8.2 Performing commissioning

Running noises during operation

Identical axes can generate different running noises depending on the paramet

erisation, mode of operation, type of mounting, installation environment and com

ponents.

Requirement

– Mounting of the drive system checked.

– No foreign objects in the movement space of the propulsion system.

– No mechanical overload of the axis and dynamic setpoint deviation not

exceeded (e.g.overrunning the end position) due to force and torque peaks.

• Commissioning of the drive system (e.g. control and homing) èInstruction

manual for drive axis, www.festo.com/sp.

9 Operation

WARNING!

Risk of injury due to unexpected movement of components.

• Protect the positioning range from unwanted intervention.

• Keep foreign objects out of the positioning range.

• Perform commissioning with low dynamic response.

10 Maintenance

10.1 Safety

WARNING!

Unexpected movement of components

Injury due to impact or crushing.

• Before working on the product: secure the slide to prevent unintentional

movement.

CAUTION!

For vertical or slanted mounting position: when power is off, moving parts can

travel or fall uncontrolled into the lower end position.

Injury due to impacts or crushing.

• Bring moving parts of the product into a safe end position or secure them

against falling.

10.2 Cleaning

1. Clean the product with a soft cloth. Do not use aggressive cleaning agents.

2. If necessary, clean the guide rail with a soft lintfree cloth without detergent.

Then apply a thin layer of lubricant to the guide rail.

10.3 Lubrication

Lubrication interval and accessories

NOTICE!

The lubrication interval Sint is dependent on the load acting on the product.

Load factors include e.g.:

• Dusty and dirty environment

•Nominal stroke > 2000mm or < 300mm

•Speed > 2m/s

•Ambient temperature > +40°C

•Service age of product > 3years

• Travel profile matches triangular operation (frequent acceleration and brak

ing)

If one of these factors applies:

• Halve lubrication interval Sint.

If several factors apply at the same time:

• Divide service interval Sint by four.

Lubrication Recirculating ball bearing guide Guide rail

Lubrication interval – Calculate the comparative loading factor fv

using the formula for combined loads

è Tab. 10 General data,

EGC70/80/120/185FA.

– Lubrication intervals Sint as a function of the

load comparison factor fv can be taken from

the diagram.

If required, e.g.if the

grease layer is insuffi

cient.

Accessories èwww.festo.com/spareparts

Lubrication point Lubrication hole Surface

Lubricant Roller bearing grease LUBKC1

Lubrication Recirculating ball bearing guide Guide rail

Pressure grease gun with pinpoint nozzle LUB1, 647958Grease gun

– Lubrication adapter, axial output,

LUB1TRI, 647959

– Lubrication adapter, radial output,

LUB1TRL, 647960

–

Tab. 7 Overview of lubrication intervals and accessories

Lubricate guide

Recirculating ball bearing guide (EGC-…-GK/GV)

Lubrication hole, both sides

Grease quantity per lubricating hole:

EGC ... GK/GV (size), 2 lubrication holes, lateral (left and right)

– 70: 0.3g

– 80: 0.6g

– 120: 1.2g

– 185: 3.6g

Tab. 8 Lubrication overview

1. Inject lubricant into all lubrication holes.

2. During the lubrication process, travel the entire distance in order to distribute

the lubricant evenly inside the machine.

11 Malfunctions

11.1 Fault clearance

WARNING!

Unexpected movement of components

Injury due to impact or crushing.

• Before working on the product: secure the slide to prevent unintentional

movement.

WARNING!

Risk of injury due to unexpected movement of components.

• Protect the positioning range from unwanted intervention.

• Keep foreign objects out of the positioning range.

• Perform commissioning with low dynamic response.

CAUTION!

For vertical or slanted mounting position: when power is off, moving parts can

travel or fall uncontrolled into the lower end position.

Injury due to impacts or crushing.

• Bring moving parts of the product into a safe end position or secure them

against falling.

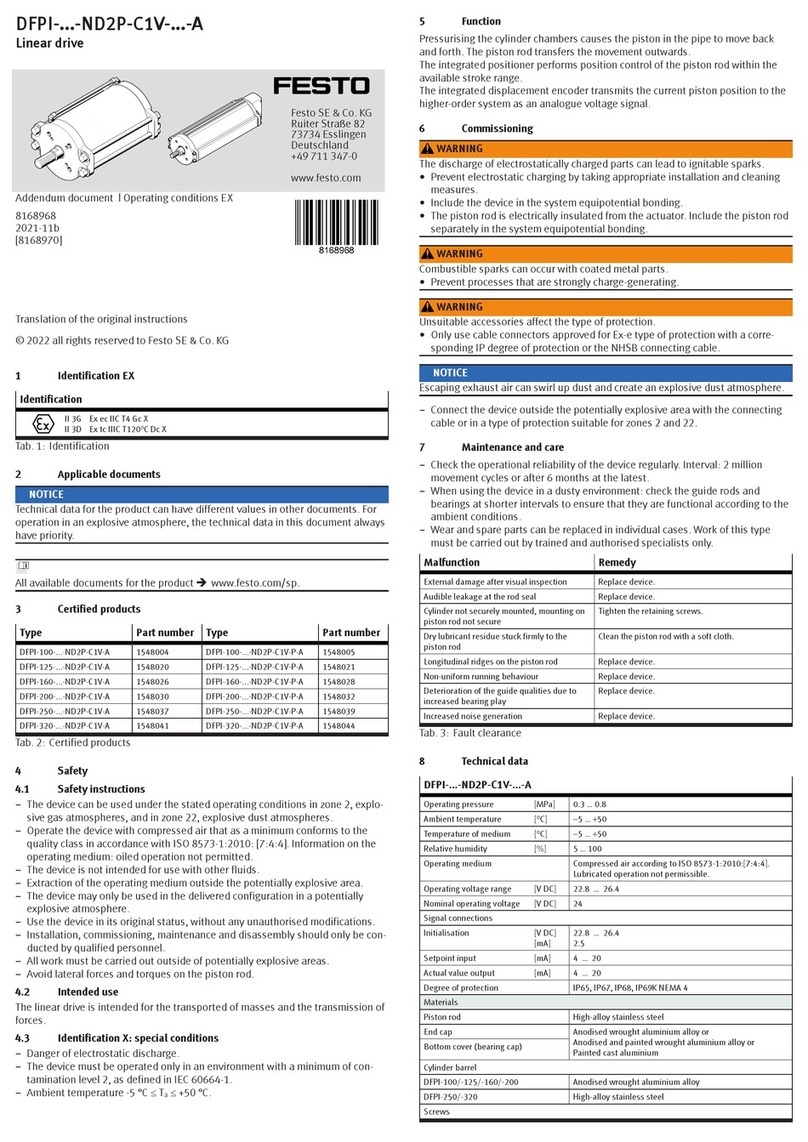

Malfunction Possible cause Remedy

Torsional stresses – Install axis without tension. Note the flat

ness of the contact surface

è 7.3 Fasten axis.

– Change the layout of the attachment com

ponent (e.g.payload).

– Align axes parallel to one another.

Resonance oscillation

of the axis

Change the travel velocity.

Wear on guide – Contact local Festo Service.

– Replace axis èwww.festo.com/catalogue.

Loud running noises,

vibrations or rough

running of the axis

Insufficient lubrication

of guide

Lubricate the guide è 10.3 Lubrication.

Vibrations on the slide Operation at the reson

ant frequency of the

axis

– Change the travel velocity.

– Change the acceleration.

– Increase axis stiffness (e.g.shorter support

distances).

– Change the payload geometry.

Long oscillations of the

profile

The resonant fre

quency from the profile

and useful load are too

low

– Increase axis stiffness (e.g.shorter support

distances).

– Change the payload geometry.

Loads too high Reduce forces and torques. Consider dynamics.Slide does not move

Screws too long for fix

ing the attachment

component (e.g.pay

load)

Observe the screwin depth

è 7.4 Mounting the attachment component.

Overruns the end posi

tion

Sensor does not switch Check sensor, installation and parameterisation.

Tab. 9 Overview of fault clearance