3

Signet 2551 Display Magmeter

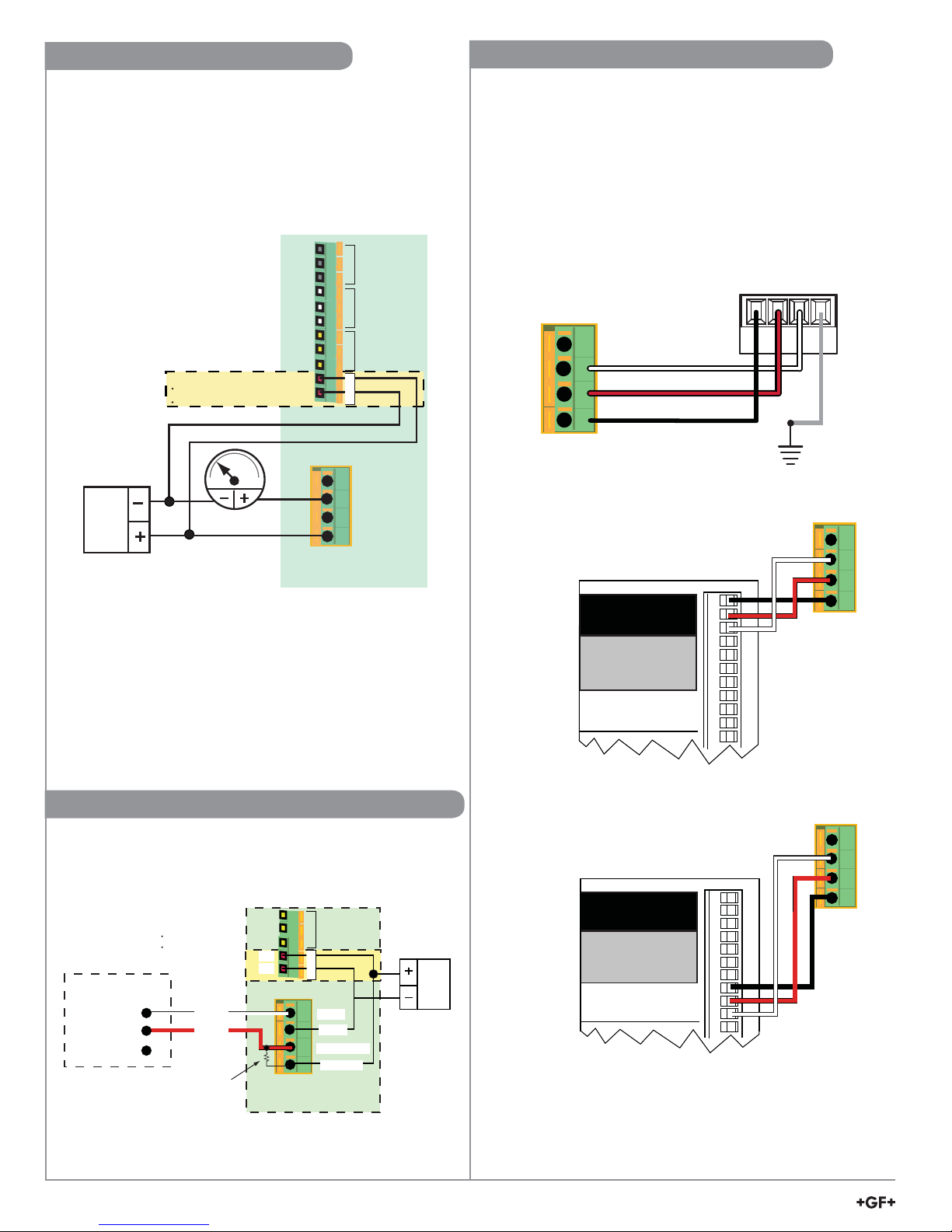

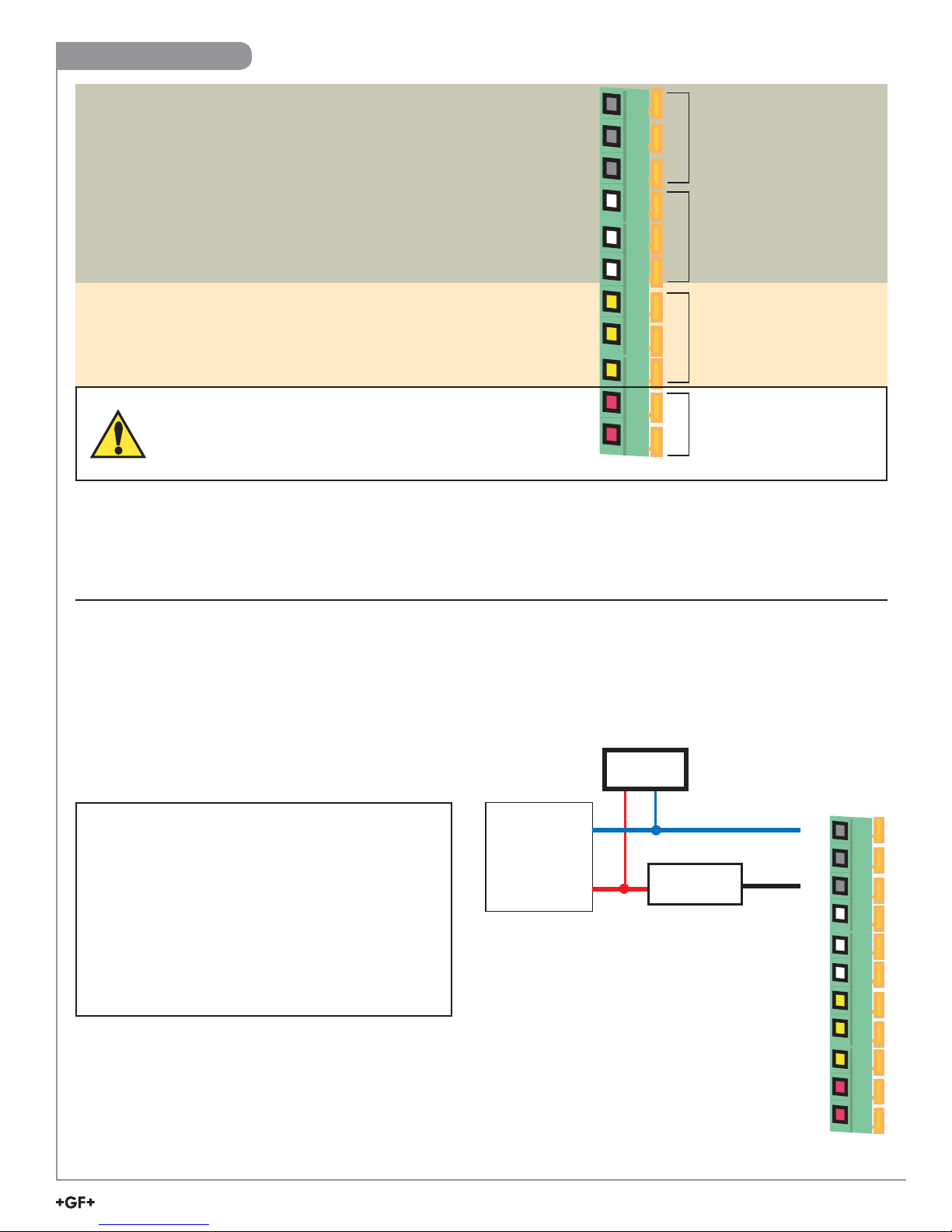

Power Requirements

4 to 20 mA .....................21.6 to 26.4 VDC, 22.1 mA max.

400 mV p-p maximum ripple voltage

Frequency......................5 to 26.4 VDC, 15 mA max.

Digital.............................5 to 6.5 VDC, 15 mA max.

Auxiliary.........................9 to 24 VDC, 0.4A max

(only required for units with relays)

Reverse polarity and short circuit protected

Current output (4 to 20 mA)

Max Loop Resistance....300

Loop Accuracy...............32 A max. error (25 °C @ 24 VDC)

Temp. drift......................± 1 A per °C max.

Power supply rejection ...± 1 A per V

Isolation: .......................Low voltage < 48 VAC/DC from

electrodes and aux power

Maximum cable .............300 m (1000 ft)

Error condition ...............22.1 mA

Frequency output

Output modes................Freq, Freq÷10, or Mirror Relay 1

Max. Pullup Voltage.......30 VDC

Max. Current Sink..........50 mA, current limited

Maximum cable .............300 m (1000 ft)

Reverse Polarity Protected to -40 V

Digital (S3L) Output

Serial ASCII, TTL level 9600 bps

Compatible with Signet 8900 and 9900

Maximum cable ......Application dependent (See 8900 manual)

Relay Specifications

Relay 1 and 2 Type........Mechanical SPDT

Rating ............................5 A @ 30 VDC max.,

5 A @ 250 VAC max.

Relay 3 Type..................Solid State

Rating ............................50 mA @ 30 VDC, 50 mA @ 42 VAC

Hysteresis......................Adjustable, plus timer delay

Trigger Delay .................Adjustable (0 to 9999.9 sec.)

Relay Modes..................Off, Low, High, Window, and

Proportional Pulse

Relay Source.................Flow Rate, Resettable Totalizer

Error Condition ..............Selectable; Fail Open or Fail Closed

Display

Characters.....................2 x 16

Contrast.........................User-set in four levels

Backlighting ...................Requires external 9-24 VDC,

0.4 mA max. (only on relay versions)

Environmental Requirements

Enclosure ......................NEMA 4X / IP65 (with cap installed)

Case ..............................PBT

Display window..............Polyamide

Storage Temperature.....-20 °C to 70 °C (-4 °F to 158 °F)

Relative Humidity...........0 to 95% (non-condensing)

Operating Temperature:

Ambient......................-10 °C to 70 °C (14 °F to 158 °F)

Media .........................0 °C to 85 °C (32 °F to 185 °F)

Operating pressure:

Maximum ...................10.3 bar @ 25 °C (150 psi @ 77 °F)

1.4 bar @ 85 °C (20 psi @ 185 °F)

Specifications

General

Pipe size range..............DN15 to DN900 (½ in. to 36 in.)

Flow Range ...................Minimum: 0.05 ms (0.15 ft/s)

(Bi-directional) ...............Maximum: 10 ms (33 ft/s)

Linearity.........................±1% of reading +0.01 ms (0.033 ft/s)

Repeatability..................±0.5% of reading @ 25 °C (77 °F)

Minimum Conductivity ...20 S/cm

Wetted Materials

Sensor body and Electrodes and Grounding ring:

-P0, -P1, -P2 ..............Polypropylene and 316L SS

-T0, -T1, -T2...............PVDF and Titanium

-V0, -V1,-V2 ...............PVDF and Hastelloy-C

O-rings .......................FPM (standard) EPDM, FFPM

(optional)

The user is responsible for determining

the chemical suitability of these materials

for a specific application.

Standards and Approvals

•

CE

•

UL/CUL (for display versions with relays)

• NSF (3-2551-P versions only)

• RoHS compliant

China RoHS (visit gfsignet.com for details)

• Manufactured under ISO 9001 for Quality, ISO 14001

for Environmental Management and OHSAS 18001 for

Occupational Health and Safety.

Declaration of Conformity according to FCC Part 15

This device complies with Part 15 of the FCC rules.

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and,

(2) This device must accept any interference received,

including interference that may cause undesired operation.

10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

160

170

180

.7

1.4

2.1

2.8

3.4

4.1

4.8

5.5

6.2

6.9

7.6

8.3

9.0

9.7

10.3

11.0

11.7

12.4

(bar)(psi)

0

-20 020

40 60 80 100 120

°F

°C

-4 32 68 104 140 176 212 248