Ferno Australia | 11 Johnstone Road, Brendale QLD 4500 | +61 7 3881 4999 | INFO@FERNO.COM.AU | FERNO.COM.AU ©FERNO AUSTRALIA / 00583 JUNE 2022 | Page 3 of 4

NOTICE

• EMPLOYERS: It is your responsibility to ensure all users are instructed and trained in the correct use and maintenance of the equip-

ment. Once equipment is issued, it is assumed appropriate training has been completed.

• USERS: You must consult AS/NZS 1891.4 for selection, use, maintenance and training requirements and be competent in the use

of equipment before beginning any tasks requiring its use. It is your responsibility to read and understand these instructions.

Always use equipment safely and properly. Check equipment before and after use.

• GENERAL: This document contains general tting instructions. Instructions are not all inclusive. Modifying the equipment can cause

injury and damage and will nullify any warranty and place full responsibility for any accident or injury on the equipment owner.

Fitting the Harness

1. Read the instructions carefully and check the harness labelling

to ascertain that you have the correct harness for the task.

2. Inspect the harness webbing and hardware for signs of wear

or damage.

3. Hold up the harness by the rear dorsal D-ring/loop and

untangle any straps that may have twisted during storage.

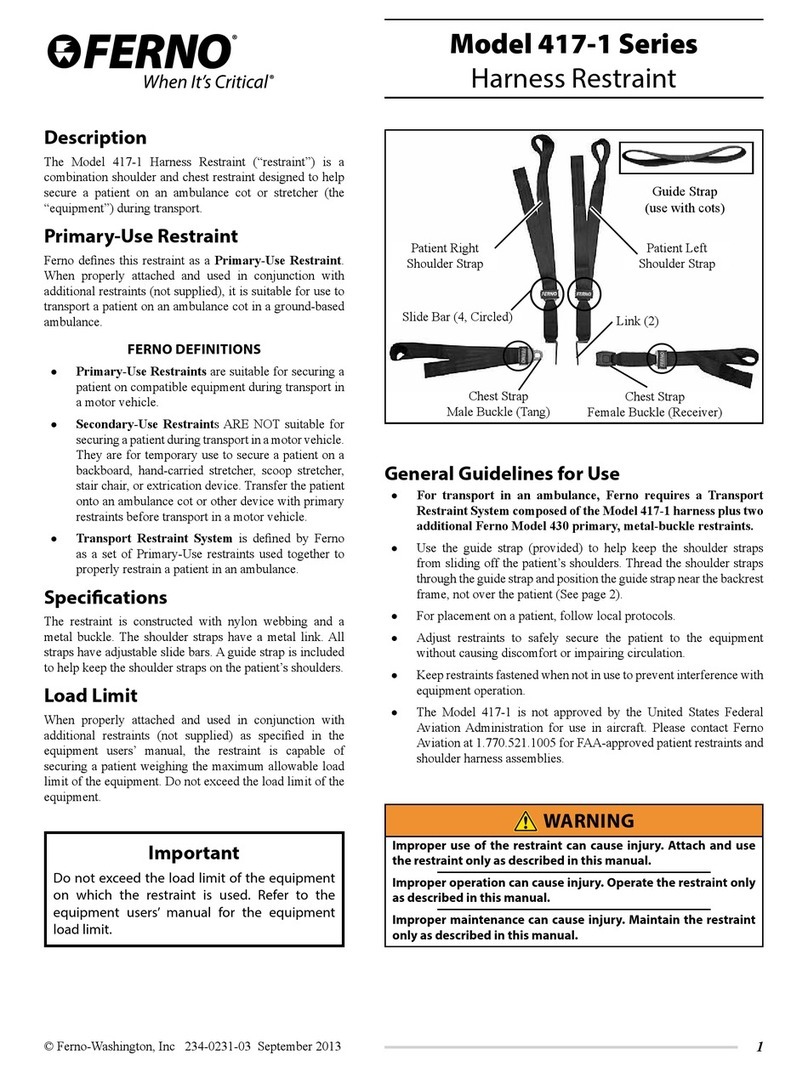

4. Separate the shoulder straps and familiarise yourself with

the layout of the harness. Release the sternum strap and leg

buckles from their respective links.

5. Put on the harness by passing your arms through the shoulder

straps as if putting on a jacket. Adjust the shoulder buckles to

the appropriate length/height.

6. Fasten chest strap with buckle, ensuring each buckle plate lays

at against its mate. Adjust for a comfortable t. Check that

the rear fall arrest D-ring is positioned centrally on your back

between your shoulder blades.

7. Pass both leg straps between your legs making sure there

are no twists in the straps. Using the same method as before,

connect the left leg strap’s buckle to the left leg link, and the

right leg strap buckle to the right leg link. Adjust both for a

comfortable t.

8. Tighten and adjust the shoulder straps. Re-adjust the front

sternum strap and leg buckles. The Rear Dorsal Attachment

Point should be positioned midway between your shoulder

blades. The nished tting should feel snug but not restrict

movement in any way.

9. Secure loose ends with keepers and check for twists, misaligned

webbing and disconnected buckles.

Inspecting the Harness

To maintain the safety and serviceability of this product the

following inspections must be performed.

1. OPERATOR INSPECTION

The operator/wearer shall inspect the product before and after

each use. Check all webbing, thread and metal components for

excessive wear or damage. Refer any signs of deterioration to a

competent person for a decision on the safety and serviceability

of the product.

Harnesses and lanyard assemblies should be destroyed

or returned to the manufacturer for inspection if a fall has

been sustained.

2. PERIODIC INSPECTION

A full periodic inspection shall be conducted every six months

by a competent person. Use the provided checklist as a guide

for determining the condition of the product. Check for signs of

contaminants such as oil, grease, paint etc.

Periodic inspections shall be recorded in the product’s

Inspection and Maintenance Log. A sample log is provided in

these Instructions.

NOTICE

Exposure to chemicals and hazardous atmospheres can cause

damage to bres and components that are not immediately

visible.

If any part of an assembly is to be exposed to chemicals such

as cleaning materials or hazardous atmospheres, the user

should consult the manufacturer to determine whether the

part is suitable for continued use.

Maintenance

This product should be cleaned regularly to maintain its condition

and serviceability. Clean as indicated below.

1. AFTER EACH USE

After each use, wipe down the product to remove any dust

or dirt. If there is any sign of contaminants such as oil, grease,

paint, etc tag the product as unt for use and refer it to a

competent person for inspection.

2. DURING PERIODIC INSPECTION

Hand wash the product with Ferno Rope and Harness Wash

every alternate periodic inspection (ie. every twelve months).

The harness may require more frequent washing depending

on the conditions it is exposed to.

Hang the product in a sheltered, shaded area away from direct

heat to dry completely.

• Do not machine wash

• Do not tumble dry

Refer to the manufacturer for advice on removing dicult

stains.

Storage

Store the product away from direct sunlight and protected from

dust, moisture and corrosive atmospheres.