Fasep 2000 srl Rev. 1.1

Balatron B350.G3 10 September 2012

iii

ORIGINAL INSTRUCTIONS

TABLE OF CONTENTS

WARNING .......................................................................................... ii

SYMBOLSANDCONVENTIONS ........................................................................ ii

1 PRESENTATION ............................................................................1-1

1.0 Intended Use .......................................................................1-1

1.1 Definitions .........................................................................1-1

1.2 Lifter - Intended Use .................................................................1-2

2 INSTALLATION .............................................................................2-2

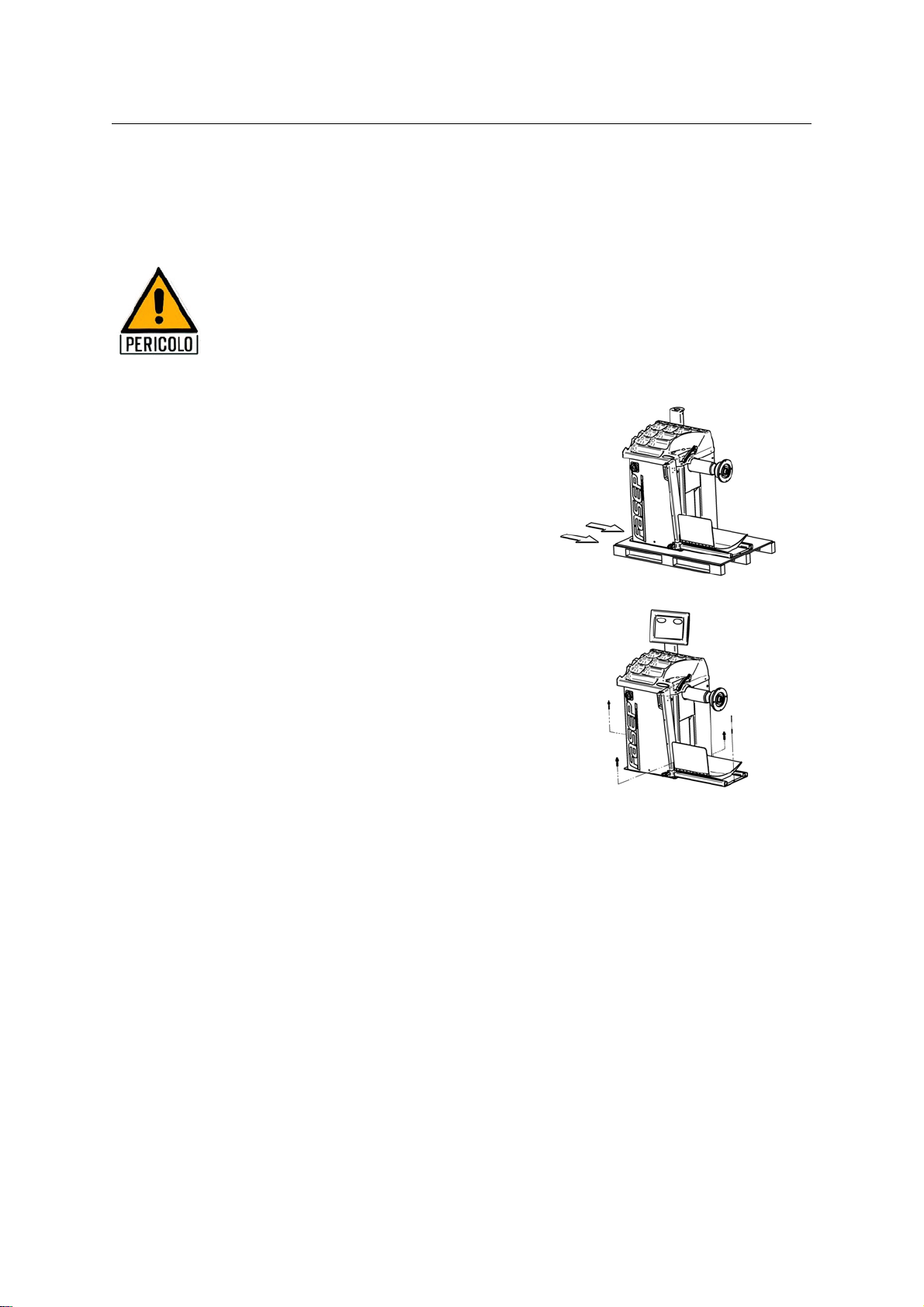

2.1 Movingtheunit......................................................................2-2

2.2 Assemblingtheunit ..................................................................2-2

2.3 Installation .........................................................................2-2

2.4 ElectricalHookup....................................................................2-2

2.5 Aircompressed .....................................................................2-3

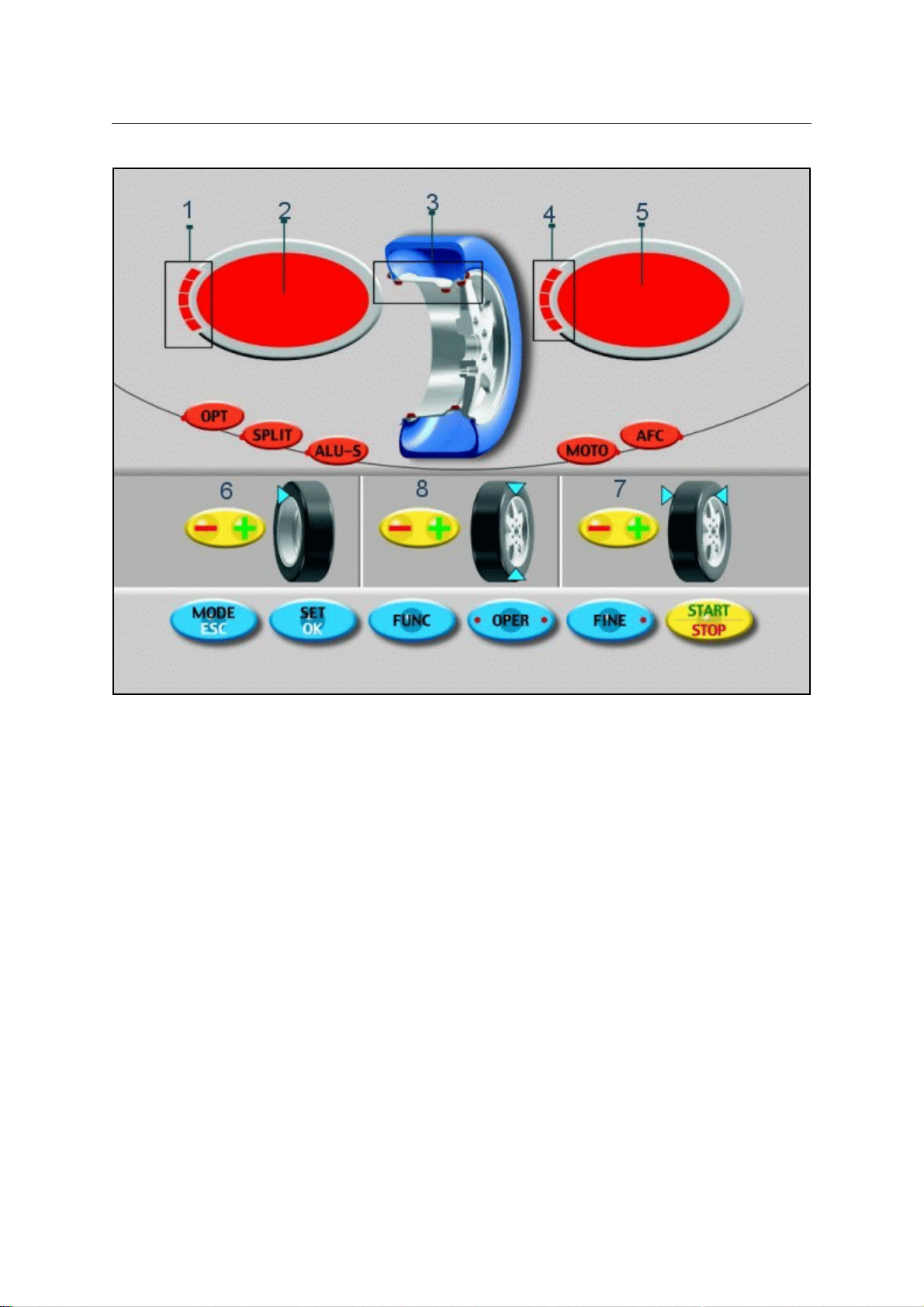

3 USETHECONTROLPANEL ..................................................................3-1

3.1 Meaning of keys at the keyboard ........................................................3-1

3.2 Meaning of Led Indicators .............................................................3-1

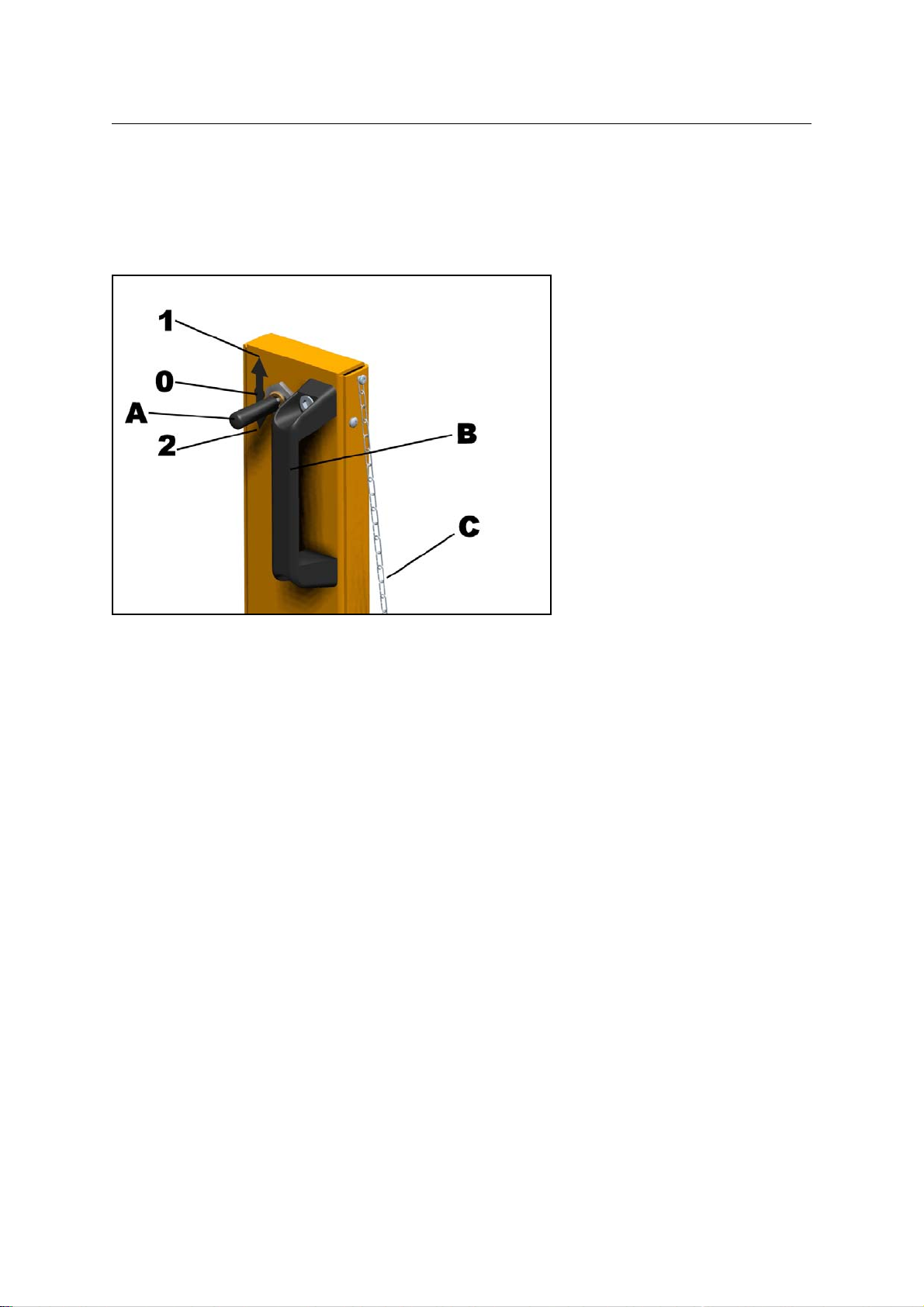

3.3 Useofthelifter......................................................................3-2

4 CALIBRATION ..............................................................................4-1

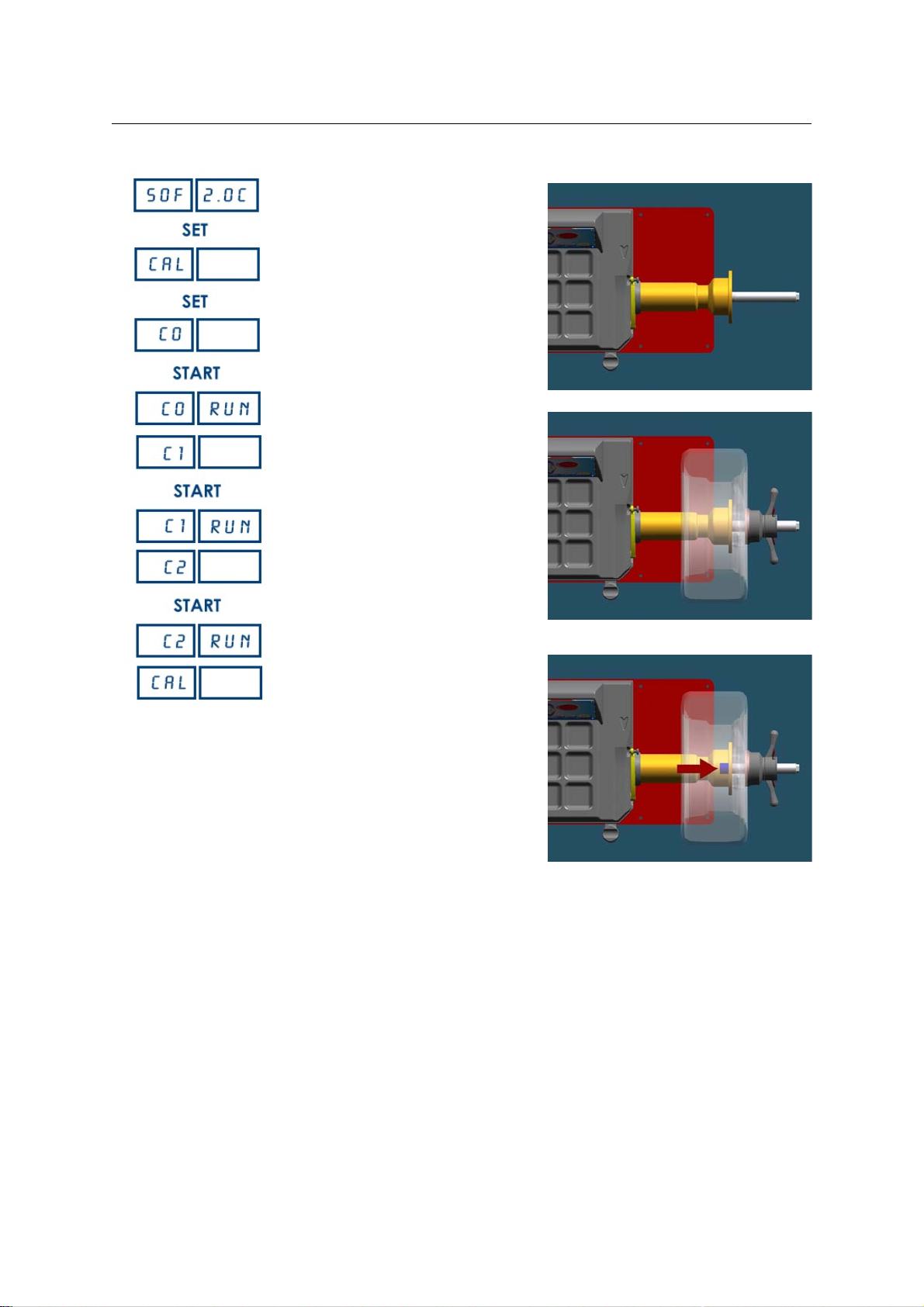

4.1 How to calibrate the Wheel Balancer B350-T ..............................................4-1

4.2 How to calibrate the Wheel Balancer B350-TC .............................................4-2

4.3 How to control the calibration of Wheel Balancer B350-T .....................................4-3

4.4 How to control the calibration of Wheel Balancer B350-TC ....................................4-4

5 MEASUREMENTANDCORRECTIONOFUMBALANCE ............................................5-1

5.1 Placing the wheel on the wheel balancer ..................................................5-1

5.2 How to compensate umbalance of flanges using AFC function .................................5-1

5.3 Input of Rim Dimensions (trucks) ........................................................5-2

5.4 Detecting and correction of the umbalance ................................................6-1

6 HOWTOOPTIMIZEUMBALANCEOFTHEWHEEL................................................7-1

7 HOW TO USE SPLIT WEIGHT FUNCTION .......................................................8-1

8 SPECIAL FUNCTIONS MENU ..................................................................9-1

8.1 Enterinthespecialfunctionsmenu......................................................9-1

8.2 Diagnostic sensors menu ..............................................................9-1

8.3 Statisticmenu ......................................................................9-1

8.4 UserSetup.........................................................................9-1

APPENDIX ........................................................................................ A-1

A: TechnicalData ............................................................................. A-1

B: Environmental Data, Safety Features and Requirements ............................................ B-2

C: Errors and Malfunctions recognized by the Computer ............................................... C-2