C850 4 532015 - Rev.B

ENGLISH

Translation of the original instructions

INDEX

1 GENERAL............................................................................................................................................................. 5

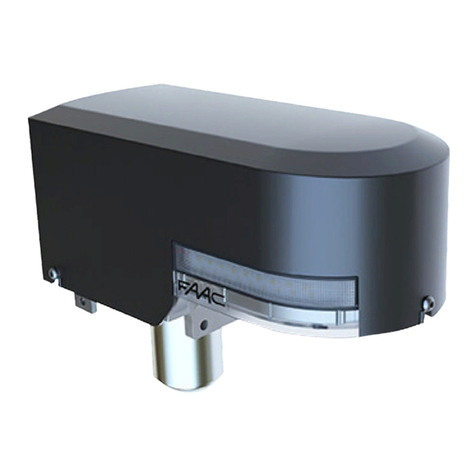

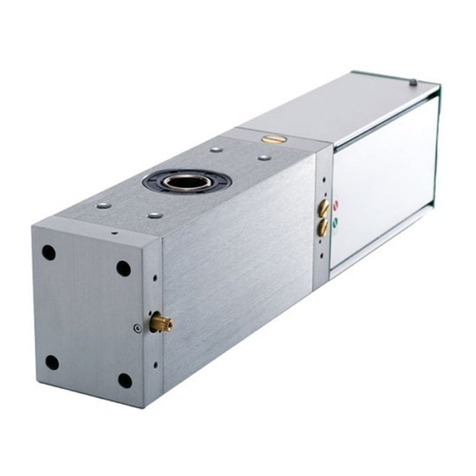

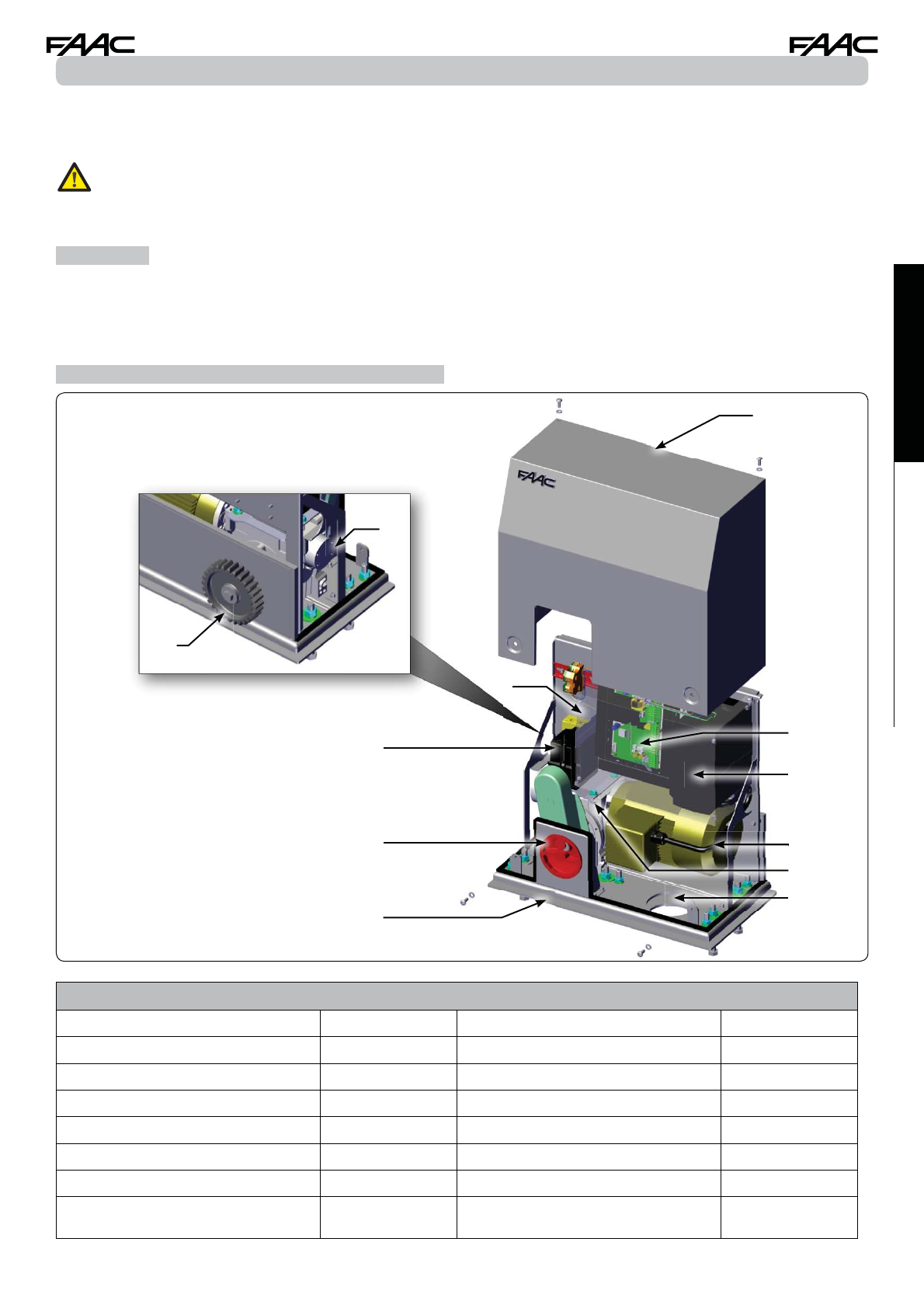

2 DESCRIPTION AND TECHNICAL SPECIFICATIONS ........................................................................................ 5

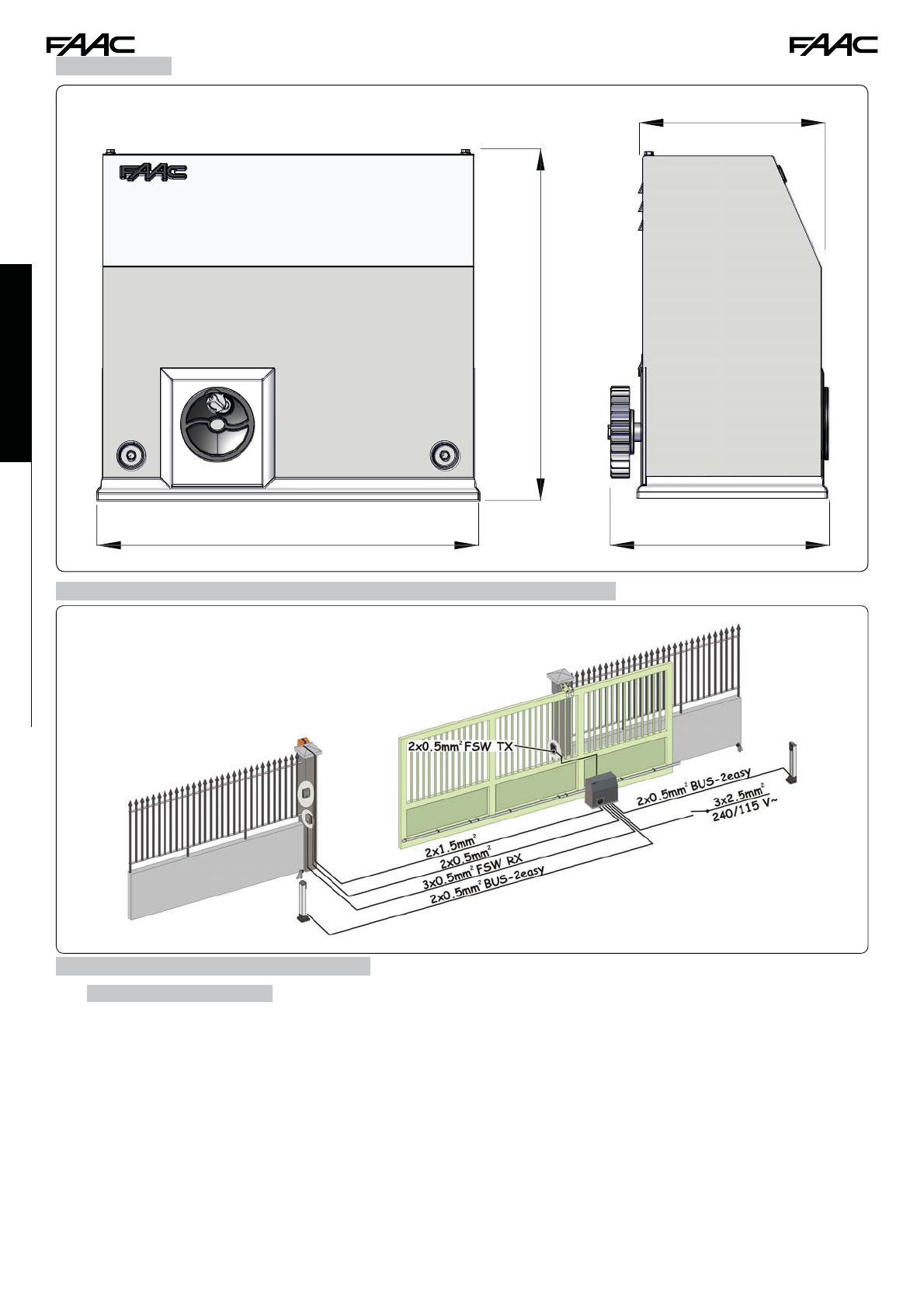

3 DIMENSIONS ....................................................................................................................................................... 6

4 ELECTRICAL PREPARATIONS (standard system with right-hand opening) ................................................ 6

5 INSTALLING THE AUTOMATED SYSTEM ........................................................................................................ 6

5.1 PRELIMINARY CHECKS........................................................................................................................................6

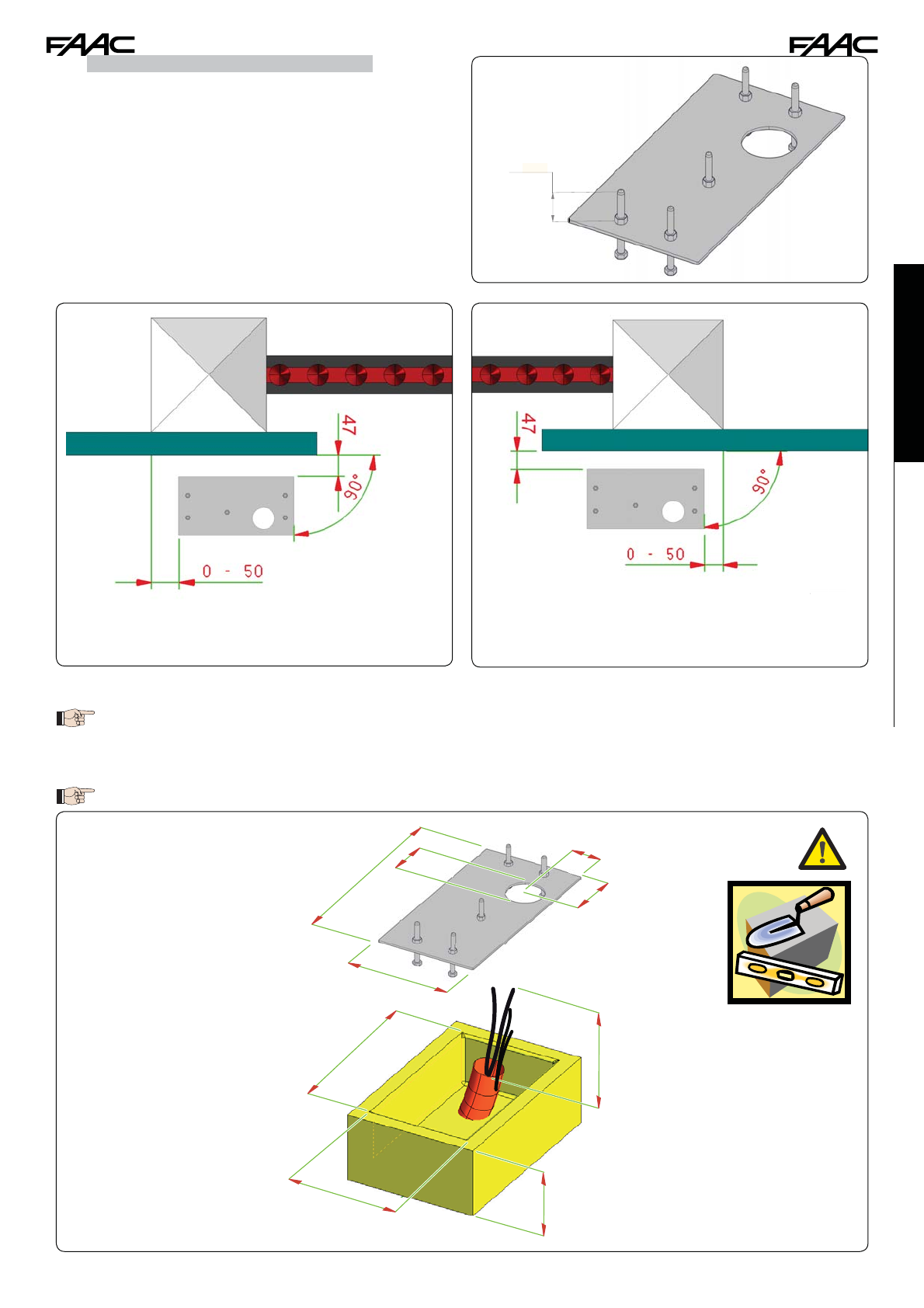

5.2 WALLING IN THE FOUNDATION PLATE ............................................................................................................7

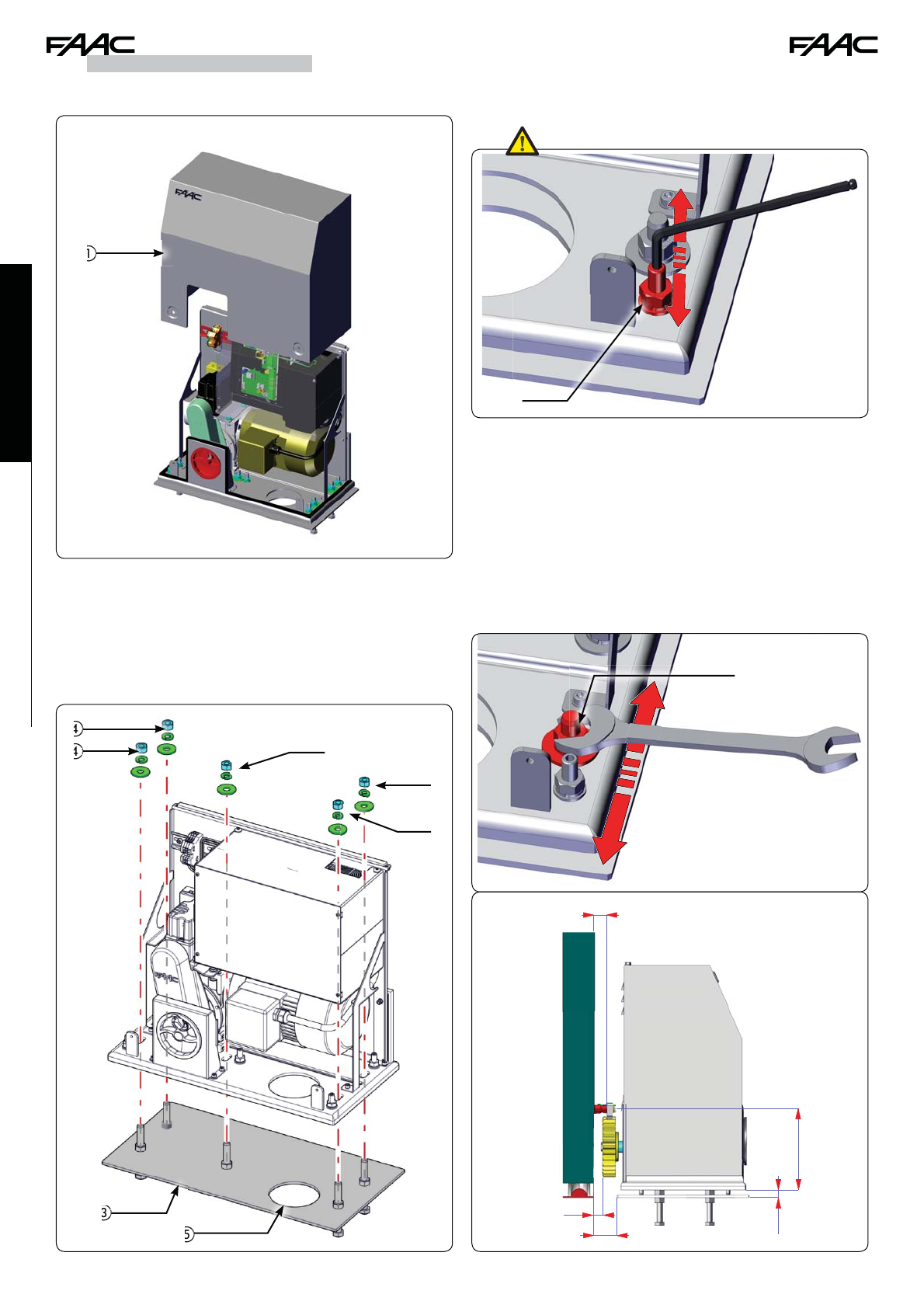

5.3 MECHANICAL INSTALLATION ............................................................................................................................8

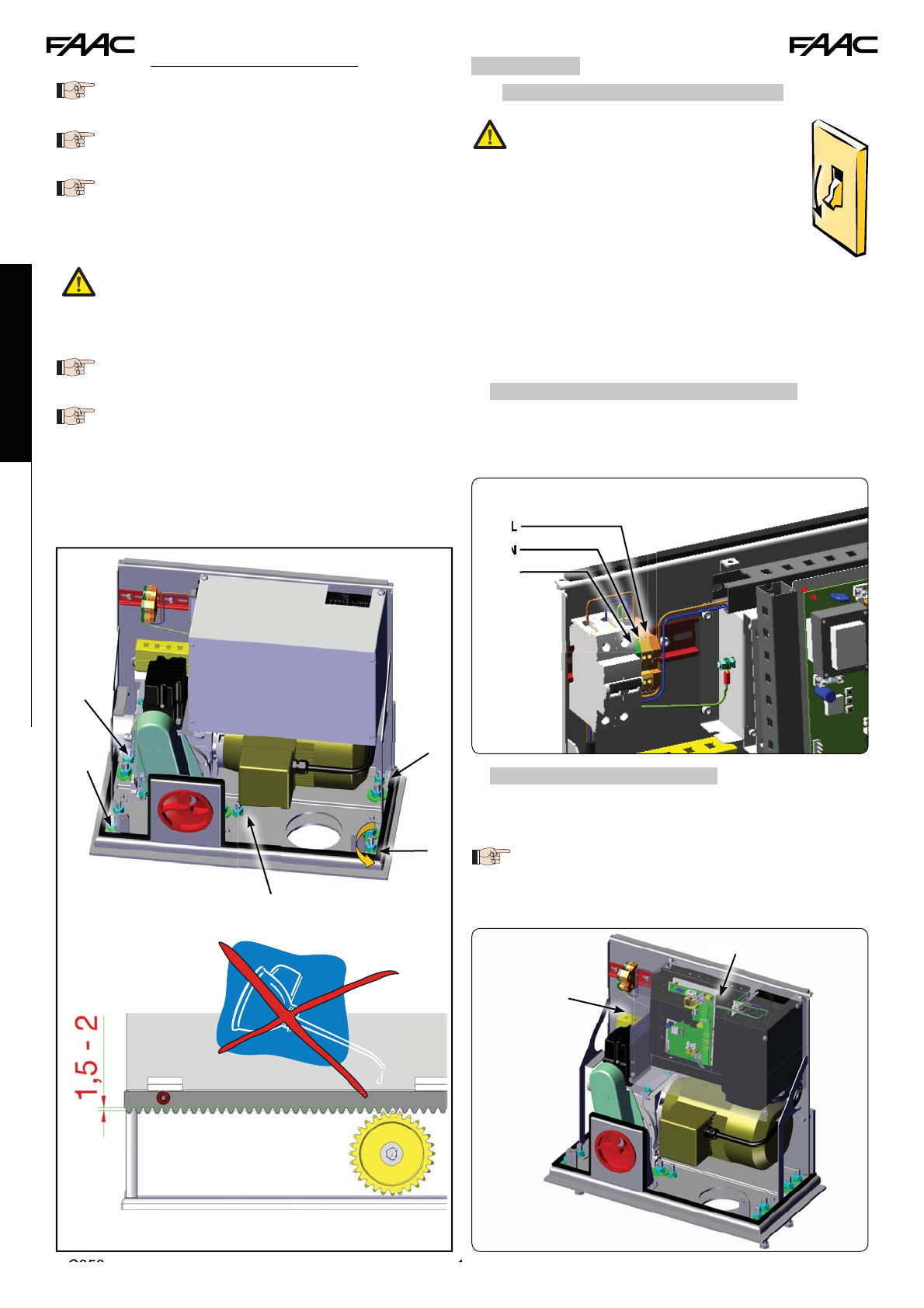

5.4 INSTALLING THE RACK .......................................................................................................................................9

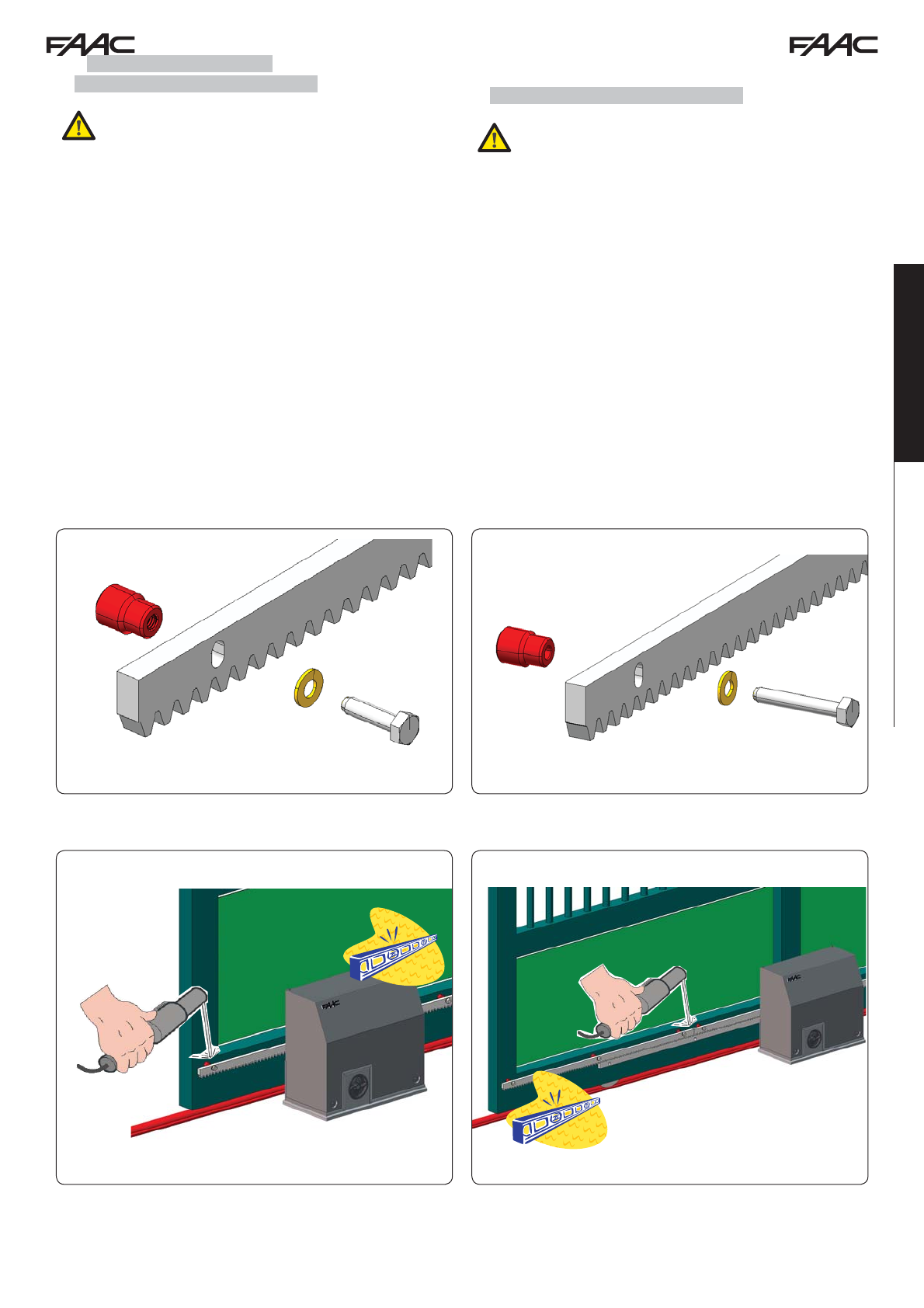

5.4.1 WELD-ON STEEL RACK (Fig. 13)..............................................................................................................................9

5.4.2 SCREW-ON STEEL RACK (Fig. 14) ...........................................................................................................................9

6 OPERATION ...................................................................................................................................................... 10

6.1 CONNECTING THE CONTROL BOARD.............................................................................................................10

6.1.1 CONNECTIONS MADE BY THE INSTALLER...........................................................................................................10

6.1.2 ELECTRONIC CONTROL UNIT ...............................................................................................................................10

6.2 FINAL ADJUSTMENT OF THE LIMIT SWITCHES ............................................................................................11

7 TESTING THE AUTOMATED SYSTEM ............................................................................................................ 13

8 RELEASING/LOCKING THE OPERATOR ....................................................................................................... 13

9 MAINTENANCE ................................................................................................................................................ 13

10 REPAIRS ......................................................................................................................................................... 13

11 E850 ELECTRONIC CONTROL UNIT ............................................................................................................. 14

11.1 WARNINGS ........................................................................................................................................................14

11.2 E850 TECHNICAL SPECIFICATIONS ..............................................................................................................14

11.3 E850 LAYOUT AND COMPONENT DESCRIPTION..........................................................................................14

11.3.1 E850 LAYOUT .........................................................................................................................................................14

11.3.2 E850 COMPONENT DESCRIPTION........................................................................................................................14

11.4 ELECTRICAL CONNECTIONS..........................................................................................................................15

11.4.1 TERMINAL BOARD J1 - ACCESSORIES (FIG. 28)................................................................................................15

11.4.2 PHOTOCELL CONNECTION TO RELAYS AND SAFETY DEVICES WITH “N.C.” CONTACT.............................16

11.4.3 BUS PHOTOCELL CONNECTION ..........................................................................................................................16

11.4.4 TERMINAL BOARD J2, FLASHING LAMP (FIG.28)...............................................................................................17

11.4.5 TERMINAL BOARD J9 - POWER SUPPLY (FIG. 34).............................................................................................17

11.4.6

Connectors J3, J5 - rapid connection opening and closing limit switches ............................................................................................................17

11.4.7 FREQUENCY SELECTOR DS1 (FIG. 27) ...............................................................................................................17

11.4.8 CONNECTOR J4 - MINIDEC, DECODER AND RP CONNECTOR.........................................................................17

11.4.9 REVERSING GATE OPENING CONNECTIONS FROM RIGHT TO LEFT .............................................................17

11.5 PROGRAMMING ...............................................................................................................................................20

11.5.1 BASIC PROGRAMMING LEVEL.............................................................................................................................20

11.5.2 CHANGING THE PRE-SETTINGS...........................................................................................................................21

11.5.3 NEW BUS E850 SIGNAL.........................................................................................................................................21

11.5.4 ADVANCED PROGRAMMING LEVEL ....................................................................................................................22

11.5.5 SETTING THE INTEGRATED LOOP DETECTOR ..................................................................................................23

11.8 EXPERT PROGRAMMING LEVEL ...................................................................................................................24

11.6 E850 BOARD START-UP ...................................................................................................................................24

11.6.1 VERIFYING THE BOARD LEDs..............................................................................................................................24

11.6.2 VERIFYING THE BUS STATUS...............................................................................................................................24

11.7 TESTING THE AUTOMATED SYSTEM..............................................................................................................24

11.8.1. PERSONALISING THE OPERATING LOGIC.........................................................................................................25

1 11.9 OPERATING LOGICS TABLES .....................................................................................................................26

12 OMRON INVERTER CONTROL UNIT............................................................................................................. 28

12.1 DESCRIPTION OF THE INVERTER CONTROL PANEL .................................................................................28

12.2 PROGRAMMING THE INVERTER ...................................................................................................................30

12.3 12.3 INVERTER DEFAULTS .............................................................................................................................31

12.4 INVERTER ERROR............................................................................................................................................33

12.5 OPTIONAL ACCESSORIES...............................................................................................................................34

12.5.1 EXTERNAL PROGRAMMING KEYBOARD.............................................................................................................34