746 E R 4 732099 - Rev.D

Translation of the original instructions ENGLISH

TABLES

1 Symbols: notes and warnings on the instructions............. 5

2 Symbols: safety signs and symbols (EN ISO 7010)............. 5

3 Symbols: personal protective equipment ...................... 5

4 Symbols: warnings on packaging. .............................. 6

5 Technical data (referring to 230 V~50 Hz/115 V~60 Hz)..... 9

6 Symbols: tools ....................................................15

7 Board technical data.............................................23

8 Basic programming ..............................................29

9 Advanced Programming ........................................ 29

10 LEDs on the board ...............................................35

11 Status of the automation........................................ 35

12 Scheduled maintenance ........................................36

CONTENTS

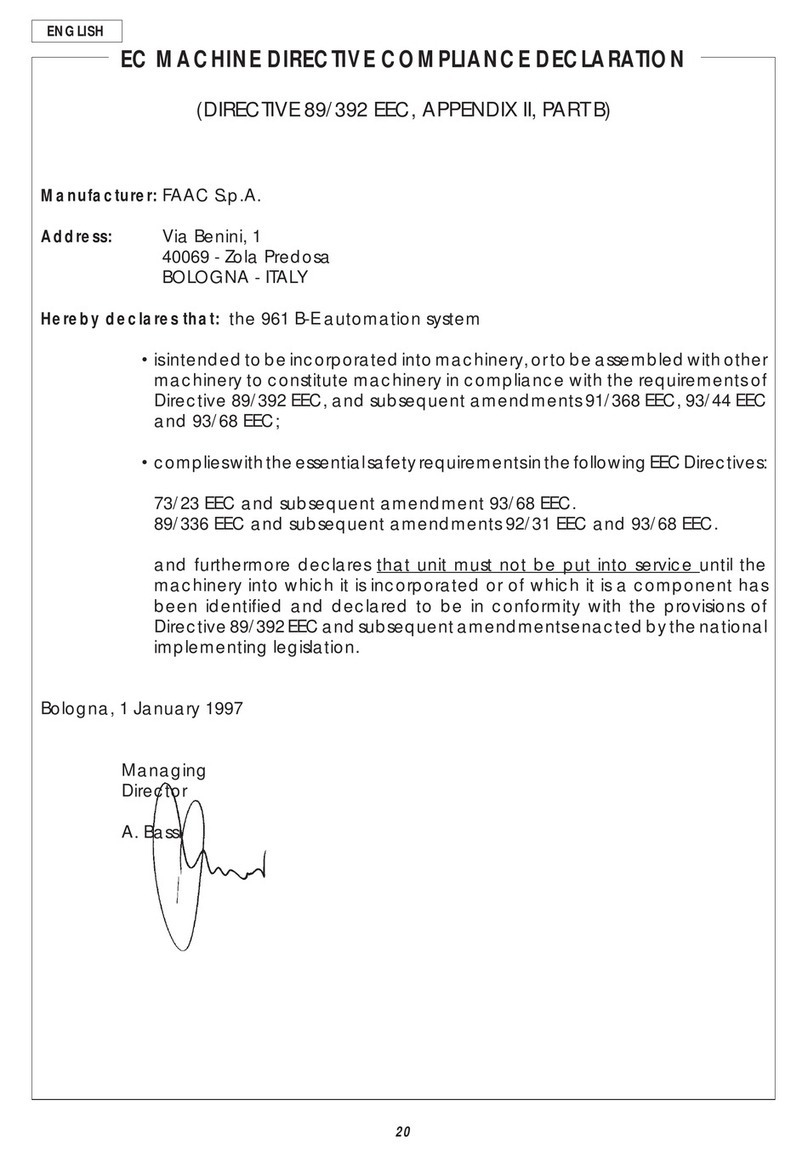

EU Declaration of conformity ................................... 3

Declaration of incorporation for partly completed machinery3

1. INTRODUCTION TO THIS INSTRUCTION MANUAL.......... 5

1.1 Meaning of the symbols used................................... 5

2. SAFETY RECOMMENDATIONS .................................. 6

2.1 Installer safety .................................................... 6

2.2 Transport and storage............................................ 6

2.3 Unpacking and handling ........................................ 7

Vent closure ....................................................... 7

2.4 Disposal of the product ......................................... 7

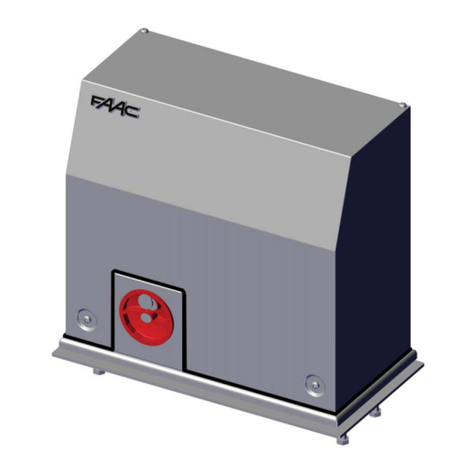

3. 746 E R ............................................................... 8

3.1 Intended use ...................................................... 8

3.2 Limitations of use................................................. 8

3.3 Unauthorised use................................................. 8

3.4 Emergency use.................................................... 8

3.5 Product identification ............................................ 9

Product warnings................................................. 9

3.6 Technical specifications .......................................... 9

3.7 Component identification ...................................... 10

Components supplied .......................................... 10

Components supplied separately.............................. 10

3.8 Dimensions....................................................... 11

3.9 Manual operation................................................ 11

Releasing the gearmotor ....................................... 11

Restoring operation ............................................. 11

4. INSTALLATION REQUIREMENTS............................... 12

4.1 Mechanical requirements....................................... 12

4.2 Electrical system ................................................. 12

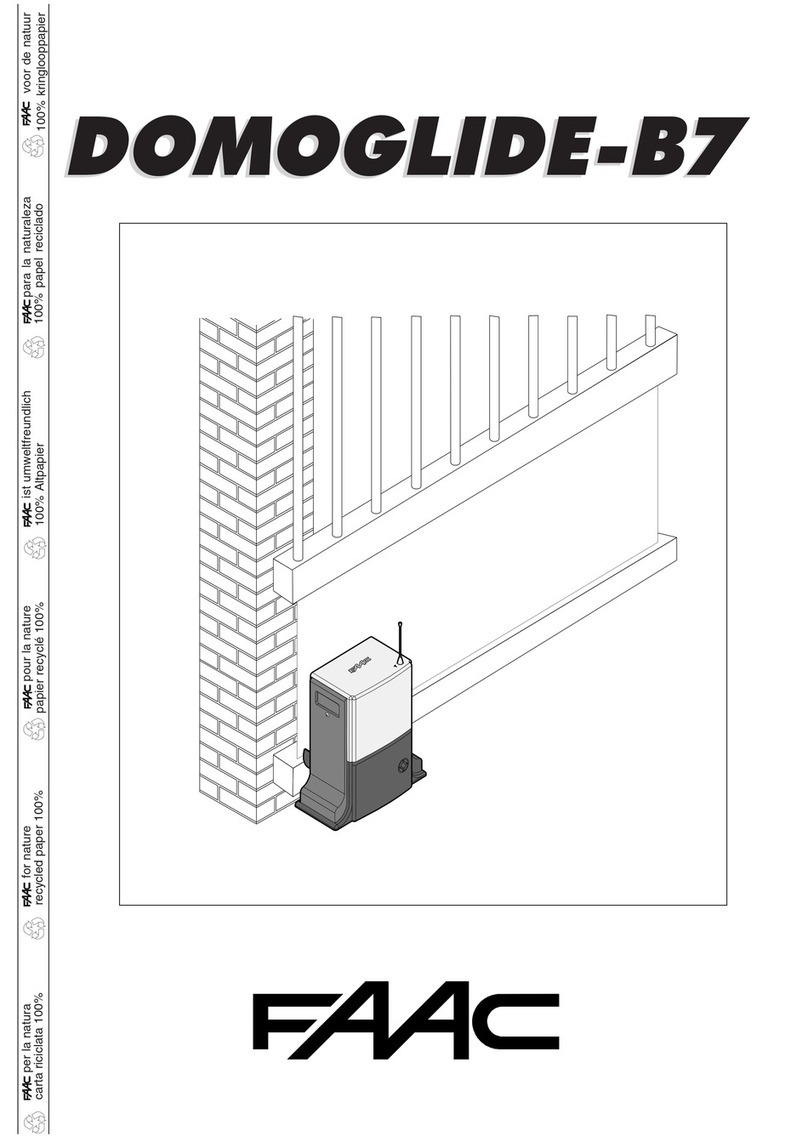

4.3 Example system.................................................. 13

4.4 Installation dimensions ......................................... 14

5. MECHANICAL INSTALLATION .................................. 15

Tools required.................................................... 15

5.1 Installing the foundation plate................................. 15

5.2 Installing the gearmotor........................................ 16

Open the vent hole.............................................. 16

5.3 Installing the rack................................................ 17

Steel rack - Weld-on fastenings ................................ 17

Steel rack - Screw-on fastenings ............................... 18

Nylon rack ........................................................ 19

5.4 Adjusting and checking......................................... 20

5.5 Fastening the gearmotor permanently ....................... 20

5.6 Installing the cover .............................................. 21

6. OPTIONAL EQUIPMENT ......................................... 21

6.1 Release lock with personalised key............................ 21

7. ELECTRONIC INSTALLATION ................................... 22

7.1 Removing the cover from the board .......................... 22

7.2 Board 780D....................................................... 22

Components ..................................................... 22

Status LEDs....................................................... 22

7.3 Connections...................................................... 23

Motor ............................................................. 23

Flashing light .................................................... 23

Magnetic encoder ............................................... 23

Start-up capacitor ............................................... 23

Transformer ...................................................... 23

Magnetic limit stop sensor ..................................... 23

ADDENDUM

1 Foundation for leaves of max weight and width ............. 40

Control devices and accessories ............................... 24

Radio receiver/decoder board ................................. 25

Earthing the gearmotor......................................... 25

Power cable ...................................................... 25

7.4 Installing the cable glands...................................... 26

7.5 Installing the board cover ...................................... 26

8. START-UP........................................................... 27

Set-up procedure................................................ 27

8.1 Installing the limit switches .................................... 28

8.2 Programming the board ........................................ 29

Restoring factory settings ...................................... 29

8.3 Operating logics ................................................. 30

8.4 Adjusting the anti-crushing system ........................... 31

Limiting the static force......................................... 31

Obstacle detection .............................................. 31

Checks ............................................................ 31

9. PUTTING INTO SERVICE ......................................... 32

9.1 Final operations.................................................. 32

10. ACCESSORIES .................................................... 32

10.1 Flashing light ................................................... 32

10.2 Photocells ....................................................... 33

10.3 Sensitive edges................................................. 34

10.4 LED/timed lamp, traffic light control, electric lock ......... 34

11. DIAGNOSTICS.................................................... 35

11.1 Connection status.............................................. 35

11.2 Status of the automation...................................... 35

11.3 Request assistance alert ....................................... 35

12. MAINTENANCE .................................................. 36

12.1 Routine maintenance.......................................... 36

13. INSTRUCTIONS FOR USE ...................................... 38

13.1 Safety recommendations...................................... 38

13.2 Emergency use ................................................. 39

13.3 Manual operation .............................................. 39

Releasing the gearmotor ....................................... 39

Restoring operation ............................................. 39