Advanced Menu ............................ 48

Change a Parameter (in the Advanced Menu) ........... 48

Parameters Reset ............................ 48

Check/Monitor Function ....................... 48

5.5.5 Control Card .............................. 49

5.6 Safety Microswitch ............................... 49

5.7 Potentiometer (IMx BT only) ......................... 49

5.8 Hourmeter (IMx BB only) ........................... 50

5.9 Charger ..................................... 50

5.10Batteries ..................................... 50

5.11Adjustments .................................. 51

5.11.1Battery Control Card (IMx BB only) ................. 51

5.11.2Charger (CB) .............................. 51

Charging curve SetUp ......................... 52

Error Codes of Charger ........................ 52

5.11.3ECO Function (solo IMx B/BT) .................... 52

5.12Maintenance and Checks ........................... 53

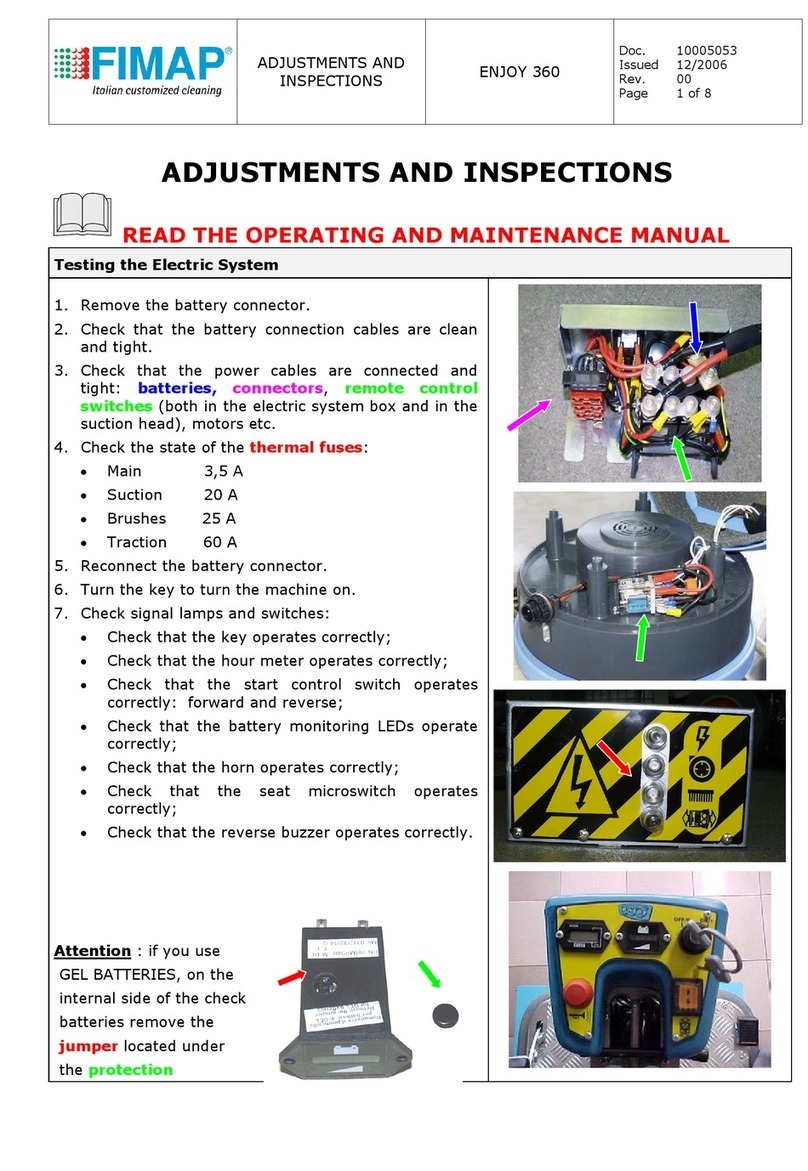

5.12.1Electrical System ............................ 53

Checks .................................. 53

5.12.2Batteries ................................. 53

Checks .................................. 53

5.13Alarm Table (IMx B/BT only) ......................... 54

5.13.1Alarms .................................. 54

Alarms of Overcurrent and Temperature .............. 54

Traction Alarms ............................ 54

General Alarms ............................. 54

5.14Menu Tables (IMx B/BT only) ........................ 55

5.14.1Menu Tree ................................ 55

5.14.2Working Menu ............................. 56

5.14.3Advanced Menu ............................ 56

General Sets .............................. 57

Brushes Sets .............................. 57

Pumps Sets ............................... 58

Vacuum Sets .............................. 58

Traction Sets .............................. 59

Check / Monitor ............................ 60

5.15Technical Features ............................... 61

5.16Recommended Spare Parts .......................... 61

6 Mechanical Rubbing System 62

6.1 Structure .................................... 62

6.2 Description ................................... 62

6.3 Adjustments .................................. 63

6.3.1 Adjustment system .......................... 63

6.4 Maintenance and checks ........................... 63

6.4.1 Motor .................................. 63

Checks: ................................. 63

Maintenance: .............................. 63