1

1

2

2

3

3

4

4

5

5

6

6

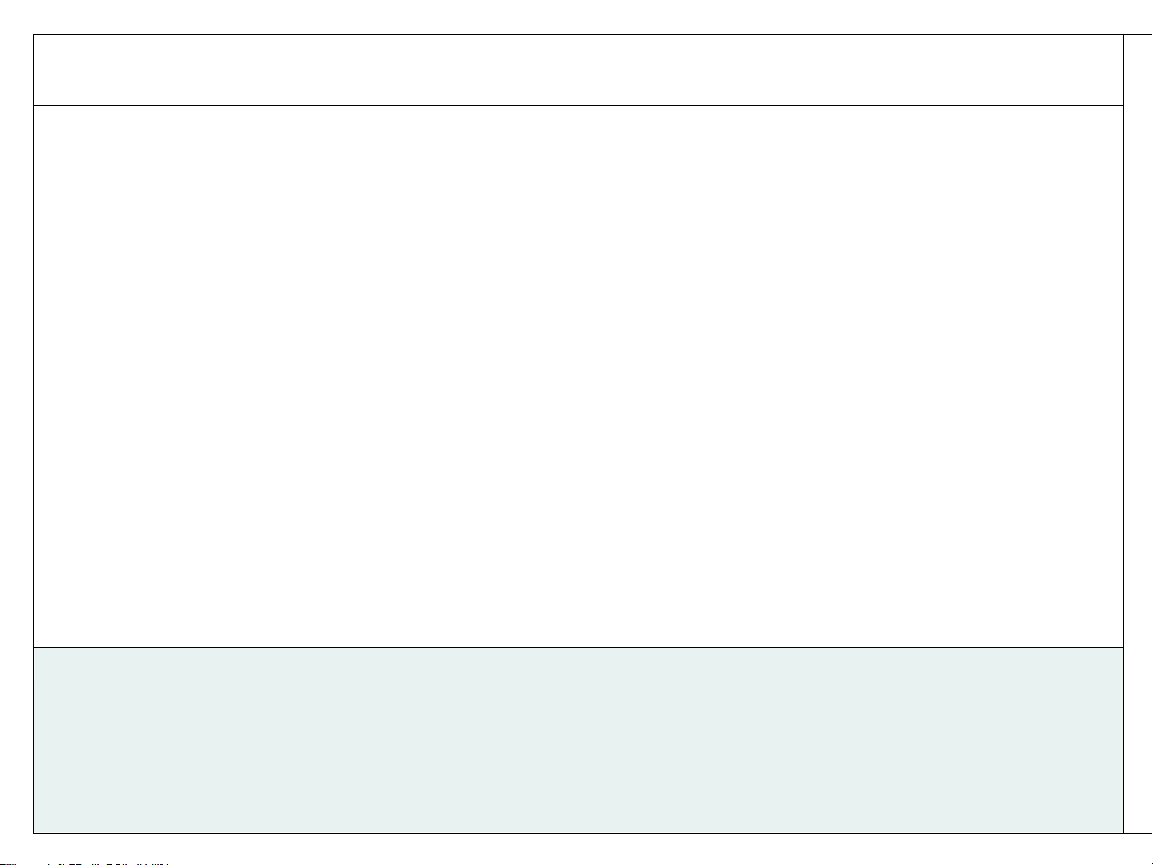

DD

CC

BB

AA

C8

4.7uF, 10V

C9

0.1uF, 25V

Vosns-

1

Vosns+

2

Trk/ss

3

ITH

4

Vrng

5

RT

6

Run

7

ExtVCC

8

Mode/PLL

9

Vin

10

IntVCC 11

PGND 12

BG 13

SW 14

TG 15

Boost 16

PGood 17

Sns+ 18

Sns- 19

Vout 20

SGND 21

U1

LTC3833

GND

J4

GND

J2

VIN

J1

1.2 V / 20 A

VOUT

J3

R2

15k

C3

22pF

C1

220pF

R12

100k

R11

560k

RUN VIN

R13

1k

MODE

VCC

VOUT

VOUT

RUN

VCC

MODE

VIN

VIN

C5

4.7uF, 10V

R9

2.2

C7

0.1uF, 25V

R10

10.0k

PGOOD

PGOOD

C2

0.1uF, 25V

TRK/SS

R4

10.0k

R3

10.0k

VOUT

Remote sensing

R8

39.2k

R7

Zero

R5

Opt

VCC

R16

Opt

R15

680

S- S+

S-

S+

C4

0.1uF, 25V

C15

0.1uF, 25V

SJ3

R22

47

C17

100pF

D2

SDM03U40

R21

22

D1

SDM03U40

C16

100pF

R19

0 Ohm

R20

0 Ohm

2

P1

optional

2

P2

optional

C18

Optional

1

TP3

Keystone 5015

1

TP4

Keystone 5015

1

TP1

Keystone 5015

1

TP2

Keystone 5015

R14

1k

C6

Optional

1

TP5

Keystone 5015

SYNC

1

TP6

Keystone 5015

RUN

1

TP7

Keystone 5015

PGOOD

TRK/SS

1

TP8

Keystone 5015

TRACK

C10

10uF, 35V

Q2

EPC2015

C22 C23

C11

4.7uF, 35V

U2

LM5113TM

C19

0.1uF, 25V

SJ4

SJ1 SJ2

GND

A

B

Y

VDD

U3

NC7SZ00L6X

VCC

C24

47uF, 6.3V

EXT

EXT

1

TP9

Keystone 5015

C12

47pF

EPC2014

Q1

L1

270nH

C14

C13 C20

C21

D3

Optional

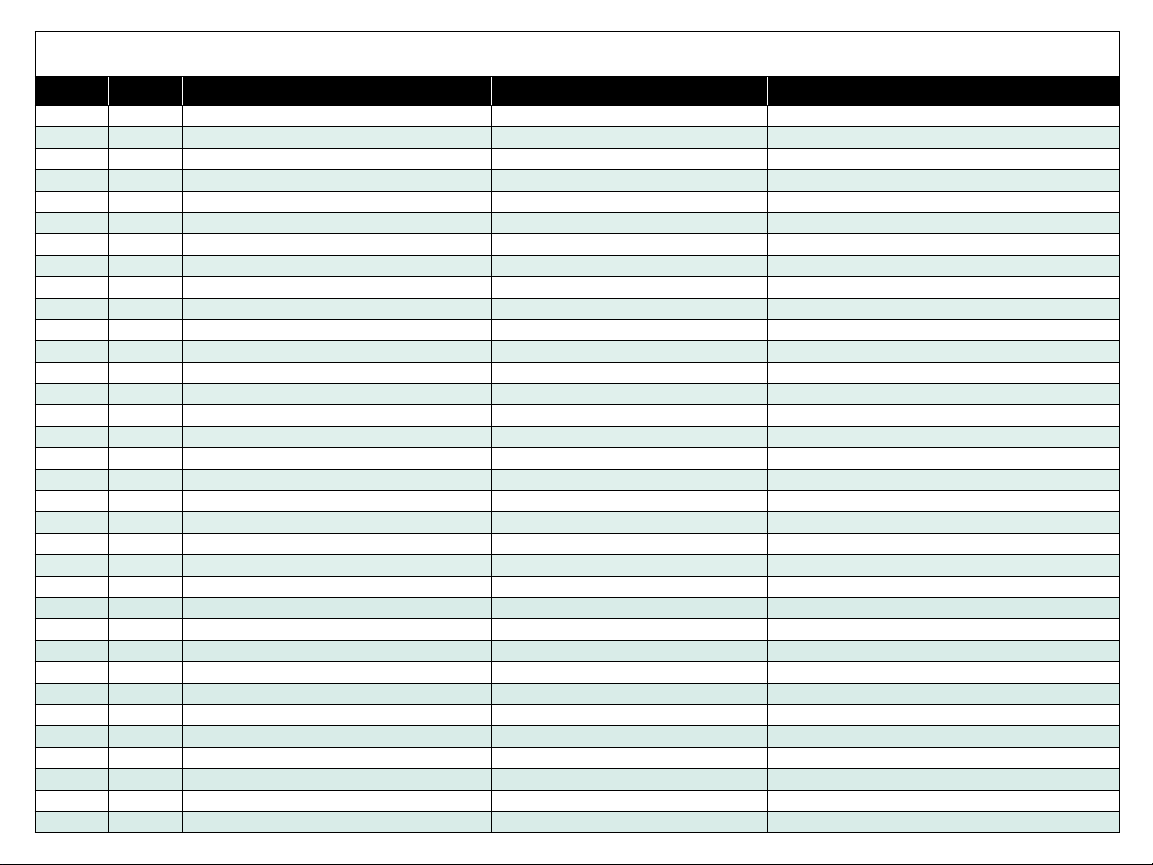

Table 2 : Bill of Material

Item Qty Reference Part Description Manufacturer / Part #

1

1 C1 Capacitor, 220pF, 5%, 50V, NP0 Murata, GRM1885C1H221JA01D

2 1 C3 Capacitor, 22pF, 5%, 50V, NP0 Murata, GRM1885C1H220JA01D

3 6 C2, C4, C7, C9, C15, C19 Capacitor, 0.1uF, 10%, 25V, X5R TDK, C1005X5R1E104K

4 2 C5, C8 Capacitor, 4.7uF, 10%, 10V, X5R TDK, C1608X5R1A475K

5 1 C10 Capacitor, 10uF, 20%, 35V, X5R Taiyo Yuden, GMK325BJ106KN

6 2 C11, C22, C23 Capacitor, 4.7uF, 10%, 35V, X7R TDK, C2012X6S1V475K125AB

7 5 C13, C14, C20, C21, C24 Capacitor, 47uF, 20%, 10V, X5R TDK, C2012X5R1A476M

8 2 C16, C17 Capacitor, 100pF, 5%, 50V, NP0 Kemet, C0402C101K5GACTU

9 3 D1, D2, D4 Schottky Diode, 30V Diodes Inc., SDM03U40-7

10 4 J1, J2, J3, J4 Banana Jack Keystone, 575-4

11 1 L1 Inductor, 270nH Coilcraft, SLC1175-271ME

12 1 Q1 eGaN® FET EPC, EPC2014

13 1 Q2 eGaN® FET EPC, EPC2015

14 1 R2 Resistor, 15.0K, 1%, 1/8W Stackpole, RMCF0603FT15K0

15 3 R3, R4, R10 Resistor, 10.0K, 1%, 1/10W Stackpole, RMCF0603FT10K0

16 3 R7, R19, R20 Resistor, 0 Ohm, 1/16W Stackpole, RMCF0402ZT0R00

17 1 R8 Resistor, 39.2K, 1%, 1/8W Stackpole, RMCF0603FT39K2

18 1 R9 Resistor, 2.2 Ohm, 5%, 1/16W Yageo, RC0402FR-072R2L

19 1 R11 Resistor, 560K, 1%, 1/8W Stackpole, RMCF0603FT560K

20 1 R12 Resistor, 100K, 1%, 1/8W Stackpole, RMCF0603FT100K

21 2 R13, R14 Resistor, 1.00K, 5%, 1/10W Rohm, MCR03EZPJ102

22 1 R15 Resistor, 680 Ohm, 5%, 1/8W Stackpole, RMCF0603FT680R

23 1 R21 Resistor, 22 Ohm, 5%, 1/8W Stackpole, RMCF0603JT22R0

24 1 R22 Resistor, 47 Ohm, 5%, 1/8W Stackpole, RMCF0603JT47R0

25 9 TP1, TP2, TP3, TP4, TP5, TP6, TP7, TP8, TP9 Measurement Point Keystone Elect, 5015

26 1 U1 I.C., Buck Regulator Linear Technology, LTC3833EUDC#PBF

27 1 U2 I.C., Gate driver Texas Instruments, LM5113

28 1 U3 I.C., Logic Fairchild, NC7SZ00L6X

29 4 Nylon Stand-os Keystone, 8834

30 0 R5, R16 Optional Resistors

31 0 C6, C12, C18 Optional Capacitors

32 0 D3 Optional Diode

33 0 P1, P2 Potentiometer, 500 Ohm, 0.25W Murata, PV37Y501C01B00

34 0 SJ1, SJ2, SJ3, SJ4 Optional SMA Connectors

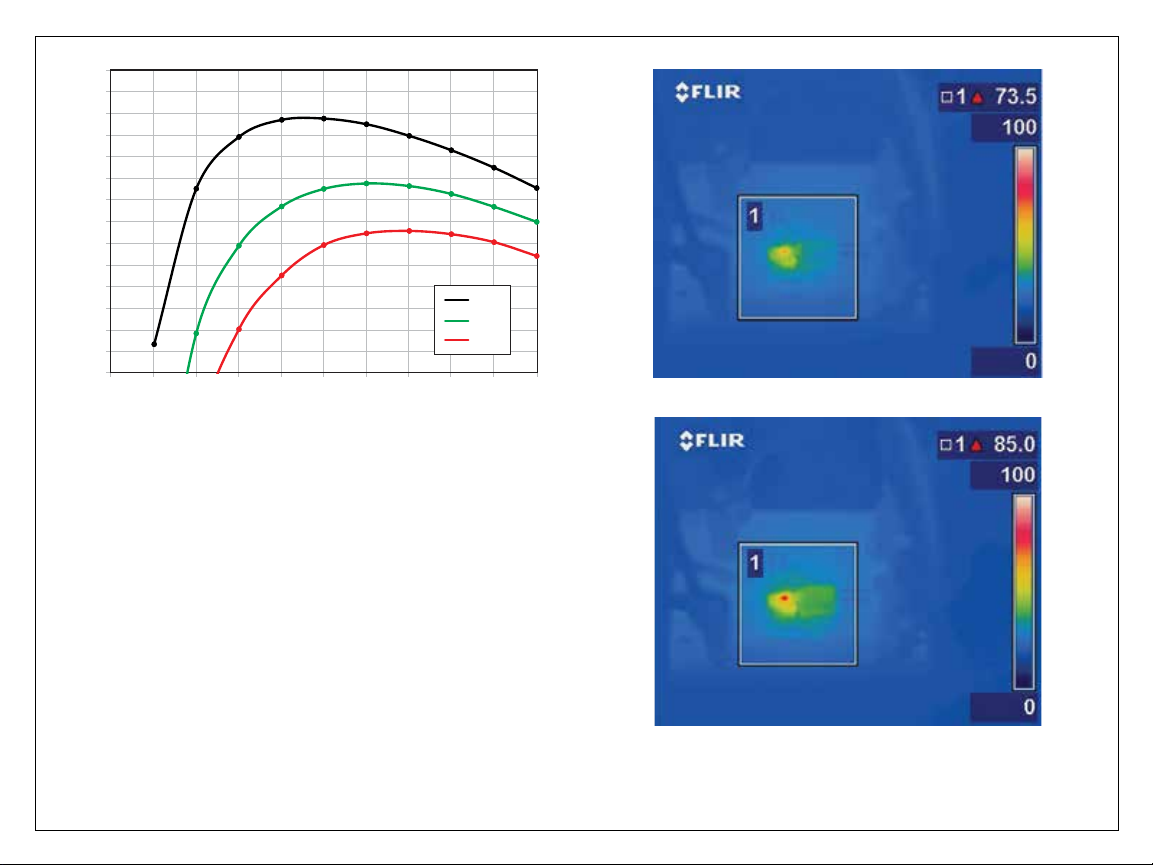

THERMAL CONSIDERATIONS

The EPC9101 demonstration board thermal images for steady

state full load operation are shown in Figure 6. The EPC9101 is

intended for bench evaluation with low ambient temperature

and forced air cooling for higher currents. Care must be taken

to not exceed the absolute maximum die temperature of 125°C

and stay within the constraints of the other components within

the circuit.

NOTE. The EPC9101 demonstration board does not have any current or thermal

protection on board.

Figure 6:Thermal images of EPC9101 under full load conditions

Figure 5:Typical eciency curves for 24 V, 19V and 12 V input including

controller and LDO losses

81

82

83

78

79

80

84

85

86

87

88

89

90

91

92

Eciency

0 2 4 6 8 10 12 18 2014 16

12 VIN

19 VIN

24 VIN

12 VIN, 20 AOUT, 200LFM

24 VIN, 20 AOUT, 200LFM

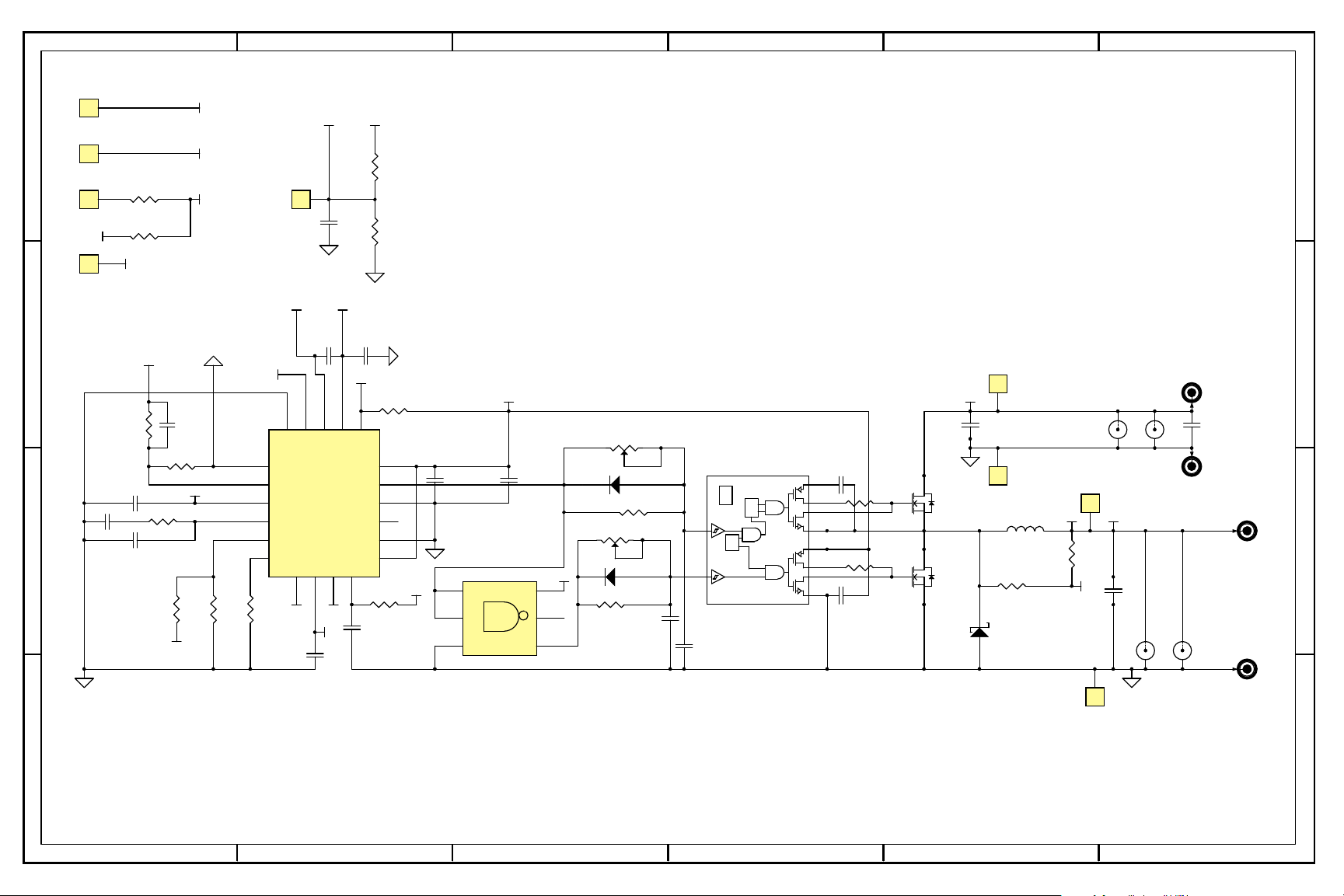

Demonstration Board – EPC9101 Schematic

Rev. 2.0