2

Content

1. Introduction..................................................................................................................................................3

2. Safety Instructions.......................................................................................................................................3

3. Box Content.................................................................................................................................................3

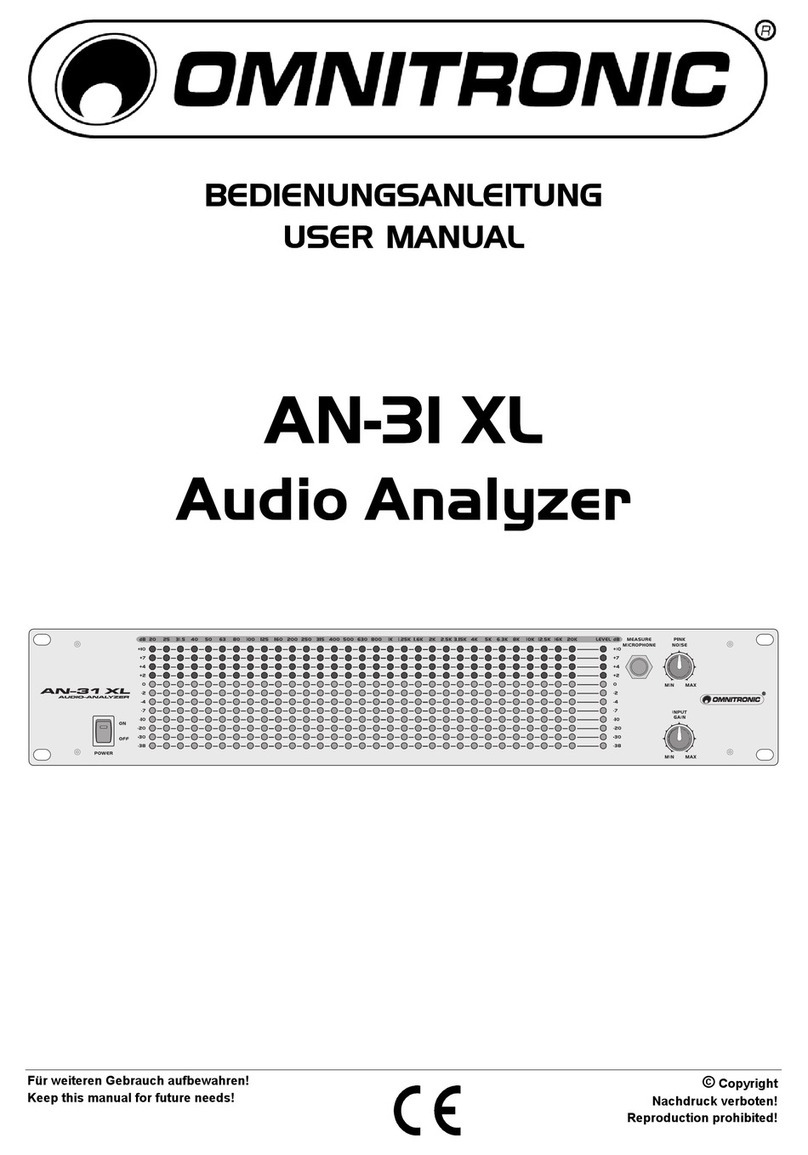

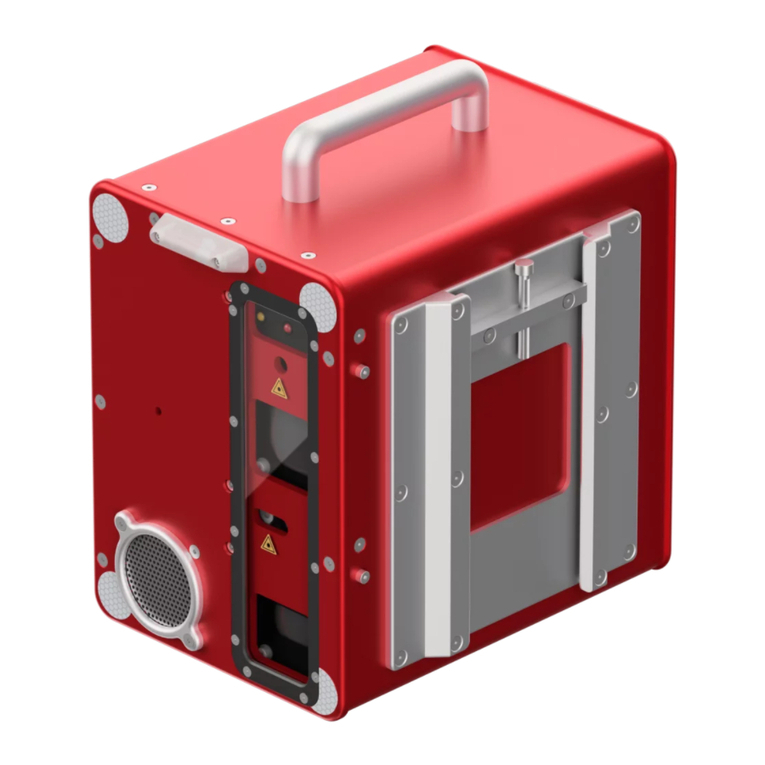

4. Device Description.......................................................................................................................................4

4.1. Front Panel..........................................................................................................................................4

4.2. Rear Panel ..........................................................................................................................................4

5. Measured Parameters.................................................................................................................................5

6. Installation ...................................................................................................................................................6

7. Connection ..................................................................................................................................................6

7.1. Grounding Conductor..........................................................................................................................7

7.2. Supply Voltage ....................................................................................................................................7

7.3. Voltage Measuring Inputs....................................................................................................................7

7.4. Current Measuring Inputs....................................................................................................................7

7.5. RS485 ................................................................................................................................................8

7.6. Ethernet...............................................................................................................................................8

7.6.1. Connection of EMK-01 to LAN.................................................................................................8

7.6.2. Connection of EMK-01 to Wi-Fi ...............................................................................................8

7.6.3. Connection of EMK-01 to LAN with NAT server.......................................................................9

7.7.USB......................................................................................................................................................10

7.8. Temperature Sensor............................................................................................................................10

7.9. Digital Inputs / Outputs........................................................................................................................10

8. Device Settings............................................................................................................................................11

8.1. Language ............................................................................................................................................11

8.2. Measurement – Main Parameters.......................................................................................................11

8.2.1. Connection Type .....................................................................................................................12

8.2.2. Nominal Voltage.......................................................................................................................13

8.2.3. Nominal Current.......................................................................................................................13

8.2.4. Flicker ......................................................................................................................................13

8.2.5. Ripple Control ..........................................................................................................................13

8.2.6. Voltage Transformers...............................................................................................................13

8.2.7. Current Transformers...............................................................................................................13

8.2.8. Averaging ................................................................................................................................14

8.2.9. Energy......................................................................................................................................14

8.3. Communication Settings .....................................................................................................................14

8.3.1. Ethernet ...................................................................................................................................14

8.3.2. Web Server ..............................................................................................................................15

8.3.3. Modbus TCP ............................................................................................................................15

8.3.4. FTP Server...............................................................................................................................15

8.3.5. TCP Converter .........................................................................................................................15

8.3.6. RS485 ......................................................................................................................................15

8.4. Analyser ..............................................................................................................................................16

8.5. NTP Server / Time Zone .....................................................................................................................16

8.6. E-mail..................................................................................................................................................16

8.7. Transient .............................................................................................................................................17

8.8. Events .................................................................................................................................................18

8.8.1. Voltage Dip ...............................................................................................................................19

8.8.2. Voltage Swell............................................................................................................................19

8.8.3. Rapid Voltage Change (RVC)...................................................................................................19

8.9. Inputs / Outputs...................................................................................................................................20

8.10. Alarms ...............................................................................................................................................20

8.12. Data Storage.....................................................................................................................................22

8.13. Memory Settings ...............................................................................................................................22

8.14. About.................................................................................................................................................22

9. Operation.....................................................................................................................................................22

9.1.Numeric................................................................................................................................................23

9.1.1. Flicker........................................................................................................................................23

9.2. Harmonics...........................................................................................................................................23

9.3. Vectors ................................................................................................................................................23

9.4. Bar Graphs..........................................................................................................................................24

9.5. Scope..................................................................................................................................................24

9.6. Events .................................................................................................................................................24

9.6.1. List of Events ............................................................................................................................24

9.6.2. Rapid Voltage Change (RVC)...................................................................................................25

9.6.3. List of Transients.......................................................................................................................25

9.6.4. Power Cuts ...............................................................................................................................25

10. Web Interface ............................................................................................................................................26

11. Firmware Update .......................................................................................................................................26

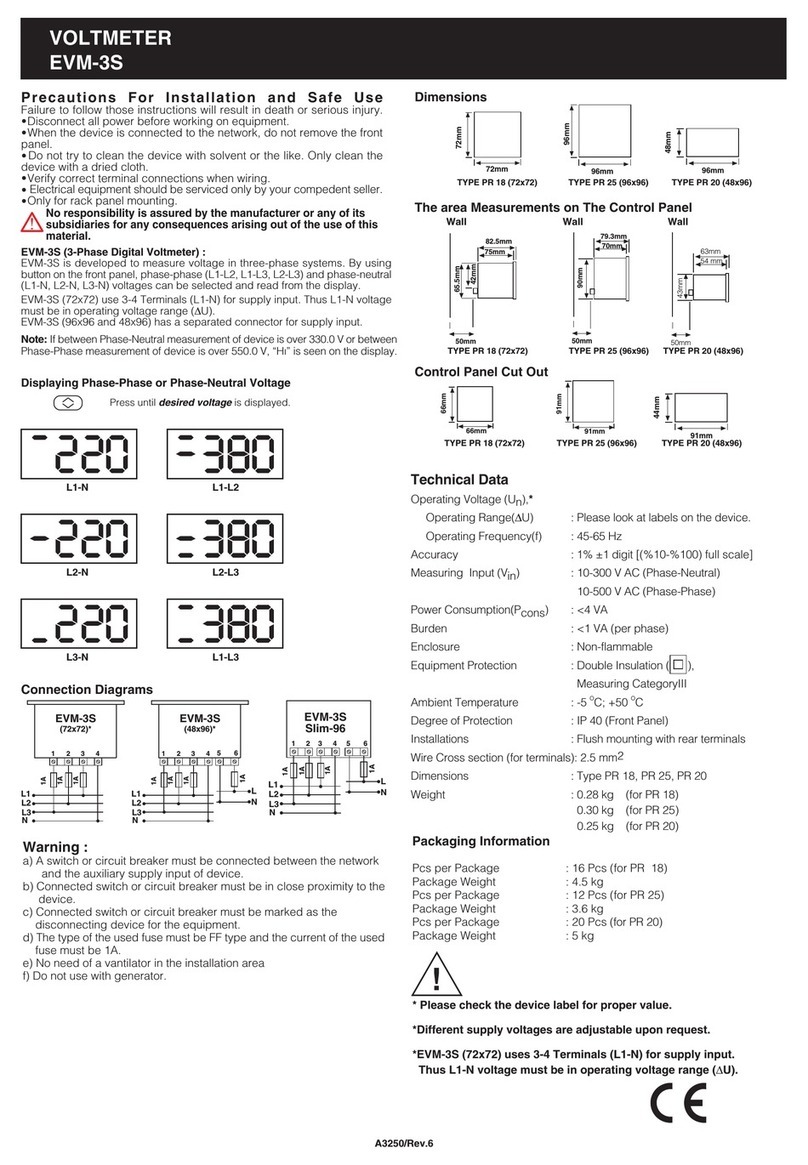

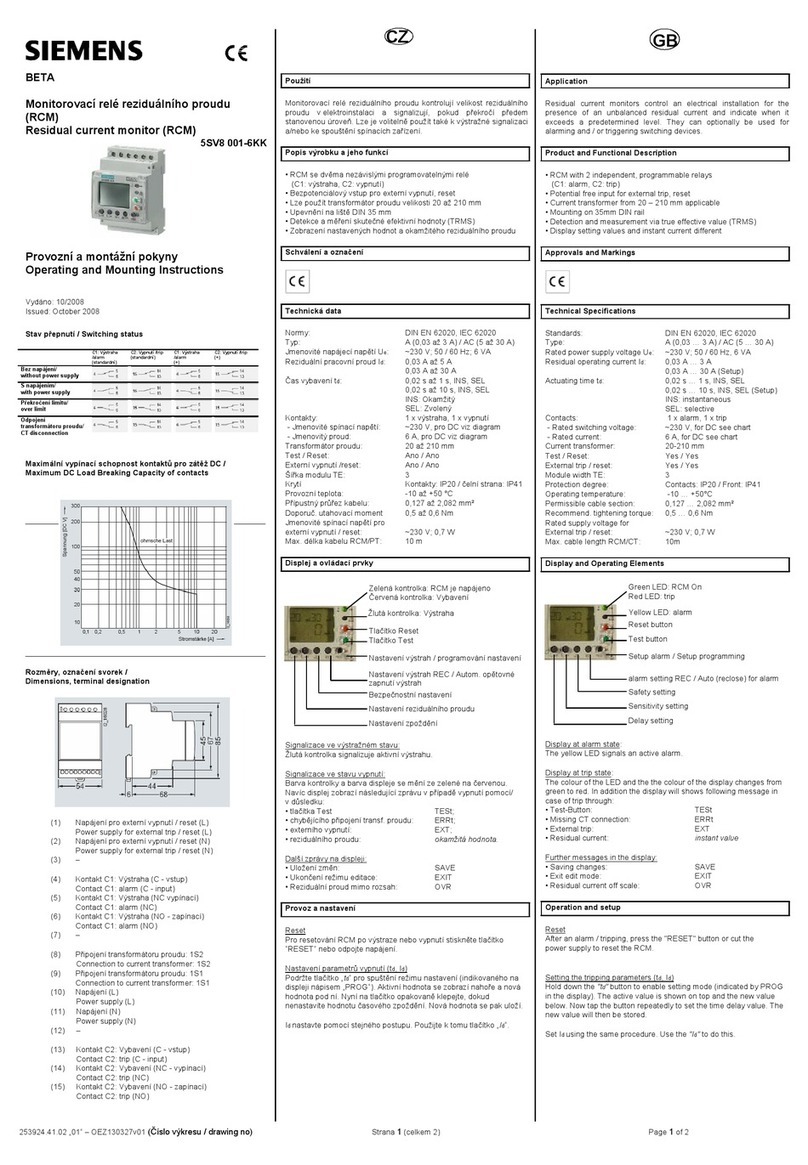

12. Technical Specications ............................................................................................................................27