Models: LF700 / LF800 / LF900

1-4

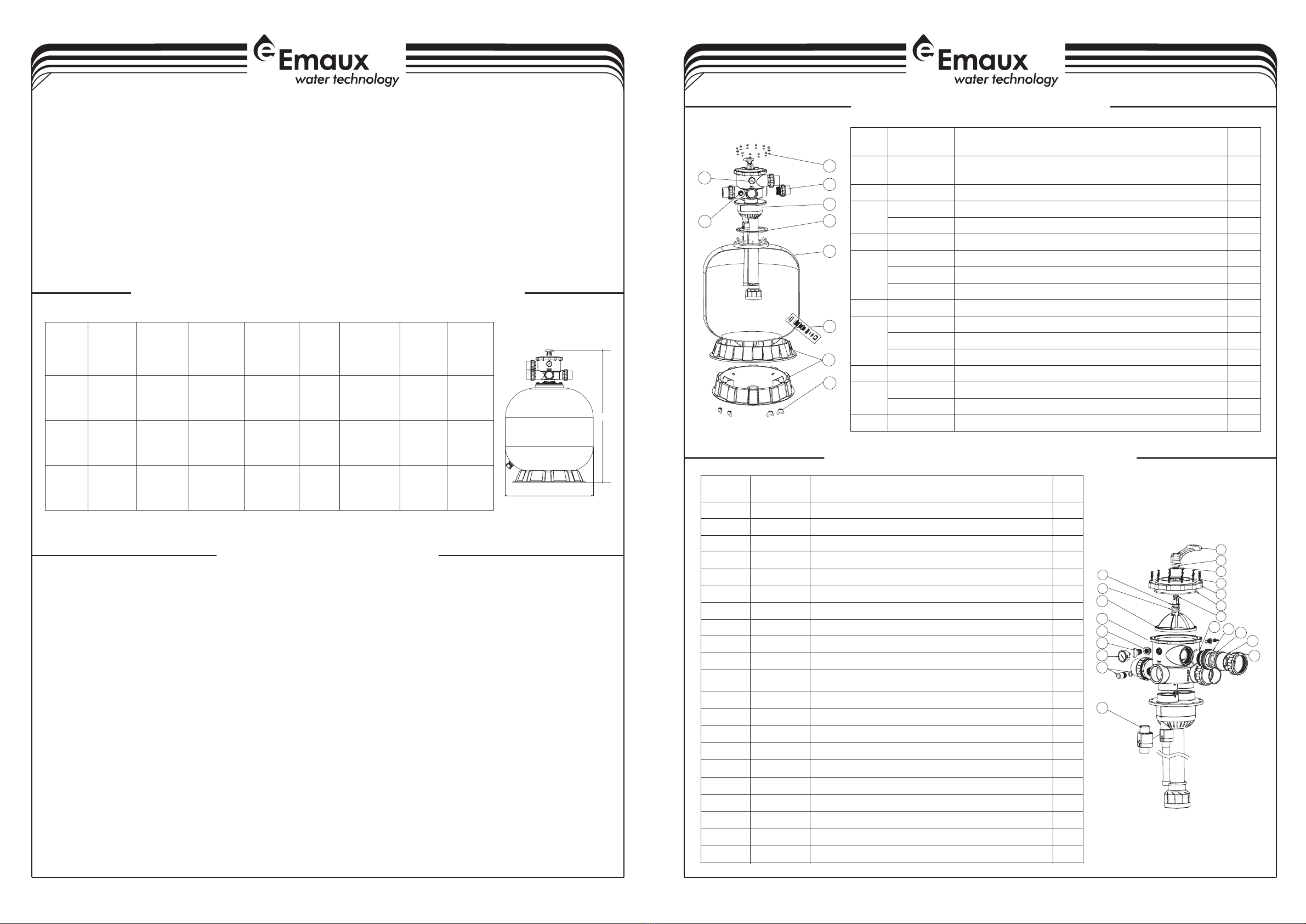

FUNCTION

INSTALLATION

Only simple tools (screwdriver and wrenches), plus pipe sealant for plastic adapters, are required to install and

service the filter.

1) The Bio-tank should be install/placed on a level concrete slab, very firm ground, or equivalent. Position the filter so

that the piping connections, control valve are convenient and accessible for operation and service.

2) Loading the Bio-ring media. Bio-ring media is loaded through the top opening of the tank.

a. Loosen flange clamp and remove filter control valve (if previously installed).

b. We recommend filling tank approximately 1/2 way with water to provide a cushion effect when the Bio-ring is

poured in. This helps protect the under-drain laterals from excessive shock.

3) Assemble filter control valve to filter tank.

a. Insert filter control valve (with Gasket in place) into the tank neck, fill-in half tank of water, taking care that the

center pipe slips into the hole in the bottom of the valve.

The Bio-Tank uses special Bio-Ring to remove dirt particles from pool water. (Special of the bigger particle) The Bio-

Ring is loaded into the filter tank and functions as a permanent dirt removing media. The special structure of Bio-

Ring will easy for bacteria grow up, bacteria can decompose the dirt and remind feed can produce toxic

(ammonium) into the water , over rate of ammonium will kill the animals. The bacteria can decompose the

ammonium. Advantageous to maintain the pool ecological balance in good level.

When the control valve is in the FILTER position, the pool water which contains suspended dirt particles, is pumped

through your piping system and is automatically directed by the patented filter control valve to the top of the filter

tank. As the pool water is pumped through the filter, dirt particles are trapped by the sand bed, and filtered out. The

cleaned Pool water is returned from the bottom of the filter tank, through the control valve and back to the pool

through the piping system. This entire sequence is continuous and automatic. It provides for total recirculation of

pool water through your filter and piping System.

After a period of time, the accumulated dirt in the tank causes a resistance to flow, and the flow diminishes. This

means it is the time to clean your tank. Turn the control valve in the BACKWASH position, the water flow is

automatically reversed through the tank by the main tube, the water go the tank by the end of the main tube, the

design diffuser will create a anti clock wise water flow inside the tank, flushing the previously trapped dirt and debris

will be centralize at the bottom of the tank, than the one–way valve open, the dirt will roll up and though the valve

and out the waste line. Once the tank is back-washed of dirt, set control valve to RINSE position and run pump for

about 1/2 to 1 minute, and then set the control valve in the FILTER position, to resume normal filtering.

NOTE: Turn pump off before changing valve position.

4-4

By-passes filter for circulating water to pool

Used after backwash to flush dirt from valve

Cleaning filter by reversing the flow

By-passes filter, used for vacuuming to waste or lowering water level

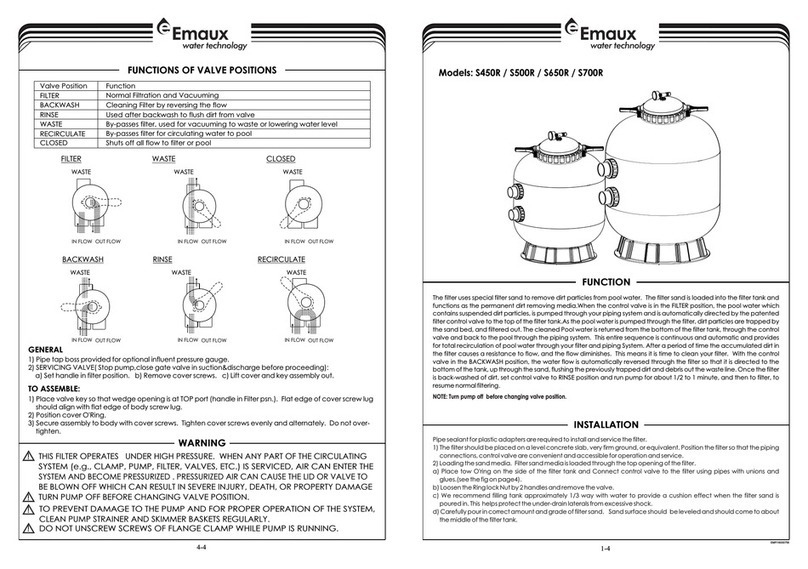

CLOSED Shuts off all flow to filter or pool

RECIRCULATE

WASTE

RINSE

BACKWASH

FILTER

Valve Position

Normal filtration

Function

Bio-Tank circulation systems operate under hazardous pressure during start up, normal operation, and after

pump shut off. Failure to follow safety and operation instructions could result in violent separation of the

pump housing and cover, and/or filter housing and clamp due to pressure in the system, which could cause

property damage, severe personal injury, or death. Before servicing pool circulation system, all system and

pump controls must be in off position and filter manual air relief valve must be in open position.

Do not change filter control valve position while system pump is running.

For protect and keep the tank in good condition operate, regular clean-up water pump strainer and pool

skimmer baskets

WARNING

FUNCTIONS OF VALVE POSITIONS

WASTE

FILTER

BACKWASH RINSE

WASTE

RECIRCULATE

CLOSED

WASTE WASTE

WASTE WASTE WASTE

IN FLOW O FLOWUT

GENERAL

1) Pipe tap boss provided for influent pressure gauge. (optional )

2) Servicing valve ( Stop pump, close gate valve in suction & discharge before proceeding)

a Set handle in filter position. b Remove cover screws. c Lift cover and key assembly out.. . .

TO ASSEMBLE:

1) Place valve key so that wedge opening is at TOP port (handle in Filter position.).

2) Position cover O'Ring. Flat edge of cover screw lug should align with flat edge of body screw lug.

3) Secure assembly to body with cover screws, tighten cover screws evenly and alternately. Do not over-tighten.

EMFI17022512

IN FLOW O FLOWUT IN FLOW O FLOWUT

IN FLOW O FLOWUT IN FLOW O FLOWUT IN FLOW O FLOWUT

B

更改内容

更改型号名称