Fasep 2000 srl Rev. 1.0

Videotronic V644.G3: User’s Manual 27 november 2013

iii

ORIGINAL INSTRUCTIONS

TABLE OF CONTENTS

WARNING ............................................................................................. ii

SYMBOLSANDCONVENTIONS........................................................................... ii

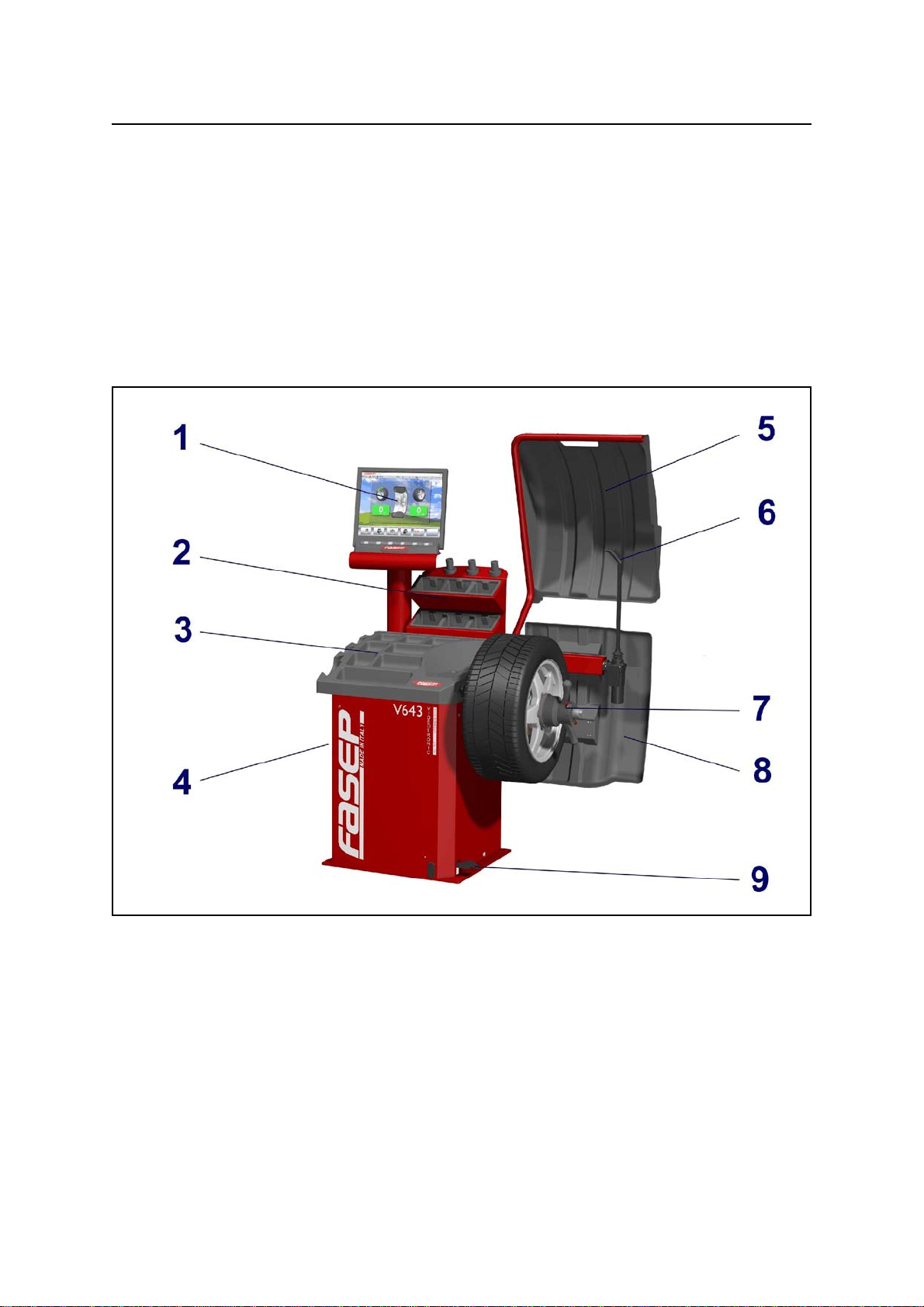

1 PRESENTATION ............................................................................. 1-1

1.0 IntendedUse......................................................................... 1-1

1.1 Definitions ........................................................................... 1-1

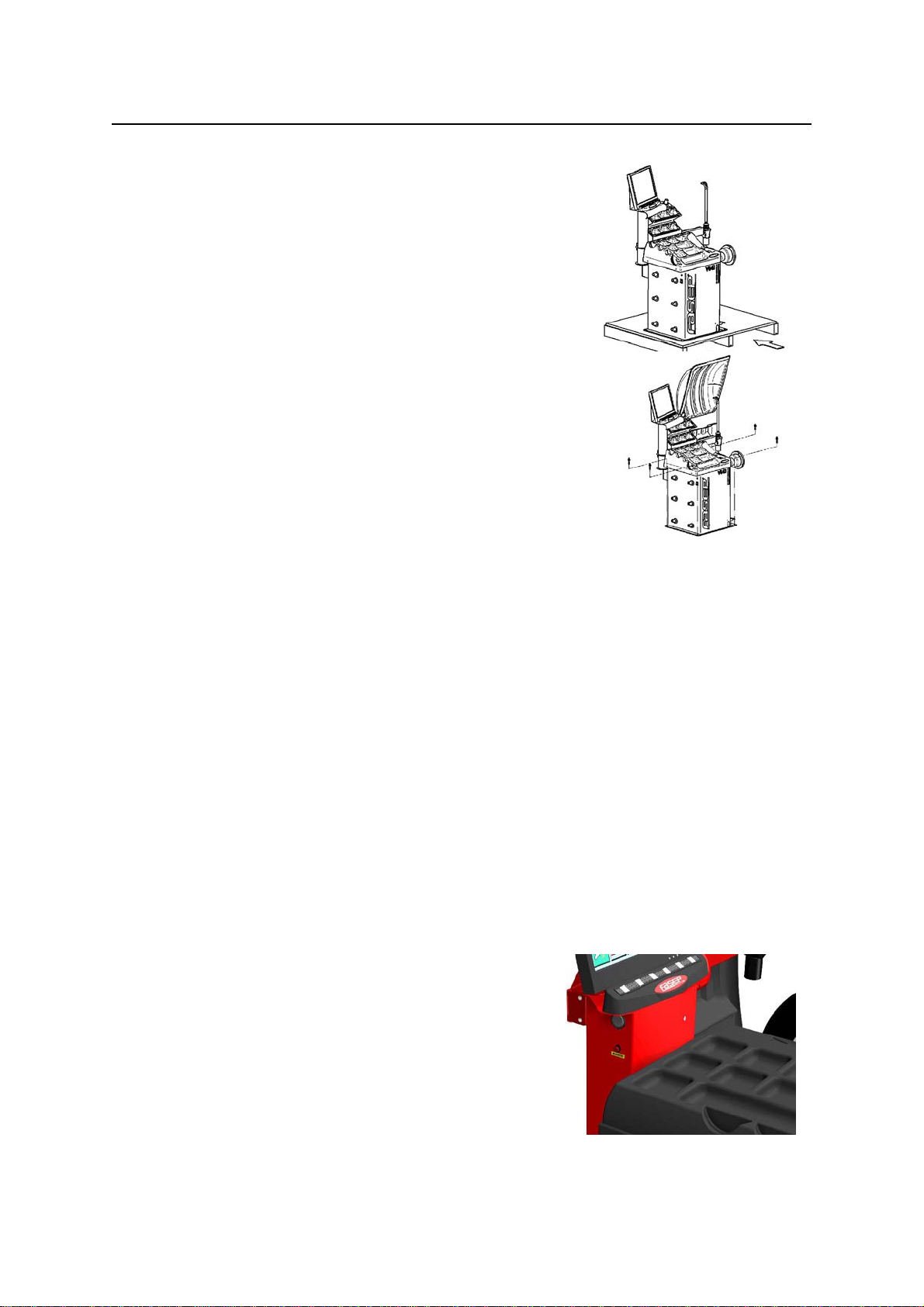

2 INSTALLATION............................................................................... 2-1

2.1 Movingtheunit ....................................................................... 2-1

2.2 Assemblingtheunit.................................................................... 2-1

2.3 Installation ........................................................................... 2-1

2.4 ElectricalHookup ..................................................................... 2-1

2.5 CompressedairHookup(PLmodelsonly) .................................................. 2-1

2.6 Power .............................................................................. 2-1

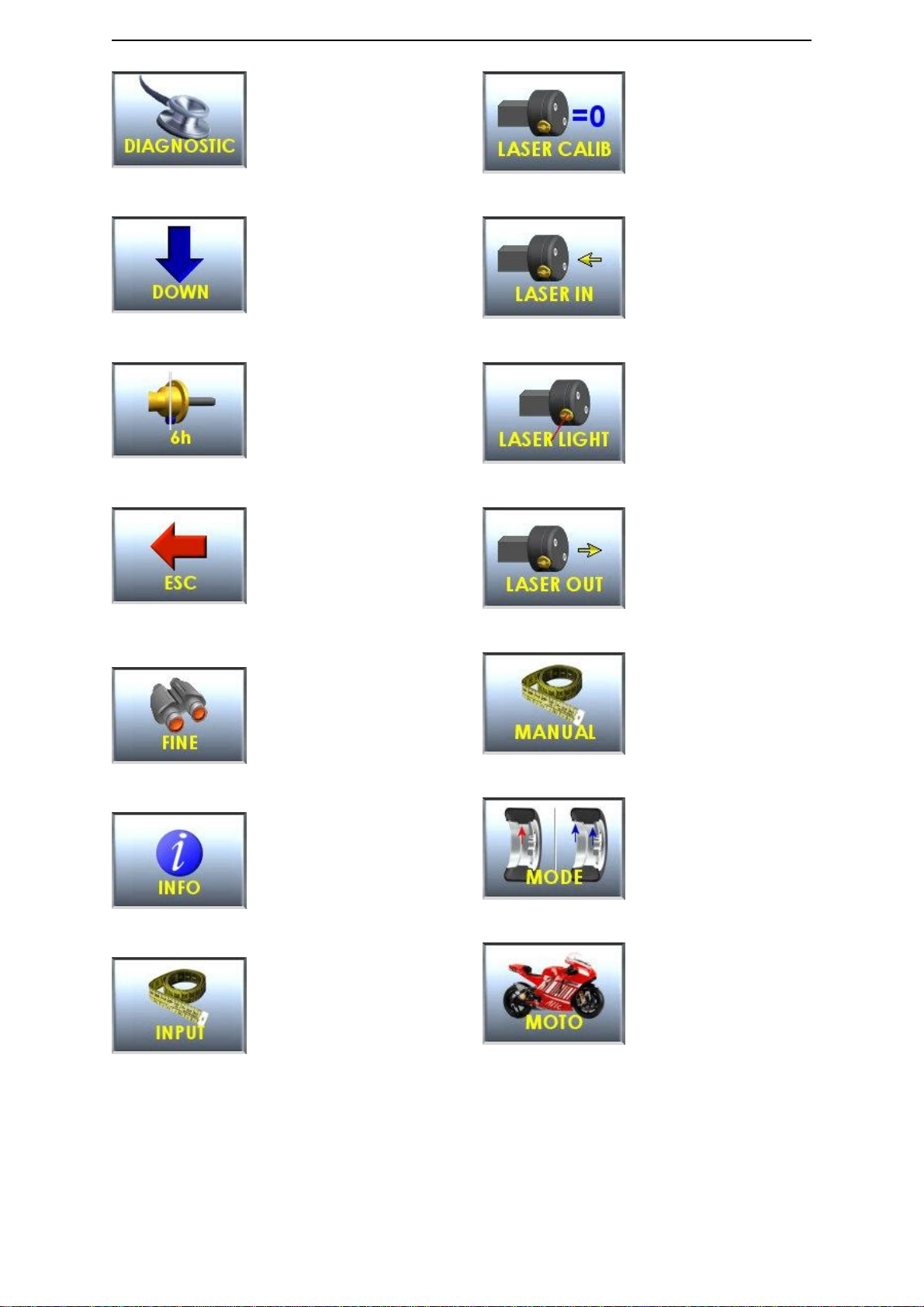

3 USEOFCONTROLPANEL..................................................................... 2-2

3.1 Meaningoftheiconsonthescreen........................................................ 2-2

4.0 CALIBRATIONOFWHEELBALANCER........................................................... 2-5

4.1 Howtocalibratethewheelbalancer ....................................................... 2-5

4.2 How tocontrol the calibration of wheel balancer and position weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

5 CalibrationALU-SE ............................................................................ 3-5

6 CalibrationSME............................................................................... 3-6

7 MEASUREMENT AND CORRECTION OF UMBALANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

7.1 Placing the wheel rim on the wheel balancer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

7.2 Input of Rim Dimensions (external measuring system version) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

7.3 Input of Rim Dimensions (ALU-SE or LASER version) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

7.4 Detectingandcorrectingumbalance....................................................... 3-8

7.5 How toapply the weight using ALU-SE applicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

7.6 HowtoapplytheweightusingLASER ..................................................... 3-9

7.7 HowtouseSPLITProgram.............................................................. 3-9

8 HOWTOOPTIMIZEUNBALANCEOFTHEWHEEL................................................. 4-1

9 SPECIALFUNCTIONS......................................................................... 5-1

9.1 Languageselection .................................................................... 5-1

9.2 Setup............................................................................... 5-1

APPENDIX........................................................................................... A-2

A: Technicaldata........................................................................ A-2

B: Environmental Data, Safety Features and Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

C: Errors and Malfunctions recognized by the Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

D: How toremove thebattery from the product safely. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3