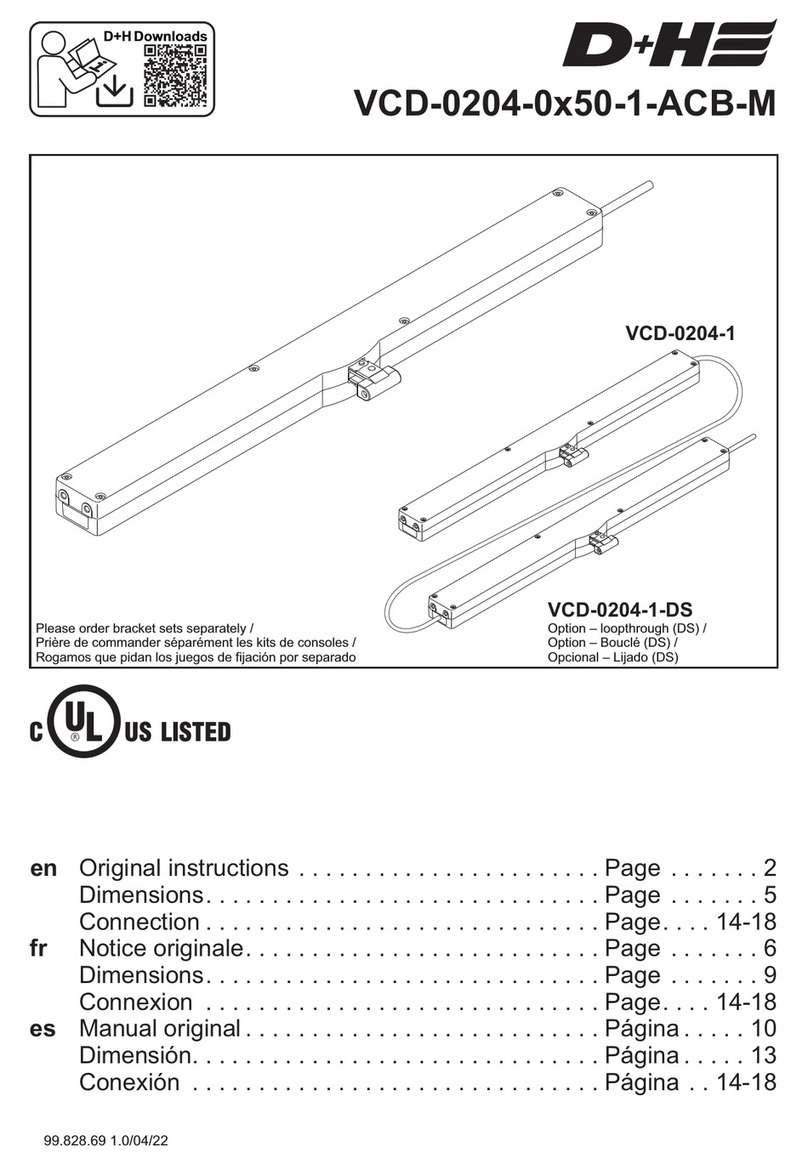

350

500

600

700

800

1000

1100

1200

1300

247,5

322,5

372,5

422,5

472,5

576,5

628,5

678,5

728,5

A B

421

496

546

596

646

750

802

852

902

H

Dimensions

B

173,5 mm A

40 mm

51 mm

H

10/12 English 11/12

English

KA 34-ACB / KA 54-ACB KA 34-ACB / KA 54-ACB

99.828.64 1.3/05/2099.828.64 1.3/05/20

Connection

Master

Master

Slave

5 cm 1,5 cm

Master Slave

2 3

4

1

8

350

500

600

700

800

1000

1100

1200

1300

247,5

322,5

372,5

422,5

472,5

576,5

628,5

678,5

728,5

A B

421

496

546

596

646

750

802

852

902

H

Dimensions

B

173,5 mm A

40 mm

51 mm

H

D+H Mechatronic AG

Georg-Sasse-Str. 28-32

22949 Ammersbek, Germany

Tel.: +4940-605 65 239

Fax: +4940-605 65 254

E-Mail: [email protected]

www.dh-partner.com

© 2020 D+H Mechatronic AG, Ammersbek

Rights to technical modifications reserved

100 % Recycled paper 99.828.64 1.3/05/20

This manual suits for next models

2

Table of contents

Other D+H Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Zimmer

Zimmer PowerStop PHE16X10LSAK-A Installation and operating instructions

Opex

Opex Falcon+ Operator's manual

Hardinge

Hardinge FlexC Low Profile Dead-Length Collet System Style... Installation instructions and parts list

Axminster Trade

Axminster Trade AT50LP Ultimate Edge Original instructions

Innova

Innova XTIRPA IN-8020 Instruction and safety manual

Kval

Kval ON-3V Service manual