Floe VSD6500 User manual

Other Floe Boating Equipment manuals

Floe

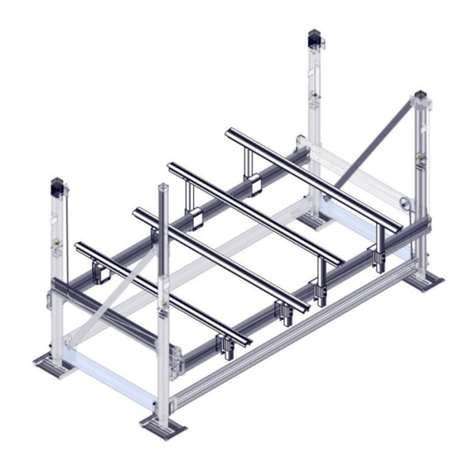

Floe V2602 LENGTH BUNKS User manual

Floe

Floe V1600 PWC User manual

Floe

Floe V-2000 User manual

Floe

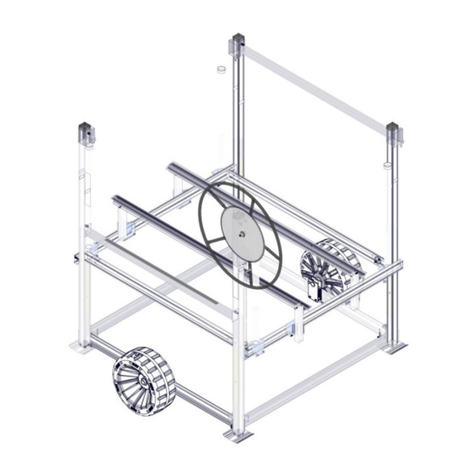

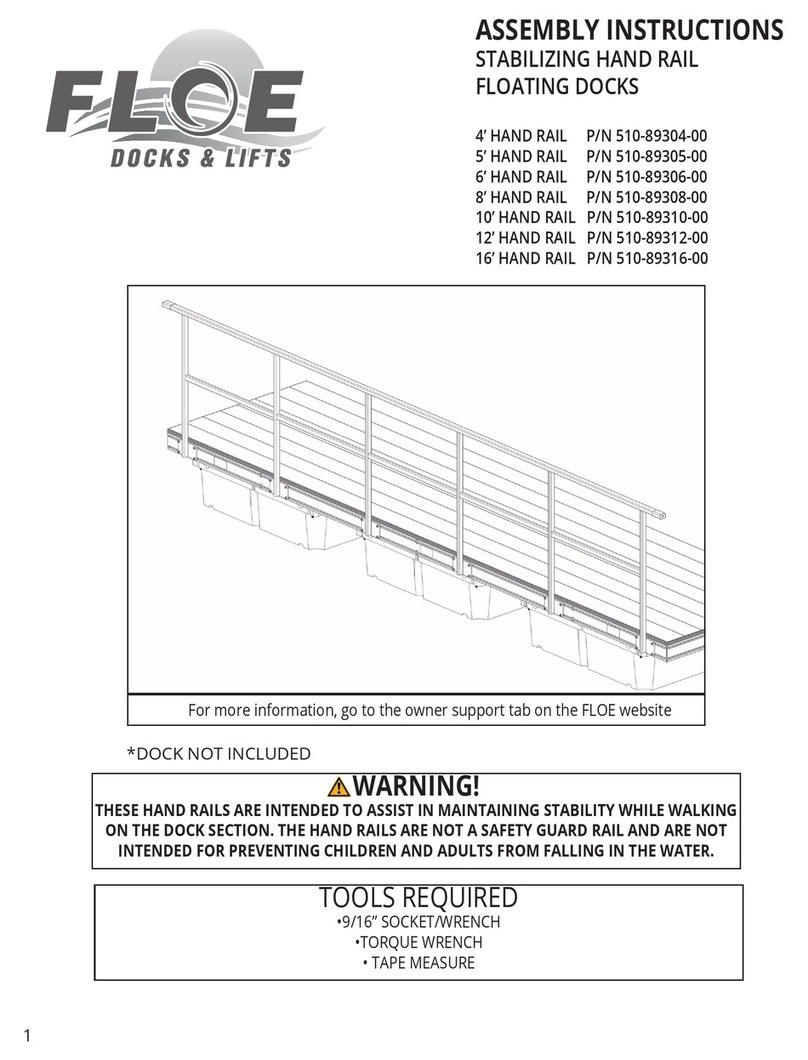

Floe 510-89304-00 User manual

Floe

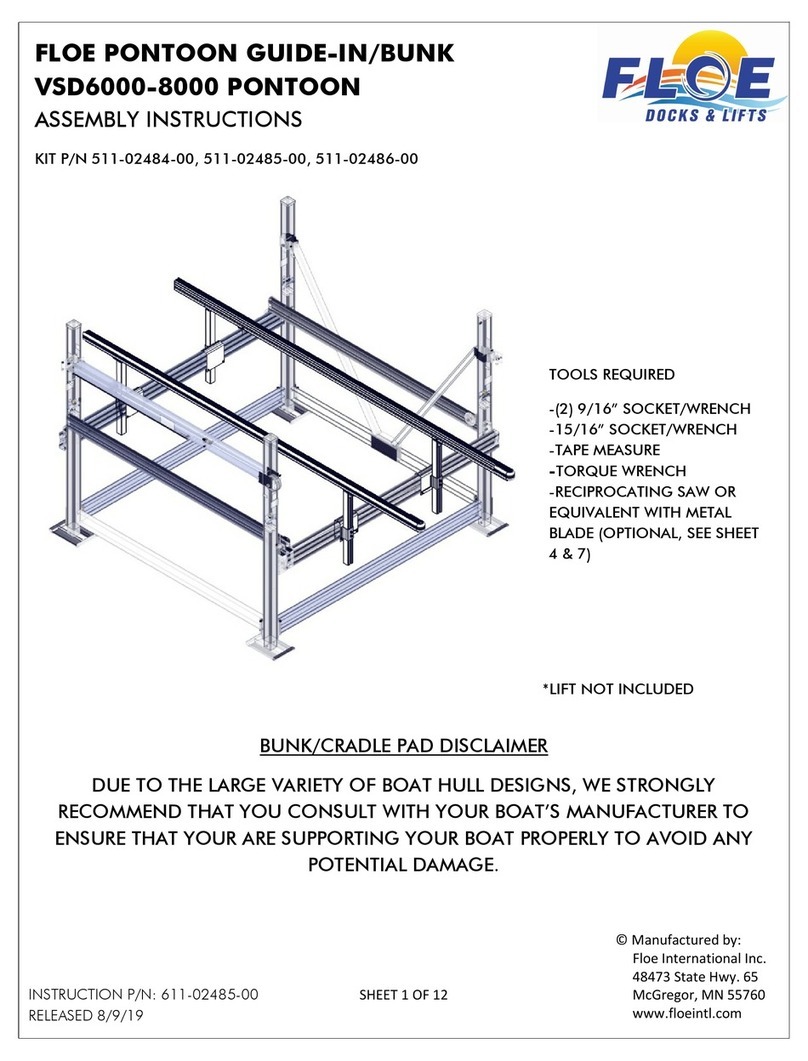

Floe VSD 6000 User manual

Floe

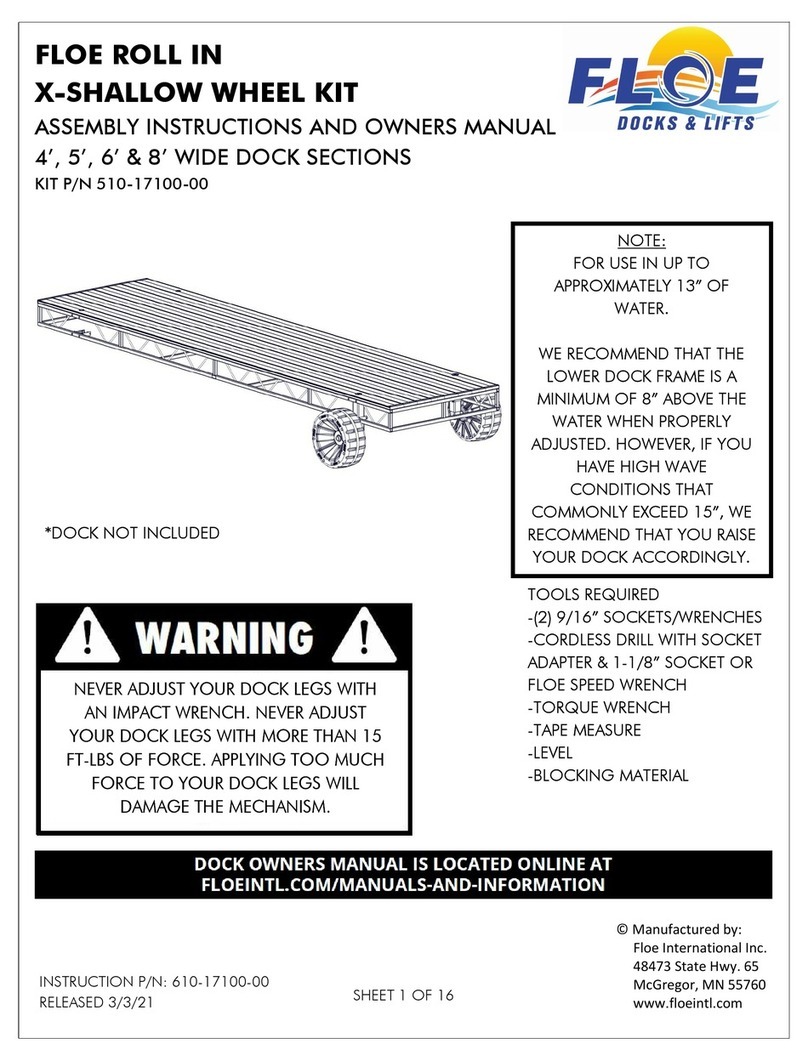

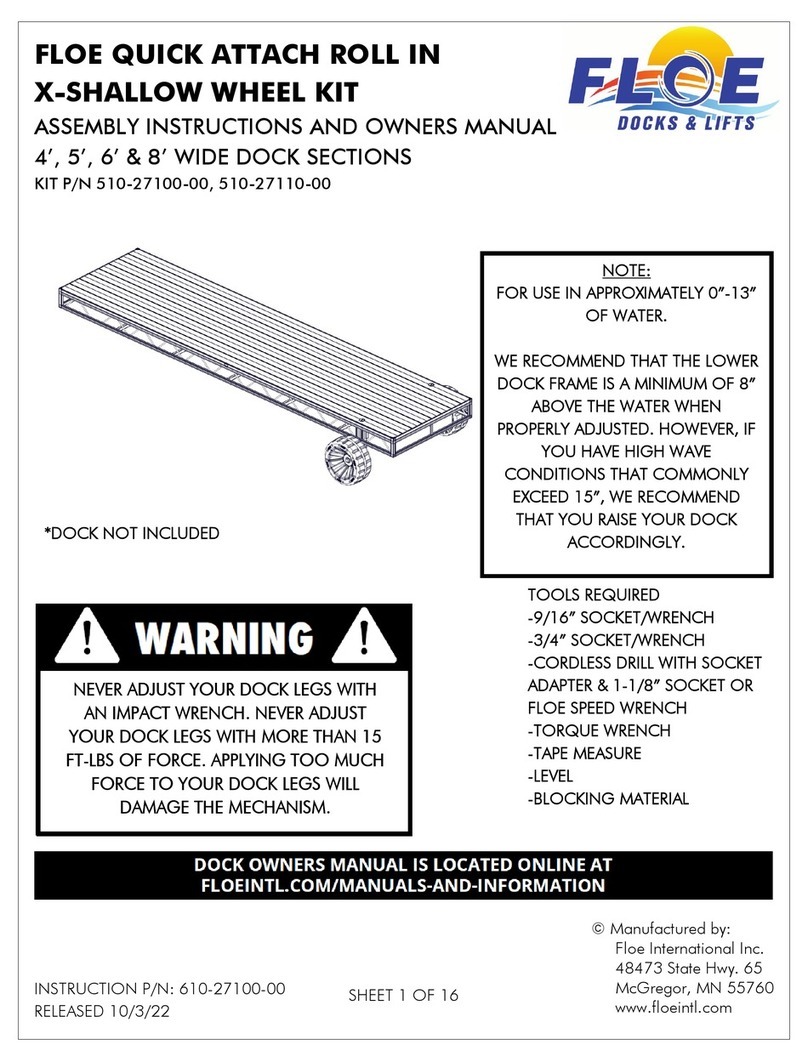

Floe 510-27100-00 Quick start guide

Floe

Floe MAXIS User manual

Floe

Floe VSD Guide

Floe

Floe VSD 5000 User manual

Floe

Floe 510-20000-00 User manual

Floe

Floe 510-17700-00 User manual

Floe

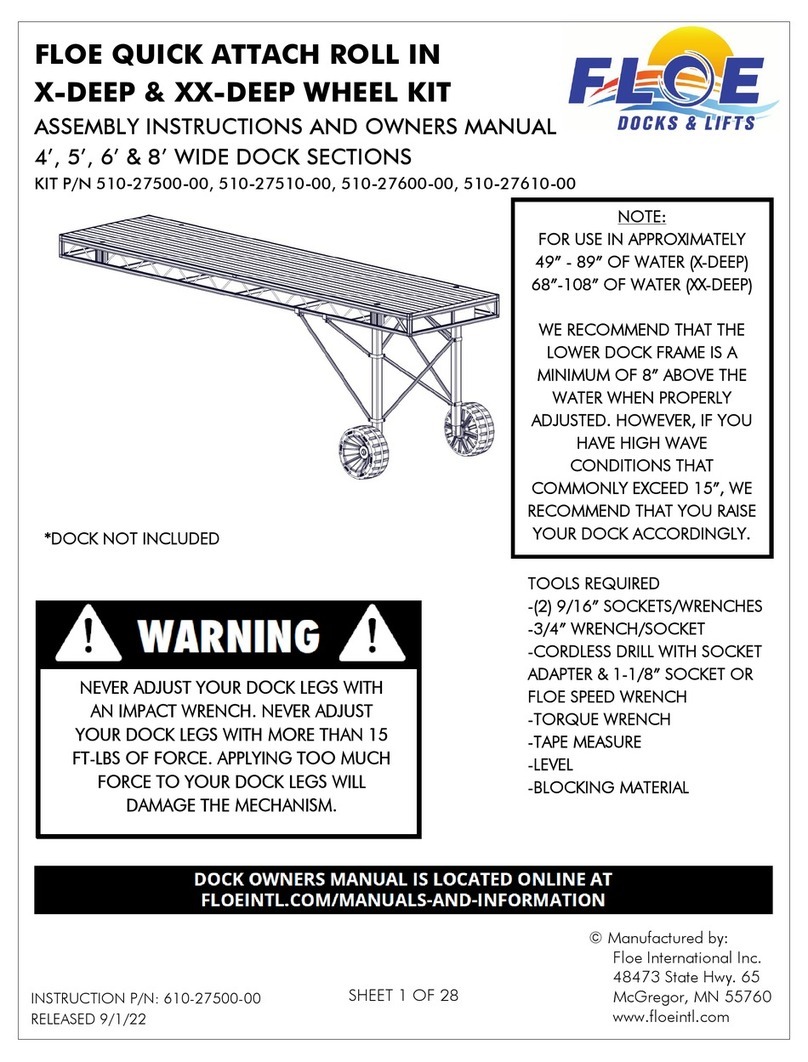

Floe 510-27500-00 Quick start guide

Floe

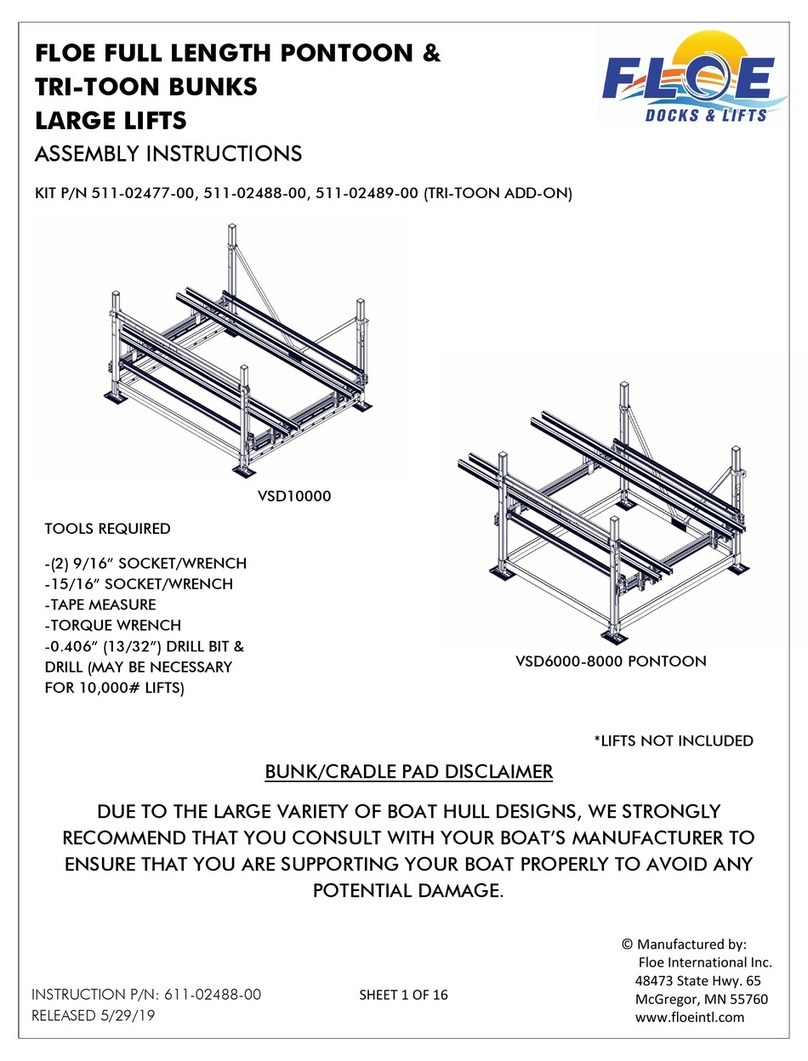

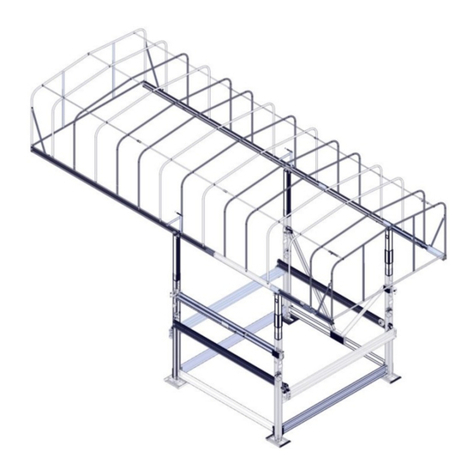

Floe FULL LENGTH BUNKS User manual

Floe

Floe 510-27200-00 Quick start guide

Floe

Floe PONTOON CRADLE PADS User manual

Floe

Floe 510-27300-00 Quick start guide

Floe

Floe VSD 8000 User manual

Floe

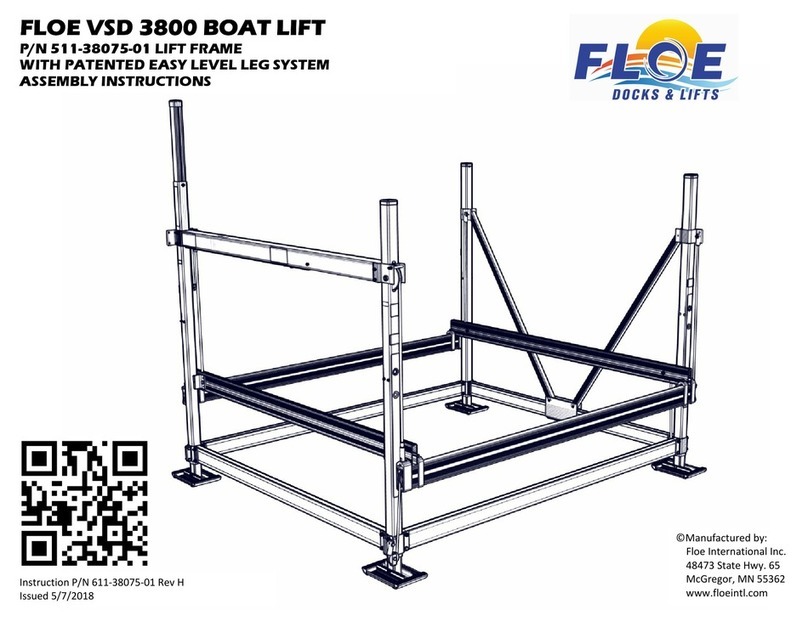

Floe VSD 3800 User manual

Floe

Floe V-2000 User manual

Floe

Floe 510-27400-00 Quick start guide

Popular Boating Equipment manuals by other brands

Humphree

Humphree HCS-5 installation manual

Vetus

Vetus BOW4512D Operation manual and installation instructions

Dock Doctors

Dock Doctors SLIDING BOARDING STEP Assembly instructions

Mastervolt

Mastervolt Mass Combi 12/2000-100 Quick installation

Zattini Group

Zattini Group bamar BOXTRON E14S Use and maintenance instruction manual

SeaView

SeaView PM5-FMD-8 installation instructions