3363103 (A3-D-P)

3363103

© Dräger Safety UK Limited

Edition 13 – August 2019 (Edition 01 – August 2014)

Subject to alteration

Draeger Safety UK Limited

Ullswater Close Tel +44 1670 352 891

Blyth, NE24 4RG Fax +44 1670 356 266

United Kingdom www.draeger.com

1 For your safety

1.1 General safety statements

●Before using this product, carefully read the Instructions for Use.

●Strictly follow the Instructions for Use. The user must fully understand

and strictly observe the instructions. Use the product only for the

purposes specified in the Intended Use section of this document.

●Do not dispose of the Instructions for Use. Ensure that they are

retained and appropriately used by the product user.

●Only fully trained and competent users are permitted to use this

product.

●Comply with all local and national rules and regulations associated

with this product.

●Only trained and competent personnel are permitted to inspect, repair

and service the product. Dräger recommend a Dräger service contract

for all maintenance activities and that all repairs are carried out by

Dräger.

●Properly trained service personnel must inspect and service this

product as detailed in the Maintenance section of this document.

●Use only genuine Dräger spare parts and accessories, or the proper

functioning of the product may be impaired.

●Do not use a faulty or incomplete product, and do not modify the

product.

●Notify Dräger in the event of any component fault or failure.

1.2 Definitions of alert icons

Alert icons are used in this document to provide and highlight text that

requires a greater awareness by the user. A definition of the meaning of

each icon is as follows:

WARNING

Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation which, if not avoided, could

result in physical injury or damage to the product or environment. It may

also be used to alert against unsafe practices.

NOTICE

Indicates additional information on how to use the product.

2 Description

2.1 Product overview

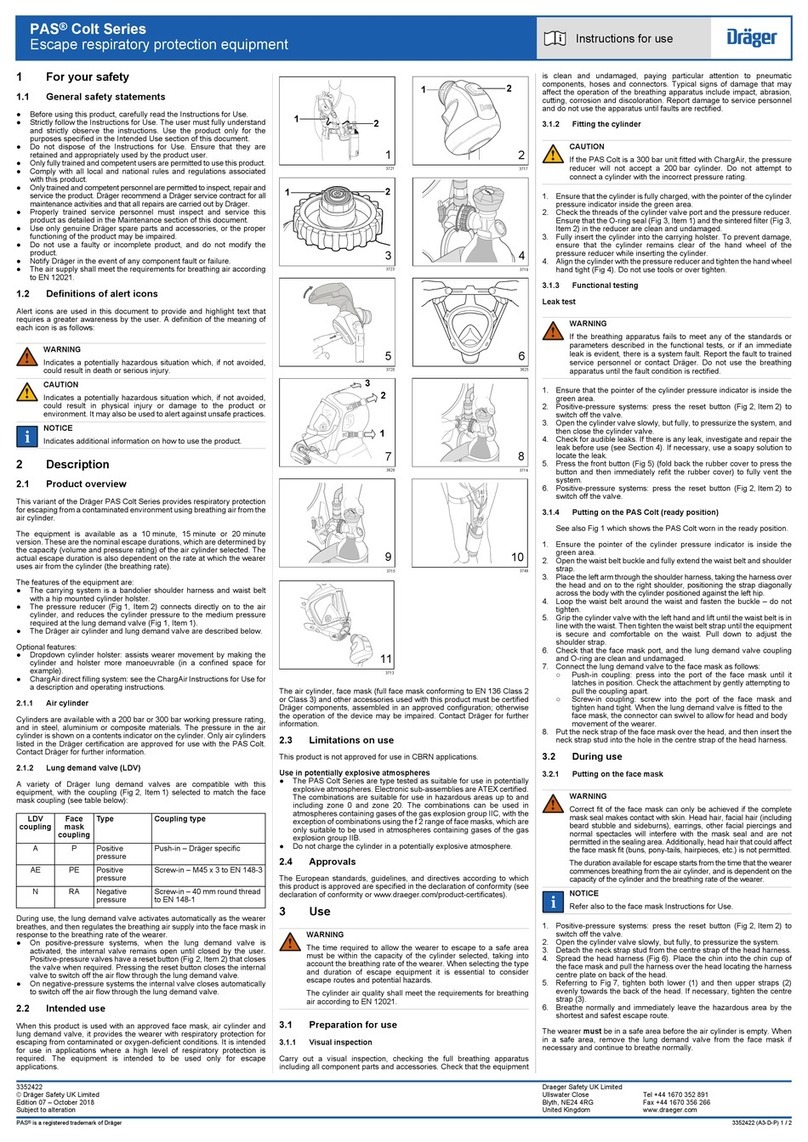

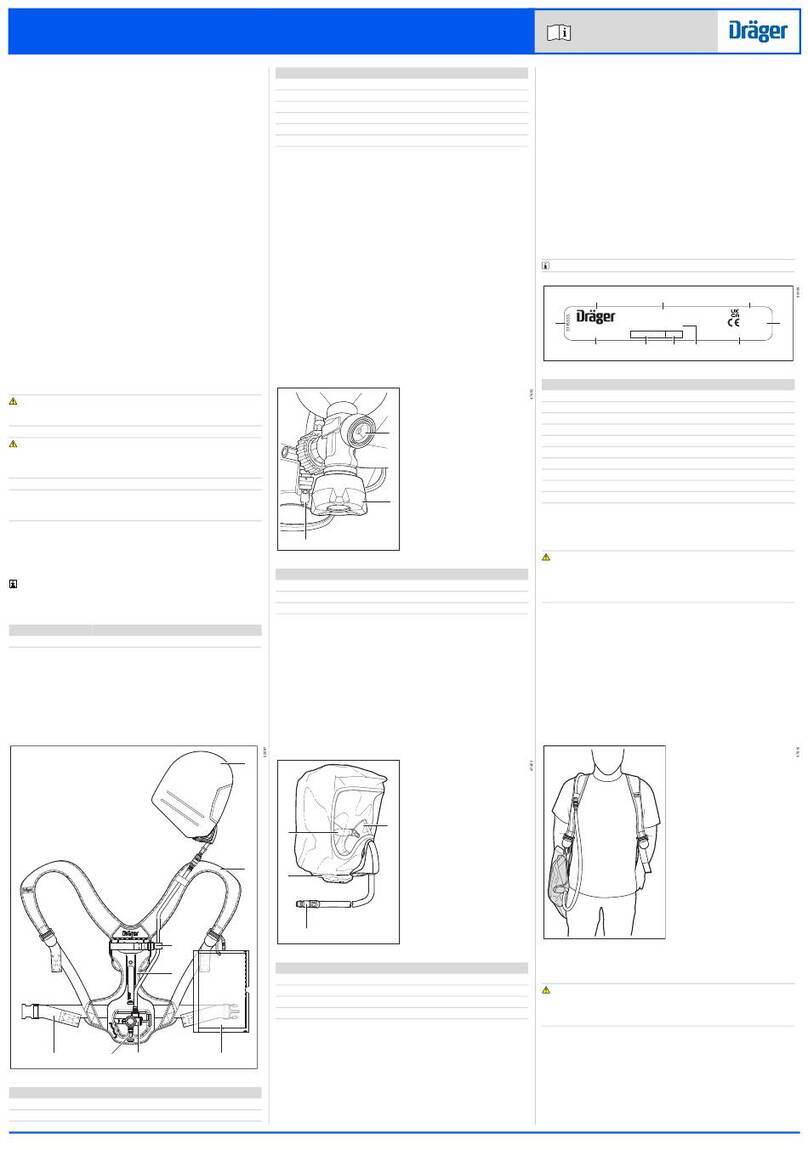

The Dräger X-plore 9500 (Fig A) is a belt mounted manifold that is used to

connect an external breathing air supply (an airline) to a mask. The

manifold has an input connector (4) to connect the airline, and has an

output at a mask adaptor (1) to connect the mask.

During use, a pressure reducer inside the manifold supplies a continuous

flow of air from the airline to the mask. This air flow is within the safe limits

required at the mask. An excess flow valve inside the mask adaptor

releases excess air continuously during use to maintain the correct air

pressure inside the mask. The pressure reducer has an adjustable flow

control valve (2) which allows the wearer to adjust the air flow within preset

limits.

The whistle (3) is a low input pressure warning device. The whistle sounds

during use to alert the wearer if the breathing air supply falls below the

pressure required to provide adequate breathing air.

The X-plore 9500 is used with a compatible Dräger face mask from the

FPS 7000, X-plore 6000 or Panorama Nova series of masks (the Dräger

X-plore 6300 mask is shown). The compatible Dräger masks are classified

as Class 4B according to EN 14594:2018. For a full description of the

mask see the Instructions for Use supplied with the product.

Radio-frequency identification (RFID) is an option available for this product

to allow electronic asset management and tracking using a radio-

frequency reader. When fitted, the passive RFID tag is positioned inside

the manifold casing.

2.1.1 Breathing air supply

The breathing air supply (airline supply) is an external source of breathing

air from an air cylinder or compressor arrangement capable of supplying

the specified air quality, pressure and flow rates (see Section 3.1 for

details).

2.2 Intended use

The X-plore 9500 is intended for use with approved Dräger compressed

airline breathing equipment to provide respiratory protection against the

effects of harmful substances. The equipment is intended to be used as an

airline respirator at a work area.

The compressed airline breathing equipment and other accessories used

with this product must be certified Dräger components, assembled in an

approved configuration; otherwise the operation of the device may be

impaired. Contact Dräger for further information.

Use in potentially explosive atmospheres

The X-plore 9500 is type tested as suitable for use in potentially explosive

atmospheres. Electronic sub-assemblies are ATEX certified. The

combinations are suitable for use in hazardous areas up to and including

zone 0 and zone 20. The product temperature class is T6 unless a passive

RFID tag is fitted in which case the temperature class is T4. The

combinations can be used in atmospheres containing gases of the gas

explosion group IIB.

The air supply must be located:

●In zone 1 if flammable gasses of class IIA are present.

●In zone 2 if flammable gasses of classes IIA, IIB, or IIC are present.

There is no restriction for use in areas containing flammable dust.

2.3 Limitations on use

This product is not approved for use in CBRN (chemical, biological,

radiological and nuclear) applications.

2.4 Approvals

The European standards, guidelines, and directives according to which

this product is approved are specified in the declaration of conformity (see

www.draeger.com/product-certificates).

PED important note: The X-plore 9500 is designed for use with airline

breathing-air supply systems only and is classified as safe and suitable for

use under the PED regulations – category SEP (Sound Engineering

Practice). The equipment cannot be certified to PED regulations.

2.5 Marking and symbols

The product type is indicated on the label on the manifold casing, and the

product serial number is marked on the body of the manifold.

Marking on the air supply hose indicates that the hose is heat resistant (H)

and/or antistatic (S).

3 Use

3.1 Breathing air supply

WARNING

The quality of the air supply shall meet the requirements for breathing air

according to EN 12021 in EU countries, or AS/NZS 1715:2009 in Australia

and New Zealand. Do not use oxygen or oxygen-enriched air. The

moisture content of breathing air should be controlled within the specified

limits in the standard to avoid freezing the equipment.

Carry out a risk assessment of the workplace to ensure that it is not

possible to connect to any air supply other than breathable air (e.g.

Nitrox).

WARNING

Adequate protection may not be provided by the equipment in certain

highly toxic atmospheres.

The user must ensure that the capacity of the air supply system is

sufficient for every user connected to it. The user must also ensure that

they can retreat safely if the supply from the airline fails.

Use a breathing air cylinder arrangement with a pressure reducer, or a

fixed or mobile compressor with a suitable filtration and air heating or

cooling system. Ensure that the air supply meets the air quality

requirements, and complies with the following pressure and flow

requirements:

●Input pressure 3.3 to 10 bar

●Input flow 350 to 1200 litres/minute

The equipment can be safely operated with an input pressure as low as

3.0 bar at the manifold input connector. If the pressure at the manifold falls

below 3.3 bar there could be a small inaudible airflow from the whistle.

The maximum number of users that can be connected simultaneously to

Dräger breathing air supply equipment is specified in the supply equipment

Instructions for Use.

It must be possible to move the air supply around a hazardous area if using

a breathing air cylinder arrangement. Conductive floors are mandatory in

zone 1 and zone 21 if flammable dusts with a minimum ignition energy of

less than 10 mJ are present.

3.1.1 Compressed air supply hose

●Ensure that the airline coupling is compatible with the product input

coupling. The standard input coupling is a Rectus 96 Series or CEJN-

type male quick coupling (other couplings are available from Dräger).

●The maximum working pressure of the Dräger compressed air supply

hose is 30 bar.

●Ensure that supply hoses with a total length greater than 50 m have an

appropriate earth connection.

EU countries

When using Dräger approved hose: a maximum of 100 m of hose may be

used, and no more than four individual hoses (a maximum of five hose

connections) are permitted in the airline.

Australia and New Zealand

Approved hoses must be used for the AS/NZS approval standard to be

valid. Hoses from 5 to 30 m or coupled to 90 m may be used.

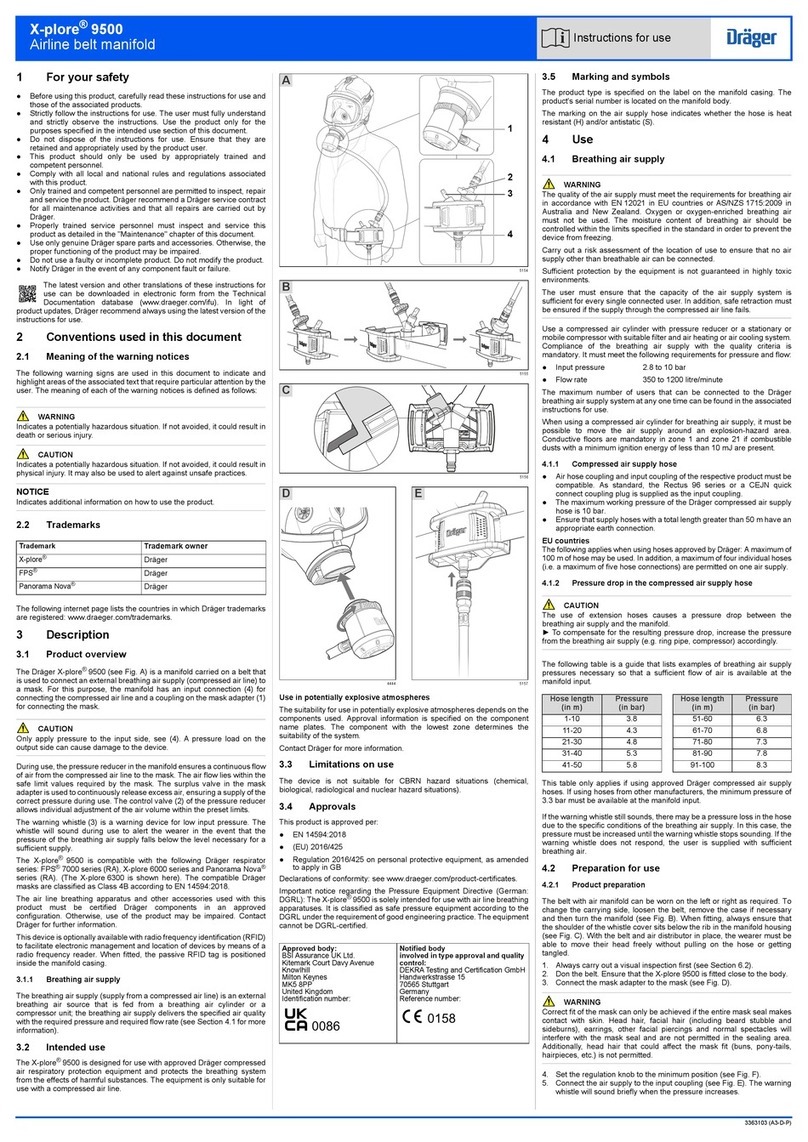

3.1.2 Compressed air supply hose pressure drop

Using extension hoses causes a pressure drop between the breathing air

supply and the manifold. The pressure from the breathing air supply must

therefore be increased accordingly to compensate for any pressure drop

due to the length of hose used. The table below shows the pressure

required at the breathing air supply to ensure that the minimum pressure

of 3.3 bar is available at the manifold input connector.

This table is only applicable when using Dräger approved hose. When

using hose from any other manufacturer, the minimum input pressure of

3.3 bar must be supplied at the manifold input connector.

3.2 Preparation for use

3.2.1 Preparing the product

The manifold can be worn on the left or right side. To swap sides, loosen

the belt, remove the backplate if fitted and rotate the manifold (Fig B).

When reassembling, ensure that the lip of the whistle cover sits under the

rib in the manifold bracket (Fig C). Ensure that the position of the manifold

on the waist allows full head movement without pulling the hose, and that

the hose will not present a snag hazard.

1. Carry out a visual inspection (see Section 5.2).

2. Put on the belt and adjust as necessary. Ensure that the X-plore 9500

is fitted tightly against the body.

3. Connect the mask adaptor to the mask (Fig D).

WARNING

Correct fit of a mask can only be achieved if the complete mask seal

makes contact with skin. Head hair, facial hair (including beard stubble

and sideburns), earrings, other facial piercings and normal spectacles will

interfere with the mask seal and are not permitted in the sealing area.

Additionally, head hair that could affect the face mask fit (buns, pony-tails,

hairpieces, etc.) is not permitted.

4. Set the control knob to the minimum flow position (Fig F).

5. Connect the airline supply to the input coupling (Fig E). The whistle will

sound briefly as the pressure increases.

6. Ensure that the pneumatic hoses are not kinked or compressed by

clothing or equipment.

7. Put on the mask (see the Instructions for Use supplied with the mask).

8. Take several deep breaths to ensure that sufficient air is available and

then breathe normally.

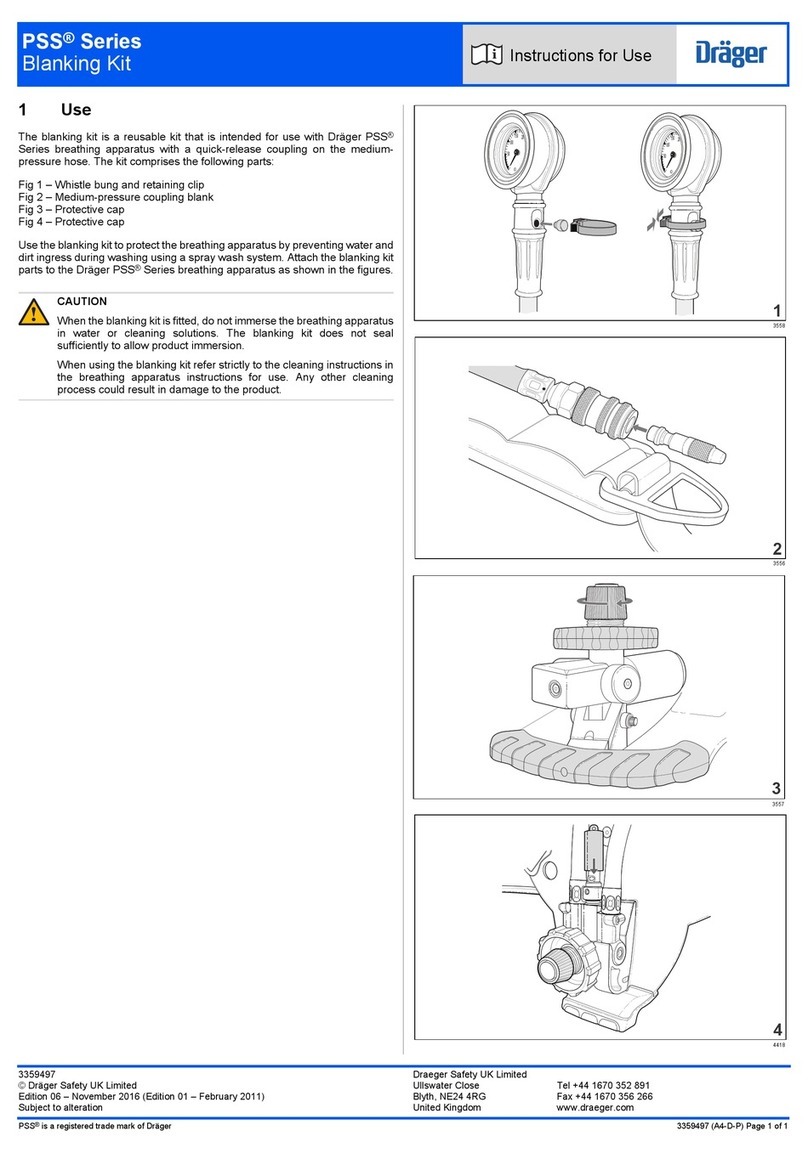

Hose length in

metres

Pressure in bar Hose length in

metres

Pressure in bar

1–10 3.8 51–60 6.3

11–20 4.3 61–70 6.8

21–30 4.8 71–80 7.3

31–40 5.3 81–90 7.8

41–50 5.8 91–100 8.3