QUICK START GUIDE

EPC – EFFICIENT POWER CONVERSION CORPORATION | WWW.EPC-CO.COM | COPYRIGHT 2017 | | 3

Demonstration System EPC9112

MECHANICAL ASSEMBLY

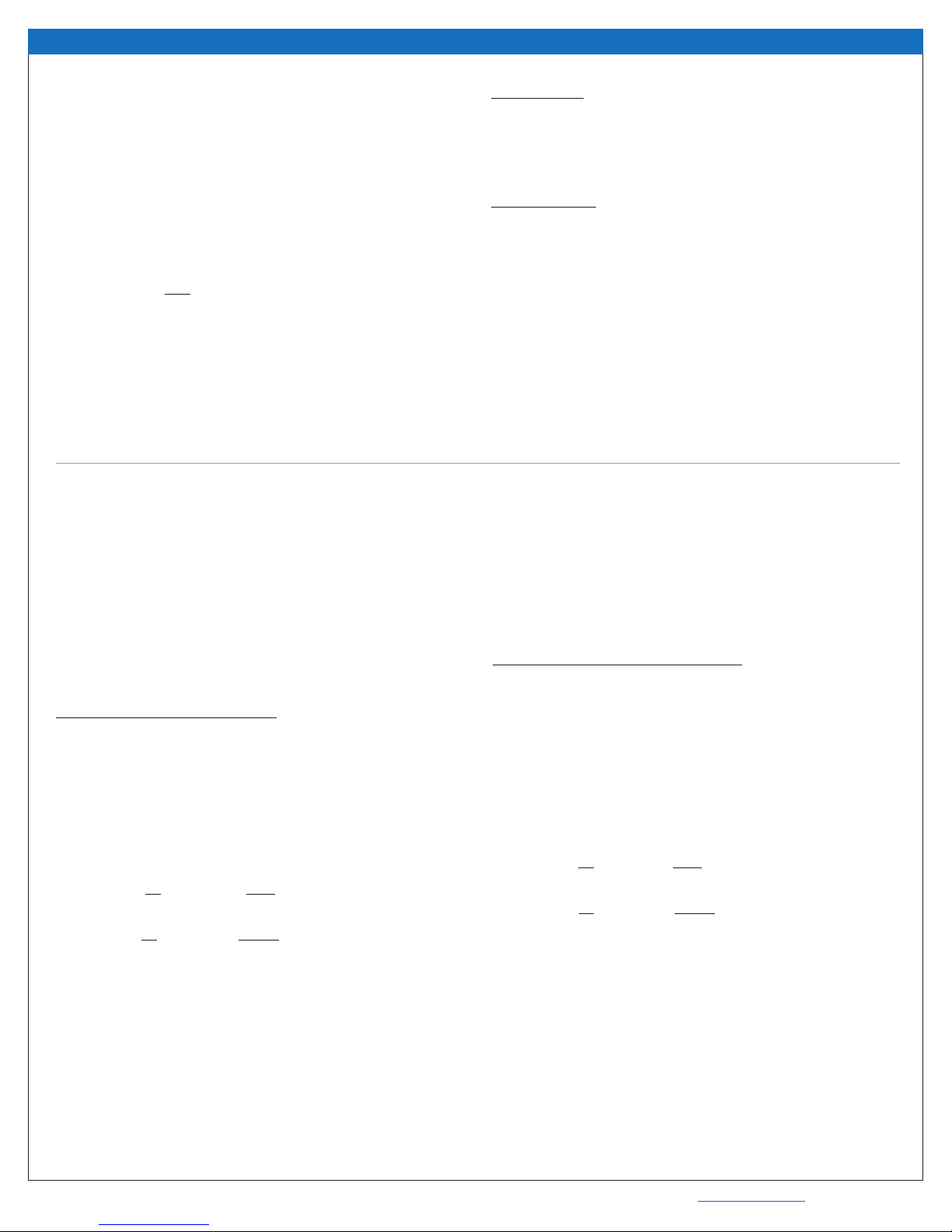

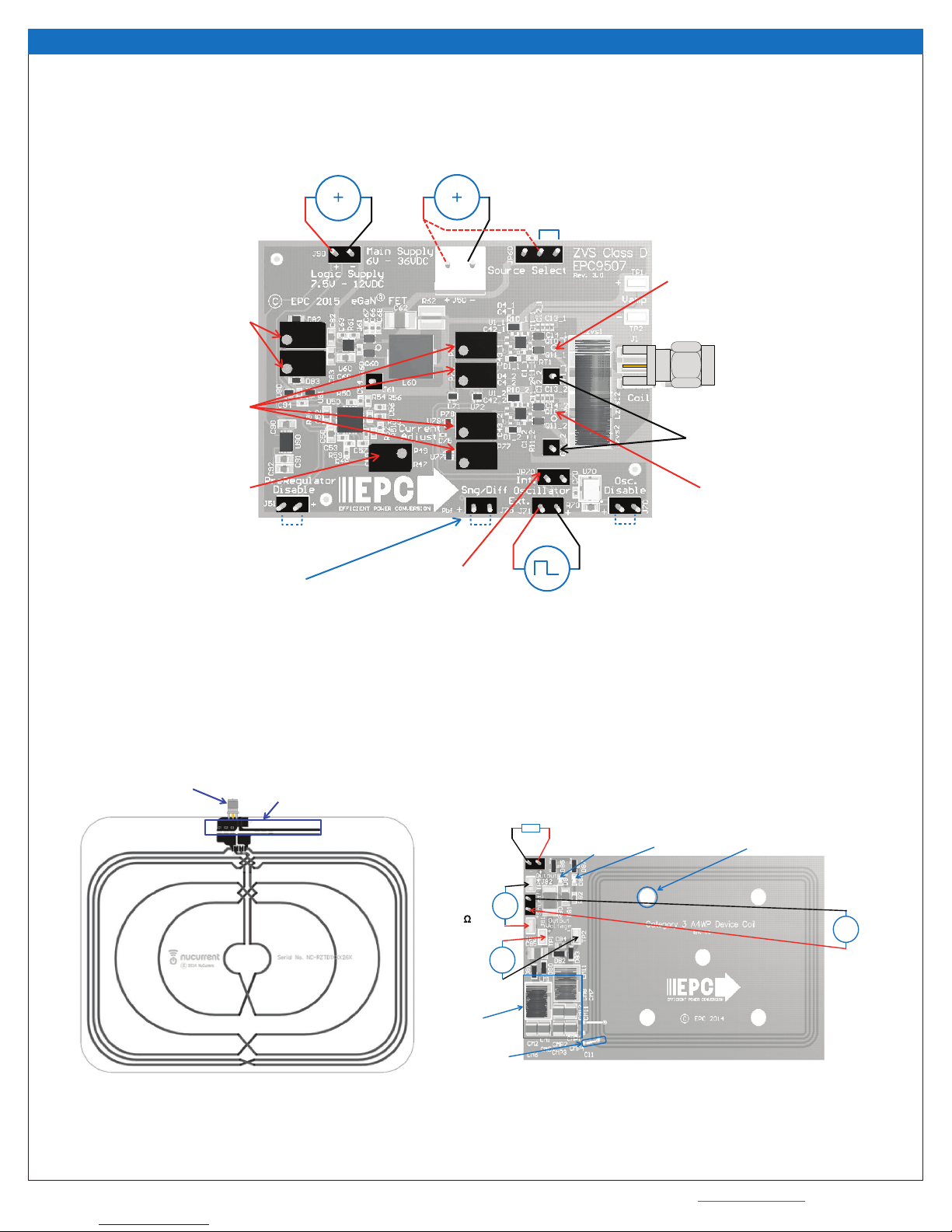

The assembly of the EPC9112 Wireless Demonstration kit is simple and

shown in Figure 1.The source coil and amplier have been equipped with

reverse polarity SMA connectors. The source coil is simply connected to

the amplier.

The device board does not need to be mechanically attached to the

source coil.

DESCRIPTION

The Amplier Board (EPC9507)

Figure 1 shows a diagram of the EPC9507 ZVS class-D amplier with pre-

regulator. The pre-regulator is set to a specied DC current limit (up to 1.5

A) by adjusting P49 and operates from 8 V through 36 V input. The output

voltage of the pre-regulator is limited to approximately 2 V below the

input voltage. The pre-regulator can be bypassed by moving the jumper

(JP60) over from the right 2 pins to the left 2 pins. To measure the current

the amplier is drawing, an ammeter can be inserted in place of the jumper

(JP60) in the location based on the operating mode (pre-regulator or bypass).

The amplier comes with its own oscillator that is pre-programmed to 6.78

MHz ± 678 Hz. It can be disabled by placing a jumper into J70 or can be

externally shutdown using an externally controlled open collector / drain

transistor on the terminals of J70 (note which is the ground connection). The

switch needs to be capable of sinking at least 25 mA. An external oscillator

can be used instead of the internal oscillator when connected to J71 (note

which is the ground connection) and the jumper (JP70) is moved from the

right 2 pins to the left 2 pins.

The pre-regulator can also be disabled in the same manner as the oscillator

using J51. The pre-regulator can be bypassed, to increase the operating

voltage (with no current or thermal protection) to the amplier or to use

an external regulator, by moving the jumper JP60 from the right 2 pins to

the left 2 pins. Jumper JP60 can also be used to connect an ammeter to

measure the current drawn by the amplier (make sure the ammeter

connects to the pins that correspond to the mode of operation either

bypass or pre-regulator).

Single Ended Operation Hardware implementation

The amplier can be congured for single ended operation where only

devices Q1 and Q2 are used. In this mode only LZVS1 and CZVS are used to

establish ZVS operation. If a permanent single ended conguration is

required and Q11 and Q12 are populated, then the following changes

need to be made to the board:

1) Remove R77 and R78 OR P77 and P78

2) Short out C42_2 and C43_2

3) Short the connection of JMP1 (back side of the board)

4) Remove LZVS12 (if populated)

5) Add LZVS2 (390 nH)

6) Check that CZVS2 is populated, if not then install.

7) R71 and R72 may need to be adjusted for the new operating

condition to achieve maximum eciency (see section on ZVS timing

adjustment).

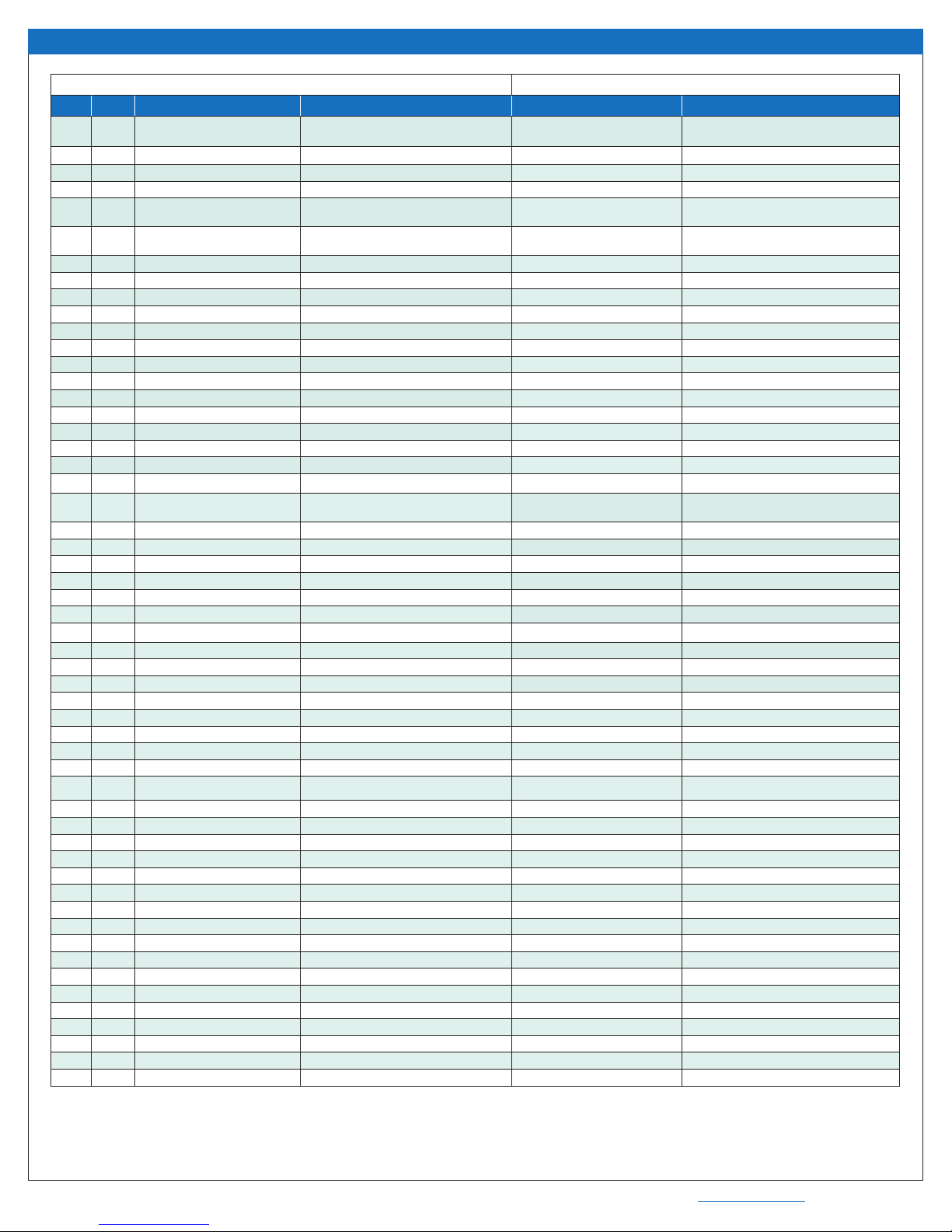

ZVS Timing Adjustment

Setting the correct time to establish ZVS transitions is critical to achieving

high eciency with the EPC9507 amplier. This can be done by selecting

the values for R71, R72, R77, and R78 respectively. This procedure is best

performed using potentiometers P71, P72, P77, and P78 installed that is

used to determine the xed resistor values. The procedure is the same for

both single ended and dierential mode of operation (as applicable per

operating mode). The timing MUST initially be set WITHOUT the source coil

connected to the amplier. The timing diagrams are given in Figure 4 and

should be referenced when following this procedure. Only perform these

steps if changes have been made to the board as it is shipped preset.

The steps are:

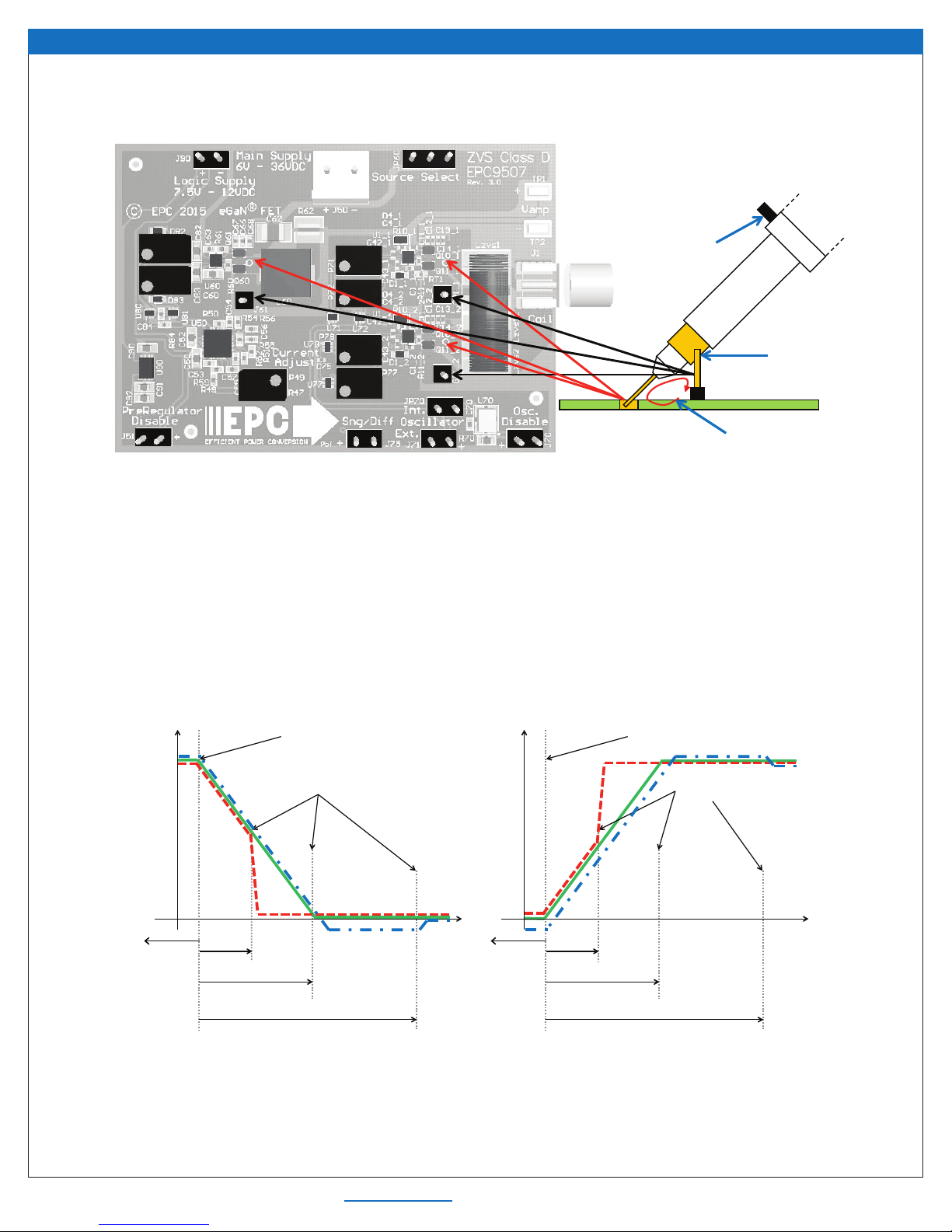

1. Remove the jumper in JP60 and insert it into J51 to place the EPC9507

amplier in bypass mode. With power o connect the main input

power supply (+) bus to the center pin of JP60 (pin 2) and the ground of

the main power to the ground (-) connection of J50 -VIN.

2. With power o, connect the control input power supply bus to +VDD

(J90). Note the polarity of the supply connector.

3. Connect a LOW capacitance oscilloscope probe to the probe-hole J2

between the two eGaN FETs Q10_x and Q11_x and lean against the

ground post as shown in Figure 3.

4. Turn on the control supply – make sure the supply is between 7V and 12

V range (7.5 V is recommended).

5. Turn on the main supply voltage to the required predominant

operating value (such as 24 V but NEVER exceed the absolute

maximum voltage of 36 V).

6. While observing the oscilloscope adjust P71 or P77 for the rising

edge of the waveform so achieve the green waveform of gure 4.

Repeat for the falling edge of the waveform by adjusting P72 or P78.

Repeat for the other eGaN FET pair if using dierential mode operation.

7. Check that the setting remains optimal with a source coil attached.

In this case it is important that the source coil is TUNED to resonance

WITH an applicable load. Theoretically the settings should remain

unchanged. Adjust if necessary.

8. Replace the potentiometers with xed value resistors. Congure the

EPC9507 amplier back to normal operation by removing the power

connections to J50 and JP60, removing the jumper in J51 and inserting

it back into JP60 (right 2 pins 2 & 3).

Determining Component Values for LZVS

The ZVS tank circuit is not operated at resonance, and only provides the

necessary negative device current for self-commutation of the output

voltage at turn o. The capacitance CZVS is chosen to have a very small

ripple voltage component and is typically around 1 µF. The amplier supply

voltage, switch-node transition time will determine the value of inductance

for LZVSx which needs to be sucient to maintain ZVS operation over the DC

device load resistance range and coupling between the device and source

coil range and can be calculated using the following equation:

(1)

LZVS = ∆tvt

8 ∙ fsw∙ COSSQ