3709773 (A3-D-P) 4 / 5

PSS® AirBoss Agile

Self-contained breathing apparatus Instructions for use

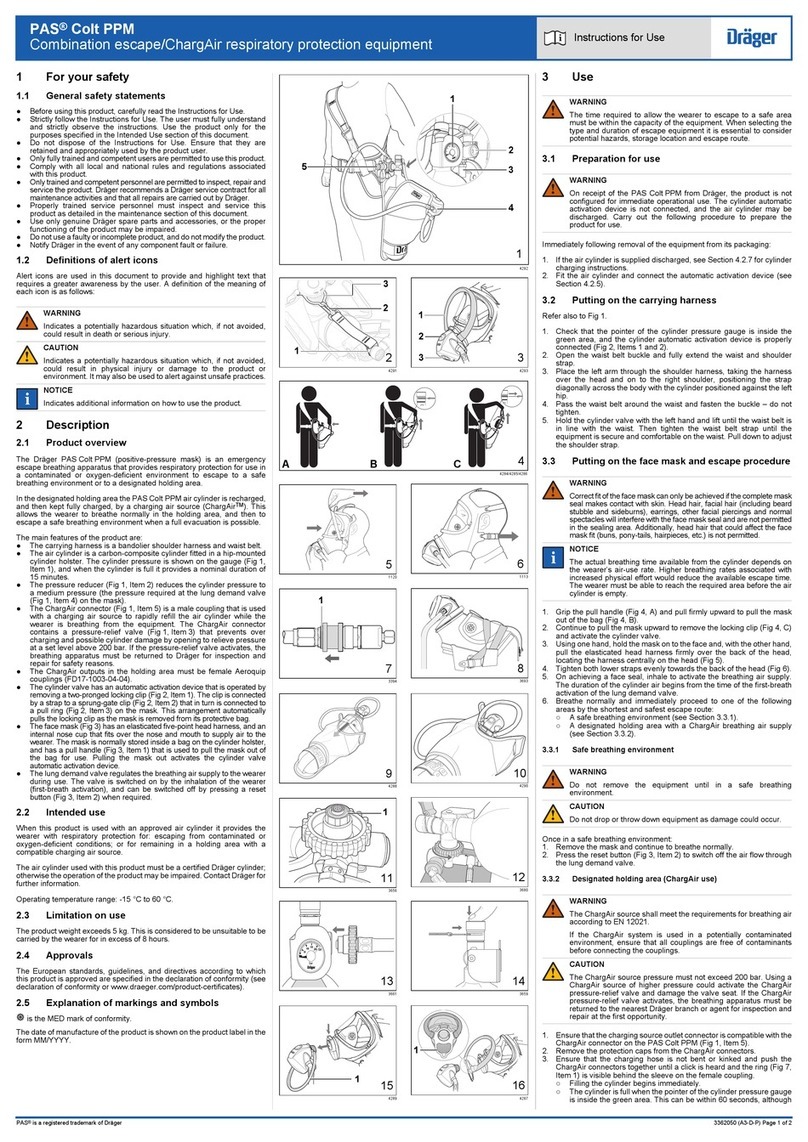

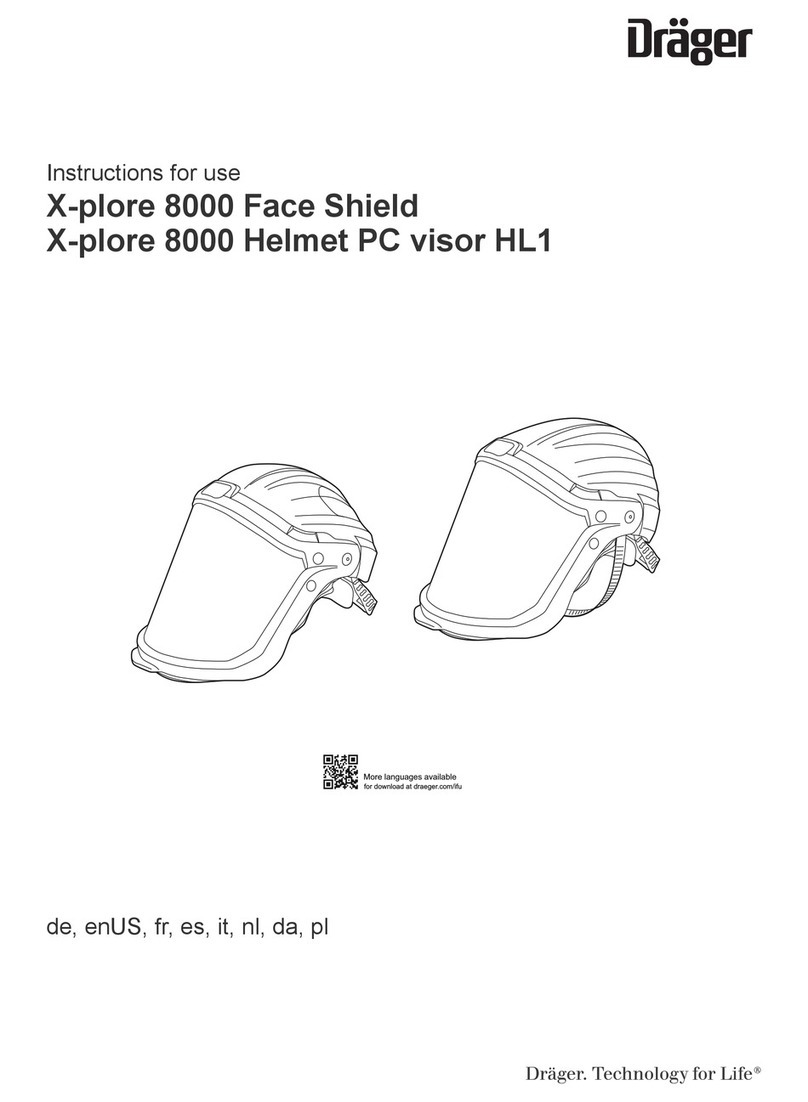

4.4.7.7 Adjusting the single cylinder strap

1. Fit the cylinder but do not close the cam lever (see section 4.4.7.1).

2. Move the adjuster buckle (Fig 32, Item 1) so that the stitching is:

– Below the centre bar of the adjuster buckle (A, single cylinder

strap).

– Above the centre bar of the adjuster buckle (B, twin cylinder strap

configured for use with a single cylinder).

3. Close the cam lever, and check that the cylinder is secure.

4. If the cylinder is not secure, release the cam lever and move the

adjuster buckle to adjust cylinder strap tension.

– Move the adjuster buckle toward the cam lever to loosen the strap.

– Move the adjuster buckle away from the cam lever to tighten the

strap.

5. Continue to test and adjust until the cylinder is secure.

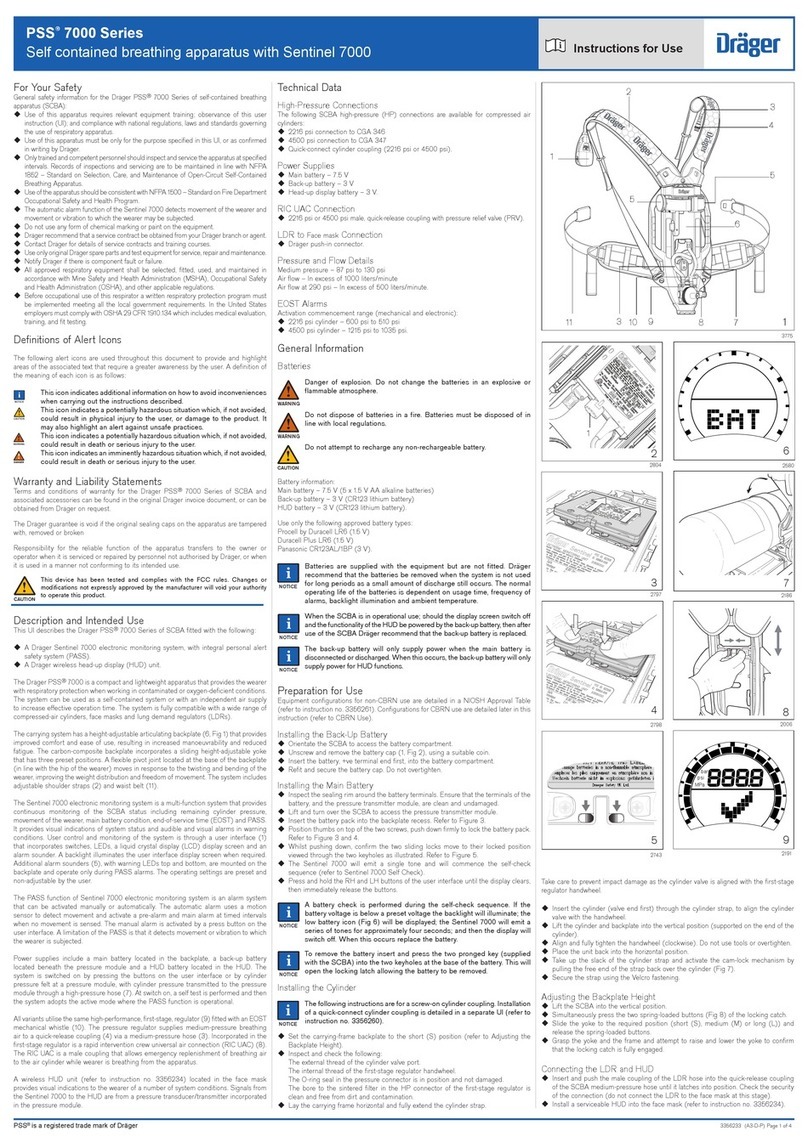

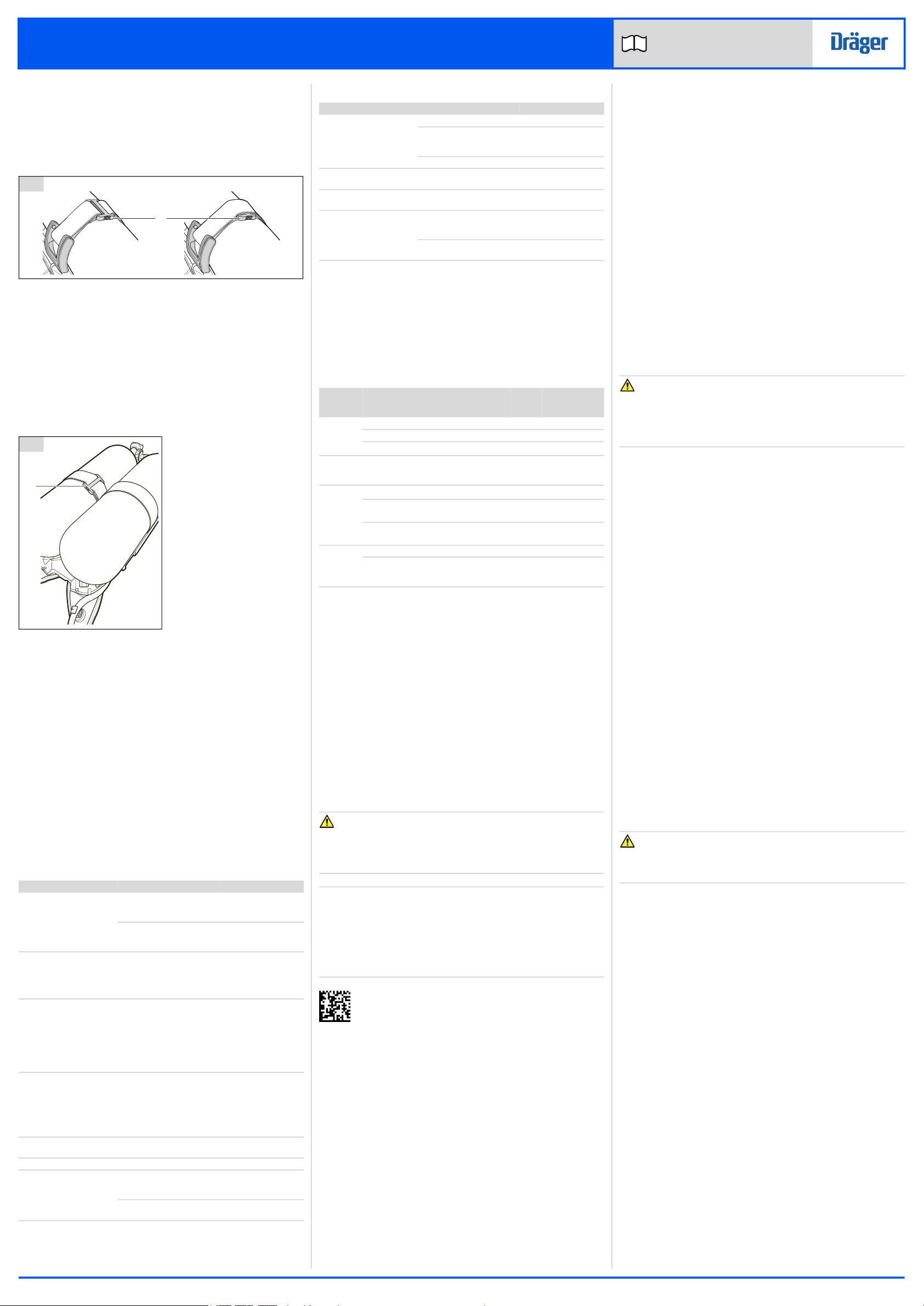

4.4.7.8 Adjusting the twin cylinder strap

1. Fit the cylinders but do not close the cam lever (see section 4.4.7.2).

2. Move the adjuster buckle (Fig 33, Item 1) so that the stitching is below

the centre bar of the adjuster buckle.

3. Close the cam lever, and check that the cylinders are secure.

4. If the cylinders are not secure, release the cam lever and move the

adjuster buckle to adjust cylinder strap tension.

– Move the adjuster buckle toward the cam lever to loosen the strap.

– Move the adjuster buckle away from the cam lever to tighten the

strap.

5. Continue to test and adjust until the cylinders are secure.

5 Troubleshooting

The troubleshooting guide shows fault diagnosis and repair information

applicable to users of this product. Further troubleshooting and repair

information is available in instructions for use supplied with associated

equipment.

Where the troubleshooting guide shows more than one fault or remedy,

carry out repair actions in the order that they appear in the guide.

Contact trained service personnel or Dräger when the remedy information

indicates a service task, or if the symptom remains after all remedy actions

have been attempted.

5.1 Troubleshooting for breathing apparatus

Symptom Fault Remedy

High-pressure air leak or

failed leak test

Loose of dirty connector Disconnect, clean and

reconnect couplings

and retest

Faulty hose or component Substitute user

replaceable

accessories and retest

Air leak from medium-

pressure hose connector at

the pressure reducer

(pressure relief valve) (see

Fig 2)

Faulty O-ring, retainer,

spring, or pressure reducer

Service task

Air leak from lung demand

valve

Ice particles on sealing

elements

Allow a rush of air to

pass through the valve

by pressing the front

button (Fig 5, Item 2)

then quickly switch off

the positive pressure by

pressing the reset

button (Fig 5, Item 1)

Air leak from cylinder

connector

Ice particles on sealing

elements

Close the cylinder valve

and vent the system.

Disconnect then

reconnect the cylinder.

Pressurize the system

by opening the cylinder

valve slowly, but fully.

Poor sounding whistle Whistle dirty Clean the whistle flute

and retest

Whistle not functioning Activation mechanism fault Service task

Difficulty connecting or

disconnecting the medium-

pressure quick coupling

Dirty connector Disconnect, clean and

reconnect couplings,

and retest

Burring of the male coupling Replace the hose with

the male coupling

A B

32

5305/5469

1

33

5334

1

5.2 Troubleshooting for TX Gauge

6 Maintenance

6.1 Maintenance table

Service and test the product, including out-of-use equipment, in

accordance with the maintenance table. Record all service details and

testing. Refer also to the instructions for use for other associated

equipment.

Additional inspection and testing may be required in the country of use to

ensure compliance with national regulations.

6.2 Cleaning and disinfecting

CAUTION

Trapped water and ice inside the pneumatic system can impair the

operation of the product.

► Prevent any liquid from entering the pneumatic system, and

thoroughly dry the product after cleaning and disinfecting.

NOTICE

Using cleaning and disinfecting methods not described in this section can

damage the equipment.

► Do not exceed 60 °C for drying, and remove components from the

drying facility immediately when dry. Drying time in a heated dryer

must not exceed 30 minutes.

► Do not immerse pneumatic or electronic components in cleaning and

disinfecting solutions or water.

For information about suitable cleaning and disinfecting agents

and their specifications refer to document 9100081 at

www.draeger.com/IFU.

6.2.1 Cleaning and disinfecting the breathing apparatus

Clean the breathing apparatus if it is dirty. If the equipment has been

exposed to contaminants, disinfect any components that come into direct

and prolonged contact with the skin.

Refer also to the instructions for use for the lung demand valve, mask, and

other associated equipment.

Work equipment

– Use only clean lint-free cloths

1. Clean the breathing apparatus manually using a cloth moistened with

cleaning solution to remove excess dirt.

2. Apply disinfecting solution to all internal and external surfaces.

3. Rinse all components thoroughly with clean water to remove all

cleaning and disinfecting agents.

4. Dry all components using a dry cloth, in a heated dryer, or in air.

5. Contact service personnel or Dräger if disassembly of pneumatic or

electronic components is required.

Symptom Fault Remedy

TX Gauge fails to switch on Low batteries Replace the batteries

Low cylinder pressure Recharge cylinder to

maximum working

pressure

Unknown Service task

Amber LED flashing every

5 seconds

Low batteries Replace the batteries

Amber LED flashing every

2 seconds for 10 seconds

Failed self-test, or hardware

fault

Service task

TX Gauge face difficult to

see through window

Dirt on gauge face window Clean gauge face

window (see

section 6.2)

Gauge face window

damaged

Service task

Item Task

Every

month

Every

year

Every

10

years

Complete

product

Visual inspection (see section 6.3.1) X

Functional testing (see section 6.3.3) X

Breathing cycle and static tests1)

1. These maintenance tasks can only be carried out by Dräger or trained

service personnel. Details of the tests are contained in the technical

manual which is issued to service personnel that have attended a

relevant Dräger maintenance course.

X

Lung

demand

valve

Check the male element of the quick

coupling for burring (see section 6.3.2)

X

Pressure

reducer Inspect the sintered filter1) 2)

2. Replace the sintered filter if a drop in pressure reducer performance is

observed during a flow check or if it is visibly damaged.

X

Inspect the high-pressure connector O-

ring1) 3)

3. Replace the high-pressure connector O-ring if it is found to leak during

functional testing or if it is visibly damaged.

X

Overhaul. Contact Dräger for the Repair

Exchange (REX) service4)

4. Where the breathing apparatus is subjected to a high level of use (in

training establishments etc.), reduce the overhaul period for the

pressure reducer. In these circumstances, Dräger recommend that the

overhaul frequency should be less than 5 000 applications of use. An

application of use is defined as a single use of the fully assembled

breathing apparatus, where the user breathes from the air cylinder. It

does not include system pressurization for pre-operational checks.

X

Cylinder Check test date of cylinder X

Recertification According to national

regulations in the country

of use

6.3 Maintenance tasks

6.3.1 Visual inspection

A visual inspection must fully check the product including all component

parts and accessories.

1. Check that the product is clean and undamaged, paying particular

attention to pneumatic system components, connectors, and

elastomeric components such as hoses.

– Typical signs of damage that can affect the operation of the

product include impact, abrasion, cutting, corrosion, and

discoloration.

2. Report damage to service personnel or Dräger, and do not use the

product until faults are rectified.

6.3.2 Checking the medium-pressure quick coupling

This task applies only to breathing apparatus with a removable lung

demand valve. If there is any difficultly disconnecting or connecting, see

the troubleshooting information in section 5.

1. Press the male element into the female element of the coupling until

an audible click is heard.

2. Disconnect the male element from the female element of the quick

coupling.

3. Reconnect the quick coupling as per step 1.

6.3.3 Functional testing

WARNING

Failure of the product to meet any of the standards or parameters during

functional testing, or any visible signs of damage, indicates a possible

system fault.

► Do not use the product and report the fault to trained maintenance

personnel or contact Dräger.

6.3.3.1 Illumination test

1. Press the illumination button (Fig 2, Item 1) to turn on the gauge

illumination.

– The white LED must turn on for 3 seconds and then switch off.

6.3.3.2 Leak test

1. Press the reset button of the lung demand valve.

2. Slowly and fully open the cylinder valve (anticlockwise).

– During pressurization TX Gauge will switch on automatically and

the whistle will sound briefly.

3. Fully close the cylinder valve.

4. After one minute, check the contents gauge and then reopen the

cylinder valve.

– The gauge must not show an increase in pressure of more than

10 bar.

– Investigate and repair a failed leak test (see section 5), and then

repeat the leak test.

6.3.3.3 Whistle test

1. Fully close the cylinder valve.

2. Observe the gauge and slowly release the pressure as follows:

a. Cover the outlet port of the valve with the palm of the hand.

b. To switch on the lung demand valve press the front button (Fig 5,

Item 2).

c. Vent the system by carefully lifting the palm of the hand from the

outlet port to maintain a slow pressure decrease.

3. The whistle must begin to sound and the red LED must activate in the

range 60 bar to 50 bar.

– The whistle may not sound at the same time as the red LED

activates.

4. Continue to vent the system until fully exhausted.

5. Press the reset button of the lung demand valve.

6.3.4 Charging a compressed air cylinder

WARNING

Air quality for compressed air cylinders must meet the requirements for

breathable air according to EN 12021.

► Ensure that the air supply meets the EN 12021 requirements.

Refer to the instructions for use supplied with the cylinder and the charging

apparatus for details of charging a compressed air cylinder.

7 Transport

Transport the product in its original packaging.

8 Storage

8.1 Storage preparation

– Extend the shoulder straps, waist belt, and the straps of the mask (see

section 4.4).

– Place the mask in a protective bag (contact Dräger for supply of a

suitable bag).

– Route rubber hoses in such a way that the bend radius is not too acute

and the hose is not stretched, compressed, or twisted.

8.2 Storage conditions

– Store the product between -15 °C and +25 °C.

– Ensure that the environment is dry, free from dust and dirt, and does

not subject the equipment to wear or damage due to abrasion.

– Do not store the equipment in direct sunlight.

– Fix the product securely to any raised mounting point to prevent it from

falling.

– If storing the equipment in a vehicle, ensure that the breathing

apparatus is securely retained and does not interfere with the

operation of the vehicle.

9 Disposal

9.1 General

Dispose of the product in accordance with applicable rules and regulations

in the country of use.