8

ENGLISH

ABC

S1

S2

~10cm

~10cm

~10cm

A

B

4. INSTALLING THE AUTOMATION SYSTEM

4.1. PRELIMINARY CHECKS

To ensure safe, proper operation of the automation system, check

the following:

• The door’s structure must be suitable for automation. Make

particularly sure that dimensions of the door meet the

requirements given in the technical specifications and that

the door is sufficiently robust.

• Check the condition of the door bearings and joints.

• Check that the door moves smoothly; If necessary clean the

tracks and lubricate them with a silicone based lubricant.

Do not use grease.

• Check that the door is correctly balanced.

• Remove the mechanical door locks so that when the door is

closed it is locked only by the automation system.

• Check that there is an effective earth connection for the

geared motor.

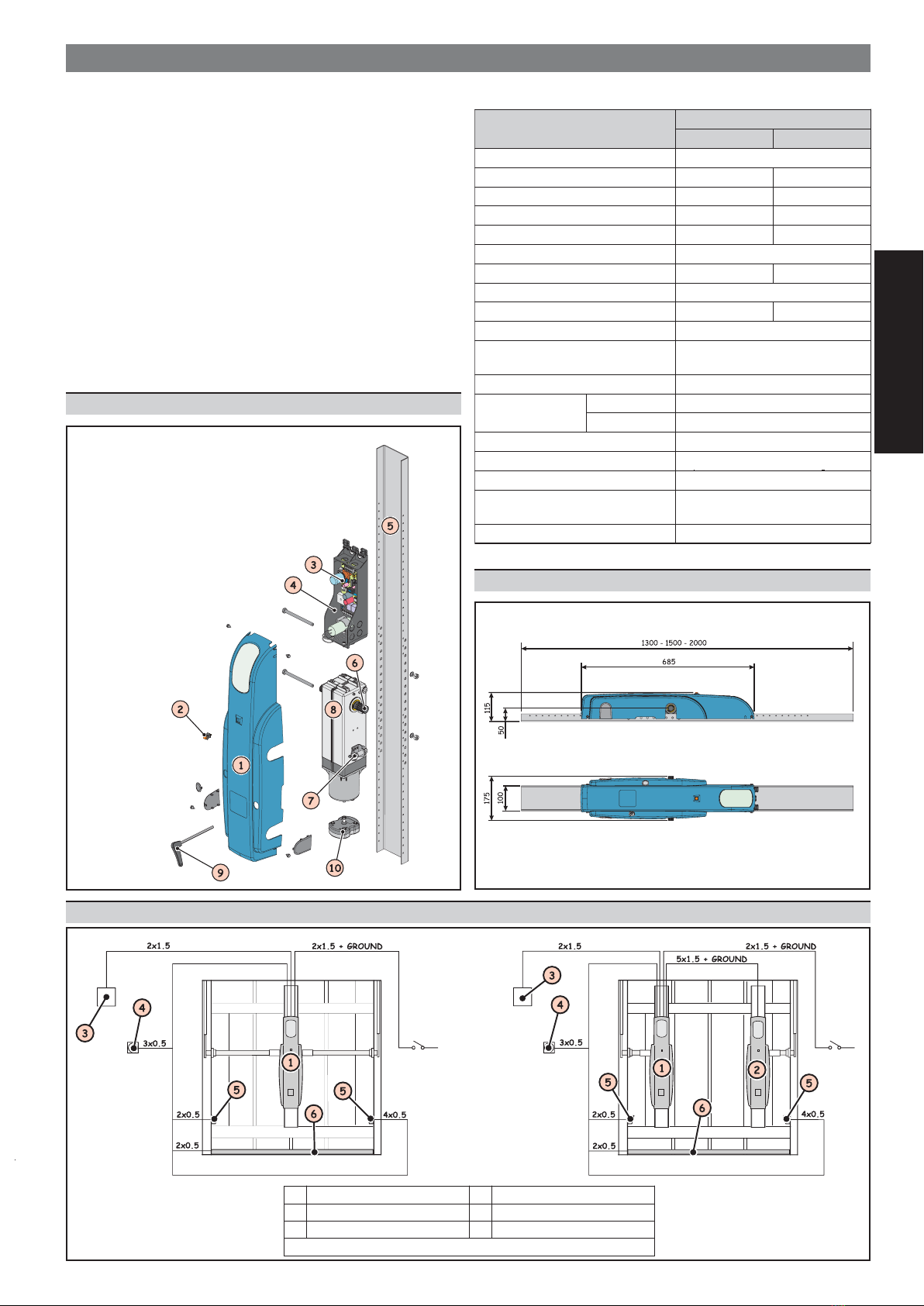

The 550 automation system is designed to operate various types

of counterbalanced up-and-over garage doors. Fig. 4 shows

the most common types:

a) single section outward swinging

b) double section outward swinging

c) single section inward swinging with horizontal tracks

4.3. POSITIONING OPERATOR/BACK PLATE

In accordance with the measurements given in Table 1, install

either a single operator at the centre of the door as shown in fig.

6 or two operators at the sides of the door as shown in fig. 7.

The operator is designed so that the geared motor unit can be

installed with the drive shaft at two different heights (see section

5).

The following instructions apply to both assembly options,

although they refer specifically to installation of the operator

with the geared motor unit output shaft at the centre.

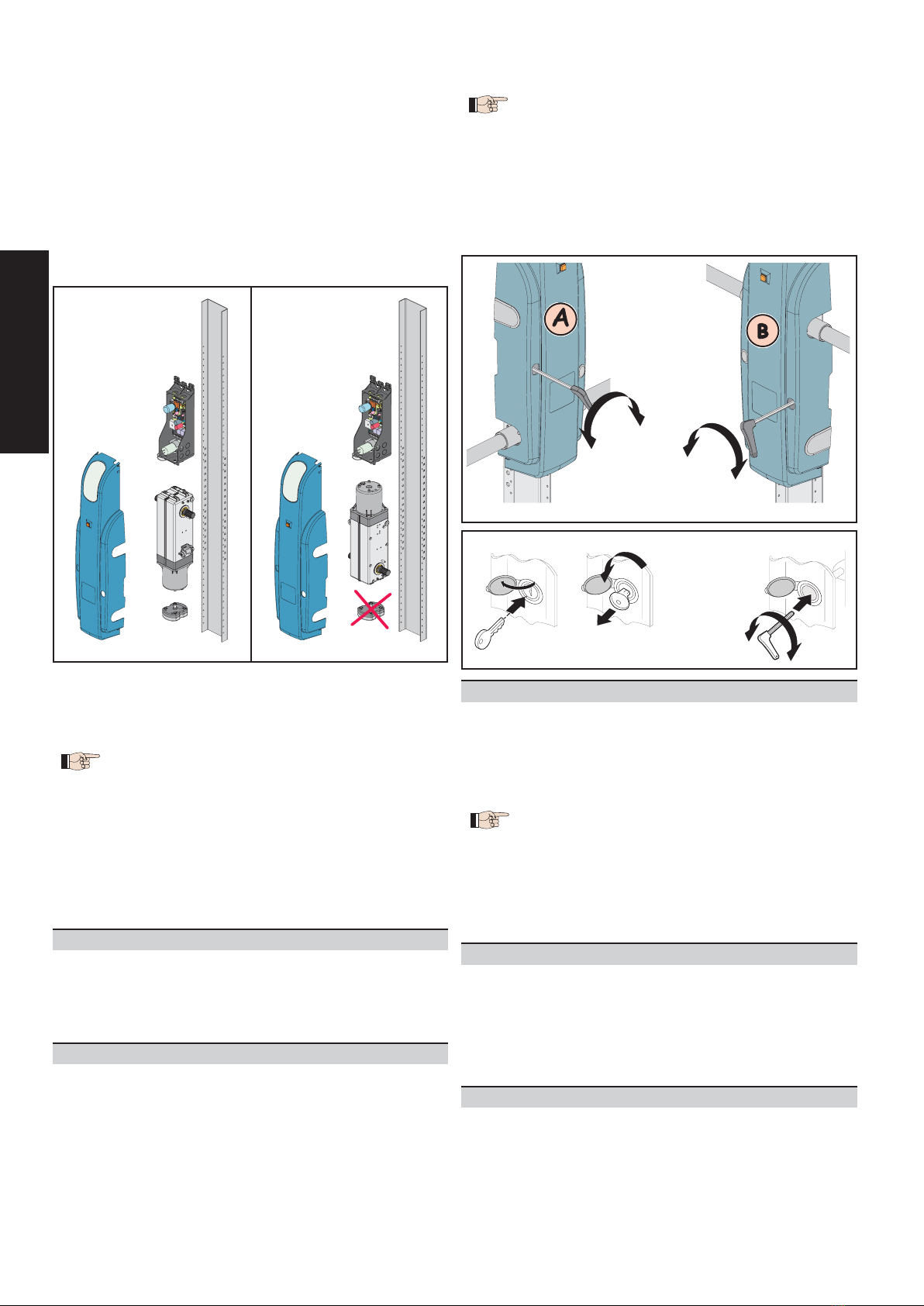

4.4. ASSEMBLY SEQUENCE

Begin installation with the garage door closed and the operator

released (see section 8).

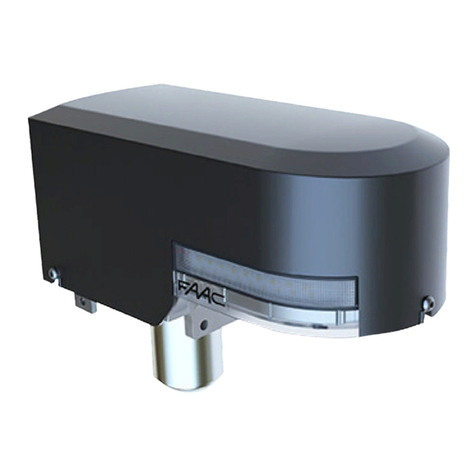

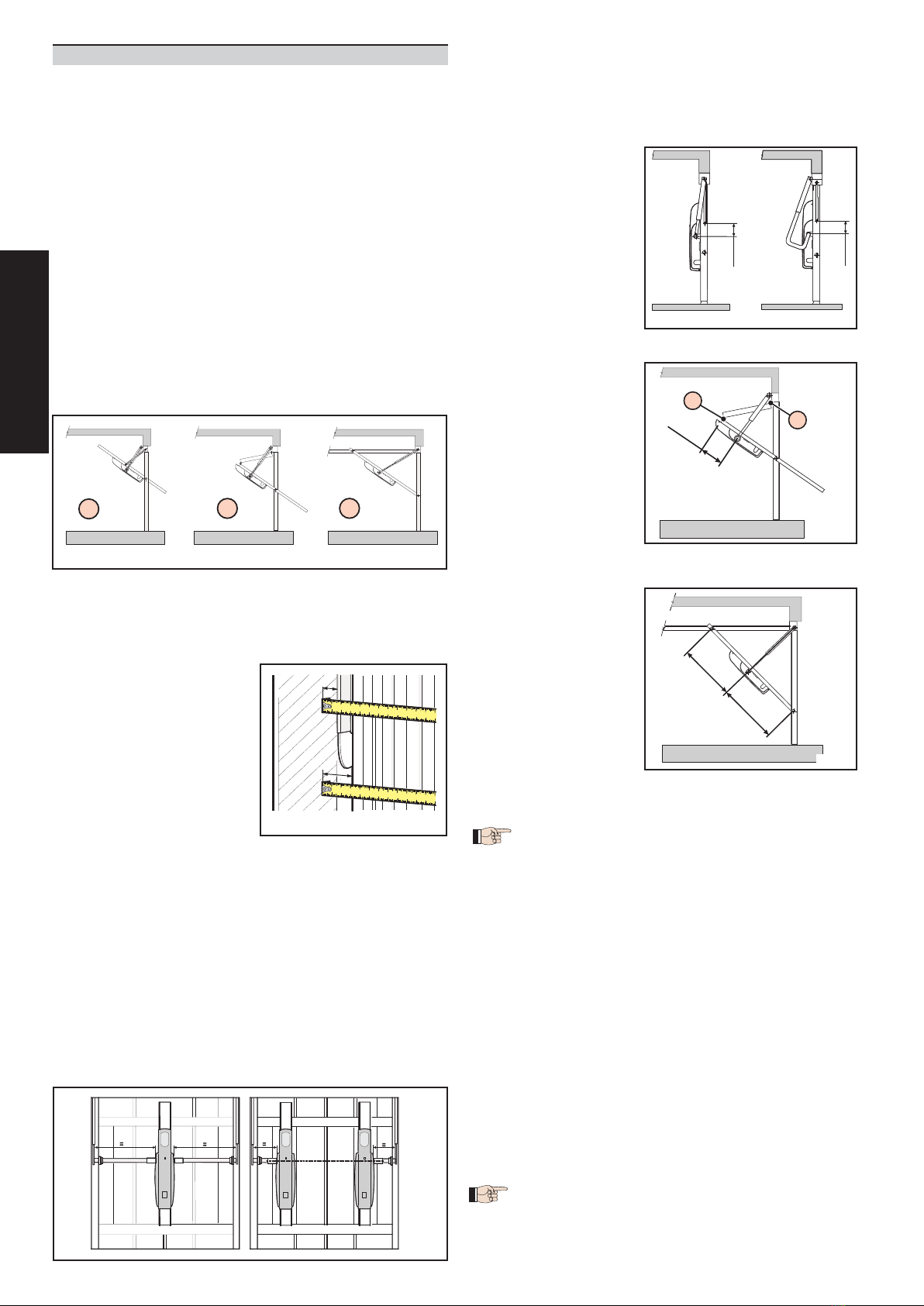

1) Determine the position of the operator shaft as follows:

• single section outward swinging garage door (fig. 8)

When the door is closed,

the axis of rotation of the

drive shaft must be about

10 cm lower than the axis

of rotation of the door.

The telescopic arms must

be attached as close as

possible to the point

where the door arm is

fixed.

•double section garage door (fig. 9)

When the door is closed,

the axis of rotation of the

drive shaft must be about

10 cm below the axis of

rotation of the door hinge.

(A).

The telescopic arms must

be attached as close as

possible to the point

where the hinges are fixed

to the door. (B).

• garage door with horizontal guides (fig. 10)

The axis of rotation of the

drive shaft must be

halfway between the two

bearings.

The telescopic arms must

be attached as close as

possible to the point

where the upper and

vertical guides meet.

2) Fix the back plate to the reinforcement ribbing of the door

panel using suitable screws for the door’s structure. It is

advisable to use nuts and bolts.

• Position the back plate in such a way that the end

with the reference marking E is facing upwards.

This reference marking indicates the point at which

the control unit is to be positioned.

• The back plate has a series of Ø 8mm holes which,

when it is fixed, allow the operator to be installed at

various heights.

• Check that the fixing position of the back plate allows

the operator to be installed in accordance with the

previously determined shaft position.

• In double operator installations, both shafts must be

aligned at the same height.

3) Fix the operator to the back plate using the nuts and bolts

provided, as shown in fig. 11.

4) Weld the upper telescopic arm fixing brackets in the position

described in the instructions for the specific type of garage

door.

In the case of curved arm installation, the brackets can be

welded directly to the existing door arms.

Fix the outer profiles of the telescopic arms to the brackets

using the pins and the nuts and bolts provided, as shown in

fig. 11.

5) Fit the transmission shafts firmly onto the drive shaft and cut

them to size as shown in figs. 6 and 7.

If limit switches are used (optional), first fit the cams as

shown in fig. 11.

4.2. POSITIONING TELESCOPIC ARMS

The gap between the existing

balancing arm and the frame

(distance ”S1” in fig. 5) must be

at least 15 mm to allow the

straight telescopic arms to rota-

te correctly.

If not, it is possible to use curved

telescopic arms which can be

installed over the top of existing

balancing arms. Check that the

gap between the door panel

and the frame is at least 20 mm

(distance ”S2” in fig. 5).

FIG.4

FIG.5

FIG.6 FIG.7

FIG.8

FIG.9

FIG.10