Friant NOVO User manual

Other Friant Indoor Furnishing manuals

Friant

Friant FSQAHTB User manual

Friant

Friant MADISON User manual

Friant

Friant Verity User manual

Friant

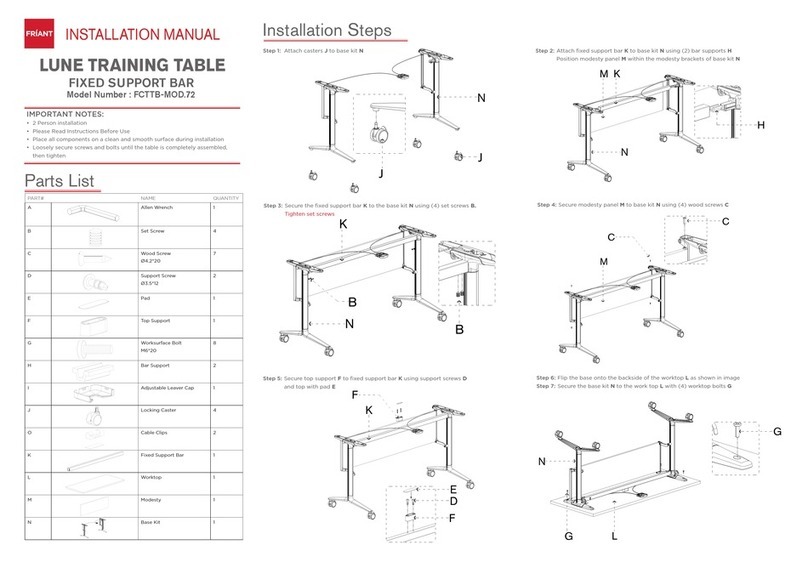

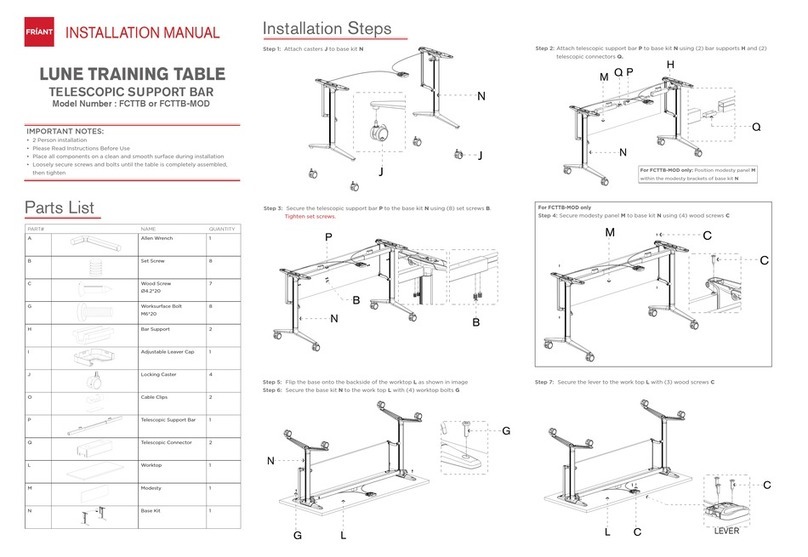

Friant LUNE FCTTB User manual

Friant

Friant FBFPED.MOB User manual

Friant

Friant MY-HITE FSQAHBT-24-2 User manual

Friant

Friant Tiles User manual

Friant

Friant MY-HITE Beam User manual

Friant

Friant CELESSE User manual

Friant

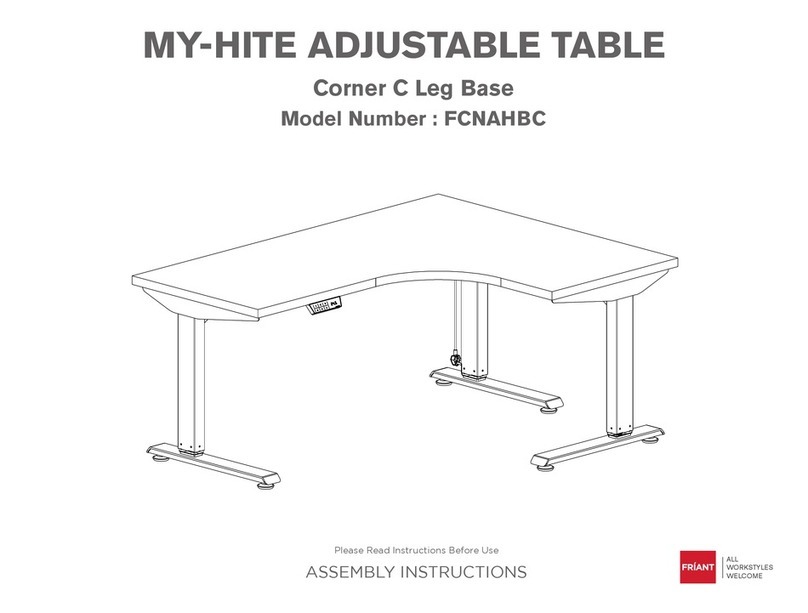

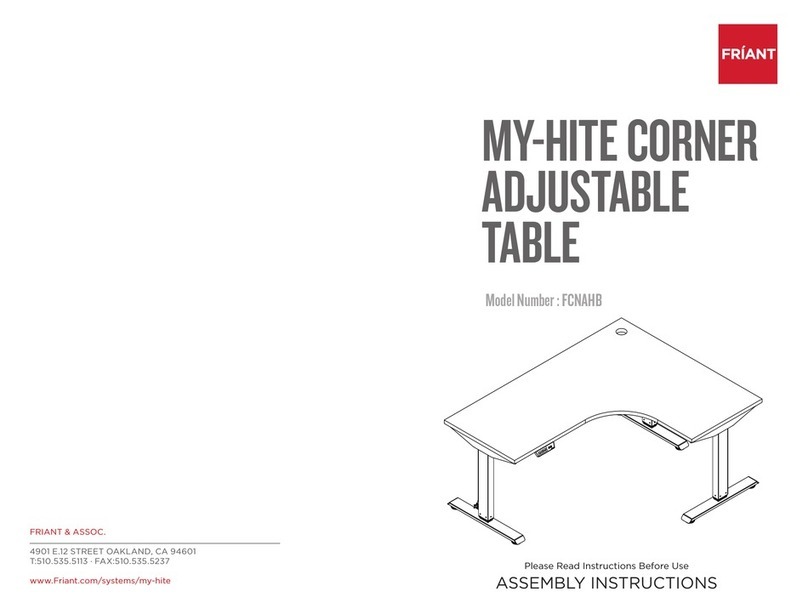

Friant FCNAHB User manual

Friant

Friant MIDZONE User manual

Friant

Friant AMENITY User manual

Friant

Friant ZONE CLASSIC FRI-BJ-MM2333M User manual

Friant

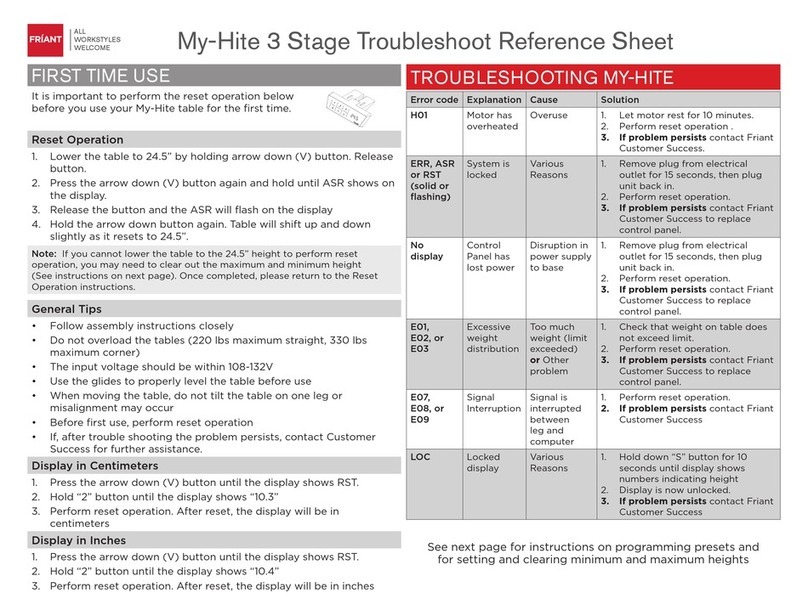

Friant MY-HITE FCNAHBT User manual

Friant

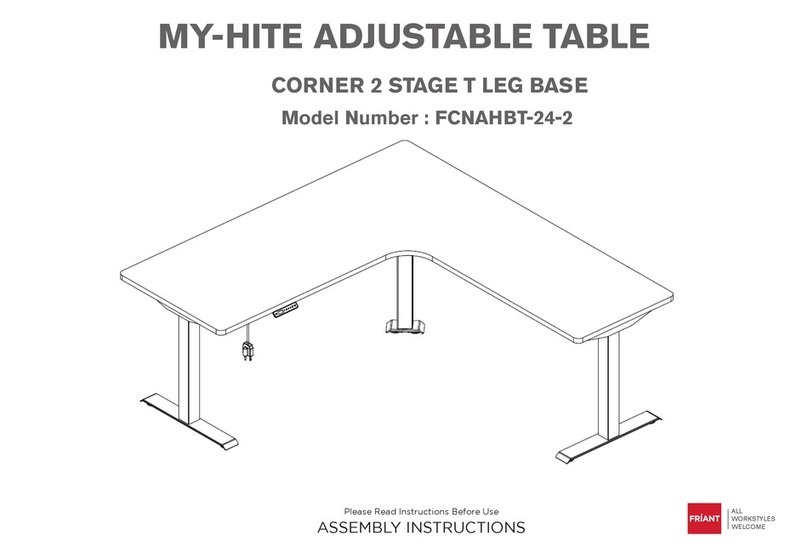

Friant FCNAHBT-24-2 User manual

Friant

Friant MY-HITE User manual

Friant

Friant FSQAHT User manual

Friant

Friant IGNITE User manual

Friant

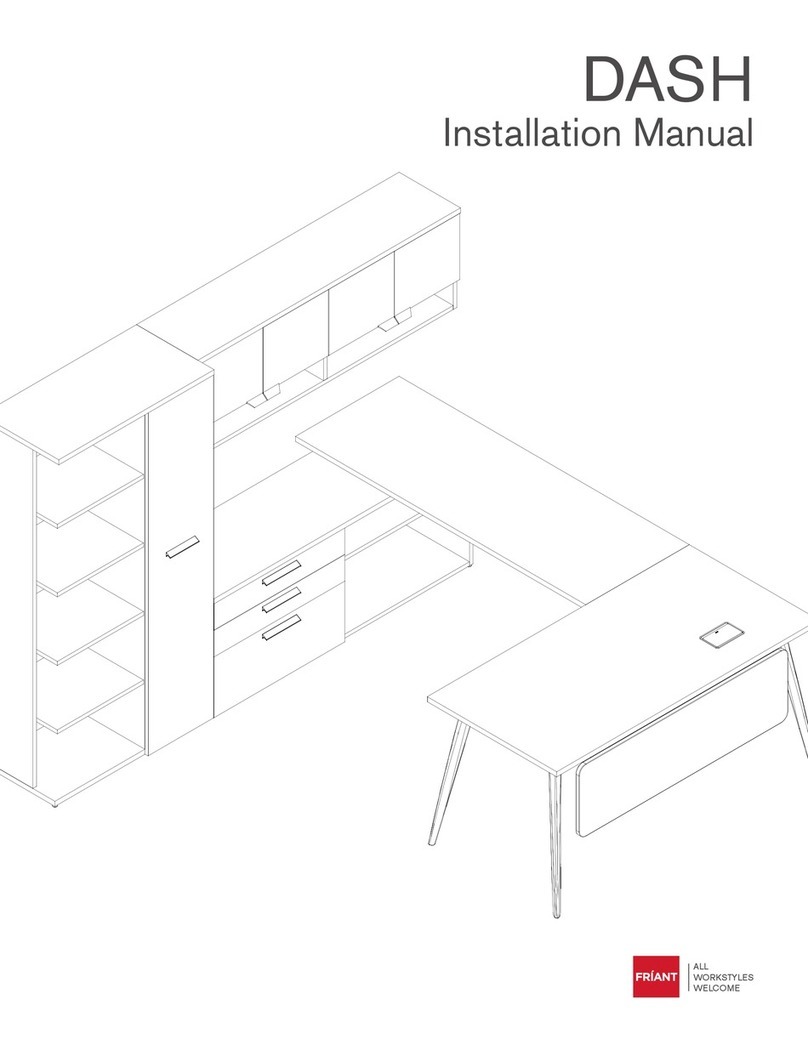

Friant DASH User manual

Friant

Friant Vektor User manual

Popular Indoor Furnishing manuals by other brands

Coaster

Coaster 4799N Assembly instructions

Stor-It-All

Stor-It-All WS39MP Assembly/installation instructions

Lexicon

Lexicon 194840161868 Assembly instruction

Next

Next AMELIA NEW 462947 Assembly instructions

impekk

impekk Manual II Assembly And Instructions

Elements

Elements Ember Nightstand CEB700NSE Assembly instructions