23

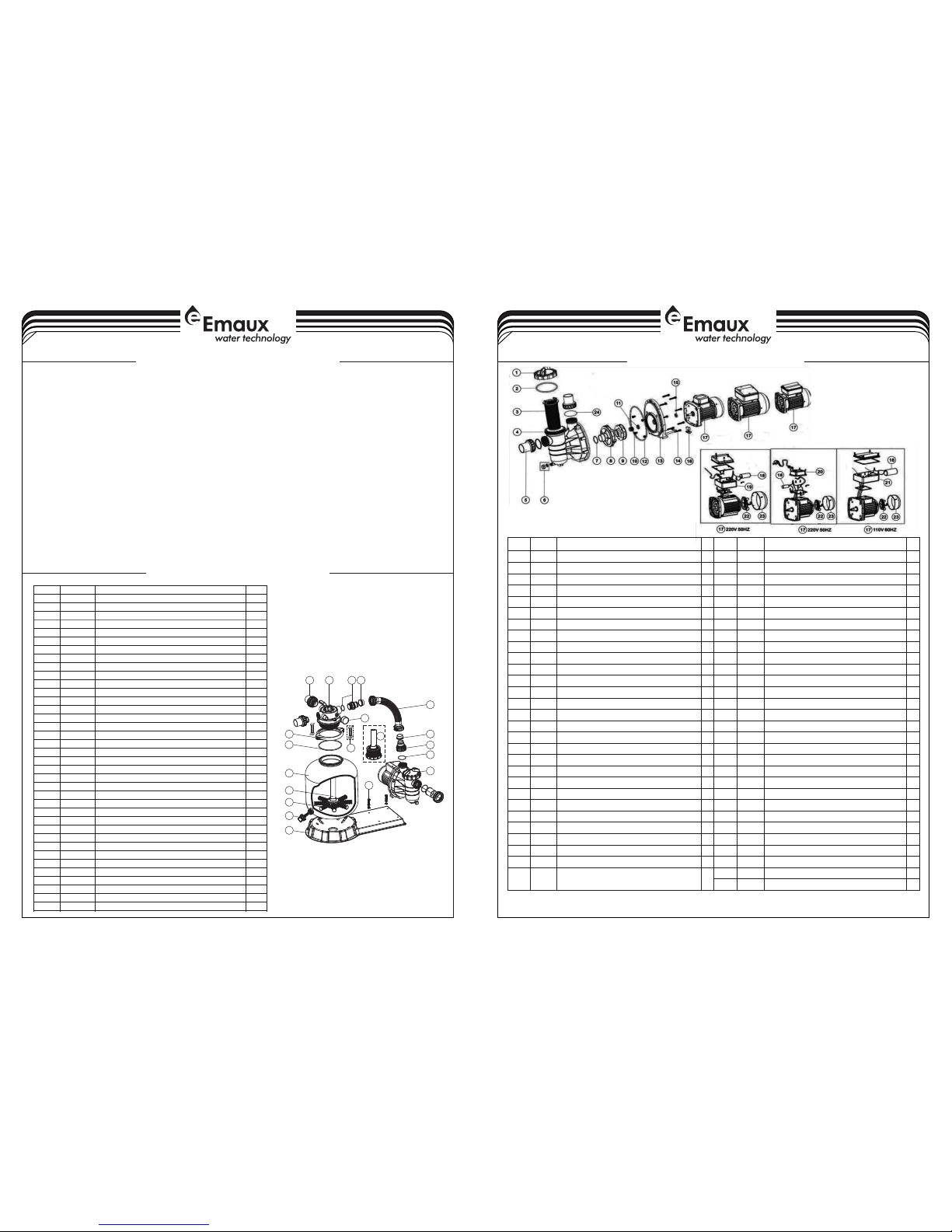

REPLACEMENT PARTS OF FILTER

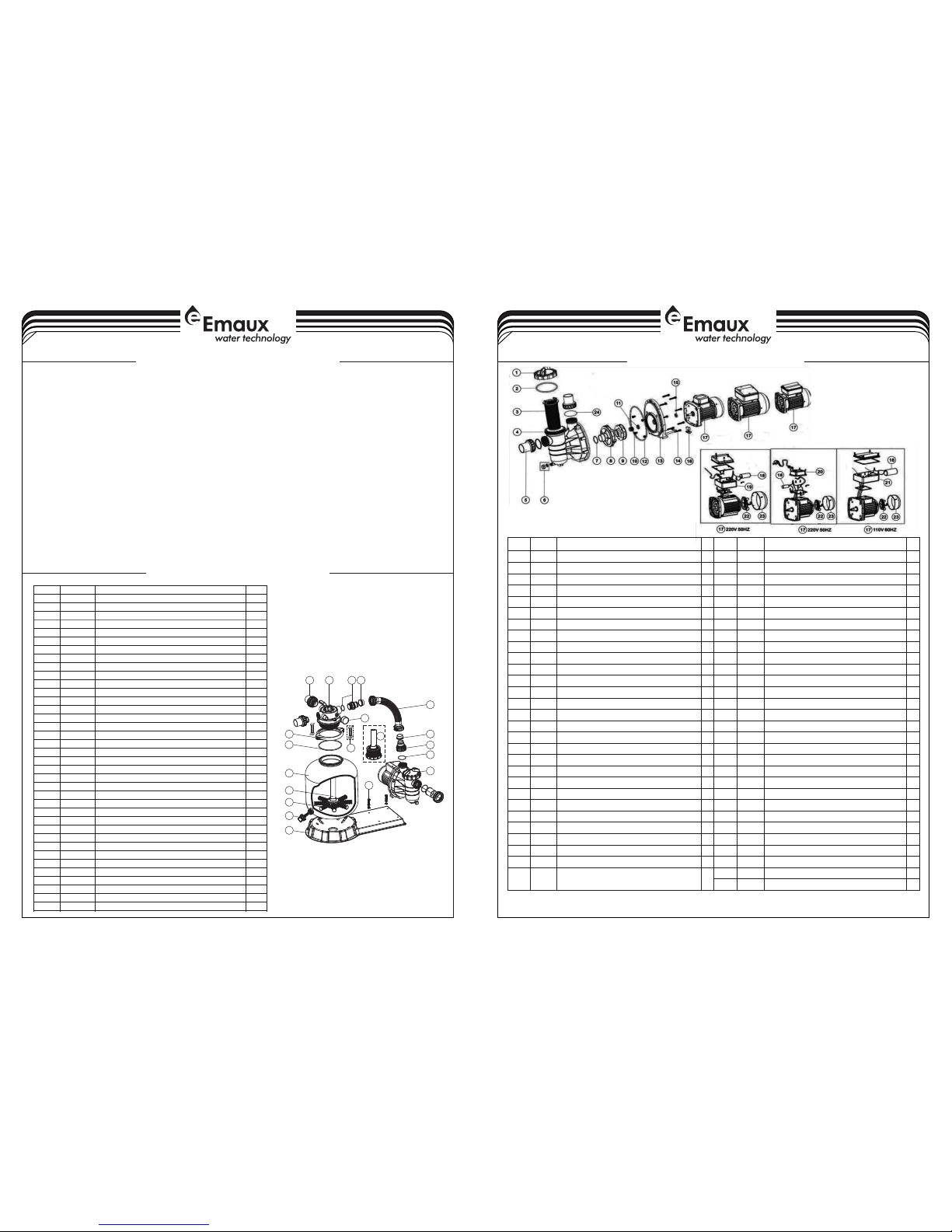

SS PUMP REPLACEMENT PARTS

1) Be sure correct amount of filter media sand is in tank and that all connections have been made and are secure.

2 Depress control valve handle and rotate to BACKWASH position. (To prevent damage to control valve seal, )

3 Prime and start pump. Never tun pump dry! Running pump dry may damage seals,causing leakage and flooding!)

Fill pump with water before starting motor. (be sure all suction and return lines are open), allowing the filter tank

to fill with water. Once water is flowing out of the waste line, run the pump for at least 1 minute. The initial

back-washing of the filter is recommended to remove any impurities or fine sand particles in the sand media.

4 Turn pump off and set valve to RINSE position. Start pump and operate until water in sight glass is clear, about )

normal filter mode, filtering dirt particles from the pool water.

5 Adjust pool suction and return valves to achieve desired flow. Check system and filter for water leaks and tighten)

6 Note the initial pressure gauge reading when the filter is clean. (It will vary from pool to pool depending upon the )

than the initial "clean" pressure you noted, it is time to backwash the filter (see BACKWASH under filter and control

NOTE: During initial clean-up of the pool water it may be necessary to backwash frequently due to the unusually

INSTALL/START-UP OF FILTRATION

always depress handle before turning.)

1/2 to 1 minute. Turn pump off and set valve to FILTER position and restart pump.The filter is now operating in the

connections, bolts, nuts, as required.

pump and general piping system.) As the filter removes dirt and impurities from the pool water, the accumulation

in the filter will cause the pressure to rise and flow to diminish. When the pressure gauge reading is 1.5 bar, higher

heavy initial dirt load in the water.

valve functions).

10

2 1 35

6

5

8

9

16

15

18

17

13

12

11

4

7

14

19

1.5"-4Way Top Mount V alve (B lack/ W hite Colour)

1.5" Union Set W ith O-R ing (Bl ack/ Wh ite Colour)

Hose adaptor with O-R ing

Plastic Pressure Ga uge wit h O-Rin g (35psi)

Connector fo r press ure gau ge/st opper

FSP350-4W Plastic H ose wit h Nut

FSP400-4W Plastic h ose wit h Nut

FSP450-4W Plastic h ose wit h Nut

FSP500-4W Plastic h ose wit h Nut

FSP650-4W Plastic h ose wit h Nut

Pump 0.20hp, 220V/5 0Hz, Si ngle Ph ase

Pump 0.33hp, 220V/5 0Hz, Si ngle Ph ase

Pump 0.50hp, 220V/5 0Hz, Si ngle Ph ase

Pump 0.75hp, 220V/5 0Hz, Si ngle Ph ase

Pump 1.00hp, 220V/5 0Hz, Si ngle Ph ase

P350 Lateral Assemb ly with C enter P ipe

P400 Lateral Assemb ly with C enter P ipe

P450 Lateral Assemb ly with C enter P ipe

P500 Lateral Assemb ly with C enter P ipe

P650 Lateral Assemb ly with C enter P ipe

FSP/F350-4-6W Com bo Base

FSP/F400-6W - FSP/F 650-6 W Combo b ase

Notes:

1* 88281205B is 1.5"-4Way Top Mount Valve in Black Colour

1* 88281205W is 1.5"-4Way Top Mount Valve in White Colour

2* 89280102B is 1.5" Union Set With O-Ring in Black Colour

2* 89280102W is 1.5" Union Set With O-Ring in White Colour

Motor S D/SQ/SS/ ST020(22 0V/60HZ)

Motor S D/SQ/SS/ ST033(22 0V/60HZ)

Motor S D/SQ/SS/ ST050(22 0V/60HZ)

Motor S D/SQ/SS/ ST075(22 0V/60HZ)

1.5" Un ion (Black / White Colo ur)

Motor S D/SQ/SS/ ST100(22 0V/60HZ)

Motor S D/SQ/SS/ ST120(22 0V/60HZ)

Motor S D/SQ/SS/ ST020(11 0V/60HZ)

Motor S D/SQ/SS/ ST033(11 0V/60HZ)

Impel ler SS120( 220V/50H Z)

Motor S D/SQ/SS/ ST050(11 0V/60HZ)

Impel ler SD020/ SD50/SQ2 0/SQ50/S S20/SS50/ST20 /ST50

Motor S D/SQ/SS/ ST075(11 0V/60HZ)

Impel ler SD33/S D75/SQ33 /SQ75/SS 33/SS75/ST33/ST75

Motor S D/SQ/SS/ ST100(11 0V/60HZ)

Impeller S D05 0/S D10 0/SQ050/SQ100/SS050/ SS1 00/ ST0 50

Motor S D/SQ/SS/ ST120(11 0V/60HZ)

Impeller S D07 5/S D12 0/SQ075/SQ120/SS075/ SS1 20/ ST0 75

Capac itor for SS/ SD/SQ/ST 050 Pump 110 V

Impel ler SD100/ SQ100/SS 100/ST10 0(220V/50HZ)

Capac itor for SC0 50 & SS/SD/S Q/ST075 Pu mp 110V

Impel ler SD020/ SQ020/SS 020/ST02 0(220V,110V/6 0HZ)

Capacito r for S C07 5 & SS/ SD/ SQ/ST100-124 Pump 110 V

Impel ler SD033/ SQ033/SS 033/ST03 3(220V,110V/6 0HZ)

Capac itor for SS/ SD/SQ/SP /ST050 Pum p

M8 x 16 Scr ew with Wash er

Capac itor for SS/ SD/SQ/SP /ST075 & SC0 50 Pump

Capac itor for SS/ SD/SQ/SP /ST100-1 20

Capac itor for SS/ SD/SQ/ST 020 Pump 110 V

Capac itor for SS/ SD/SQ/ST 033 Pump 110 V

Capac itor for SS/ SD/SQ/ST 020 AMU020 P/TP(50/ 60Hz)

Capac itor for SS/ SD/SQ/ST 033 Pump

Cable B ox for SD,SQ ,SP,ST05 0-120 Pump

Motor S D020/SQ0 20/SS020 /ST020(2 20V/50HZ)

Cable B ox for SQ/ST /SD020-0 33, SS020- SS030 Pump

Motor S D033 (220V /50Hz)

Cable B ox for SA/ ST/ S D 110V

Motor S D050/SQ0 50/SS050 /ST050(2 20V/50HZ)

Cooling Fa n for S S/S D/S Q/S T050-SS/SD/SQ/ST1 20 Pu mp

Motor S D075/SQ0 75/SS075 /ST075(2 20V/50HZ)

Cooling Fa n for S S/S D/S Q/S T020-SS/SD/SQ/ST0 30 Pu mp

Motor S D100/SQ1 00/SS100 /ST100(2 20V/50HZ)

Fan Cov er for SS/SD /SQ/ST02 0-SS/SD/ SQ/ST030 P ump

Motor S D120/SQ1 20/SS120 /ST120(2 20V/50HZ)

Fan Cov er for SQ/SP /SS/SD/S T050-SQ/ SP/SS/SD /ST120

Notes: 5* 8928 0105B i s 1.5" Un ion in Black Colour

5* 89280105W i s 1.5" Un ion in Wh ite Colour