VII

8164-9001-400 / 1198

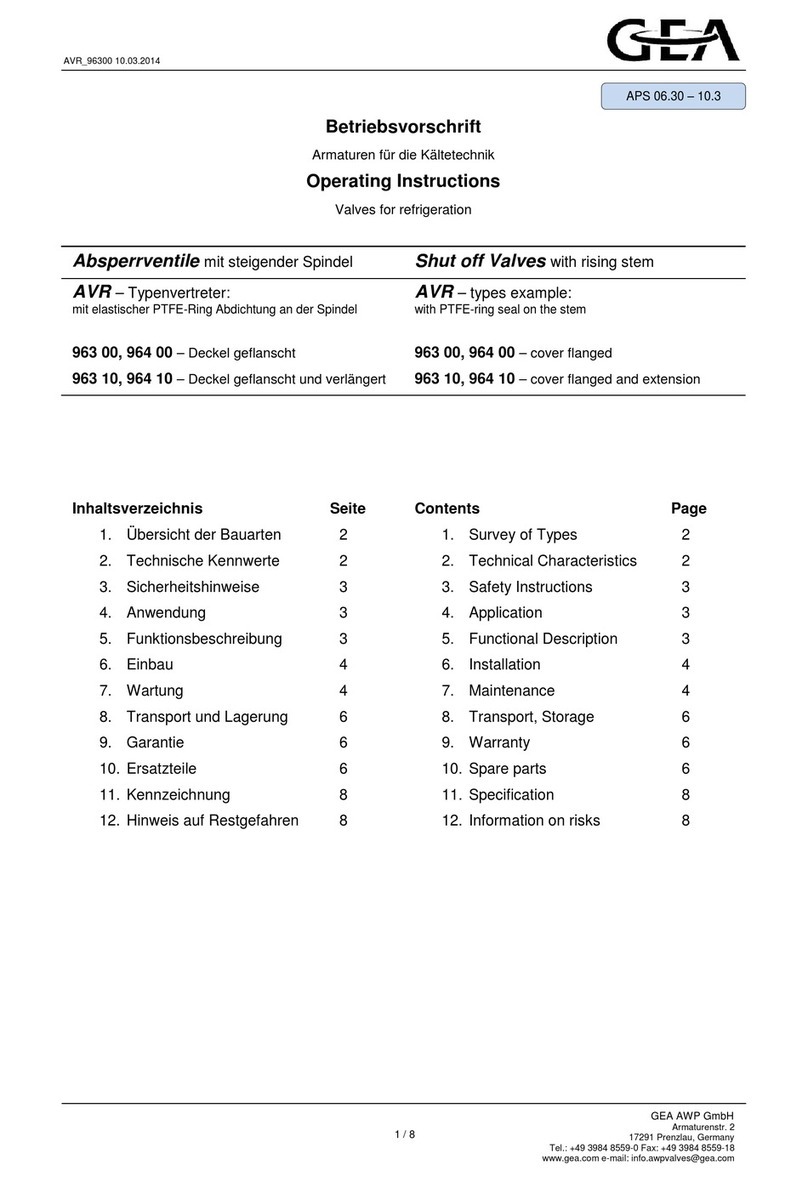

1 General description 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Application 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Equipment 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Control cabinet 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 General layout plan 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Control system 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Design 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Classification specifications 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Special designs 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Assembly 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.1 Control unit 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.2 Electrical connection 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.3 Fuse terminals 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 Installing the control unit in the control cabinet 12. . . . . . . . . . . . . . . . .

2.5.1 Loosening the fixing bracket 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Control unit 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Technical specifications 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Getting acquainted with the operating elements 19. . . . . . . . . . . . . . . .

3.2.1 Function keys 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.2 Softkeys 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.3 System keyboard 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Overview of display pages 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Selecting operating modes 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.1 Calling up the system function menu 26. . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.2 Calling up the system function menu 27. . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.3 Exiting the system function menu 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 Password protection 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.1 Entering the password 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6 The start screen 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.7 Interfaces 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Operation 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Switching on the control unit 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Start screen 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Calling up separator data 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Calling up the process text page 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 Calling up the separator data page 41. . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6 Calling up system times 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6.1 Determining the separating time 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7 Timer overview 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.8 Calling up the timer table 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.9 Calling up digital inputs 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.10 Calling up digital outputs 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.11 Calling up analog inputs 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.12 Calling up analog outputs 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.13 Calling up service addresses 54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.14 Calling up operator times 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.15 Calling up the system settings 57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.16 Loading a new program 60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.16.1 The UD 700 60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.16.2 Loading data from the UD 700 to the C7-623 61. . . . . . . . . . . . . . . . . .