QUICK START GUIDE

EPC – EFFICIENT POWER CONVERSION CORPORATION | WWW.EPC-CO.COM | COPYRIGHT 2015 | | PAGE 4

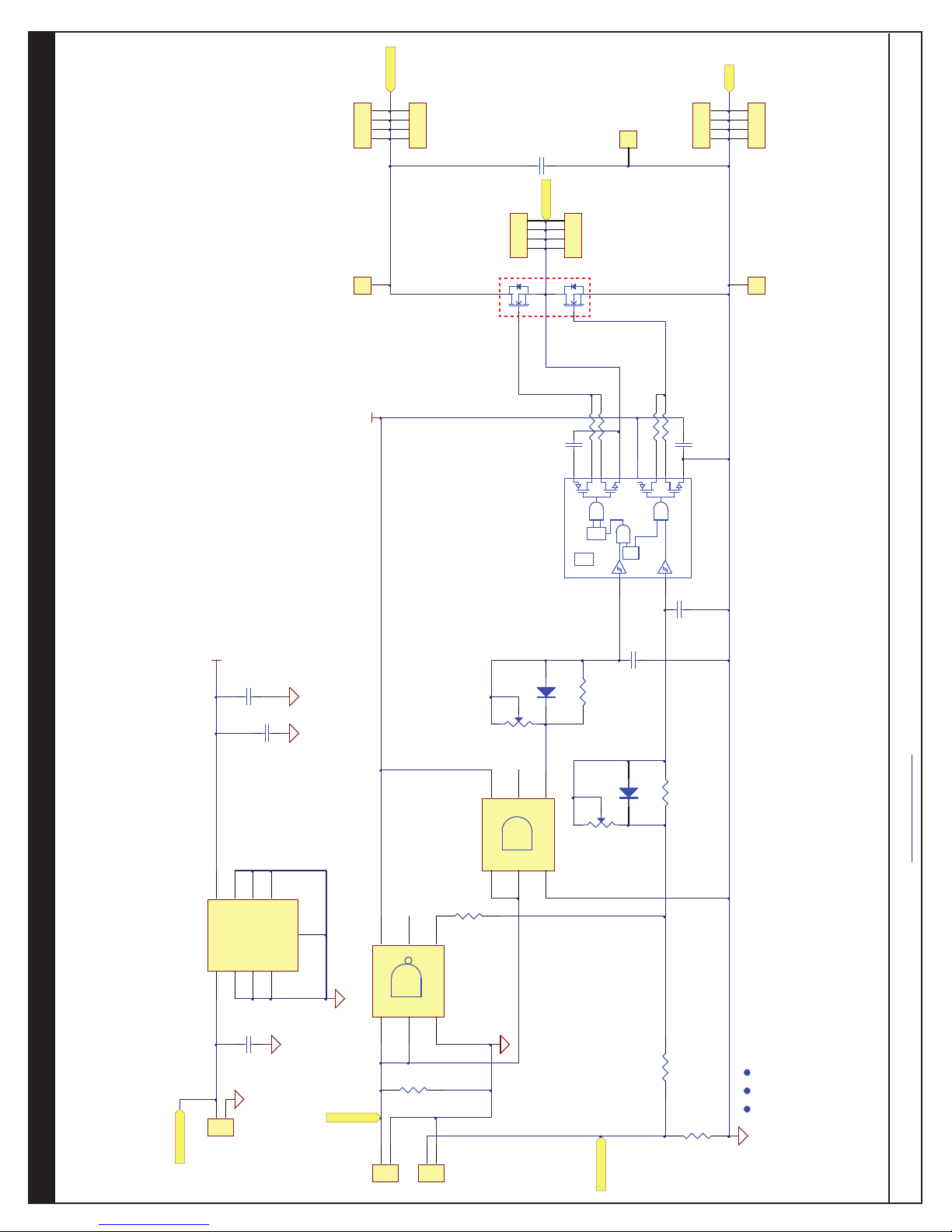

EPC9055

THERMAL PERFORMANCE

400 LFM

The EPC9055 development boards showcase the EPC2106 eGaN FETs.

These development boards are intended for bench evaluation with low

ambient temperature and convection cooling. The addition of heat-

sinking and forced air cooling can signicantly increase the current rating

Figure 4:TypicalWaveforms for EPC9055. VIN = 80V to 5V/3 A (500 kHz) Buck converter showing rising and falling edges,

CH1: (VPWM) Input logic signal – CH2: (IOUT) Output inductor current – CH4: (VOUT) Switch node voltage

of these devices, but care must be taken to not exceed the absolute

maximum die temperature of 150°C.

NOTE. The EPC9055 development boards do not have any current or

thermal protection on board.

Table 2: Bill of Materials

Item Qty Reference Part Description Manufacturer / Part #

1 3 C4, C10, C11,

Capacitor, 1 µF, 10%, 25 V, X5R

Murata, GRM188R61E105KA12D

2 2 C9, C19

Capacitor, 0.1 µF, 10%, 25 V, X5R

TDK, C1005X5R1E104K

3 2 C16, C17

Capacitor, 100 pF, 5%, 50 V, NP0

Kemet, C0402C101K5GACTU

4 1 C21

Capacitor, 1 µF, 10%, 100 V, X7R

TDK, CGA4J3X7S2A105K125AE

5 2 D1, D2

Schottky diode, 30 V

Diodes Inc., SDM03U40-7

6 3 J1, J2, J9

Connector

2pins of Tyco, 4-103185-0

7 1 J3, J4, J5, J6, J7, J8

Connector

FCI, 68602-224HLF

8 1 Q1

eGaN-IC monolithic half bridge

EPC, EPC2106

9 1 R1

Resistor, 10.0 K, 5%, 1/8 W

Stackpole, RMCF0603FT10K0

10 2 R2, R15

Resistor, 0 Ohm, 1/8 W

Stackpole, RMCF0603ZT0R00

11 1 R4

Resistor, 22 Ohm, 1%, 1/8 W

Stackpole, RMCF0603FT22R0

12 1 R5

Resistor, 47 Ohm, 1%, 1/8 W

Stackpole, RMCF0603FT47R0

13 4 R19, R20, R23, R24

Resistor, 1 Ohm, 1/16 W

Stackpole, RMCF0402FT1R00

14 2 TP1, TP2

Test point

Keystone Elect, 5015

15 1 TP3

Connector

1/40th of Tyco, 4-103185-0

16 1 U1

I.C., logic

Fairchild, NC7SZ00L6X

17 1 U2

I.C., gate driver

Texas Instruments, LM5113

18 1 U3

I.C., regulator

Microchip, MCP1703T-5002E/MC

19 1 U4

I.C., logic

Fairchild, NC7SZ08L6X

20 0 R14

Optional resistor

21 0 D3

Optional diode

22 0 P1, P2

Optional potentiometer

Figure 4 (a) – Rising Edge Figure 4 (b) – Falling Edge

3.75 ns fall time

1.7 ns rise time 550 MHz ringing

13V