_______________________________________________________________________________________________________________________________

European Safety Systems Ltd. Impress House, Mansell Road, Acton, London W3 7QH sales@e-2-s.com Tel: +44 (0)208 743 8880

www.e-2-s.com Fax: +44 (0)208 740 4200

Document No. D209-00-511-IS-SC Issue C 13-06-17 Sheet 2 of 8

2.2 NEC Class / Zone ratings US

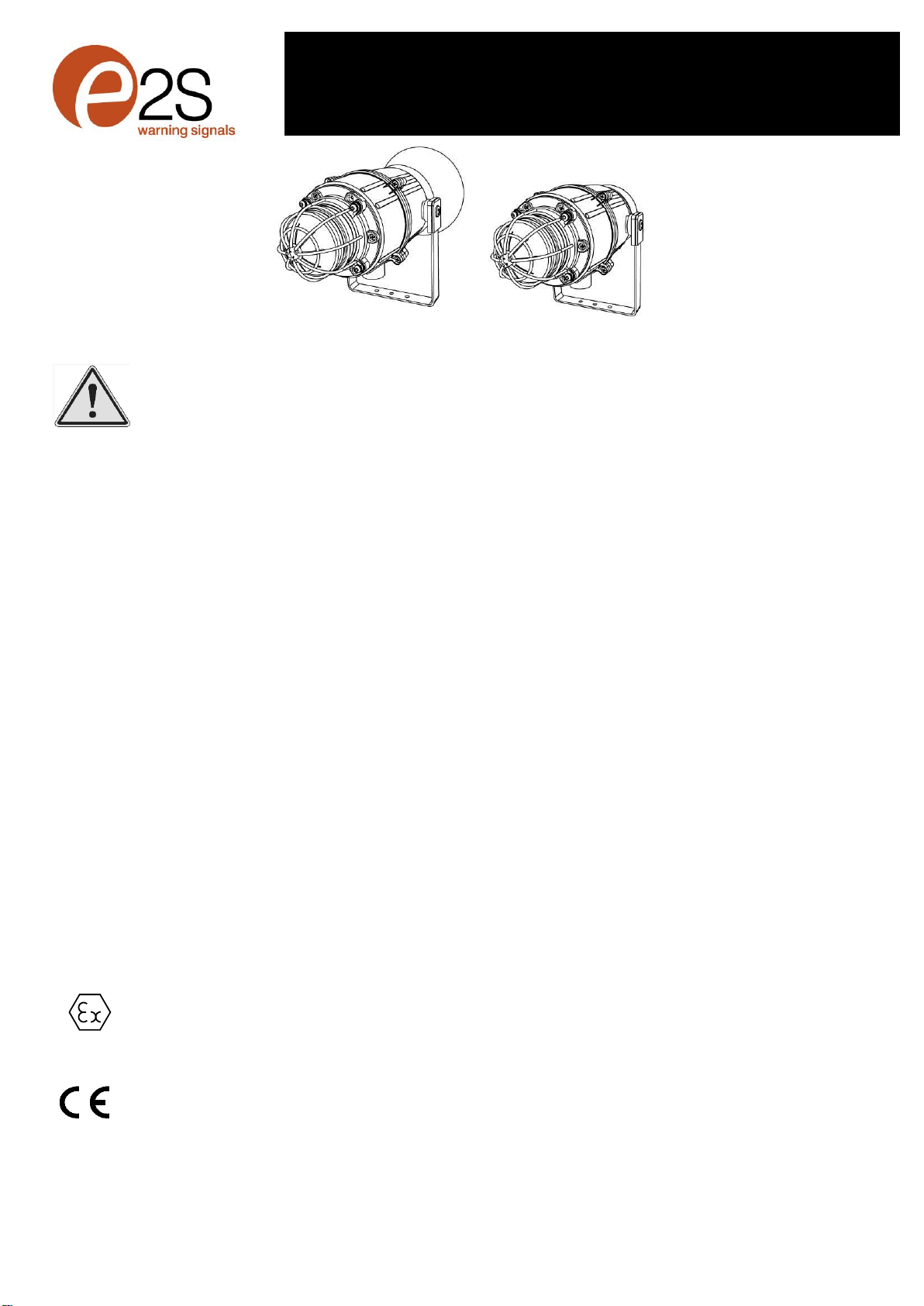

The E2xC1LD2 combined alarm horn and LED beacon

complies with the following standards:

UL 60079-0-2013

UL 60079-15-2013

UL 60079-31-2015

The E2xC1LD2 combined alarm horn and LED beacon is

rated as follows:

Class I Zone 2 AEx nA IIC Gc T3 Ta -20°C to +55°C

Zone 22 AEx tc IIIC Dc T105°C Ta -20°C to +55°C

Zone 22 AEx tc IIIC Dc T90°C Ta -20°C to +55°C

Installation must be carried out in compliance with the

National Electric Code.

2.3 CEC Class / Zone ratings Canada

The E2xC1LD2 combined alarm horn and LED beacon

complies with the following standards:

CAN/CSA C22.2 No. 60079-0:2015

CAN/CSA C22.2 No. 60079-15:2016

CAN/CSA C22.2 No. 60079-31:2015

The E2xC1LD2 combined alarm horn and LED beacon is

rated as follows:

Ex nA IIC Gc T3B Ta -20°C to +55°C

Ex nA IIC Gc T3C Ta -20°C to +40°C

Ex tc IIIC Dc T105°C Ta -20°C to +55°C

Ex tc IIIC Dc T90°C Ta -20°C to +40°C

Installation must be carried out in compliance with the

Canadian Electric Code

2.4 NEC & CEC Class / Division Ratings for US / Canada

The E2xC1LD2 combined alarm horn and LED beacon

complies with the following standards:

ANSI/ISA 12.12.01-2015

CSA C22.2 No. 213-16

The E2xC1LD2 combined alarm horn and LED beacon is

rated as follows:

Class I, Div 2, ABCD T3C Ta -20°C to +55°C

Class II, Div 2, FG T4A Ta -20°C to +55°C

Class II, Div 2, FG T5 Ta -20°C to +40°C

Class III, Div 1&2 Ta -20°C to +55°C

Installation must be carried out in compliance with the

National Electric Code / Canadian Electric Code

2.5 Ingress Protection Ratings

The product is rated for ingress Protection as follows:

IP rating per EN60079-0: IP64

IP rating per EN60529: IP66

Type rating per UL50E / NEMA250: 4 / 4X / 13

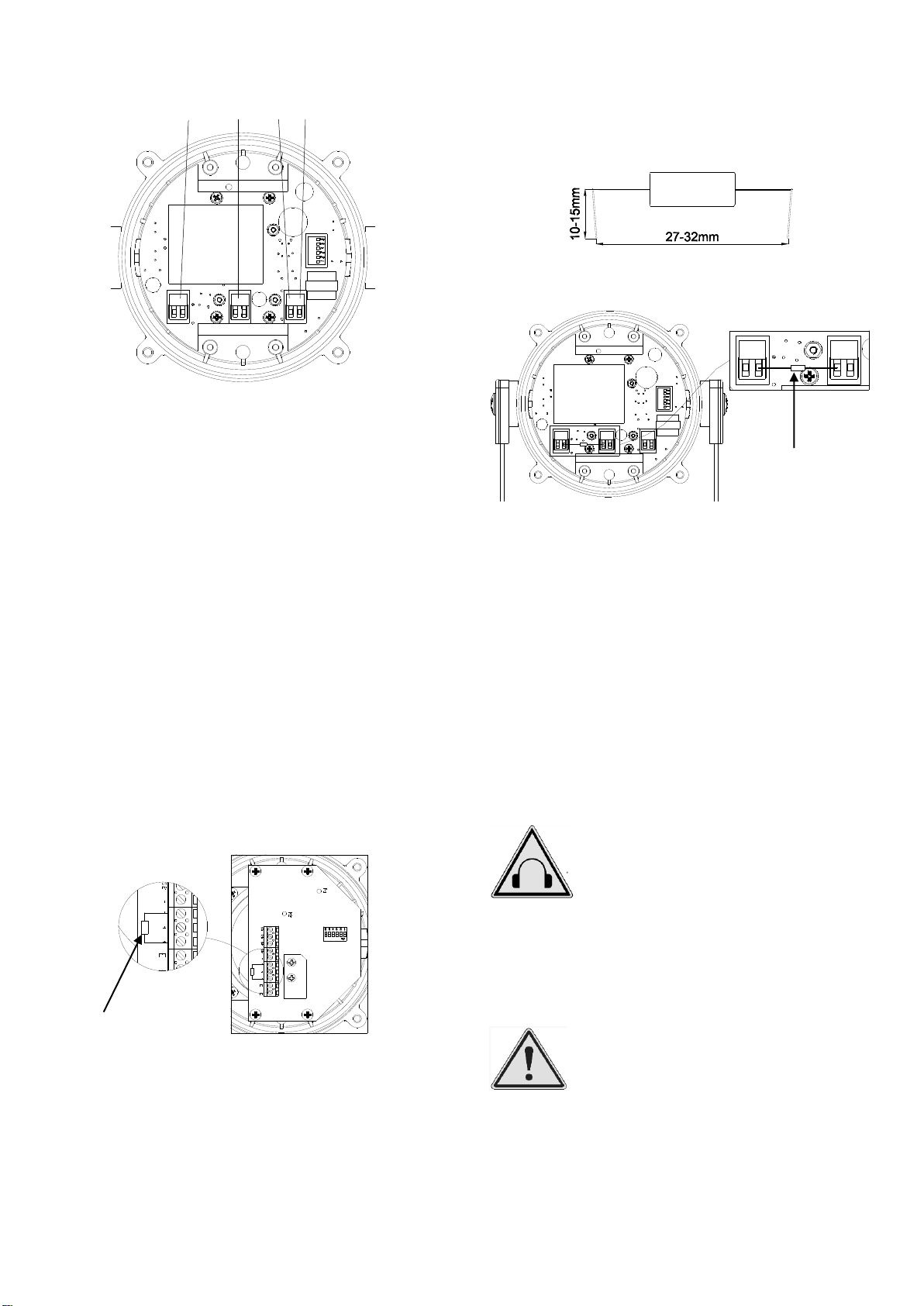

To maintain the ingress protection rating, the two off cable

entries must be fitted with suitably rated, certified cable entry

and/or blanking devices during installation.

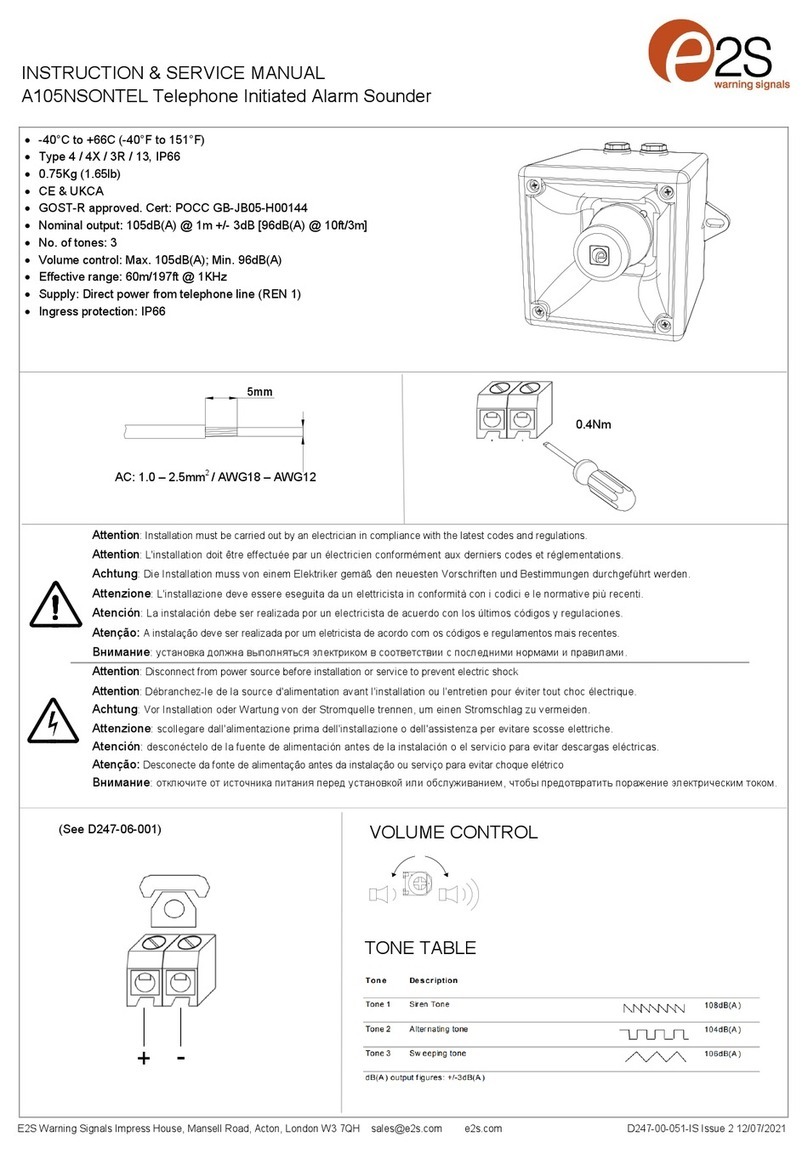

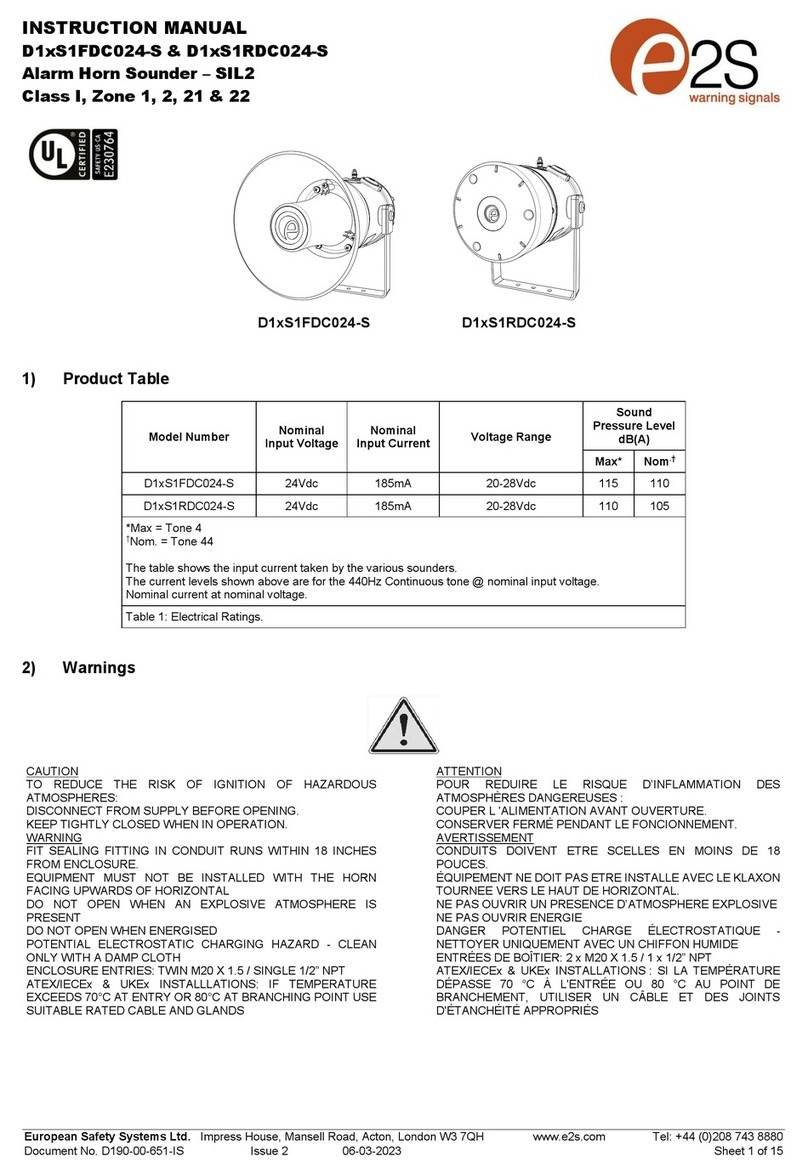

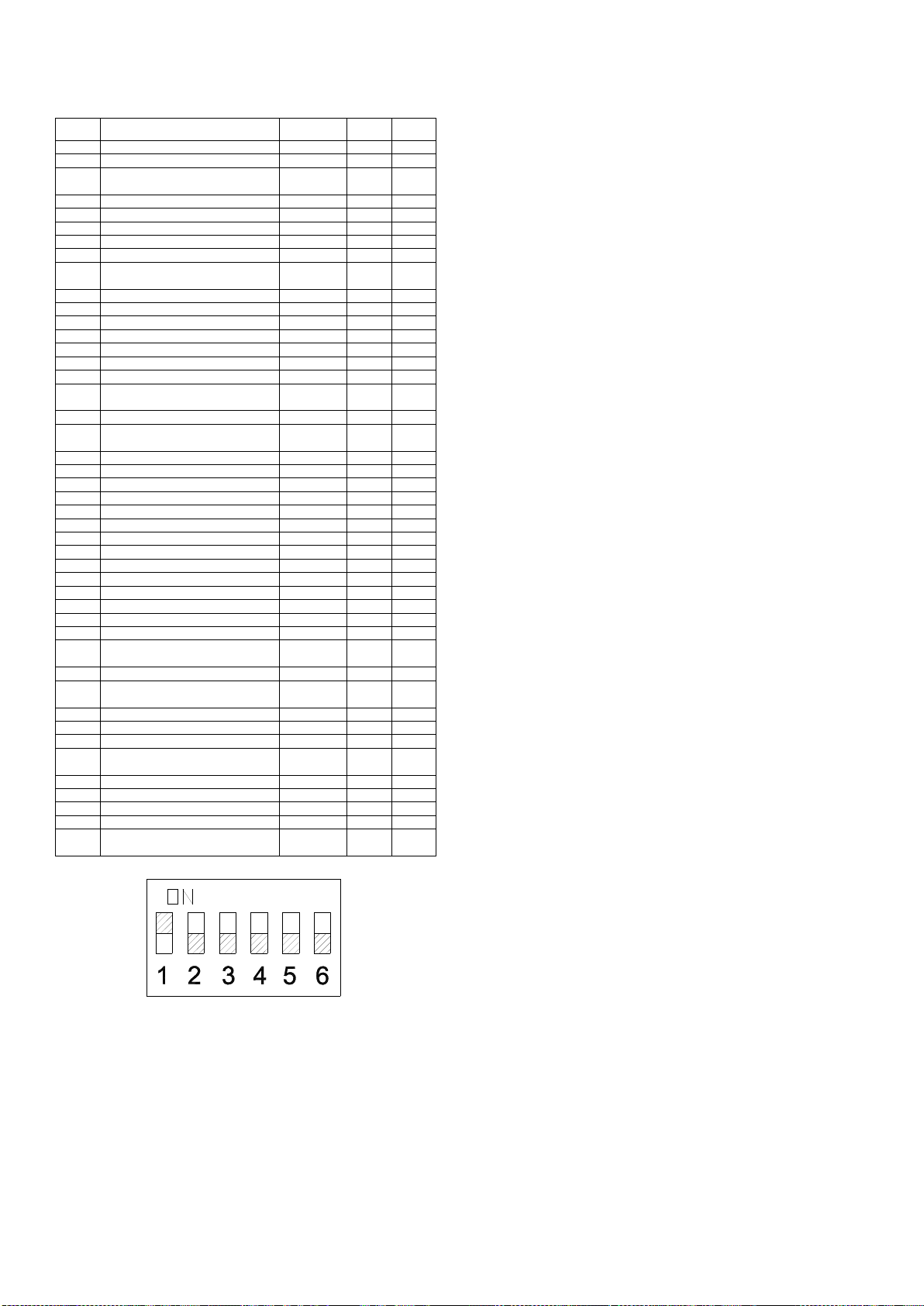

2.6 Electrical Ratings

E2xC1LD2FDC024 /

E2xC1LD2RDC024

E2xC1LD2FDC048 /

E2xC1LD2RDC048

E2xC1LD2FAC115 /

E2xC1LD2RAC115

E2xC1LD2FAC230 /

E2xC1LD2RAC230

It is important that a suitable power supply is used to run the

equipment. The power supply selected must have the

necessary capacity to provide the input current to all the

units.

The input current will vary according to the voltage input level

and the frequency of the tone selected. The current levels

shown above are for the tone resulting in max. current draw

(tone 1 - 340Hz Continuous) and worst-case input voltage

producing max. current.

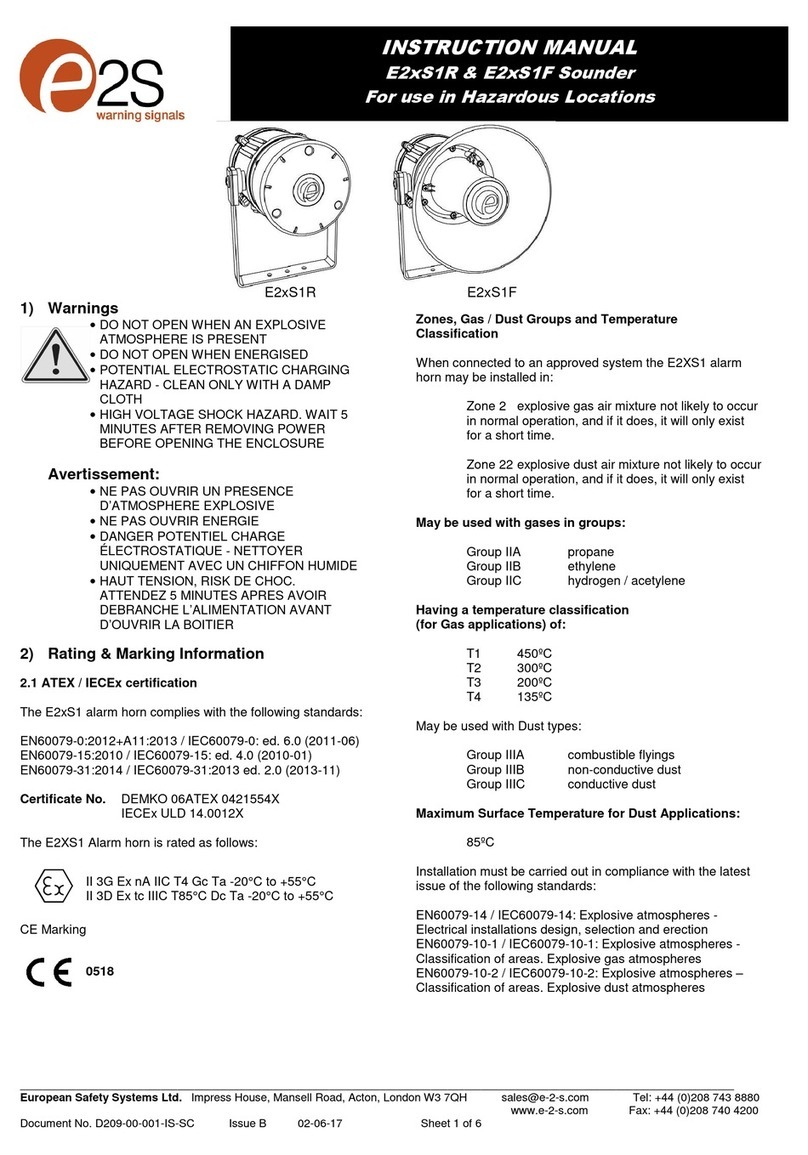

3) Special Conditions of Use

When used for a Group III application, the surface of the

enclosure may store electrostatic charge and become a

source of ignition in applications with a low relative humidity

<~30% relative humidity where the surface is relatively free of

surface contamination such as dirt, dust, or oil.

Guidance on protection against the risk of ignition due to

electrostatic discharge can be found in EN TR50404 and IEC

TR60079-32.

End user shall adhere to the manufacturer’s installation and

instruction when performing housekeeping to avoid the

potential for hazardous electrostatic charges during cleaning,

by using a damp cloth.

To maintain the ingress protection rating and mode of

protection, the cable entries must be fitted with suitably rated,

certified cable entry and/or blanking devices during

installation. If conduit is used for installation, seal conduit

within 18 inches from the enclosure.

Equipment with the flare horn shall not be installed with the

flare higher than horizontal (to avoid accumulation of dust).

The equipment incorporates metal parts isolated from earth,

having capacitance values exceeding the limits permitted in

the standards of certification. Mounting bracket –10.33pF;

Lens guard –12.33pF.

4) Location and Mounting

The location of the unit should be made with due regard to

the area over which the warning signal must be audible. They

should only be fixed to services that can carry the weight of

the unit.

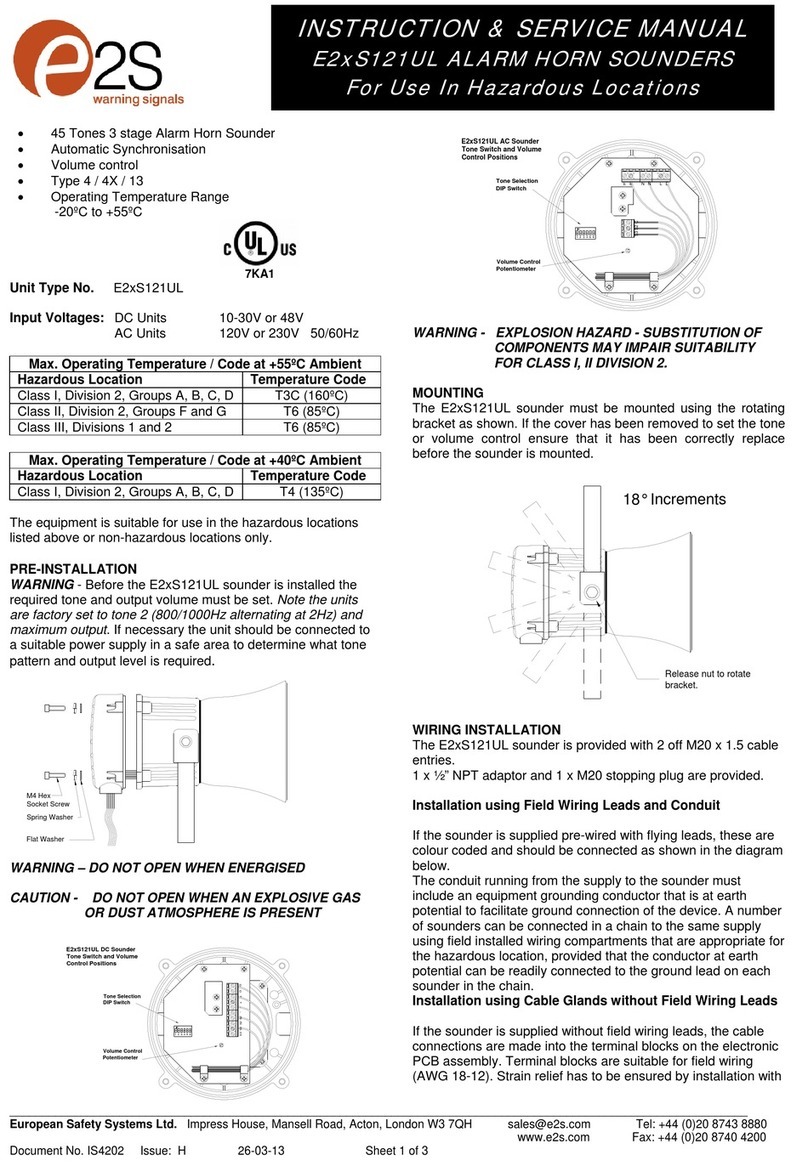

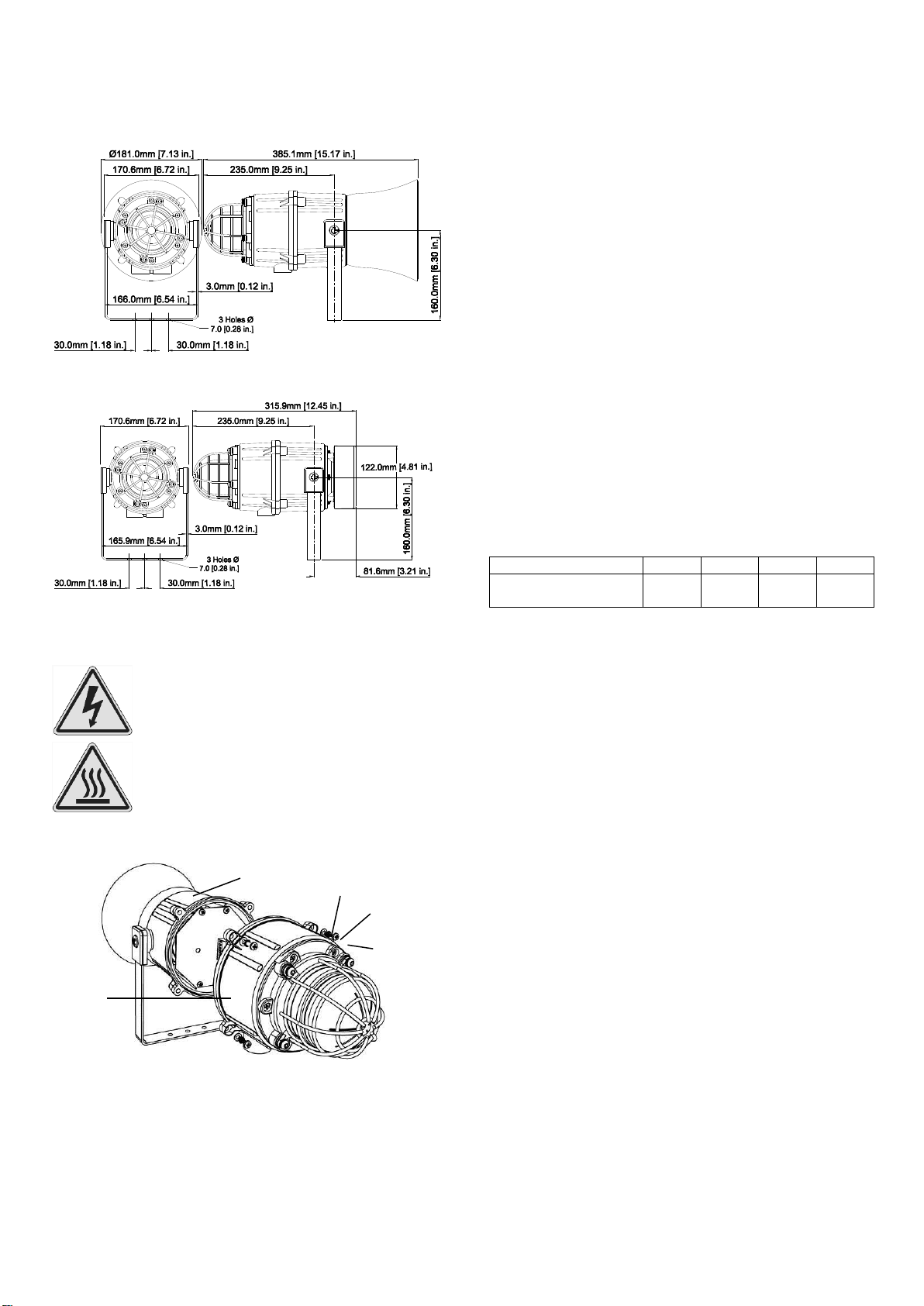

The E2x combined sounder beacon should be secured to any

flat surface using the three 7mm fixing holes on the stainless

steel U shaped mounting bracket. See Figure 1. The required

angle can be achieved by loosening the two large bracket

screws in the side of the unit, which allow adjustment of the

unit in steps of 18°. On completion of the installation the two