5

ENGLISH ENGLISH

Emergencybatteries(fig.1ref.)

In the event of a mains power cut, on-battery operation

providesarange of 30 minutes at100%use frequency.

The battery charge status test is automatic and indicated by

aLED.

Thechargecontrolboardisdesignedforremoteactivationof

a'batteryoperating'signal.

3.2 Supplementaryaccessories

Thesearethe peripheralaccessoriesforcompletingthe

automatedsystem.

-Miniswitch photocells

-T20E:outdoorkey-operatedselectorswitch

-T20I:flush-fitting key-operatedselectorswitch

-T21EF:Outdoorkey-operatedselectorswitchdesignedfor

motorrelease

-T21IF:Flush-fitting key-operated selectorswitchdesignedfor

motorrelease

-Detectionsensors.

-SD Keeper

3.3 Doorframeaccessories

Tofacilitateadaptingthe doorframeprofiletothecarriages

andtoenablecorrectfinishingoftheinstallation,FAACoffers

thefollowingseriesofarticles:

Closing profile (fig.2ref.)

Available in natural and anodised aluminium versions, the

profileisusedforclosingthespacebetweenthemobileleaf

and the wall on which the head profile is secured.

Brush for closing profiles (fig. 2 ref. )

Preventsdustreachinginsidetheheadprofile.

Pairofslidingblocks(fig.13ref.2)

Supplied as a pair, they can be secured to the wall (or on the

stationaryleaf)ordirectlyonthefloor.

Bottomtrackprofile(fig.13ref.)

Allowsthe bottom leaf profile to adapt to the sliding block

mentionedabove.

Brushfor bottomtrack profile(fig.13ref.)

Thiscompletestheon-groundtracksystem.

Leafattachmentprofile(fig.16ref.)

Allowsthe top leaf profile to adapt to thecarriage

attachments.

Pairofbottomslidingblocksforglass leaf

Theyenable the glass leaves to slide.

4. HEAD PROFILE CONFIGURATION

Tocorrectlypositiontheheadprofile parts, refer tothe

dimensionsinfigures3,4and5formodelSMandfigures6,7

and8fortwin-motormodel(SDM).

WiththeFAACseries940SMsystems,single-or double-leaf

sliding doors can be automatically activated, managed and

controlled.

TheFAACseries940automatedsystemsaresuppliedfully

assembled,wiredandtestedin the configurationrequested

by the customer on the order form, or supplied as a kit.

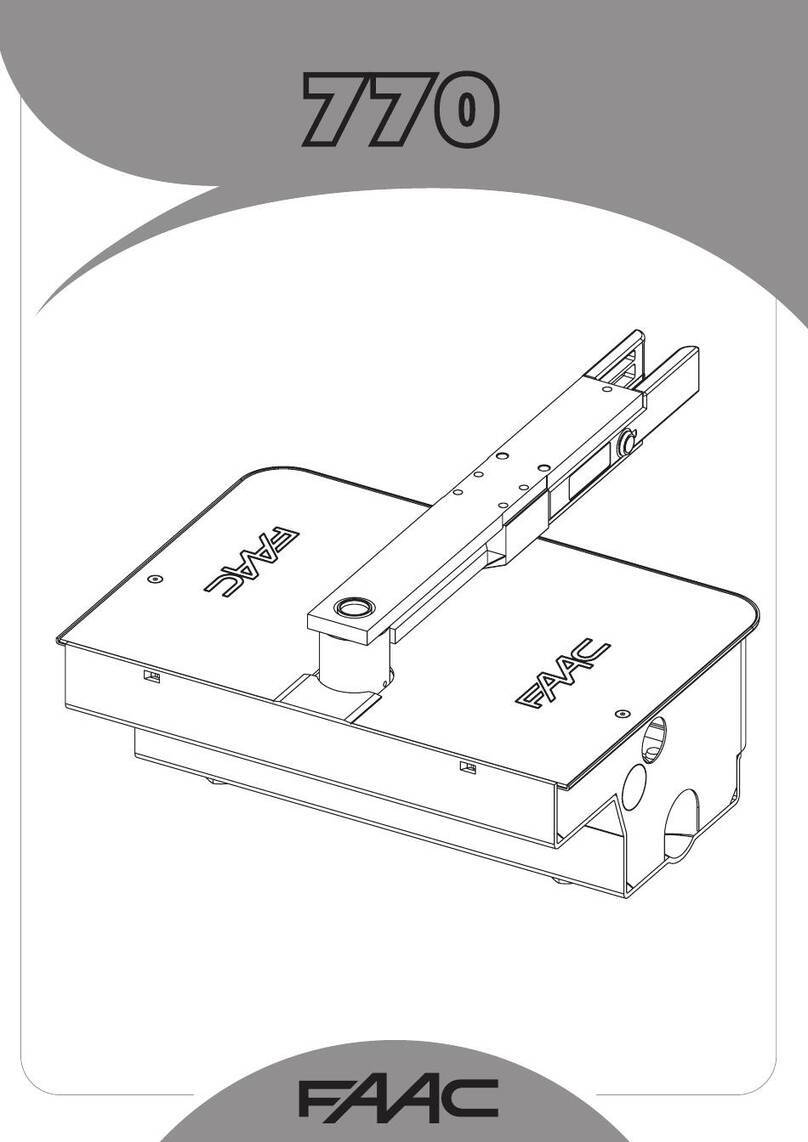

Anautomationheadprofile(fig.1)consistsofthefollowing

parts:

ProfileSM (fig.2ref.)

Thisis the supportprofile which isused when the head profile

canbeentirelyfitted on a bearing structure. Theprofile's

slidingtrack is coated with a special plastic materialwhich, in

additiontoprotecting thealuminiumprofileagainstwear,

ensuressilentoperationwithaverylowfrictioncoefficient.

Leafsupportcarriages(fig.1ref.)

Thecarriagesareprovided with twowheelsonballbearings,

a counter wheel on the lower part, and a screw system for

adjustingleafheight.

Motorunit(fig.1 ref. )

The DC motor is supplied with an encoder and a leaf locking

system(accessory).

Control unit (fig.1ref.)

Whenthe microprocessorcontrolunit ispoweredup, it

executesaninitialisationprocessofthedoor'sfunctional

parameters.

Transformer(fig.1ref.)

Openingmechanicalstop(fig.1ref.)

Transmission pulley unit (fig.1ref.)

Secondmotor(fig.1ref.)

Drivechain(fig.1ref.)

3. ACCESSORIES

FAAChasthreegroupsofarticlescomplementingthe

installationoftheautomaticdoor.

3.1 Supplied accessories for the head profile

Thesearethe articleswhich,followingarequest ontheorder

form,areassembled ontheheadprofiledirectlyby FAAC.

Theseaccessories,whichcanbe,ifnecessary,installedlater

on,areasfollows:

Fronthousing(fig.2ref.)

The front housing is available in natural or anodised

aluminium.Thesidepanelsfullyenclosethesystem.

Motor lock unit

Themotorlock unitguarantees mechanical locking of the

doorinanyposition.Asingletypeofmotorlockisusedfor

eithersingle-ordouble-leafapplications.

Themotorlockis suppliedwithaninternalrelease device(fig.

1ref.)enablingemergencyopeningifnecessary;itisalso

designedforinstallationoftheexternalrelease(paragraph3.2

key push-buttons T21EF and T21IF). The motor lock unit acts

directlyonthemotor bylockingitmechanically.

Motorlockcontrol

Thiscontrolsifthemotorlockoperatingefficientlyandchecksifthe

doorhasactuallyclosed.Ifnecessary,thesystemisdesignedfor

remoteactivationofanindicator-lightorbuzzer.

940SM-SMD SERIES AUTOMATIC DOORS

2. DESCRIPTION AND TECHNICAL SPECIFICATIONS