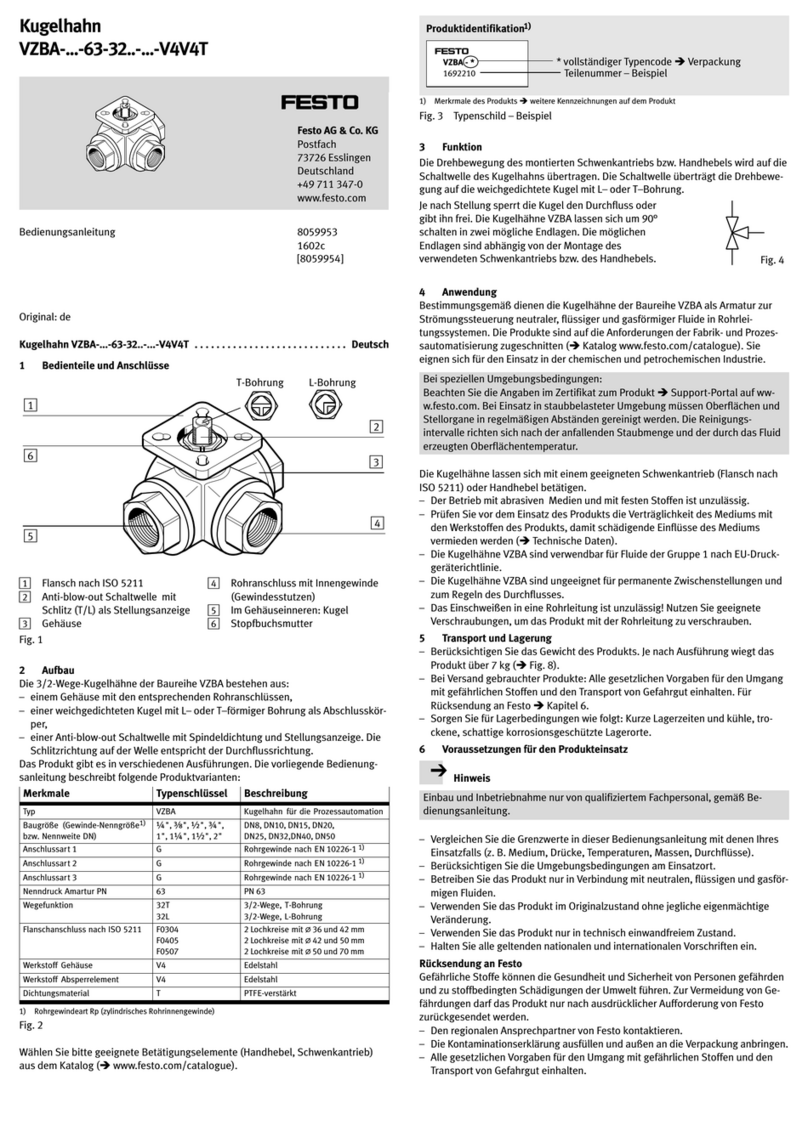

Valve parameter: ID

Parameter no. 1

Description Provides valve identification for I-Port

Values In-line valve Flanged valve

0x01: 1/8" 10 bar 0x31: F6 10 bar

0x02: 1/8" 6 bar 0x32: F6 6 bar

0x03: 1/8" 2 bar 0x33: F6 2 bar

0x11: 1/4" 10 bar 0x41: F8 10 bar

0x12: 1/4" 6 bar 0x42: F8 6 bar

0x13: 1/4" 2 bar 0x43: F8 2 bar

0x21: 1/2" 10 bar

0x22: 1/2" 6 bar

0x23: 1/2" 2 bar

Comment Read only

Fig. 11

Note

When changing the unit for pressure specifications, the parameters for the limit

values and the input word (setpoint value) are not automatically converted.

When changing the unit, also change the parameters for the upper/lower limit

value and the input word (èFig. 17).

Valve parameter: Unit for pressure indications

Parameter no. 2

Description Defines the unit for pressure indications (limit values, pressure setpoint

specification and pressure actual value specification).

Bit Bit 1.0

Values Bit 1 0 Setting Resolution

0 0 mbar (preset) 1 mbar/bit

01kPa 1 kPa/bit

10psi 0.1 psi/bit

1 1 reserved

Comment To avoid accidental pressure fluctuations, set the input word before conversion

of the unit to zero.

Fig. 12

Valve parameters: Setting of the control behaviour (presets), output data type

and measured value smoothing

Parameter no. 3

Description Parameterised via this function number are:

– Control behaviour (presets): Defines the characteristic curve used for

controlling a setpoint pressure.

– Output data type: Offers 3 options for what is presented in the output word

(data format èFig. 16):

– Output of the current pressure value

– Output as comparator bit:

Bit 0 = 0: Pressure value is outside the control range

Bit 0 = 1: Pressure value is in the control range

– Combined output of current pressure value and comparator bit. Bit 0 is used

as the comparator bit, as above It is no longer used for representing

the pressure value.

– Measured value smoothing: Sets how strongly the measured values are

smoothed for limit monitoring. This can suppress possible malfunctions.

Bit Bit 1, 0: Control behaviour (presets)

Bit 3, 2: Output data type

Bit 5, 4: Measured value smoothing

Values Bit 543210

Control behaviour setting (presets):

x x x x 0 0 Reserved

x x x x 0 1 Fast

xxxx10 General (presetting)

xxxx11 Precise

Setting of output data type:

x x 0 0 x x Reserved

xx01x x Current pressure value in the output word

(presetting)

x x 1 0 x x Comparator bit (bit 0 in the output word)

x x 1 1 x x Current pressure value and comparator bit

Settings of measured value smoothing:

00x x x x No measured value smoothing (presetting)

0 1 x x x x Smoothing over 2 values

1 0 x x x x Smoothing over 4 values

1 1 x x x x Smoothing over 8 values

Comment Bold = presetting, x = value is unimportant for this setting

Fig. 13

Valve parameter: Condition counter solenoid coil

Parameter no. 8...11 Condition counter limit

Manual A limit value for a counter (condition counter) can be set for the internal

solenoid coil in the pilot control of the pressure regulator. A message is

displayed if the limit value is exceeded, which is sent to the IO-Link master.

Bytes 11 or 8: High byte or low byte of the limit value (32 bit values, hexadecimal)

Values FFFFFFFFh:Condition counter activated, but limit value inactive

(preset)

2DC6C0h:(Example) Condition counter activated and limit value

3,000,000dset.

0: Condition counter inactive (counter and diagnostic message

deactivated, counter reset, counter actual value can be read

through 0x6B.)

Fig. 14

Valve parameter: lower / upper limit

Parameter no. 12…13 Lower limit value

14…15 Upper limit value

Description The lower and upper limit values for the pressure and diagnostic messages are

set with these parameters. Undershooting or overshooting of limit values is only

signaled if the output word diagnostics is activated via the limit value

monitoring parameter (èFig. 10).

Byte 12 or 14 low byte

13 or 15 high byte

Values Presets

– Lower limit value = 0 (low byte = 0; high byte: 0)

– Upper limit value: Max. pressure value of the valve type (èFig. 17)

Remarks The upper limit value must always be greater than the lower limit value.

The limit values are checked for validity during parameterisation. If invalid

parameters are present and the module parameter “Monitoring of

parametrisation errors” is active, a corresponding error is signaled

(èChapter 12).

Fig. 15

Process Data

Input word (setpoint value, 16 bit)

Output word (pressure value, 16 bit)

LSB (bit 0) can be used as a comparator bit with parameterisation of output data.

Fig. 16

Proportional

pressure regulator

Control

range

Range of values 1)

input word (decimal)

Range of values 1)

input word (hex)

VPPM-...-0L2H-LK-S1 0 … 2 bar 0 … 2000/290/200 0h… 07D0h/0122h/00c8h

VPPM-…-0L6H-LK-S1 0 … 6 bar 0 … 6000/870/600 0h… 1770h/0366h//0258h

VPPM-...-0L10H-LK-S1 0 … 10 bar 0 … 10000/1450/1000 0h… 2710h/05AAh/03E8h

1) If mbar/psi/kPa is set as the pressure unit

Fig. 17

Recommended parameter sets VPPM size x" (presets èFig. 13)

Tube

length 1)

Open

system

Output volumes in ml

0 … 100 100 … 1000 > 1000

0 m 3 3 2 1

1 m 3 3 2 2

3 m 3 3 3 2

5 m 3 3 3 2

1) With tubing diameter 6 mm or 8 mm

Fig. 18

Recommended parameter sets VPPM ¼" and ½" (presets èFig. 13)

Tube

length 1) 2)

Open

system

Output volumes in ml

Size ¼"

0 … 500 500 … 2000 > 2000

Size ½"

0 … 2000 2000 … 10000 > 10000

0 m 3 1 2 3

1 m 3 1 2 3

3 m 3 2 3 3

5 m 3 3 3 3

1) With tubing diameter 8 mm or 10 mm (1/4")

2) With tubing diameter 12 mm or 16 mm (1/2")

Fig. 19

7 Operation

Note

When switching off the VPPM, first make sure that the setpoint value is set to 0,

then that the supply pressure and finally the supply voltage are switched off.