Installation Instructions

Nocturne™ 220V Exterior Projection Screen by Draper

Copyright © 2015 Draper Inc. Form Nocturne_220V_Inst15 Printed in U.S.A.

If you encounter any difficulties installing or servicing your Nocturne Exterior Projection Screen

call your dealer or Draper, Inc. in Spiceland, Indiana, 765-987-7999, or fax 765-987-7142.

Caution

1Inspect all boxes to make sure you have received the proper parts.

2Open cartons lengthwise.

3All hardware must be installed level. Screens must be level and square.

4Do not wire motors in parallel without written permission from Draper.

5It is the installer’s responsibility to make sure appropriate fasteners are used

for mounting surface.

6Please read the following installation guidelines thoroughly and follow

them carefully. Failure to do so may cause product to fall or otherwise

fail, and invalidates warranty.

Continued on next page

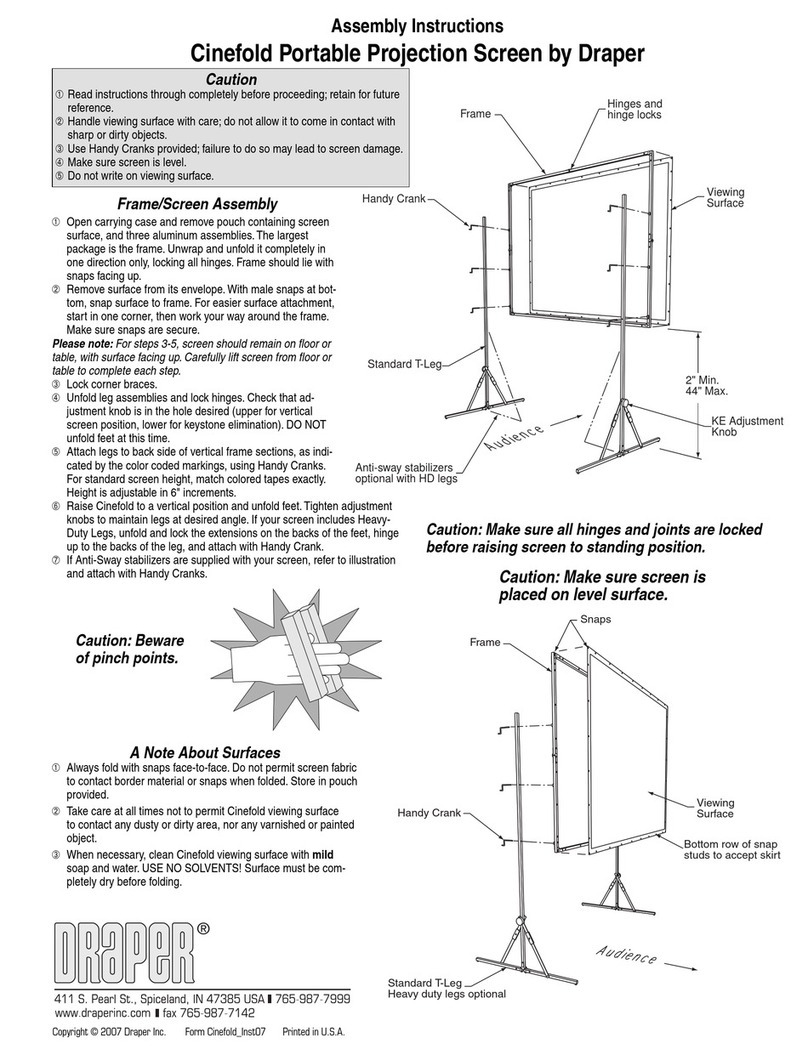

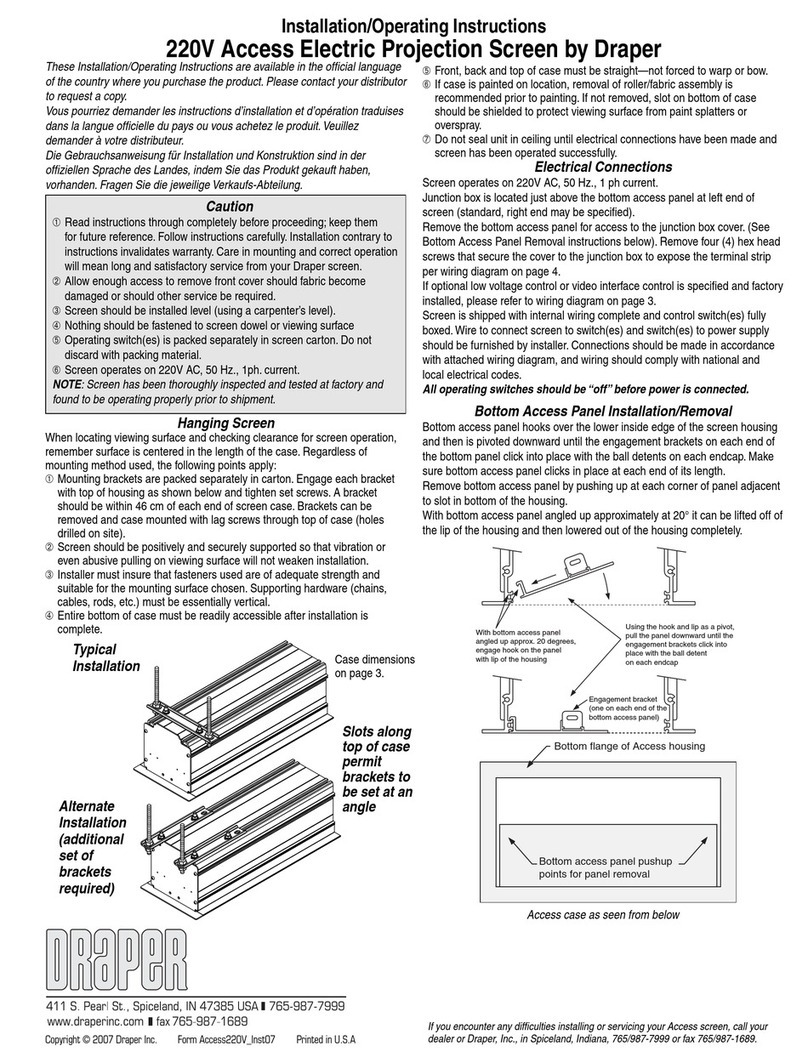

Before mounting your Nocturne Exterior Projection Screen, mark build-

ing for placement of mounting brackets and pre-drill mounting holes

and electrical access holes (if necessary) in mounting surface. It is

installer’s responsibility to make sure appropriate fasteners are used for

mounting surface. The Nocturne Exterior Projection Screen is shipped

with screen case assembly complete (see Fig. 1).

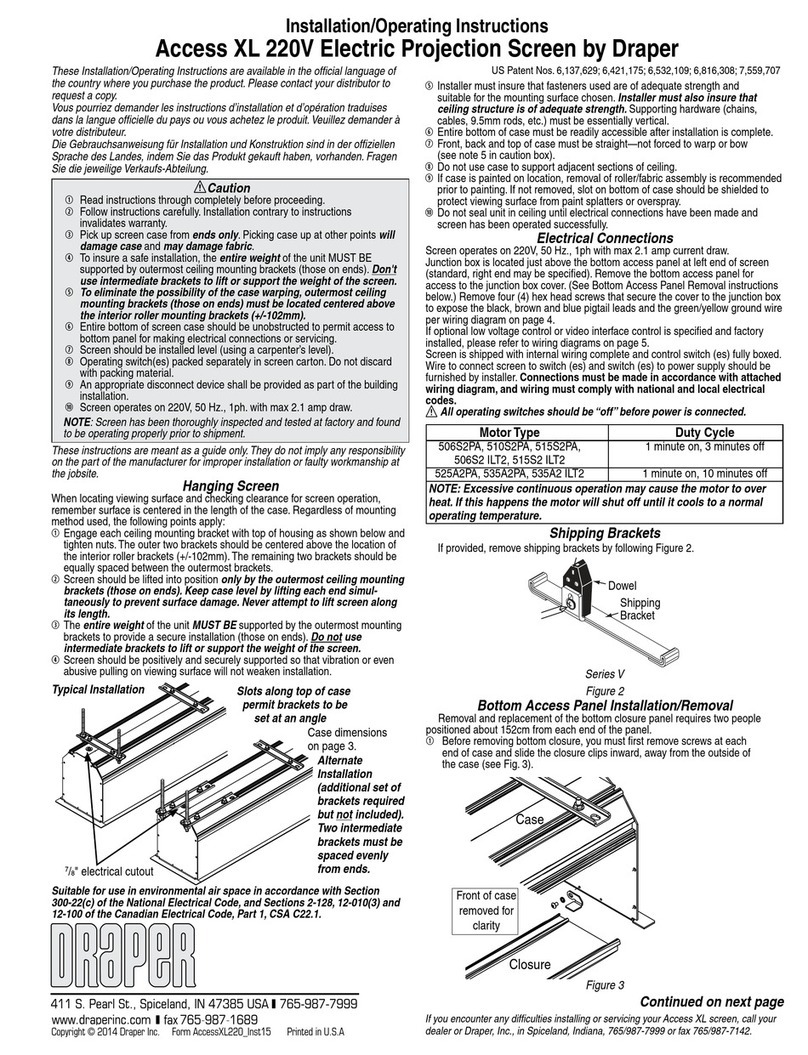

Mounting Through Back of Screen Case:

1Remove fascia from screen case. If your unit is equipped with a crank

operator, first remove the crank attachment from the unit, then remove ad-

ditional screws holding fascia onto back/top and rotate fascia up and off of

unit (see Fig. 2).

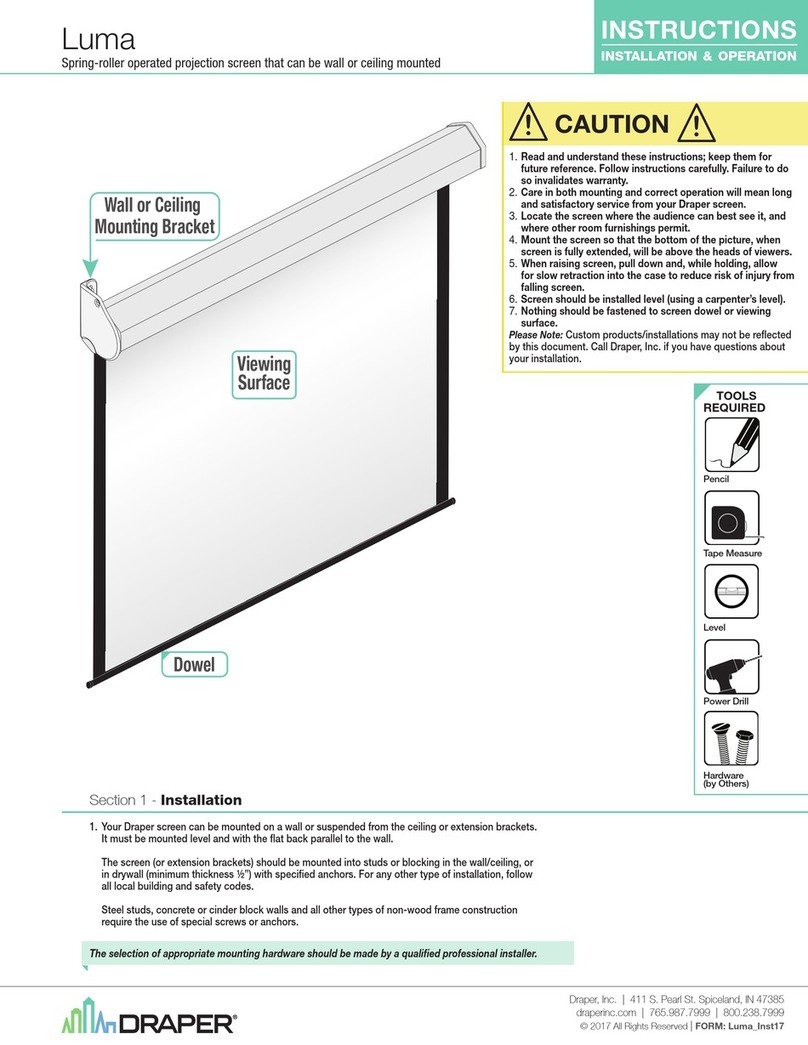

Figure 1

Drill holes for wall mounting,

using holes in endcaps as guides.

Figure 2

2Drill mounting holes in back of screen case, using holes in endcaps for

guides. Holes can also be drilled through the sides of the endcaps for

inside mounting (see Fig. 3). If this is a motorized unit, you will also need to

drill out a hole for the power and control cable to exit the screen case.

Figure 3

Mounting Through Top of Screen Case:

1Remove fascia from screen case. If your unit is equipped with a crank

operator, first remove the crank attachment from the unit, then remove ad-

ditional screws holding fascia onto back/top and rotate fascia up and off of

unit (see Fig. 2).

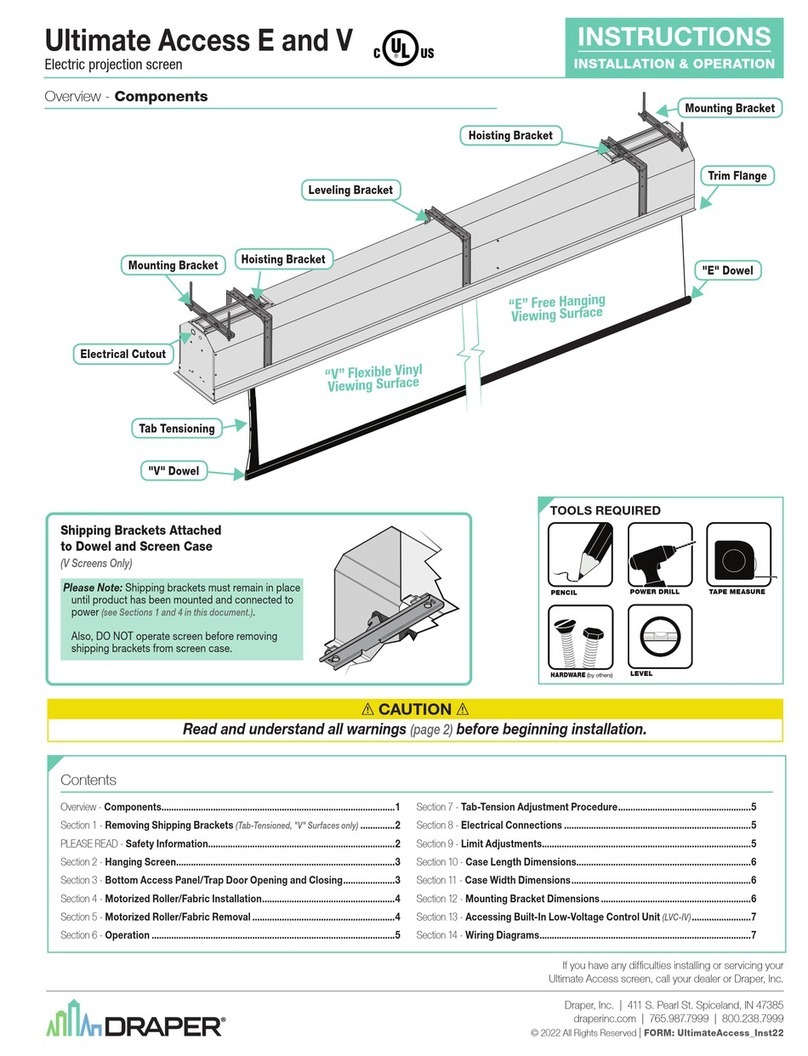

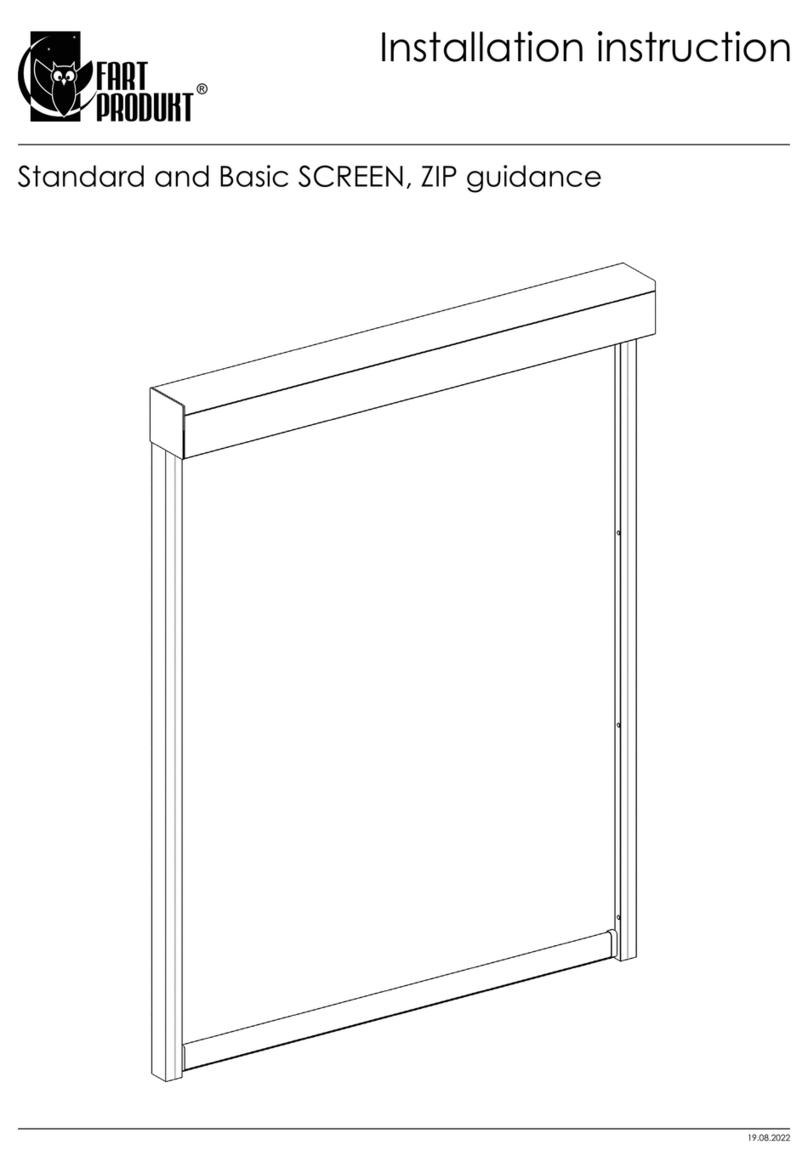

2Remove screen assembly from screen case. If motorized, remove motor

retaining clips. Pull the screen assembly away from the operator end. This

will depress the spring-loaded pin on the non-operator end. Then you can

rotate screen assembly out of the screen case (Fig. 4).

Figure 4

Motorized Crank

3Drill mounting holes in top of screen case, using holes in endcaps for

guides. If this is a motorized unit, you will also need to drill out holes for the

power and control cables to exit the screen case.

Please Note: It is the installer’s responsibility to make sure appropriate

fasteners are used for mounting surface.

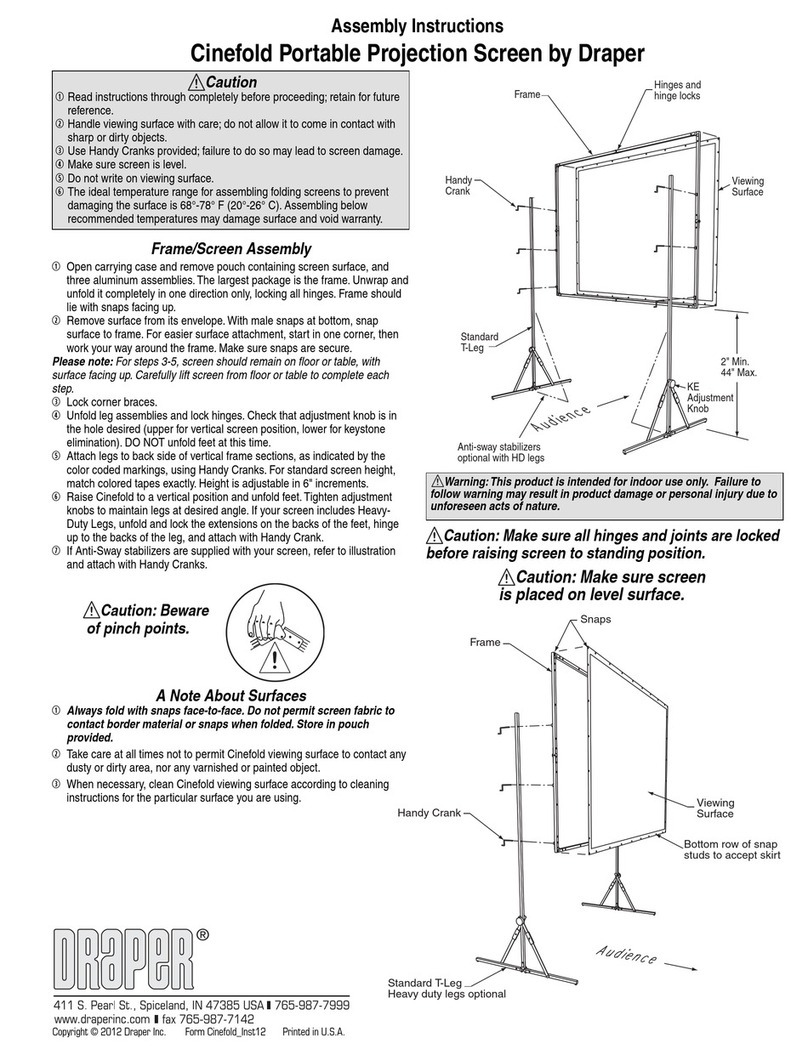

4Replace screen assembly in screen case. Place the spring-loaded pin on

the non-operator end into the endcap. Push the screen assembly toward

the non-operator end to depress the spring-loaded pin, then rotate screen

assembly into the screen case.

5Lower viewing surface approximately 12" to begin guide installation.

6If motorized, replace motor retaining clips (see Fig. 4).

Please Note: It is the installer’s responsibility to make sure appropriate

fasteners are used for mounting surface.

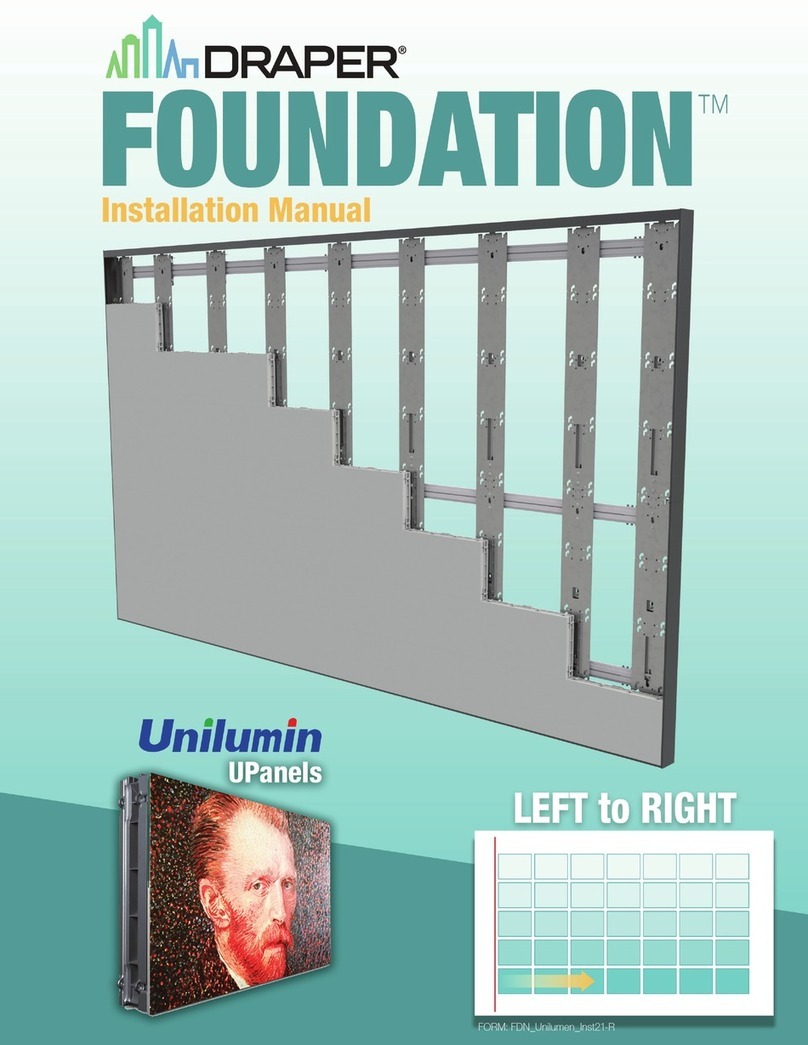

Side Cable Installation (see Fig. 5 on page 2):

Please Note: Skip this section if you elect not to install the side cable

guides.

1Attach cable deck or wall mount to mounting surface.

2Attach cable to deck or wall mount using provided washer and nut.

3After making sure of the length required, cut cable and strip the protective

jacket from the top 1".

4Insert cable through the hole provided in the end of the dowel, and then up

through hole in endcap.

5Insert stripped-off portion of cable into provided screw jacket, then tighten

in place against the side wall of the endcap with the provided screw. Make

sure the cable is taut. Tension to 8 in-lbs, so the screen will move up and

down easily along the cable.

6Replace fascia and crank operator (if provided).

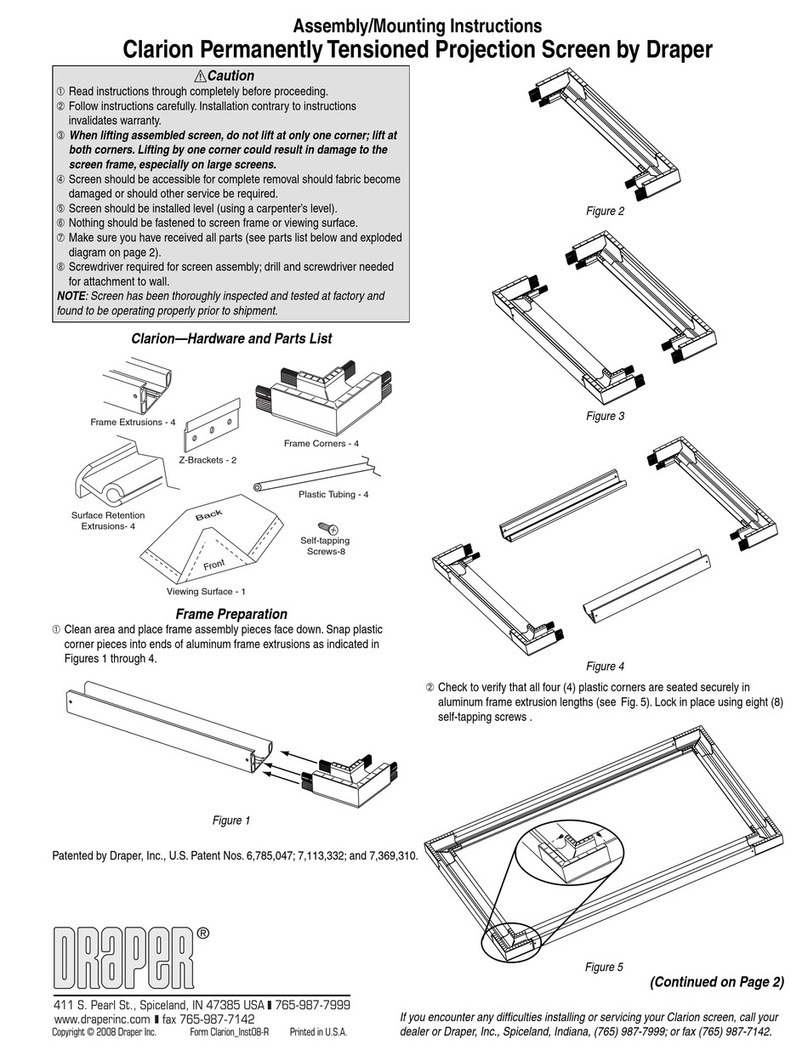

Please Note: A minimum of 1¾" is required

for the closure to hinge up, attach and close.

Please Note: A minimum of 1¾" is required for the closure to hinge up, attach

and close.

For flush ceiling mount, blocking (max.

depth 3") may also be required above

screen case to allow closure panel suf-

ficient room to hinge to open/close.

1¾"

Min.

Wall

Clg