10.3 Lubrication

Note

Check the need for shorter lubrication intervals:

• At high temperatures.

•With excessive dirt accumulation.

• In the vicinity of grease-dissolving liquids or grease-dissolving vapours.

1. Lubricate the product as required.

2. Lubricate the piston rod and the guide rail.

Use the following lubricant:

–Festo LUB-KC1

3. Move the slide by hand for even lubrication.

11 Malfunctions

11.1 Fault clearance

Fault description Cause Remedy

The slide moves unevenly. The one-way flow control valves

are not installed correctly.

Control the exhaust air flow.

The slide is in initial position

despite pressurisation.

The tubing is faulty. Check the tubing.

The slide speed is too low. The air volume is insufficient. –Increase the connection

cross-sections.

–Check the flow control valve

setting.

–Connect a volume upstream.

The slide stops in the end posi-

tion without cushioning.

The speed is too high. Reduce the speed.

The cushioning is too low. –Re-adjust the shock absorber

and the (fixed) stop è 9

Commissioning.

–Reduce the speed.

–Check the shock absorbers

and replace if necessary.

The air cushion is not present. Pressurise both supply ports

simultaneously, then exhaust

one side.

The shock absorbers are faulty. Replace the shock absorbers.

The payload is too large Reduce the payload.

Tab. 6: Fault clearance

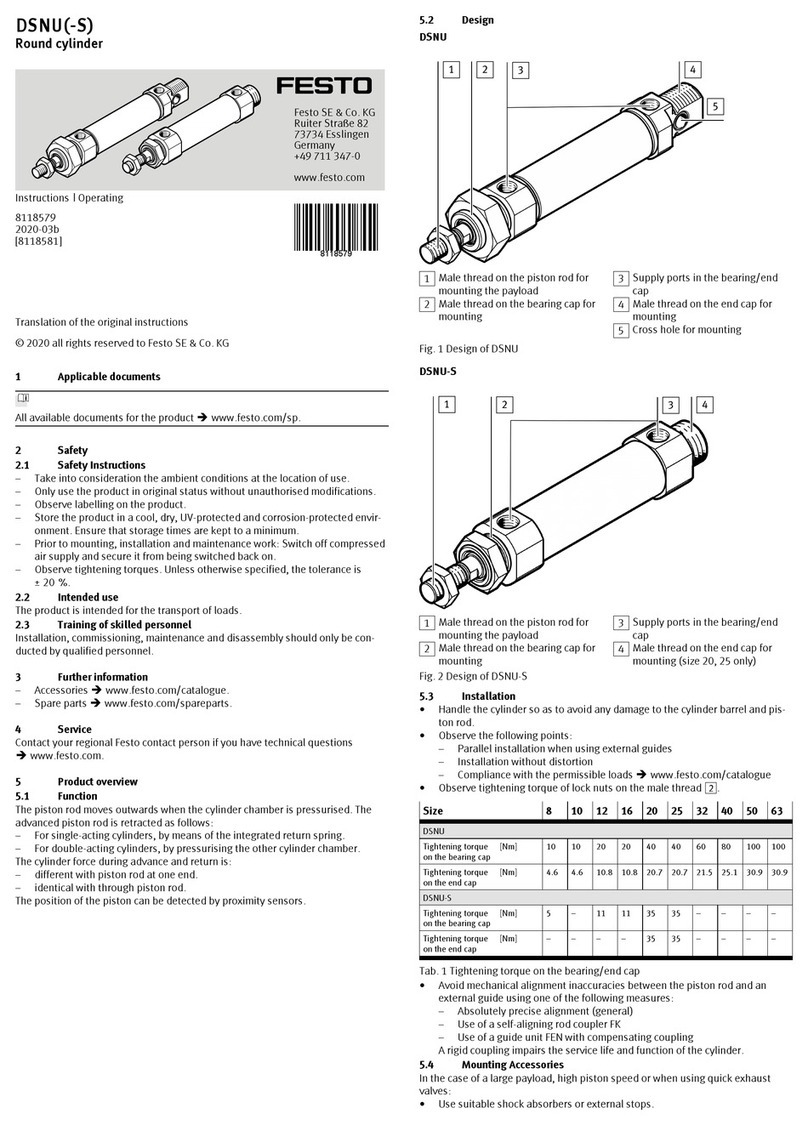

12 Technical data

DGSL-... -4 -6 -8 -10

Design double-acting drive with Scotch yoke system and ball-

bearing cage guide

Mounting position any

Cushioning

DGSL-...-E/-P elastic cushioning, without metallic end position, at both

ends

DGSL-...-P1 elastic cushioning, with metallic end position, metal end

positions at both ends

DGSL-...-Y3 – with progressive shock

absorber and metallic end

position, both ends

DGSL-...-Y11 – with pro-

gressive

shock

absorber

and metallic

end posi-

tion, both

ends

DGSL-...-N – without cushioning

Operating conditions

Operating medium Compressed air to ISO 8573-1:2010 [7:4:4]

Information on the operating

medium

lubricated operation possible, in which case lubricated

operation will always be required

Operating pressure [MPa] 0.25 … 0.8 0.15 … 0.8

[bar] 2.5 … 8 1.5 … 8

[psi] 36 … 116 22 … 116

Ambient temperature [°C] 0 … 60 (observe temperature range of proximity switches)

Repetition accuracy

DGSL-...-E/-P [mm] 0.3

DGSL-...-P1/-Y3/.../-Y11 [mm] ± 0.01

Materials

Note on materials Free of copper and PTFE

Housing, cover, yoke plate Anodised wrought aluminium alloy

Screws Steel

Piston rod, slide, adjusting

screw

High-alloy stainless steel

Cover, stops, driver Beryllium bronze, nickel-plated

DGSL-... -4 -6 -8 -10

Buffer Nitrile rubber

Seals Hydrated nitrile rubber, polyurethane

Tab. 7: Technical data DGSL, size 4 … 10

DGSL-... -12 -16 -20 -25

Design double-acting drive with Scotch yoke system and ball-

bearing cage guide

Mounting position any

Cushioning

DGSL-...-E/-P elastic cushioning, without metallic end position, at both

ends

DGSL-...-P1 elastic cushioning, with metallic end position, metal end

positions at both ends

DGSL-...-Y3 with progressive shock absorber and metallic end position,

both ends

DGSL-...-Y11 with progressive shock absorber and metallic end position,

both ends

DGSL-...-N without cushioning

Operating conditions

Operating medium Compressed air to ISO 8573-1:2010 [7:4:4]

Information on the operating

medium

lubricated operation possible, in which case lubricated

operation will always be required

Operating pressure [MPa] 0.1 … 0.8

[bar] 1 … 8

[psi] 14.5 … 116

Ambient temperature [°C] 0 … 60 (observe temperature range of proximity switches)

Repetition accuracy

DGSL-...-E/-P [mm] 0.3

DGSL-...-P1/-Y3/.../-Y11 [mm] ± 0.01

Materials

Note on materials Free of copper and PTFE

Housing, cover, yoke plate Anodised wrought aluminium alloy

Screws Steel

Piston rod, slide, adjusting

screw

High-alloy stainless steel

Cover, stops, driver Beryllium bronze, nickel-plated

Buffer Nitrile rubber

Seals Hydrated nitrile rubber, polyurethane

Tab. 8: Technical data DGSL, size 12 … 25

DGSL-... -4 -6 -8 -10

Impact energy at the end positions

DGSL-...-E/-P [Nm] 0.015 0.05 0.08 0.12

DGSL-...-P1 [Nm] 0.005 0.02 0.03 0.04

DGSL-...-Y3 [Nm] – – 0.5 1

DGSL-...-Y11 [Nm] – – – 0.5

Theoretical force at 0.6 MPa (6 bar, 87 psi)

Advancing [N] 17 30 47 68

Retracting [N] 13 23 40 51

Max. permissible forces and

torques

è www.festo.com/catalogue.

Max. velocity [m/s] 0.5 0.5 0.8 0.8

Weight min. stroke [kg] 0.08 0.16 0.24 0.4

Weight max. stroke [kg] 0.1 0.23 0.45 0.8

Tab. 9: Technical data DGSL, size 4 … 10

DGSL-... -12 -16 -20 -25

Impact energy at the end positions

DGSL-...-E/-P [Nm] 0.25 0.35 0.45 0.55

DGSL-...-P1 [Nm] 0.06 0.12 0.2 0.25

DGSL-...-Y3 [Nm] 2 4 7 10

DGSL-...-Y11 [Nm] 1 2 4 7

Theoretical force at 0.6 MPa (6 bar, 87 psi)

Advancing [N] 121 188 295 483

Retracting [N] 104 158 247 415

Max. permissible forces and

torques

è www.festo.com/catalogue.

Max. velocity [m/s] 0.8 0.8 0.8 0.8

Weight min. stroke [kg] 0.6 0.9 1.5 2.5

Weight max. stroke [kg] 1.5 2.0 4.3 6.1

Tab. 10: Technical data DGSL, size 12 … 25

DYSW-... -4 … -6 -5 … -8 -7 … -10

Cushioning distance (s) [mm] 6 8 10