2-4

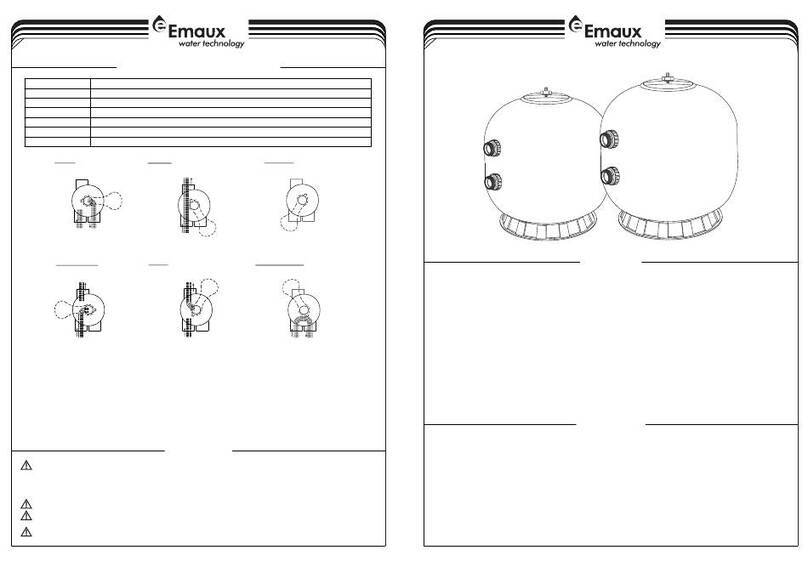

MAIN DIMENSION

REPLACEMENT PARTS OF FILTER

3-4

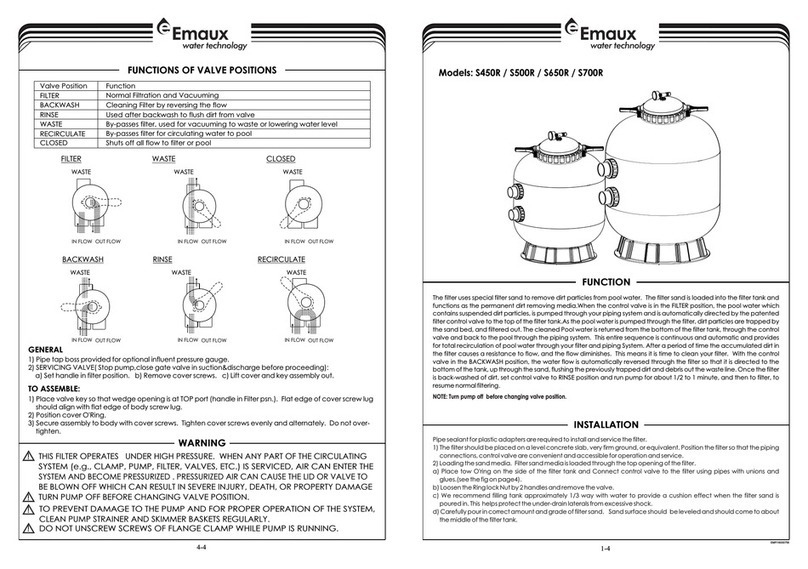

1. Be sure correct amount of filter media sand is in tank and that all connections have been made and are secure.

2. Depress control valve handle and rotate to BACKWASH position. (To prevent damage to control valve seal,

3. Prime and start pump according to pump instructions (be sure all suction and return lines are open), allowing the

4. Turn pump off and set valve to RINSE position. Start pump and operate until water in sight glass is clear, about

normal filter mode, filtering dirt particles from the pool water.

5. Adjust pool suction and return valves to achieve desired flow. Check system and filter for water leaks and tighten

6. Note the initial pressure gauge reading when the filter is clean. (It will vary from pool to pool depending upon the

initial "clean" pressure you noted, it is time to backwash the filter (see BACKWASH under filter and control

NOTE: During initial clean-up of the pool water it may be necessary to backwash frequently due to the unusually

INSTALL/START-UP OF FILTER

always depress handle before turning.)

filter tank to fill with water. Once water is flowing out of the waste line, run the pump for at least 1 minute. The initial

back-washing of the filter is recommended to remove any impurities or fine sand particles in the sand media.

1/2 to 1 minute. Turn pump off and set valve to FILTER position and restart pump.The filter is now operating in the

connections, bolts, nuts, as required.

pump and general piping system.) As the filter removes dirt and impurities from the pool water, the accumulation in the

filter will cause the pressure to rise and flow to diminish. When the pressure gauge reading is 1.5 bar, higher than the

heavy initial dirt load in the water.

valve functions).

3. Replace filter coping. Put the twelve nuts and washers onto each of the twelve bolts, then screw all the nuts on with

wrench,ensuring that all nuts are tight.

a. Carefully screw pressure gauge (with O'ring in place) into tapped hole in the filter coping. Do not over-tighten.

b. Ensure air relief valve (with O'ring in place) is tight fit to filter coping and turn it easily.

4. Connect pump to control valve opening marked PUMP.

5. Make return to pool pipe connection to control valve opening marked RETURN and complete other necessary

plumbing connections, suction lines to pump, waste, etc.

6. Make electrical connections to pump per pump instructions.

7. To prevent water leakage, be sure all pipe connections are tight.

B

A

DIMENSION TABLE

REPLACEMENT PARTS OF MULTIPORT VALVE

Item No.Part No. Product Description Qty

101013003 Handle ( Big)1

2 03018008 Pin for Handle 1

301181027 Washer for Handle(White)1

4 89281204 M6*33 T Screw with Nut 12

501021129 2.5"Side Mount Valve Standard Lid(White)1

6 02010228 O-Ring for 2.5" Valve Lid 1

702011022 O-Ring for 2.5" Valve Rotor 2

801181002 Washer for Spring(White)1

903014025 Spring for 2.5" Side Mount Valve 1

10 89280806 2.5" Valve Rotor With Spider Gasket 1

11 01021128 2.5" Side Mount Valve Bottom Body(White) 1

12 02020053 O-Ring for 2.5"Union 7

13 01171159 2.5" Union ( White)2

14 01150180 2.5" PVC Tube 90mm 2

15 01150181 2.5" Elbow Tube 1

16 01150180 2.5" PVC Tube 270mm 1

17 01013147 2.5"Connector (Black)2

01051243 2.5"Connector (white)3

18 01171158 2.5"Union ( A/E)(white)5

19 02010043 O-Ring for Union Adaptor 5

20 01013142 2.5" Side Mount Valve Plug ( White)2

21 89280104 Sight Glass With O-Ring 1

22 01111048 Connector for Pressure Gauge/Stopper(White) 2

23 89021303 Drain Plug with O'Ring(White)2

24 01013143 2.5"Connector(White)3

Model

A

High

mm

B

Diameter

mm

Valve Port

Size

Inch

Sand

Kg

9201180

S900(C) 2.5” 470

1

2

3

4

5

6

7

8

10

13

14

15

1617

20

21

1213141718

2223

9

12

11

1819

19

24

1

2

3

4

5

6

9

12

13

10

11

7

8

14

Oil Pressure Gauge With O-ring (40 psi)

Connector for Pressure Gauge/Stopper

03013003 M8 Nut*12Pc; + 03012003 M8

Washer*12Pc;

S900C Filter Tank With Base

Connector Plate Side Mount

S900C Top part of the inner tank system

S900C Bottom part of the inner tank system