3

CONTENTS

ON CONSIGNMENT OF THE MACHINE.............................................................................................................................................5

SERIAL NUMBER PLATE.................................................................................................................................................................5

INTRODUCTORY COMMENT............................................................................................................................................................5

INTENDED USE ...............................................................................................................................................................................5

TECHNICAL DESCRIPTION..............................................................................................................................................................6

SYMBOLS USED ON THE MACHINE ................................................................................................................................................7

GENERAL SAFETY REGULATIONS ...............................................................................................................................................10

PREPARATION OF MACHINE ........................................................................................................................................................11

1. HANDLING THE PACKED MACHINE.............................................................................................................................................11

2. HOW TO MOVE THE MACHINE ...................................................................................................................................................11

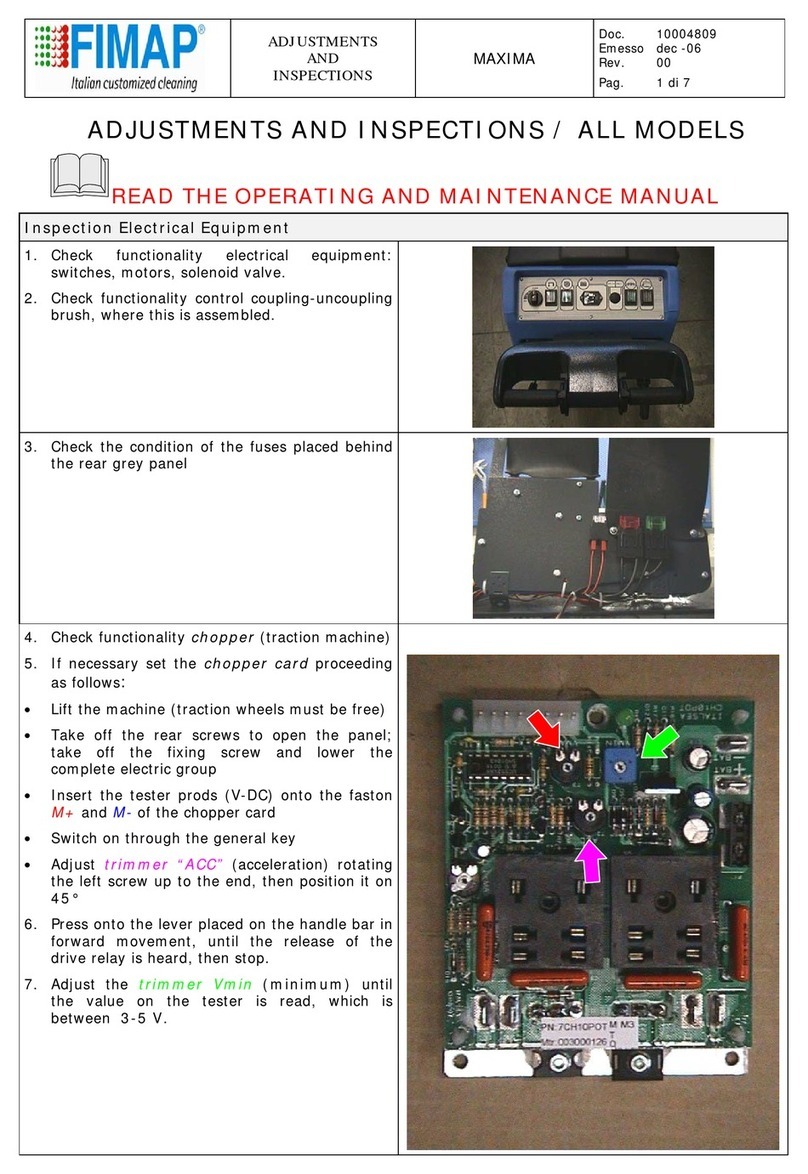

3. INSTRUMENT PANEL COMPONENTS ..........................................................................................................................................11

4. STEERING COLUMN COMPONENTS ...........................................................................................................................................12

5. FOOTBOARD COMPONENTS .....................................................................................................................................................13

6. SEAT SUPPORT COMPONENTS .................................................................................................................................................13

7. REAR COMPONENTS OF THE MACHINE......................................................................................................................................13

8. FRONT MACHINE COMPONENTS................................................................................................................................................14

9. BATTERY TYPE........................................................................................................................................................................14

10. BATTERY MAINTENANCE AND DISPOSAL..................................................................................................................................14

11. HANDLING - INSERTING BATTERIES.........................................................................................................................................15

12. CONNECTING THE BATTERIES AND BATTERY CONNECTOR .......................................................................................................16

13. CONNECTING THE BATTERY CHARGER....................................................................................................................................16

14. BATTERY CHARGE LEVEL INDICATOR (BATTERY VERSION)........................................................................................................17

15. SERVICE BRAKE – PARKING BRAKE.........................................................................................................................................17

16. WORKING FORWARD SPEED...................................................................................................................................................18

17. SIDE BRUSHES......................................................................................................................................................................18

18. INCREASING THE PRESSURE ON THE BRUSH HEAD UNIT ..........................................................................................................19

19. SOLUTION TANK....................................................................................................................................................................19

20. FILLING THE DETERGENT SOLUTION TANK...............................................................................................................................19

21. REGULATING THE DETERGENT...............................................................................................................................................20

22. RECOVERY TANK...................................................................................................................................................................21

23. ASSEMBLING THE SQUEEGEE.................................................................................................................................................21

24. ADJUSTINGTHE SQUEEGEE INCLINATION.................................................................................................................................21

25. ADJUSTINGTHE SQUEEGEE HEIGHT........................................................................................................................................21

26. CYLINDRICAL BRUSH ASSEMBLY.............................................................................................................................................22

27. SIDE BRUSH ASSEMBLY .........................................................................................................................................................23

28. PRIMING THE DETERGENT PUMP............................................................................................................................................24

WORK...........................................................................................................................................................................................25

29. WORK...................................................................................................................................................................................25

30. BRAKING SYSTEM OIL LEVEL ..................................................................................................................................................26

31. CHOPPER CIRCUIT BOARD FAULT ...........................................................................................................................................26

32. SOLUTION TANK EMPTY .........................................................................................................................................................26

33. BRUSH HEAD MOTOR UNDER PRESSURE.................................................................................................................................26

34. SIDE BRUSH HANDLING..........................................................................................................................................................26

AT THE END OF THE WORK..........................................................................................................................................................27

35. AT THE END OF THE WORK.....................................................................................................................................................27

DAILY MAINTENANCE...................................................................................................................................................................29

36. CLEANING THE VACUUM MOTOR FILTER..................................................................................................................................29

37. CLEANING THE RECOVERY TANK............................................................................................................................................29

38. CLEANING THE SQUEEGEE.....................................................................................................................................................30

39. CLEANING THE SOLUTION TANK FILTER...................................................................................................................................30

40. CLEANING DEBRIS HOPPER AND HOPPER VACUUM FILTER .......................................................................................................31

WEEKLY MAINTENANCE...............................................................................................................................................................32

41. CLEANING THE VACUUM HOSE ...............................................................................................................................................32

42. CLEANING THE SOLUTION TANK..............................................................................................................................................32

43. DETERGENT TANK CLEANING .................................................................................................................................................33