DYNOWARE RT - 224 DYNOS

98200047.03

INSTALL YOUR SOFTWARE

Quick Start Guide

2191 Mendenhall Drive, North Las Vegas, NV 89081 - 800-992-4993 - DYNOJET.COM

© 2014-2019 DYNOJET RESEARCH ALL RIGHTS RESERVED

1. Go to www.dynojet.com. From the top navigation menu, select Support>Downloads.

2. Click the Power Core Software Download banner to download the Power Core Software Suite.

3. Double-click the saved file to begin installation. Follow the on-screen prompts.

4. Double-click the Power Core program icon installed on your desktop or on your start menu. This will

run the Dynojet Application Launcher.

5. Click WinPEP 8 Dyno Control from the Application Launcher.

6. Connect to DynoWare RT Control. See page 2 for more information.

7. Turn on the DynoWare RT main module. Allow several minutes for your computer to

connect to the main module.

Nitti Grotesk Normal 9 pt

step number Bold 9 pt

HobokenHIgh-

SansSerif 30

Trade Gothic LT Std

Bold Condensed No 20, 14pt

PUSH THE LIMIT

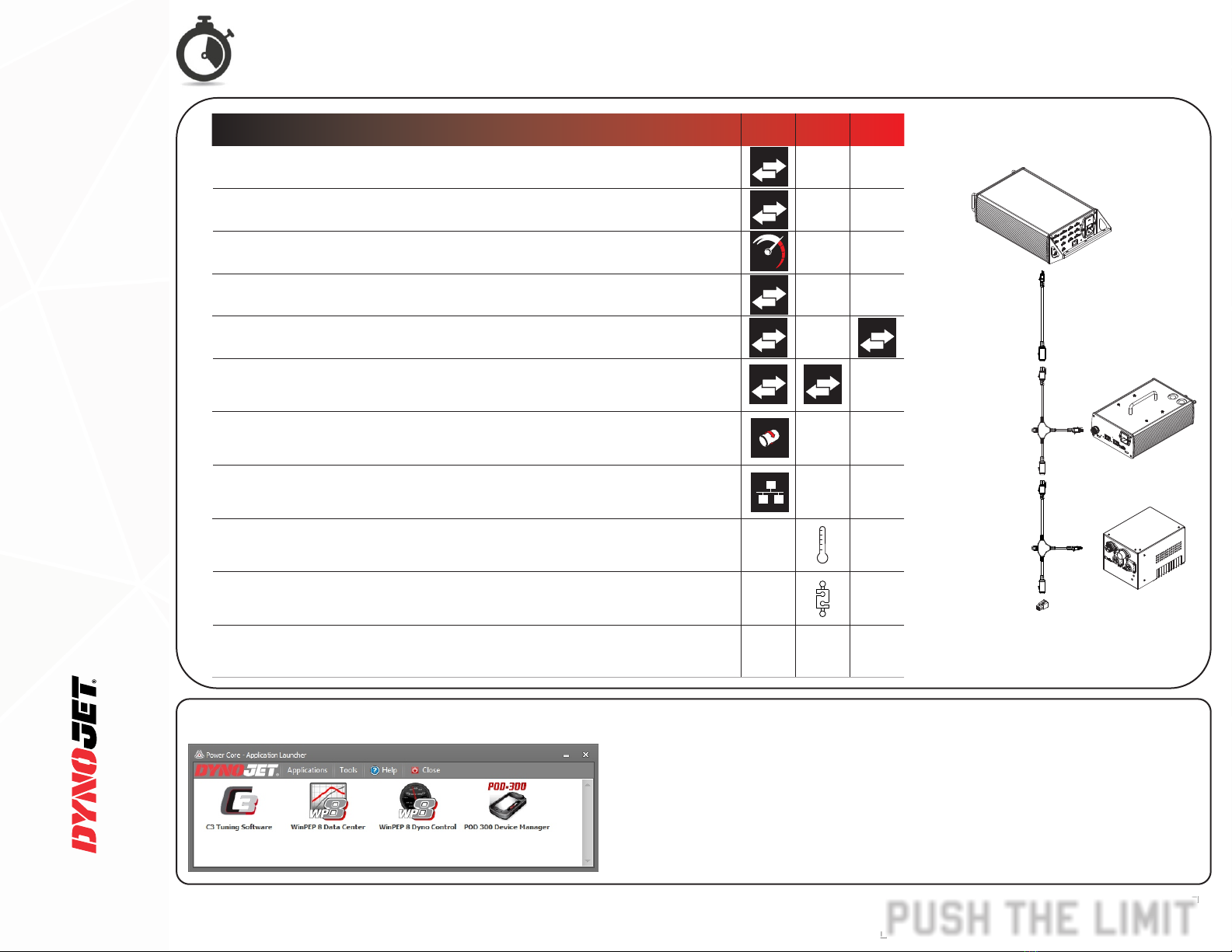

DynoWare RT

main module

Eddy Current

Brake (ECB) driver

Air Fuel Ratio

(AFR) module

CAN adapter cable

P/N 76950807

CAN dyno user cable

P/N 76950798

CAN control cable

P/N 76950791

CAN termination plug

Connect the six-pin speed/brake cable to position 1 on the DynoWare RT module.

Note: For 4WD dynos, connect the speed/brake cable from the stationary dyno to

position 1 and connect the speed/brake cable from the moveable dyno to position 2.

Connect the ethernet cable from the ethernet port on the DynoWare RT module to

your Local Area Network or directly to the network port on your computer. Refer to

your dyno installation guide for more information.

Connect the three-pin temperature sensor cable to the three-pin port on the Eddy Current

Brake driver module.

Note: Make these connections for both Eddy Current Brake driver modules for 4WD dynos.

Connect the five-pin load cell cable to the five-pin port on the Eddy Current Brake driver

module.

Note: Make these connections for both Eddy Current Brake driver modules for 4WD dynos.

Set the ID switch on the Eddy Current Brake driver module to 0 for 2WD dynos.

For 4WD dynos, set the Eddy Current Brake driver module ID switch on the

stationary dyno to 0 and set the ID switch on the moveable dyno to 2.

CABLE ROUTING DWRT ECB AFR

Connect the pendant cable to the DynoWare RT module.

Connect the atmospheric cable to the DynoWare RT module.

Connect a primary RPM pick up cable or a secondary pick up cable to the DynoWare RT

module.

Connect the CAN dyno user cable from the Air Fuel Ratio module to the DynoWare RT

module using the CAN adapter cable or the CAN network cable chain.

Connect the CAN adapter cable to the DynoWare RT module.

Connect the CAN control cable from the Eddy Current Brake driver to the DynoWare RT

module using the CAN adapter cable or the CAN network cable chain.

Note: Make these connections for both Eddy Current Brake driver modules for 4WD dynos.

I.D.

B

B

C

CB

CC