EVCO S.p.A. c-pro 3 nano | Hardware Manual ver. 1.0 | Code 114CP3NE104

page 8 of 26

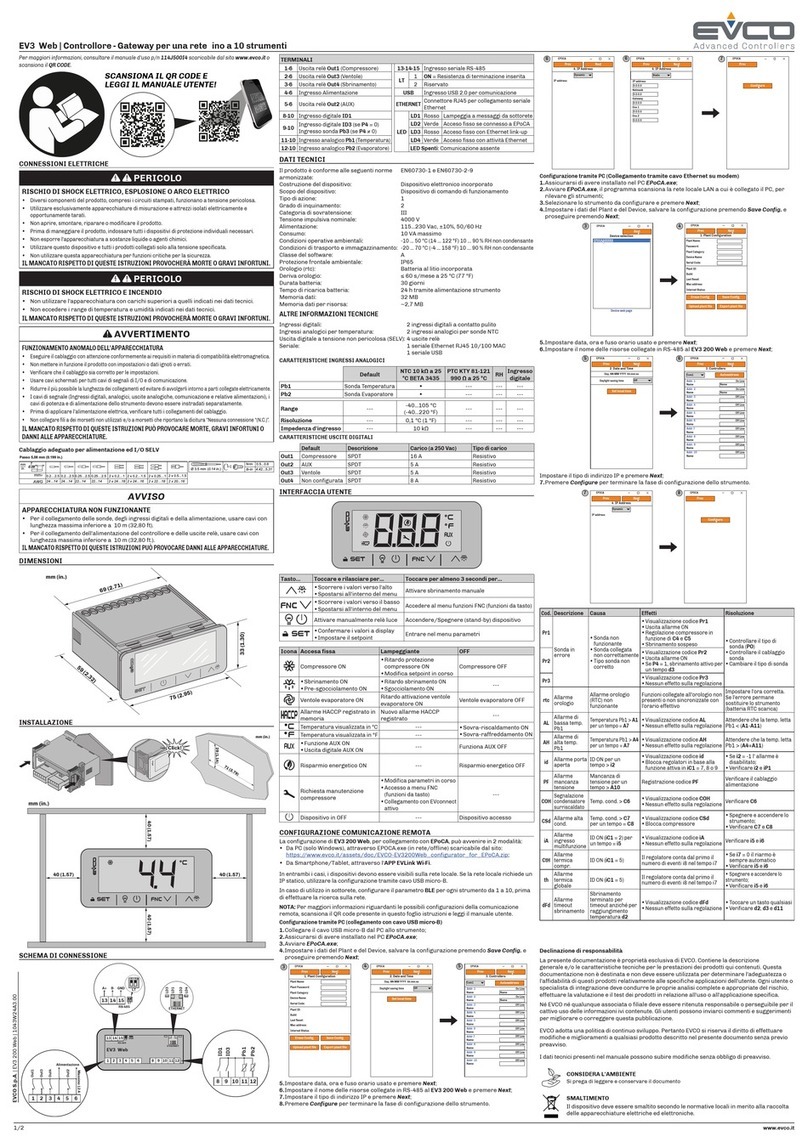

4ELECTRICAL CONNECTION

N.B.

- Do not supply further devices with the same transformer.

- Use cables of an adequate section for the current running

through them.

- o reduce any electromagnetic interference connect the power

cables as far away as possible from the signal cables and, if

necessary, connect to a RS-485 MODBUS network and/or a CAN

network by using a twisted pair.

- he device is not compatible with controllers, I/O expansions and

remote user interfaces of the c-pro series.

- For more information see section TECHNICAL SPECIFICATIONS.

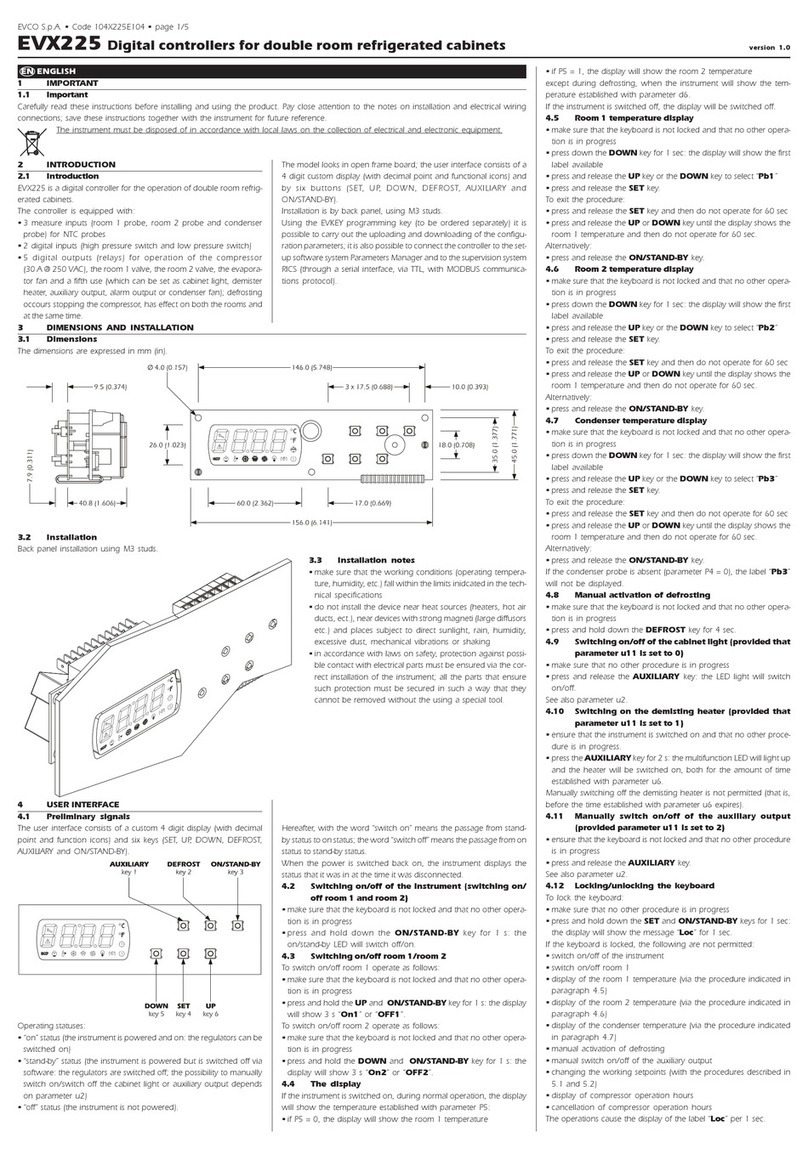

4.1 Connectors

he picture below shows the c-pro 3 nano basic connectors.

he picture below shows the c-pro 3 nano CAN connectors.

he picture below shows the c-pro 3 nano plus connectors.

he tables below describe the connectors.

Connector 1

No. DESCRIP ION

1 analogue input 6 (for P C, N C or Pt 1000 probes; can be

configured also for dry contact digital input)

2

analogue input 1 (for N C probes, 0-5 V, 0-10 V, 0-20 mA or 4-20

mA transducers; can be configured also for dry contact digital

input)

3 analogue input 7 (for P C, N C or Pt 1000 probes; can be

configured also for dry contact digital input)

4

analogue input 2 (for N C probes, 0-5 V, 0-10 V, 0-20 mA or 4-20

mA transducers; can be configured also for dry contact digital

input)

5 digital input 1 (dry contact and for pulse trains up to 2 KHz)

6 analogue input 3 (for P C, N C or Pt 1000 probes; can be

configured also for dry contact digital input)

7 digital input 2 (dry contact and for pulse trains up to 2 KHz)

8 analogue input 4 (for P C, N C or Pt 1000 probes; can be

configured also for dry contact digital input)

9 digital input 3 (dry contact)

10 analogue input 5 (for P C, N C or Pt 1000 probes; can be

configured also for dry contact digital input)

11 analogue output 1 (for 0-10 V, PWM or phase cutting signal)

12 reference (GND)

13 analogue output 2 (for 0-10 V, PWM or phase cutting signal)

14 IN RABUS port data

15 auxiliary power supply (12 VDC)

16 reference (GND)

17

device power supply (12 VAC or 24 VAC/DC, according to the

model). If the device is fed by DC power, it is not necessary to take

account of the supply voltage polarity

18

device power supply (12 VAC or 24 VAC/DC, according to the

model). If the device is fed by DC power, it is not necessary to take

account of the supply voltage polarity

Connector 2

No. DESCRIP ION

1 signal + RS-485 MODBUS master/slave port

2 signal + CAN port

3 signal - RS-485 MODBUS master/slave port

4 signal - CAN port

5 ratiometric transducer power supply 0-5 V (5 VDC)

6 reference (GND)

7 analogue output 3 (for 0-10 V, 0-20 mA or 4-20 mA signal)

8 analogue output 4 (for 0-10 V, 0-20 mA or 4-20 mA signal)

9 digital input 4 (dry contact)

10 analogue input 8 (for N C probes, 0-5 V ratiometric transducers, 0-

10 V, 0-20 mA or 4-20 mA transducers; can be configured also for