Translation of the original instructions

1 Identification EX

Identification mark

II 2G Ex h IIC T6 Gb X

II 2D Ex h IIIC T85°C Db X

Tab. 1

2 Further applicable documents

NOTICE!

Technical data for the product can have different values in other documents. For

operation in an explosive atmosphere, the technical data in this document always

have priority.

All available documents for the product èwww.festo.com/pk.

3 Safety

3.1 Safety instructions

– The device can be used under the stated operating conditions in zone 1,

explosive gas atmospheres, and in zone 21, explosive dust atmospheres.

– The product may only be used in its original status without unauthorised

modifications.

– Only use the product if it is in perfect technical condition.

– All work must be carried out outside of potentially explosive areas.

– Observe the specifications on the product labelling.

– Earth the device via the earthing screw.

– Only use media in accordance with the specifications è 11 Technical data.

3.2 Intended use

The filter regulating valve LFR regulates the compressed air in the subsequent

string to the set output pressure. The LFR thereby smoothes out pressure fluctu

ations.

3.3 Identification X: special conditions

– Danger of electrostatic discharge.

–Ambient temperature T18: -20 °C£Ta£+80°C

–Ambient temperature T3: -40 °C£Ta£+80°C

4 Further information

– Accessories èwww.festo.com/catalogue.

– Spare parts èwww.festo.com/spareparts.

5 Service

Contact your regional Festo contact person if you have technical questions

èwww.festo.com.

6 Product overview

6.1 Function

The filter regulating valve LFR removes dirt particles and condensate. The output

pressure can be adjusted within the pressure range.

6.2 Product variants

Ambient temperature T18: -20°C…+80°C

Connection Type Part number

LFR1/4D5MOMIDIT18EX4 4772764

LFR1/4DOMIDIT18EX4 4772765

LFR1/4D165MOMIDIT18EX4 4772766

LFR1/4D16OMIDIT18EX4 4772767

LFRN1/4D5MOMIDIT18EX4 4772772

LFRN1/4DOMIDIT18EX4 4772773

LFRN1/4D165MOMIDIT18EX4 4772774

¼"

LFRN1/4D16OMIDIT18EX4 4772775

LFR1/2D5MOMIDIT18EX4 4772768

LFR1/2DOMIDIT18EX4 4772769

LFR1/2D165MOMIDIT18EX4 4772770

LFR1/2D16OMIDIT18EX4 4772771

LFRN1/2D5MOMIDIT18EX4 4772776

LFRN1/2DOMIDIT18EX4 4772777

LFRN1/2D165MOMIDIT18EX4 4772778

½"

LFRN1/2D16OMIDIT18EX4 4772779

Tab. 2

Ambient temperature T3: -40°C…+80°C

Connection Type Part number

LFR1/4D5MOMIDIT3EX4 5271792

LFR1/4DOMIDIT3EX4 5271793

LFR1/4D165MOMIDIT3EX4 5271794

LFR1/4D16OMIDIT3EX4 5271795

LFRN1/4D5MOMIDIT3EX4 5271800

LFRN1/4DOMIDIT3EX4 5271801

LFRN1/4D165MOMIDIT3EX4 5271802

¼"

LFRN1/4D16OMIDIT3EX4 5271803

LFR1/2D5MOMIDIT3EX4 5271796

LFR1/2DOMIDIT3EX4 5271797

LFR1/2D165MOMIDIT3EX4 5271798

LFR1/2D16OMIDIT3EX4 5271799

LFRN1/2D5MOMIDIT3EX4 5271804

LFRN1/2DOMIDIT3EX4 5271805

LFRN1/2D165MOMIDIT3EX4 5271806

½"

LFRN1/2D16OMIDIT3EX4 5271807

Tab. 3

7 Assembly and installation

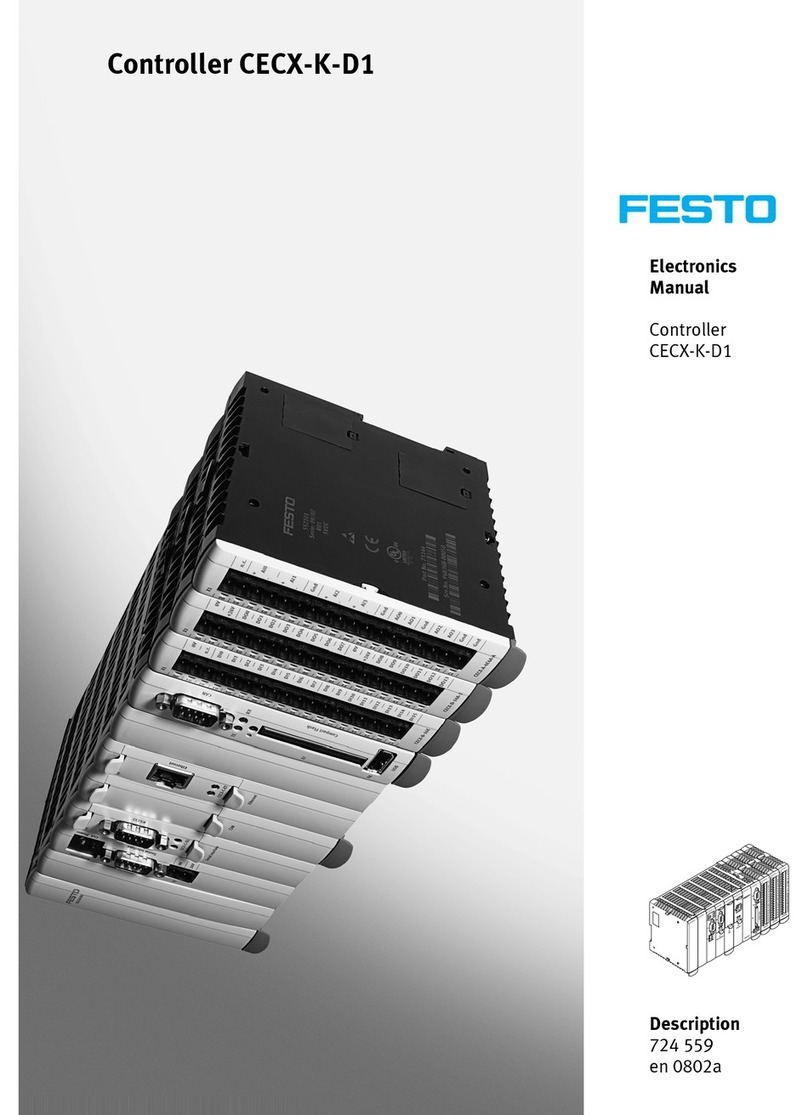

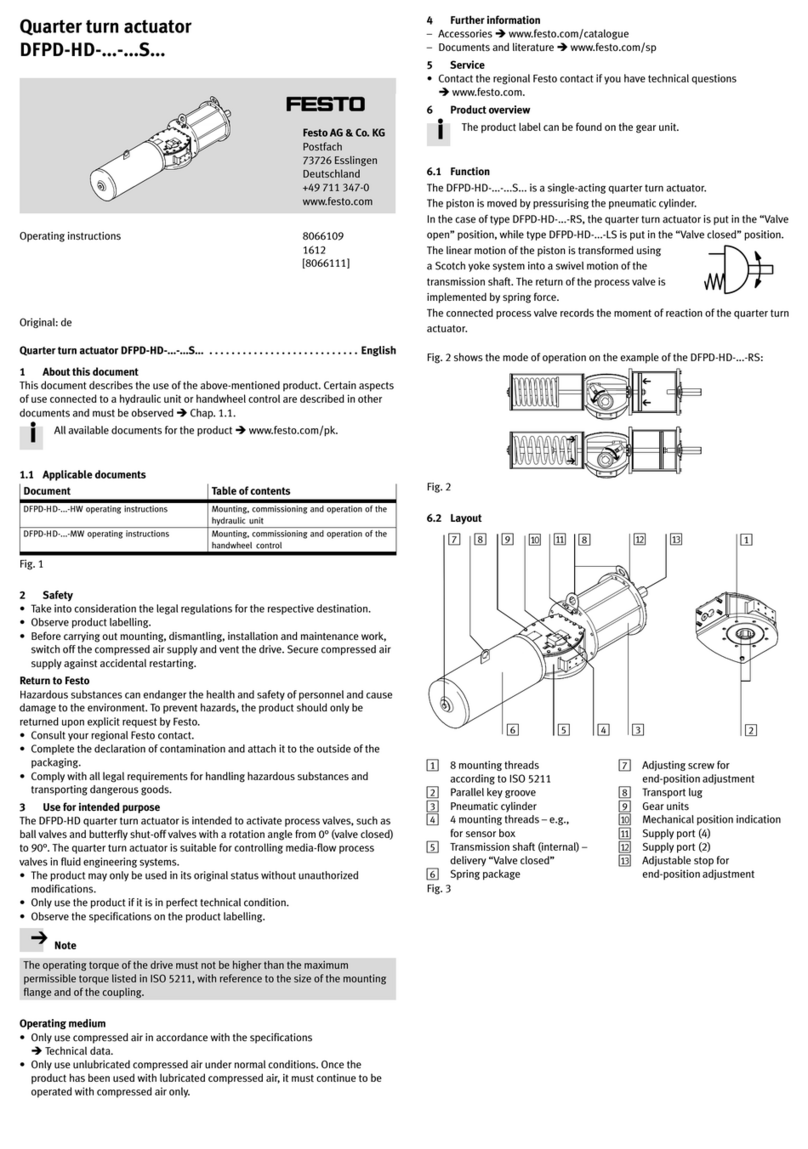

1Indication of flow direction 2Plug screw

Fig. 1

7.1 Filter regulator

1. Observe the flow direction 1 after 2.

2. Place the device at least 80mm below the filter bowl.

3. Position the device vertically (_5°).

When assembling filter combinations, observe the sequence along the flow direc

tion.

7.2 Pressure gauge

1. Remove the plug screw 2.

2. Turn pressure gauge with seal to the stop.

8107996

LFR-...-EX4-...

Filter regulator

8107996

201902b

[8107185]

Instructions| Operating

Festo SE & Co. KG

Ruiter Straße 82

73734 Esslingen

Germany

+49 711 3470

www.festo.com