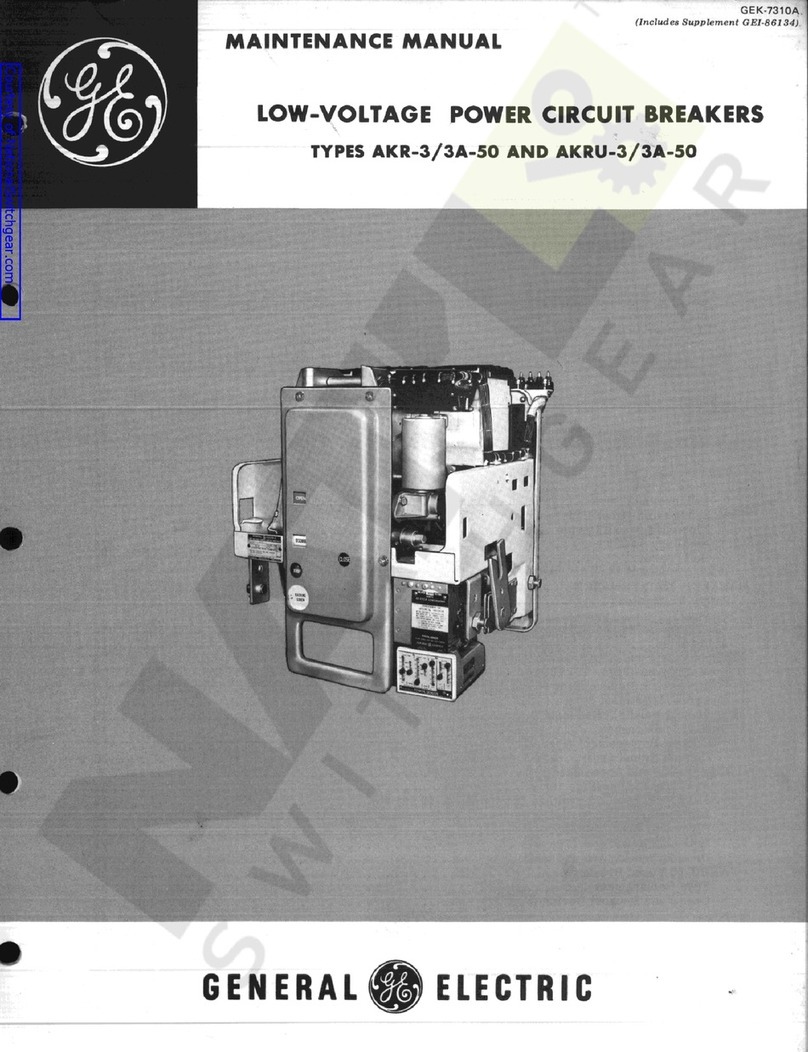

Low-Voltage Power Circuit Breakers

Table of Contents

Description Page

SECTION 1-lntroduction

......................

4

1.1

1.2

Inspection and Maintenance

....................

4

Renewal Parts

...........

,

....................

4

SECTION

2-General

Description

............

6

2.1

Frame Size

...................................

6

2.2

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3

Mounting

.....................................

7

2.4

Trip Device

...................................

7

2.5

Short Circuit Ratings

...........................

7

SECTION

3-Storage,

Safety and

Maintenance

....................

9

3.1

Storage

......................................

9

3.2

Safety

.......................................

9

3.3

Maintenance

..................................

9

SECTION

4-Breaker

Operation

.............

10

4.1

Manual Closing

..............................

10

4.2

Electrical Closing

.............................

10

4.2.1

Alternate Control Circuit

.......................

11

4.3

Connections

.................................

12

4.3.1

Stationary Breaker

............................

12

4.3.2

Drawout Breaker

.............................

12

4.4

Tripping

.....................................

13

4.5

Charging and Closing Using

the Maintenance Handle

.......................

13

SECTION

5-Contact

Maintenance

.........

14

5.1

Slow Closing the Breaker

......................

14

5.1.1

Electrical Breaker

.............................

14

5.1.2

Manual Breaker

..............................

14

5.2

Arc Quencher Removal and Inspection

...........

15

5.2.1

Removal and Replacement

.....................

15

5.3

Separation

of

Front and Back Frames

............

16

5.4

Back Frame Assembly

.........................

18

5.5

Measuring Contact Force

......................

19

5.5.1

Stationary Arcing Contacts

....................

19

5.5.2

Stationary Main and Intermediate Contacts

.......

19

5.6

Measuring Contact Wipe

.......................

19

5.7

Adjusting Contact Wipe

.......................

19

5.8

Measuring Contact

Open

Gap

..................

21

5.9

Checking Contact Sequence

...................

22

5.10 Replacement

of

Contacts

......................

22

5.10.1

Stationary Arcing Contacts

....................

22

5.10.2

Movable Arcing Contacts

......................

22

5.10.3

Movable Main and Intermediate Contacts

........

23

5.10.4

Stationary Intermediate and Main Contacts

.......

24

5.11

Assembly and Adjustment

of

Crossbar

...........

25

© 1993 GENERAL ELECTRIC COMPANY

2

Description Page

SECTION

6-Breaker

Maintenance

.........

26

6.1

Safety Precautions

...........................

26

6.2

Lubrication

..................................

26

6.3 Breaker Mechanism Adjustments

...............

26

6.3.1

Trip Latch

...................................

26

6.3.2

Latch Buffer

.................................

26

6.3.3 Reset Latch Bearing and

Prop

..................

26

6.4 Electrical Mechanism

.........................

28

6.4.1

Control Components

..........................

28

6.4.2 Charging Motor

..............................

29

6.4.3 Motor Operator Unit

...........................

30

6.4.4 Spring Discharge Interlock

.....................

32

6.5 Manual Mechanism

...........................

32

6.5.1

Mechanism Part Replacement

..................

33

6.5.2

Ratchet Pawl Replacement

.....................

35

6.5.3 Adjustments

.................................

35

6.6 Drawout Mechanism

..........................

36

6.7

Drawout Mechanism Lock

......................

36

SECTION

7-Accessories

....................

37

7

.1

Primary Disconnects

..........................

37

7.1.1

AKA 75/100

..................................

37

7

.1.2

AKS/AKST

50

................................

38

7.2

Secondary Disconnects

.......................

39

7.2.1

Replacement

................................

39

7.3

Auxiliary Switch

..............................

40

7.3.1

Replacement

................................

40

7.3.2

Adjustments

................................

40

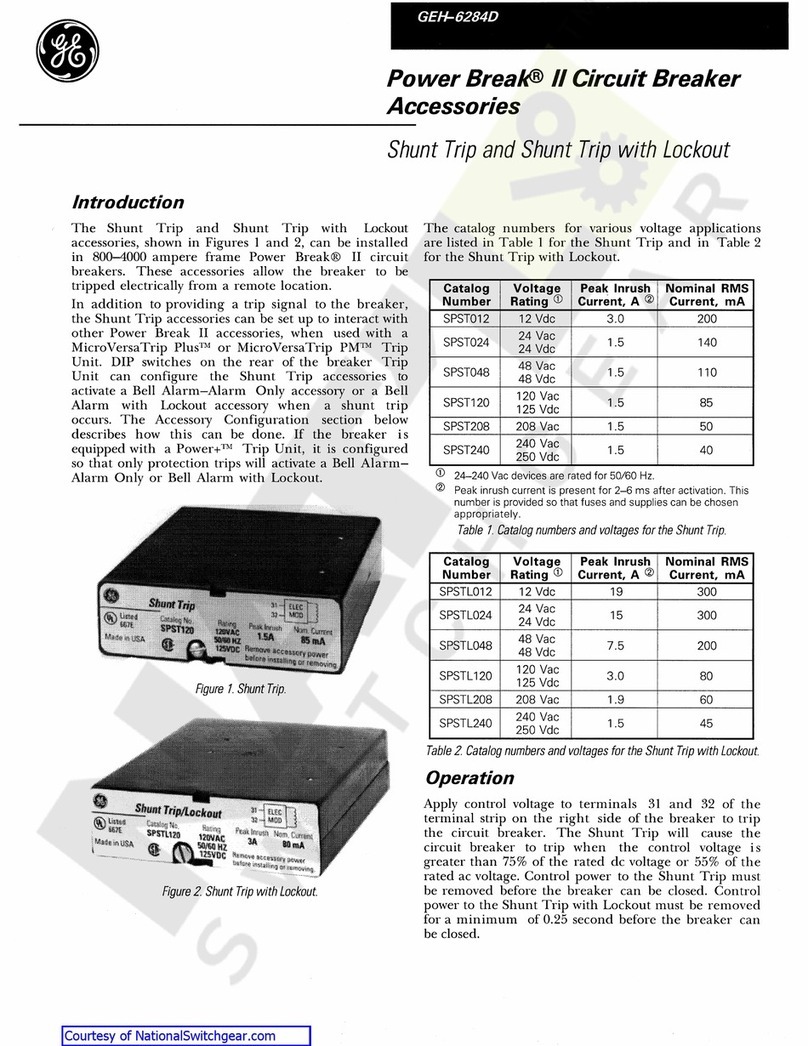

7.4

Shunt Trip

...................................

41

7.4.1

Replacement

................................

41

7.4.2

Adjustment

..................................

41

7.5

Undervoltage Device

..........................

42

7.5.1

Replacement

................................

42

7.5.2

Adjustment

..................................

42

7.6

Static Time-Delay Undervoltage

.................

43

7.7 Electric Lockout Device

........................

44

7.7.1

Adjustment

..................................

44

7.8

Bell Alarm Device

.............................

45

7

.8.1

Adjustment

..................................

45

7.9

Open Fuse Lockout Device

.....................

46

7.9.1

Coll Replacement

.............................

46

7.9.2

Adjustments

.................................

46

SECTION

8-

Type SST Overcurrent

T'

D .

np

ev1ce

......................

47

8.1

Programmer Unit

.............................

47

8.2

Current Sensors

..............................

48

8.2.1

Replacement of Current Sensors

-AKS

50

.....................................

50

8.2.2

Replacement

of

Current Sensors

-AKA 75/100

.................................

51

8.3

Flux Shift Trip Device

..........................

51

8.4

Troubleshooting

..............................

54

8.4.1

SST

Test Set

.................................

54

Courtesy of NationalSwitchgear.com