28-9067-71 AA 07/2007

For contact information for your local office, please visit

www.gelifesciences.com/contact

GE Healthcare Bio-Sciences AB

Björkgatan 30

751 84 Uppsala

Sweden

www.gelifesciences.com/protein-purification-bioprocess

GE, imagination at work, and GE monogram are trademarks of General Electric Company.

Drop Design, ÄKTA and ÄKTAprocess are trademarks of GE Healthcare companies.

All third party trademarks are the property of their respective owners.

© 2007 General Electric Company—All rights reserved

First published Jul. 2007

All goods and services are sold subject to the terms and conditions of sale of thecompany within GE

Healthcare which supplies them. A copy of these terms and conditions is available on request. Contact

your local GE Healthcare representative for themost current information.

GE Healthcare Limited

Amersham Place, Little Chalfont, Buckinghamshire, HP7 9NA, UK

GE Healthcare Bio-Sciences Corp.

800 Centennial Avenue, P.O. Box 1327, Piscataway, NJ 08855-1327, USA

GE Healthcare Europe GmbH, Munzinger Strasse 5

D-79111 Freiburg, Germany

GE Healthcare Bio-Sciences KK

Sanken Bldg., 3-25-1, Hyakunincho, Shinjuku-ku, Tokyo, 169-0073 Japan

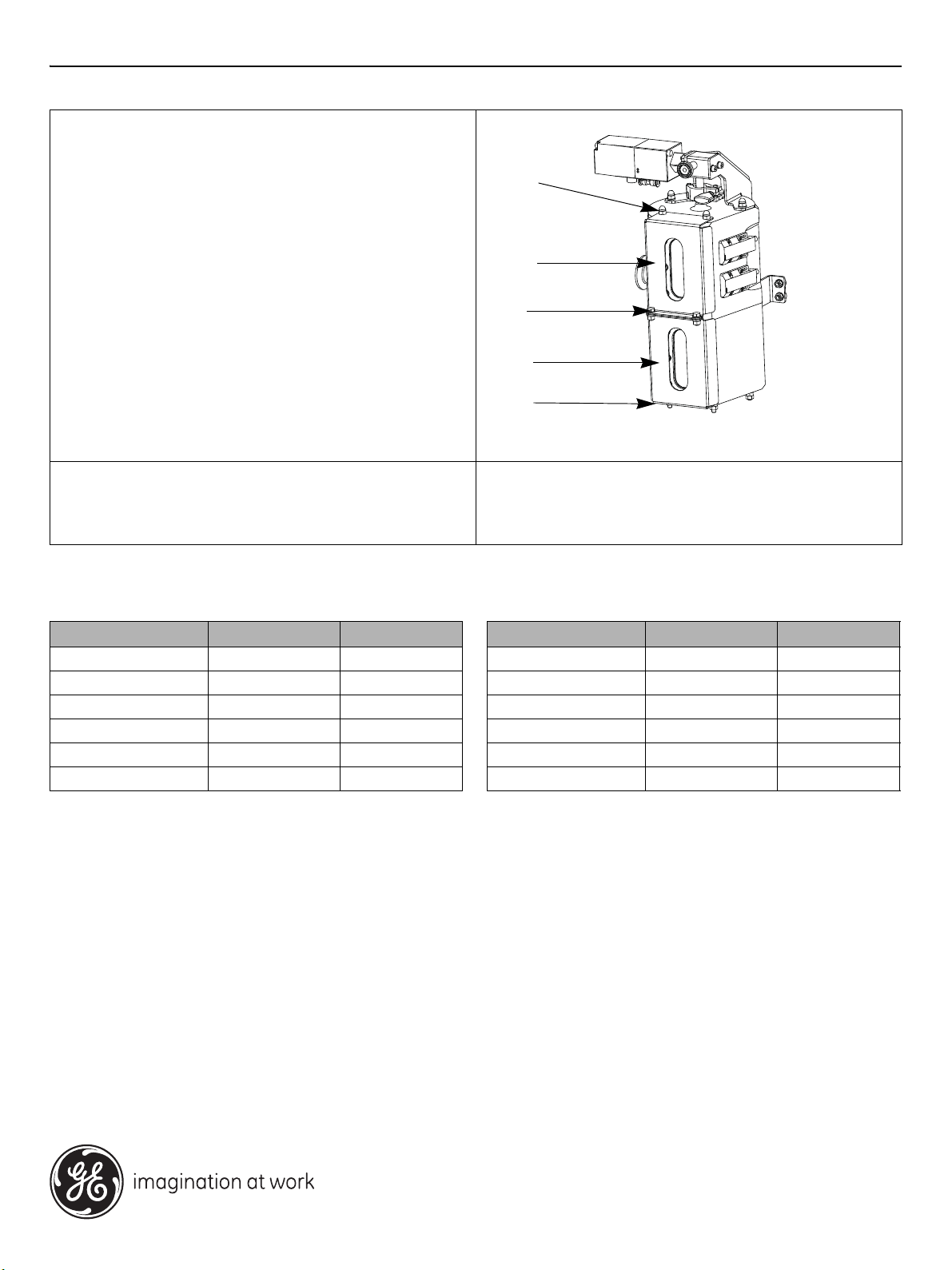

28-9266-70 AA Sightglass cover assembly instruction

Air trap parts number list

Air traps with the part numbers listed below must be fitted with the sightglass cover assembly:

3 Mount the sightglass covers

• Place the top cover (D) on the air trap, with the opening

aligned with the sight glass.

• Re-insertthefronttwoconnectingrods(C)through thetop

holes in the cover.

• Slide the bottom cover (E) over the lower ends of the two

front connecting rods (C) and align the corresponding

holes on both cover parts.

• Replace the bottom nuts (B) and washers on the front

connecting rods underneath the air trap.

• Tighten the nuts using atorque of 3 Nm (±0.3Nm). Verify

also that the other three nuts are tightened, using the

same torque value.

• Fasten the two cover parts together using bolts, washers

and nuts (F) as described in the mount procedure for 6

mm/0.5 inch systems.

4 Final connections

• ReconnecttheTCcouplingand evacuationhoseto the top

valve (A).

Dimension Material Part number

6 mm PEEK/EPDM 03-0111-41

6 mm PEEK/FEP 03-0111-42

1/2 inch PEEK/EPDM 03-0111-39

1/2 inch PEEK/FEP 03-0111-40

6 mm PP/EPDM 03-0111-45

6 mm PP/FEP 03-0111-46

Dimension Material Part number

1/2 inch PP/EPDM 03-0111-43

1/2 inch PP/FEP 03-0111-44

1 inch PEEK/EPDM 28-4051-68

1 inch PEEK/FEP 28-4051-70

1 inch PP/EPDM 28-4051-69

1 inch PP/FEP 28-4051-71