Installation Overview

432-0012-01-12 Version 110 10

You will need to supply the following items depending on the planned installation:

• For Top Down Riser—Six (6) M8 stainless steel bolts and washers to secure the top down riser

after the camera is attached—bolt length depends on mounting platform thickness.

Recommended:

M8 socket head cap screws, or

5/16” - 18 socket head cap screws, or

5/16” - 18 hex head sheet metal screws type 316 stainless steel

Apply thread locker (Loctite 262 or equivalent)

• One or more multi-function displays (MFD) or other analog or digital video display devices

• Coaxial RG6 video cable to customer-supplied analog video monitors

• Coaxial RG6 video cable to customer-supplied HD-SDI digital video monitors

• Ethernet cables to connect the M500 and the JCU II to the PoE Ethernet switch,

8-conductor T568B

• Ethernet cables to connect to the ship’s Ethernet port,

8-conductor T568B

• Miscellaneous electrical hardware, connectors, and tools

General Location Considerations

Warning: The M500 system is not designed to operate in an enclosed environment in the

presence of flammable gases. Failure to follow this warning may result in explosion or fire.

First determine a good location for mounting the M500 system body and the JCU II. The system

has four cable connections:

• Power

• Ethernet connection to PoE switch for the JCU II; the switch requires an Ethernet connection to

the JCU II and optionally to other JCU II controllers or to a shipboard network.

• HD-SDI digital video

• Composite analog video and serial data (NMEA and factory test)

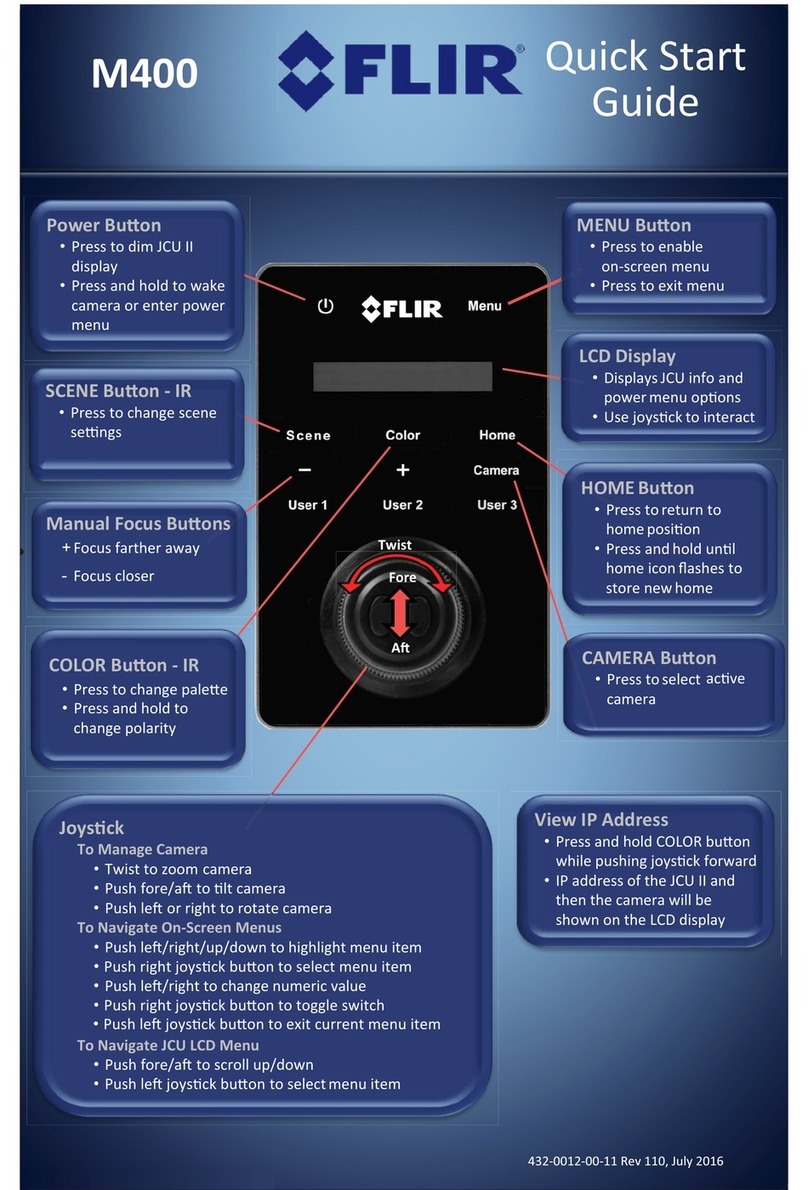

More than one JCU II can be installed to control the camera and more than one display can be

used to view the video. Also, a single JCU II can be used to control more than one camera. Most

often, the JCU II and video monitor are mounted close together, as a pair, so the video can be

viewed when the camera position (pan, tilt, zoom) is changed with the JCU II.

When determining the component locations, consider how the system may be expanded in the

future. For example, adding an additional monitor, or perhaps a JCU II and monitor pair.

Consider the following points when determining the camera location:

• Mount the M500 camera body as high as practical, but without interfering with any radar,

navigational, or communications electronics.

• To minimize interference with video signals, the camera body must be mounted

a minimum of 1 meter away from any radio frequency antenna.

• Minimize the degree to which vessel structures block the camera’s 360° view. The camera’s

continuous-pan design lets it rotate and point in all directions.