QUICK START GUIDE

EPC – EFFICIENT POWER CONVERSION CORPORATION | WWW.EPC-CO.COM | COPYRIGHT 2018 | | 5

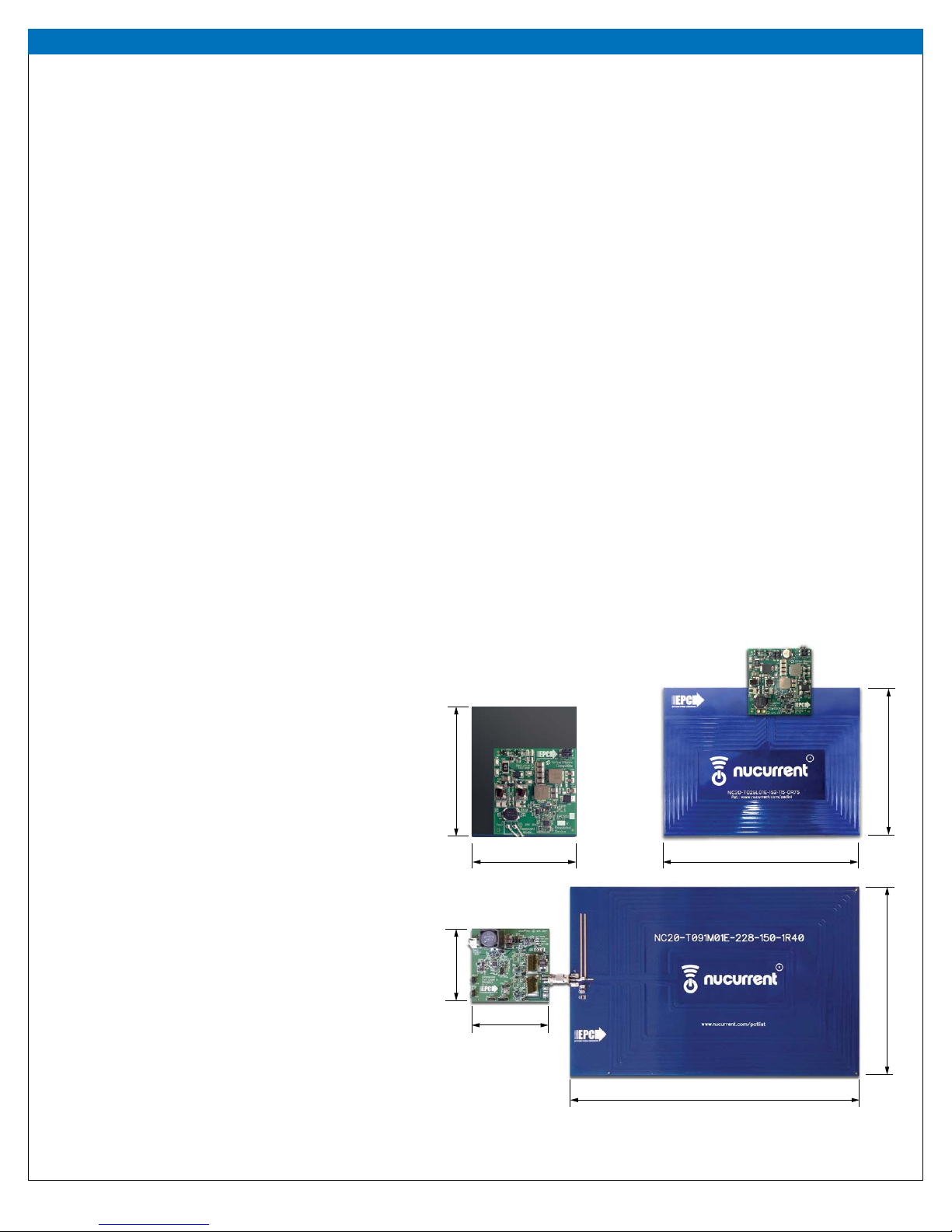

Demonstration System EPC9129

NOTE. The amplier supply voltage VAMP is absent from the equation

as it is accounted for by the voltage transition time. The COSS of the

EPC8010 eGaN FETs is on the same order of magnitude as the gate

driver well capacitance Cwell which as a result must now be included

in the ZVS timing calculation. The charge equivalent capacitance of

the eGaN FETs can be determined using the following equation:

(2)

To add additional immunity margin for shifts in coil impedance, the

value of LZVS can be decreased to increase the current at turn o

of the devices (which will increase device losses). Typical voltage

transition times range from 2 ns through 8 ns. For the dierential case

the voltage and charge (COSSQ) are doubled when calculating the ZVS

inductance.

The Source Coil

Figure 4 shows the schematic for the source coil which is Class 4

AirFuel compliant. The matching network includes only series tuning.

The matching network series tuning is dierential to allow balanced

connection and voltage reduction for the capacitors.

The Device Boards

Figure 5 shows the basic schematic diagram of the EPC9513 and

EPC9514 device boards which comprises a tuning circuit for the device

coil with a common-mode choke for EMI suppression, a high frequency

rectier and SEPIC converter based output regulator. The EPC9513 is

powered using a Category 3 AirFuel Alliance compliant device coil and

the EPC9514 is powered using a Category 5 AirFuel Alliance compliant

device coil Both are by default tuned to 6.78 MHz for the specic coil

provided with it. The tuning circuit comprises both parallel and series

tuning which is also dierential to allow balanced connection and

voltage reduction for the capacitors.

The device boards have have limited over-voltage protection using a

TVS diode that clamps the un-regulated voltage to 38 V (EPC9513) or

46 V (EPC9514) . This can occur when the receive coil is placed above

a high power transmitter with insucient distance to the transmit

coil and there is little or no load connected. During an over-voltage

event, the TVS diode will dissipate a large amount of power and the red

LED will illuminate indicating an over-voltage. The receiver should be

removed from the transmitter as soon as possible to prevent the TVS

diode from over-heating.

The EPC9513 and EPC9514 can be operated with or without the

regulator. The regulator can be disabled by inserting a jumper into

position JP50 and connecting the load to the unregulated output

terminals. In regulated mode, the design of the EPC9513 and EPC9514

controller will ensure stable operation in a wireless power system. The

regulator operates at 280 kHz (EPC9513) or 300 kHz (EPC9514) and the

controller features over current protection that limits the load current

to 1 A for the EPC9513 and 2 A for the EPC9514.

The EPC9513 and EPC9514 device boards come equipped with Kelvin

connections for easy and accurate measurement of the un-regulated

and regulated output voltages. The rectied voltage current can also

be measured using the included shunt resistor. In addition, the EPC9513

and EPC9514 have been provided with a switch-node measurement

connection for low inductance connection to an oscilloscope probe to

yield reliable waveforms.

The EPC9513 is designed to operate in conjunction with EPC9127

(10 W EPC9510)

, EPC9128 (16 W EPC9509), EPC9129 (33 W EPC9512) and

EPC9121 (10 W EPC9511) transmitter units. The EPC9514 is designed to

operate in conjunction with EPC9129 (33 W EPC9512) transmitter units.

QUICK START PROCEDURE

The EPC9129 demonstration system is easy to set up and evaluate the

performance of the eGaN FET in a wireless power transfer application.

Refer to gure 1 to assemble the system and gures 8, 9, and 10 for

proper connection and measurement setup before following the testing

procedures.

The EPC9512 can be operated using any one of two alternative methods:

a. Using the pre-regulator

b. Bypassing the pre-regulator

a. Operation using the pre-regulator

The pre-regulator is used to supply power to the amplier in this mode

and will limit the coil current, power delivered or maximum supply voltage

to the amplier based on the pre-determined settings.

The main 19 V supply must be capable of delivering 2.3 ADC. DO NOT turn

up the voltage of this supply when instructed to power up the board,

instead simply turn on the supply. The EPC9512 board includes a pre-

regulator to ensure proper operation of the board including start up.

1. Make sure the entire system is fully assembled prior to making

electrical connections and make sure jumper JP1 is installed. Also

make sure the source coil and device coil with load are connected.

2. With power o, connect the main input power supply bus to J1 as

shown in gure 8. Note the polarity of the supply connector.

3. Make sure all instrumentation is connected to the system.

4. Turn on the main supply voltage to the required value (19 V).

5. Once operation has been conrmed, observe the output voltage and

other parameters on both the amplier and device boards.

6. For shutdown, please follow steps in the reverse order.

b. Operation bypassing the pre-regulator

In this mode, the pre-regulator is bypassed and the main power is

connected directly to the amplier. This allows the amplier to be

operated using an external regulator.

Note: In this mode there is no protection for ensuring the correct

operating conditions for the eGaN FETs.

When in bypass mode it is crucial to slowly turn up the supply voltage

starting at 0 V. Note that in bypass mode you will be using two supplies;

one for logic and the other for the amplier power.

1. Make sure the entire system is fully assembled prior to making

electrical connections and make sure jumper JP1 has been removed

and installed in JP50 to disable the pre-regulator and to place the

EPC9512 amplier in bypass mode. Also make sure the source coil and

device coil with load are connected.

COSSQ =

V

AMP

0

AMP

COSS (v) dv

1