EAOM-210 FLJ.eng / ver 0.0

Pages 2 / 132

Section 1 Introd ction .............................................................................................. 4

Section 2 Installation ............................................................................................... 7

2.1 Unit Configuration ...................................................................................................... 7

2.2 Mechanical Installation ................................................................................................ 7

Figure 2.3 Side view. ................................................................................................................................... 8

2.3 Electrical Connections.................................................................................................. 8

Figure 2.4 Rear view. .................................................................................................................................. 8

Figure 2.5 AOM-210 FLJ three phase connections schematic. ......................................................... 10

Table 2.1 Unit wiring ................................................................................................................................. 12

Table 2.2 Unit wiring description............................................................................................................ 14

Electronic Engines (ECUs) and EAOM-210FLJ nit............................................................................ 16

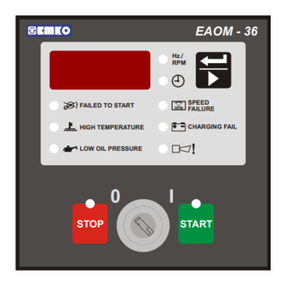

Section 3 Definition Of Front Panel And Programming.....................................................18

3.1 Front Panel Description...............................................................................................18

3.2 Programming Proce ure ..............................................................................................20

3.3 Accessing to the Operator Parameters............................................................................20

3.3.1 Changing and Saving Operator Parameter Val es.................................................................. 22

3.4 Accessing to the Technician Parameters .........................................................................24

3.4.1 Changing and Saving Technician Parameter Val es .............................................................. 33

3.5 Programmable function efinitions ................................................................................35

3.6 Pc Interface ..............................................................................................................94

3.6.1 Technical Specifications............................................................................................................... 94

3.6.2 RS-232 Serial Interface, Programming The Device Over PC or Modem ............................ 94

3.6.2.1 Cable Connection Between RS-232 Terminal of the Device and PC.............................. 94

3.6.3 Installation Instr ction ................................................................................................................. 94

3.6.3.1 Minimum system requirements.................................................................. 94

3.6.3.2 Installing AOM-210 FLJ configuration software ............................................. 94

3.6.3.3 To Run AOM-210 FLJ configuration software ................................................ 95

3.6.4 Description ...................................................................................................................................... 97

3.6.4.1 Main Menu........................................................................................... 97

File Menu.................................................................................................................................. 97

Window Menu .......................................................................................................................... 98

Program Menu ......................................................................................................................... 98

Observation Menu................................................................................................................... 99

Operator Parameters Menu................................................................................................. 103

Technician Parameters Menu ............................................................................................. 104

Adjustment Page (Calibration) Menu ................................................................................ 106

Communication Settings Menu ........................................................................................... 106

Help Menu .............................................................................................................................. 107

Section 4 Commissioning........................................................................................ 108

4.1 Manual operation..................................................................................................... 108

4.2 Auto Operation........................................................................................................ 109

4.3 Test Mo e Operation ................................................................................................ 109

Section 5 Operation .............................................................................................. 110

5.1 Controls an In icators ............................................................................................. 110

5.1.1 LCD Display Description:............................................................................................................... 110

5.1.2 Failure Indicators Description: .................................................................................................... 123