Assembly instructions (en)

748 105 / 2009-08NH

†‡

Blanking plug

VABD-…-B

Festo AG & Co. KG

Postfach

D-73726 Esslingen

++49/(0)711/347-0

www.festo.com

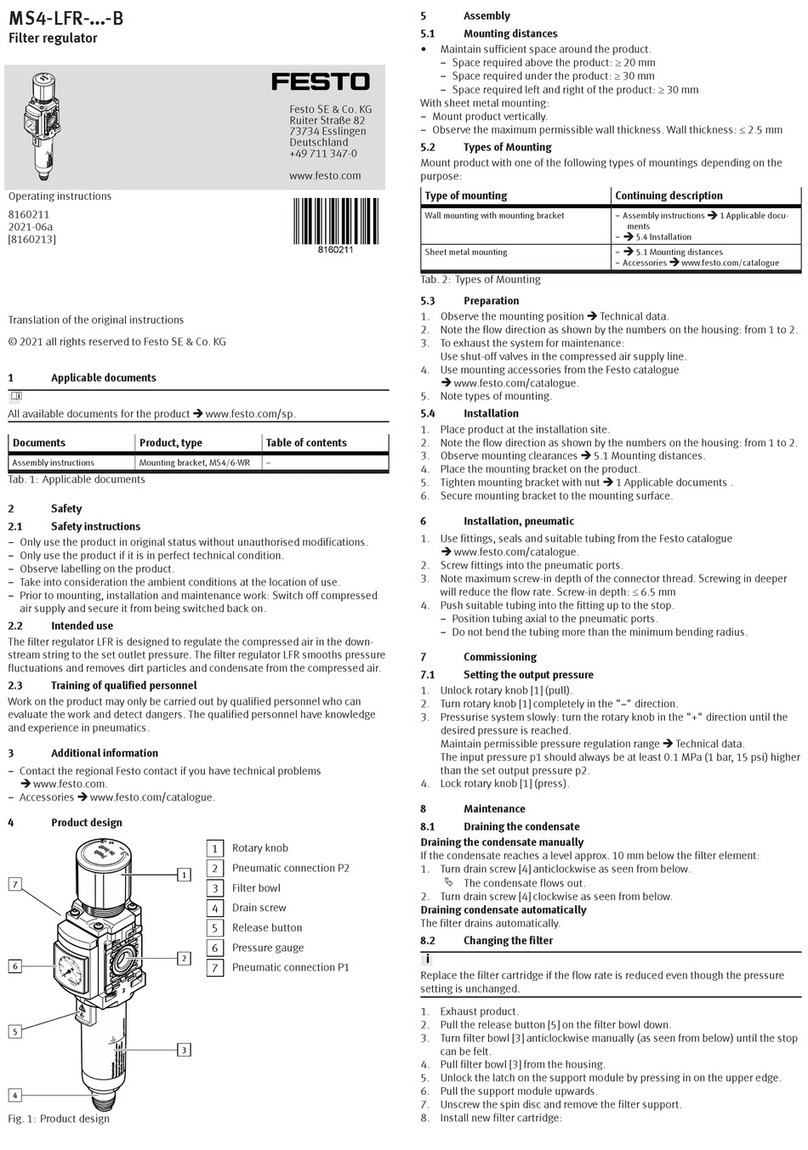

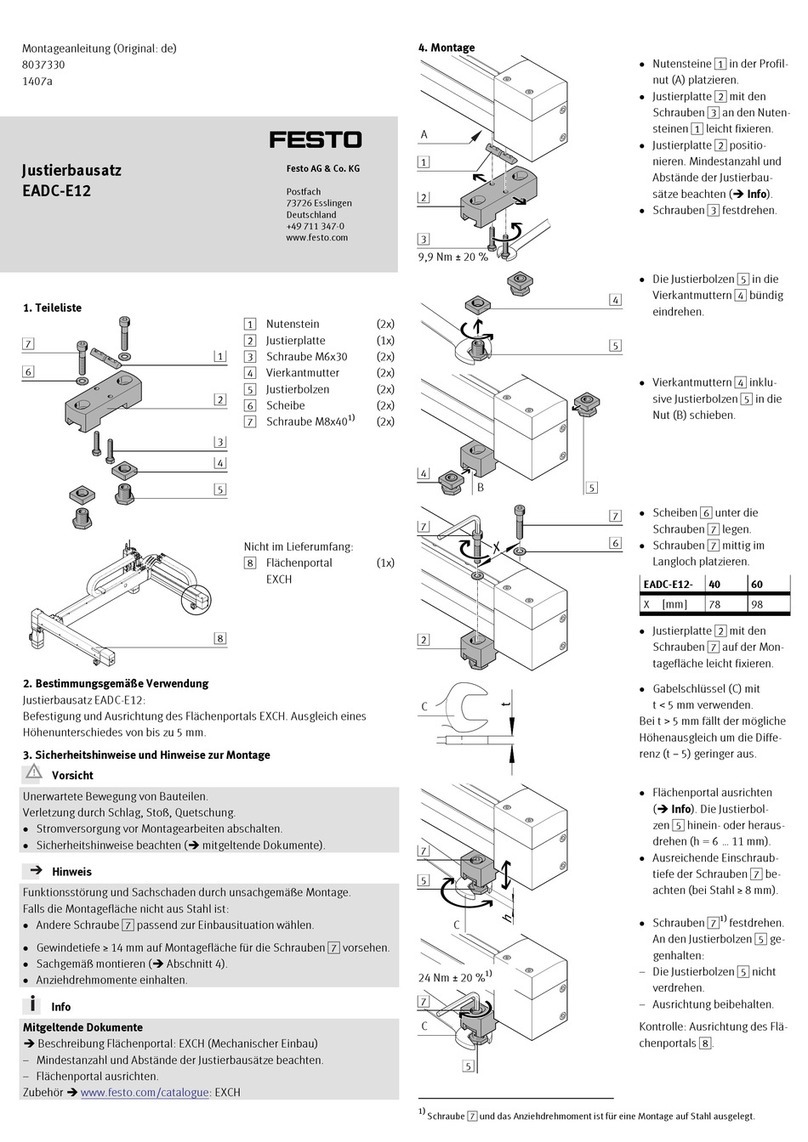

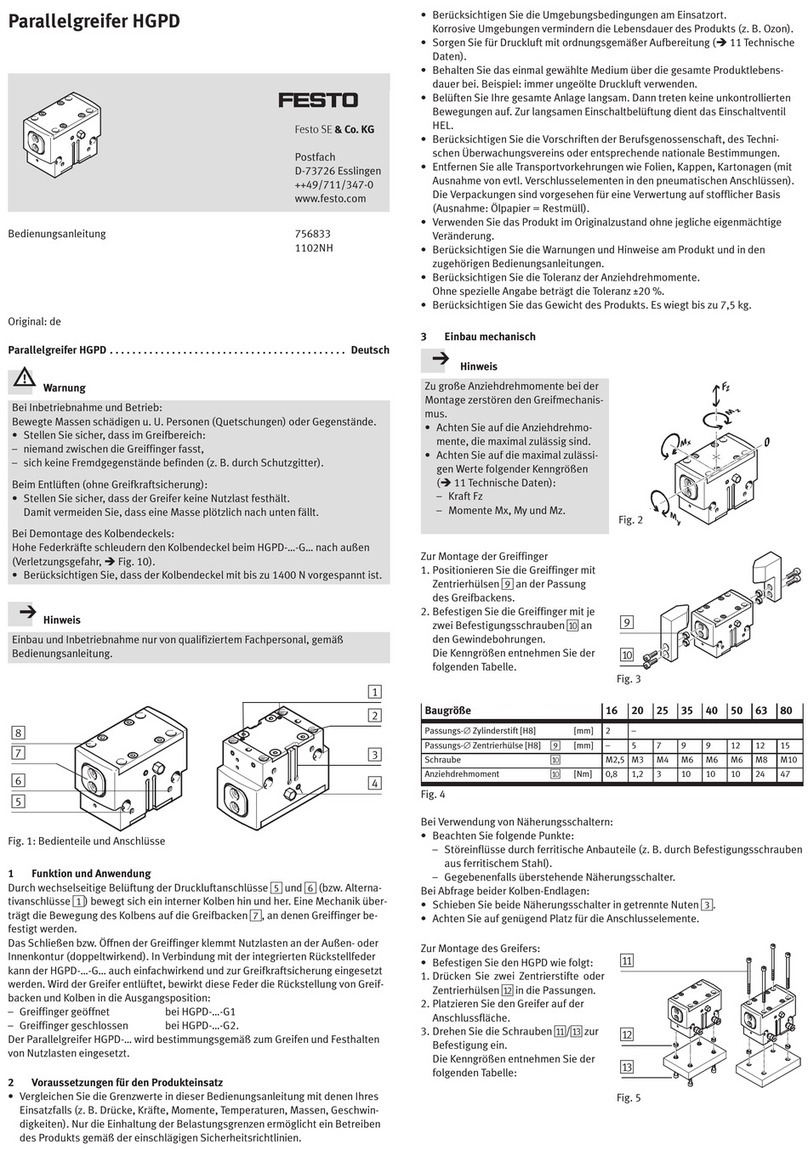

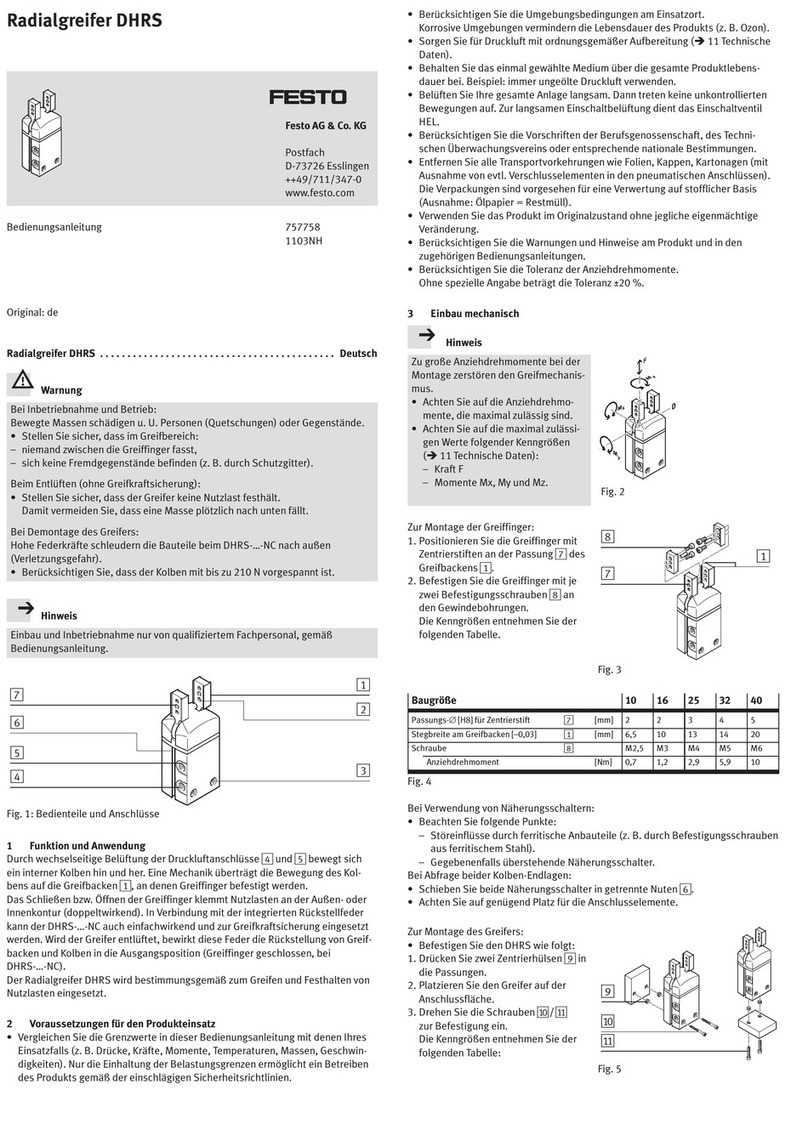

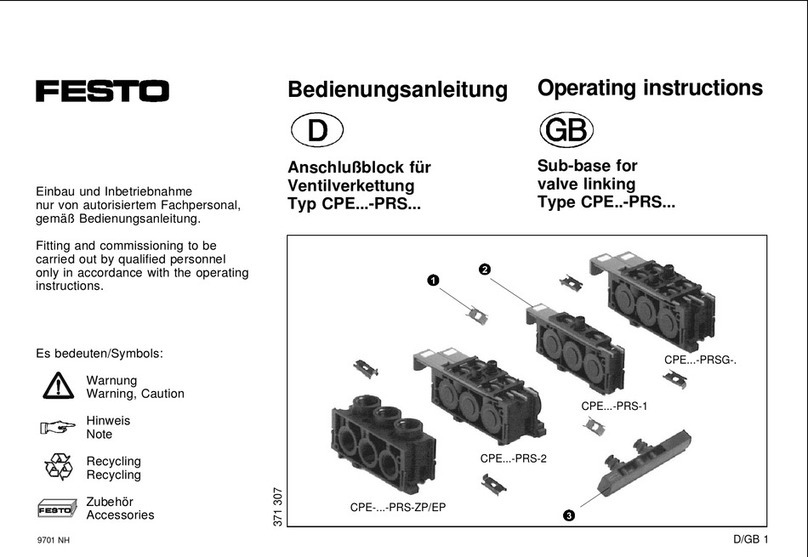

1. Parts list

14139d_1

1Blanking plug

VABD-…-B

The blanking plug VABD-…-B 1has been designed to serve as:

–Separator in channels to form pressure zones.

–Sealing plug for channels.

2. Assembly

2a. Preparing

•Choose the correct blanking plug 1!Table.

VABD-4,2-B VABD-6-B VABD-8-B VABD-10-B

Channel @[mm] 4.2 6 8 10

MA

1) [Nm] 0.3 0.7 1.3 1.3

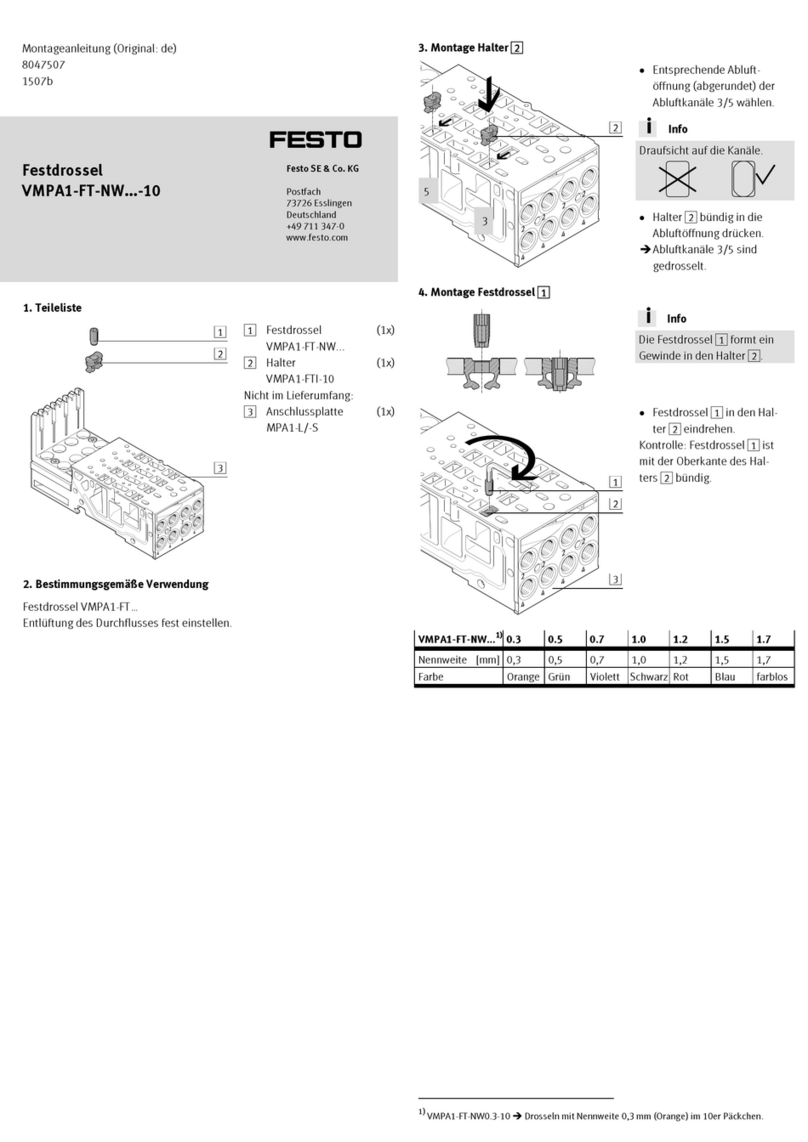

2b. Assembly example with 4 blanking plugs

14139d_2

•Push the correct blanking

plug 1into the compressed

air channels.

14139d_3

•Position the blanking plug 1

in the middle between two

valve ports.

•Stick a small screwdriver (B),

for example, at the desired

spot in one of the ports (di-

agonal in channel 3/5) to

stop the blanking plug 1.

14139d_8

•Turn to tighten the blanking

plug 1with a slotted head

screwdriver (C).

•Maintain the permitted

tightening torque

!Table.

1) Tolerance for non-toleranced tightening torques MA

MA> 0. 25 …1 Nm: ± 30%

MA> 1 Nm: ± 20%

3. After assembly

14139d_4

•Mark the position of the

blanking plugs 1at a suit-

able spot with the accompa-

nying label.

Information

•Select additional accessories from our catalogue

!www.festo.com/catalogue, e.g. supply plates for additional power

supply with several pressure zones.

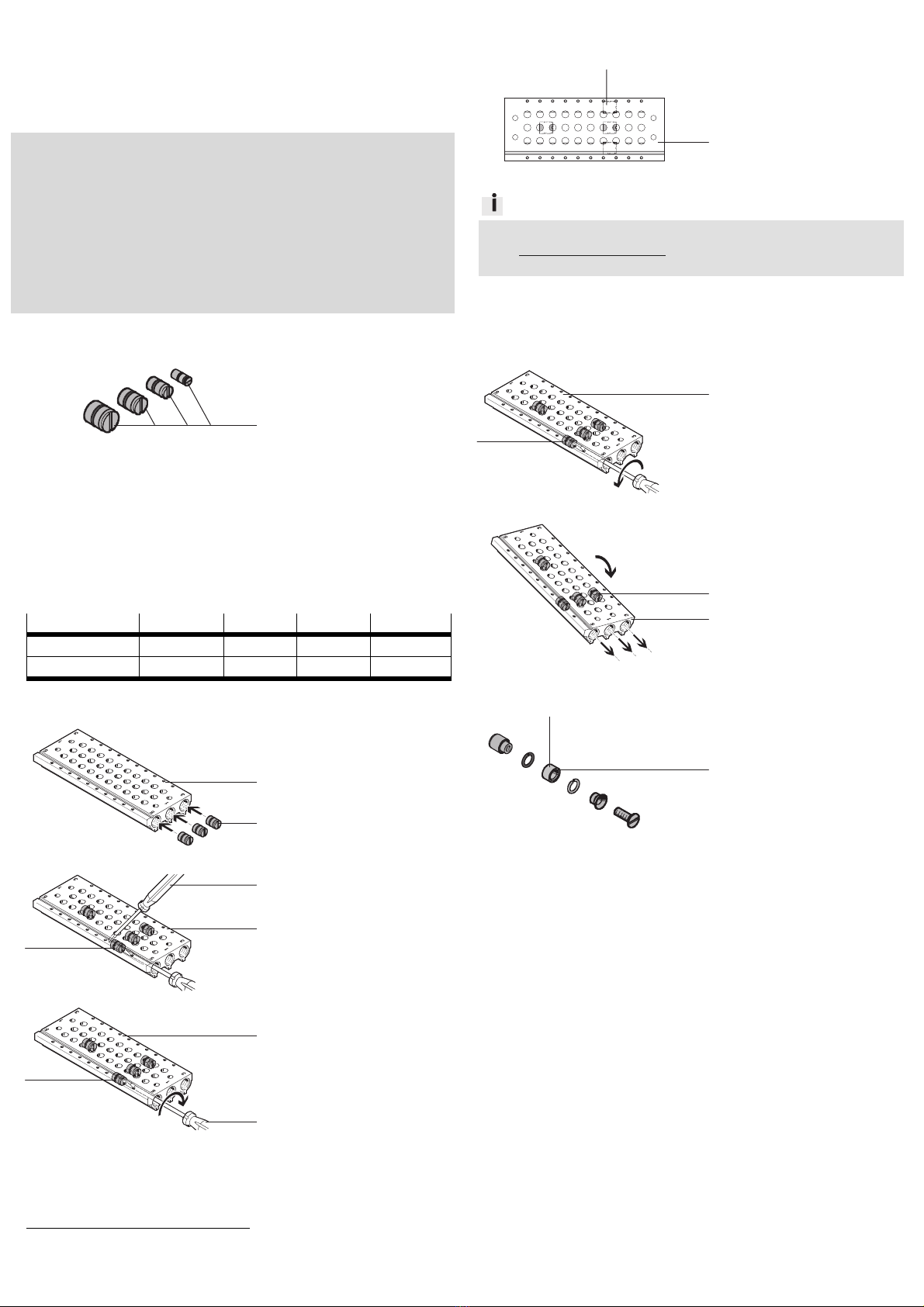

4. Disassembly

•Make sure that you do not turn the blanking plug 1too far out during

disassembly, since otherwise it will fall apart.

14139d_6

•Open the blanking plug 1

only about 1 turn.

14139d_7

•Remove the blanking plug 1

by tilting the manifold

rail (A).

If the blanking plug falls apart, put it together as follows:

14139d_5

•Pay attention to correct posi-

tion of the chamfer (X) of the

sleeve (D).

B

C

X

D