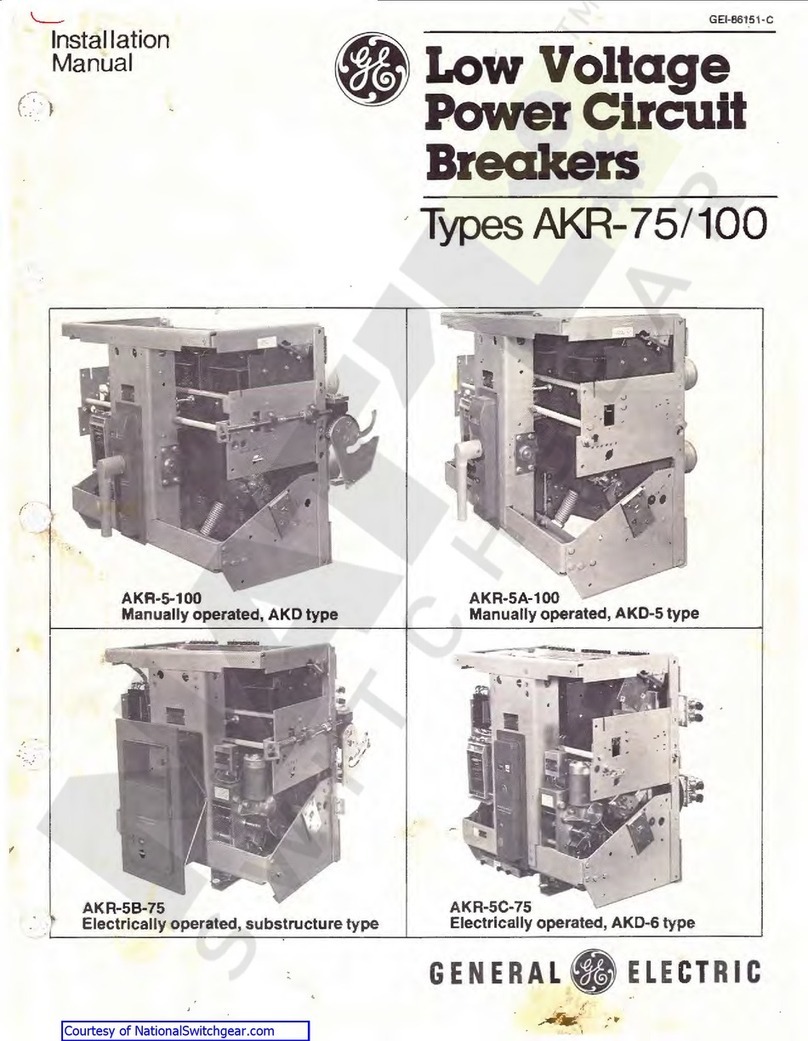

PowerVac®5kV Vertical Lift

Table of Contents

5

List of Figures

1. View of the 5kV ‘VL’ Breaker with Front Cover ............................................................................... 7

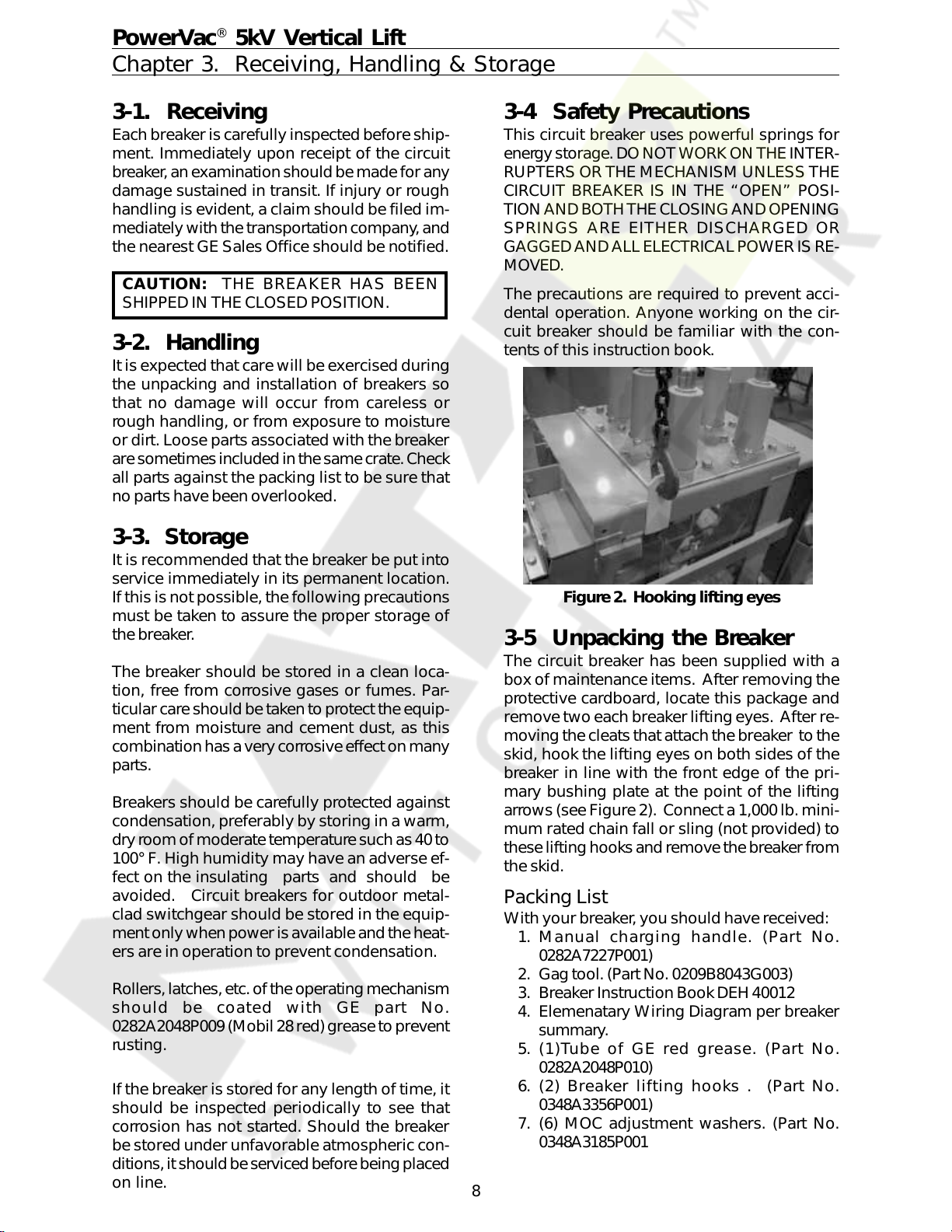

2. Hookinglifting eyes ........................................................................................................................... 8

3. ManualTrip & Close .......................................................................................................................... 9

4. PositiveInterlock ............................................................................................................................... 9

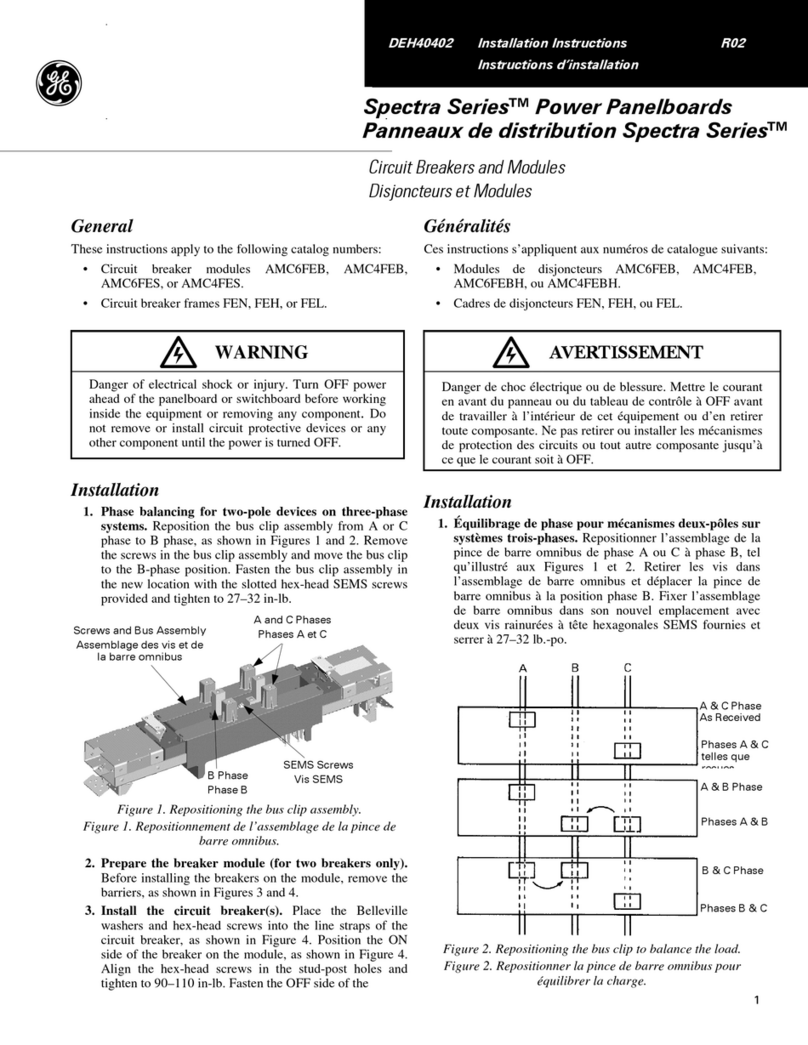

5. Rating Interference Bolt .................................................................................................................. 10

6. Positive Interlock system ................................................................................................................ 12

7. Manual charge handle ..................................................................................................................... 13

8. Primary Contact Insertion ............................................................................................................... 14

9. Primary contact penetration and wipe ........................................................................................... 15

10. MOCswitch ...................................................................................................................................... 16

11. Secondarydisconnect coupler........................................................................................................ 17

12. Front View of ML-19 Mechanism with Front Cover Removed ..................................................... 18

13. Charging & Trip system left side view ............................................................................................ 19

14. Manual Charging system right side view .......................................................................................19

15. Electrical Charging system right side view .................................................................................... 20

16. Closing linkageleft side view.......................................................................................................... 20

17. Opening spring & auxiliary switch left side view ........................................................................... 21

18. Wipe Spring assembly left side view ............................................................................................. 21

19. Typical ML-19mechanisminternalwiring connections ................................................................ 22

20. Typical breaker wiring diagram (Replacement for breakers with MS mechanisms................... 23

21. Typical breaker wiring diagram (Replacement for breakers with ML mechanisms ................... 24

22. Closing spring withgagtool inserted ............................................................................................. 25

23. Contact ErosionIndicator ................................................................................................................ 26

24. Primary contact erosion measurement-rear view ........................................................................ 26

25. Wipe indicator check and wipe measurement-rear view ............................................................. 27

26. Sample Operating Speed Graphs .................................................................................................. 33

27. Opening SpeedAdjustment............................................................................................................ 33

28. Travel Transducer Installation (Part#0144D1235G00X)............................................................... 34

29. Wipe Insulator.................................................................................................................................. 35

30. Contact GapAdjustment—OpeningBuffer.................................................................................... 36

31. Contact Gap measurement, wipe indicator check and wipe measurement ................................ 36

32. Trip coil gapadjustment .................................................................................................................. 37

33. Tripcoil buttonwithgage ................................................................................................................ 37

34. Tripcoilassembly ............................................................................................................................ 37

35. Close coilassembly-frontview ....................................................................................................... 38

36. Close coil gapadjustment-front view ............................................................................................. 38

37. SM/LS & CHG switch adjustment-left side view............................................................................ 39

38. CL/MS andpositiveInterlock switchadjustment-right sideview ................................................. 39

39. Positive Interlock ............................................................................................................................. 40

40. Adjustment of MOCSwitch/PlungerInterlock................................................................................ 41

41. Toggle Linkage Positions ................................................................................................................. 42

41A ToggleLinkagePositions (ViewfromRight Side) .......................................................................... 42

42. Toggle Linkage Positions(Viewfrom Right Side) .......................................................................... 42

42A ToggleLinkagePositions (ViewfromRight Side) .......................................................................... 42

43. Pole Assembly ................................................................................................................................. 44

44. TripCoiland Linkage(ClosingSpring Removed) .......................................................................... 46

45. Front View of ML-19 Breaker Mechanism (Lower)....................................................................... 48

46. Front View of ML-19 Breaker Mechanism (Upper) ....................................................................... 49

47. Motor Cutoff Switch ........................................................................................................................ 50

48. ClosingSpringGag .......................................................................................................................... 50

49. Front View of ML-19 Mechanism with Front Cover Removed ..................................................... 51

50. Schematic of ML-19 Mechanism .................................................................................................... 52

51. Typical stationary structure wiring ................................................................................................. 56

52. Electrical schematic diagram for vertical lift elevating mechanism ............................................ 57

53. Positive interlock M-26 units ........................................................................................................... 59

Appendix A .............................................................................................................................................. 63

List of Tables

1. Measurements .................................................................................................... 43

2. Adjustments........................................................................................................ 43

3. ML-19 Control Devices and Voltages................................................................ 47

4. Elevating Motor Troubleshooting...................................................................... 57

Trouble Reporting Form.......................................................................................... 66-67

Courtesy of NationalSwitchgear.com