8Signet 5500 Flow Monitor

Electrical

Power:

• 12 to 24 VDC or 12 to 24 VAC, unregulated, 50-60 Hz, 10 W max.

Relay contacts (2 sets):

• Mechanical SPDT contacts

• Max voltage rating: 5 A @ 30 VDC,

5 A @ 125 VAC, or

3 A @ 250 VAC, (power factor = 1.0)

• Hysteresis: User adjustable

Current output: 4 to 20 mA, non-isolated, internally powered,

fully adjustable and reversible

Update rate: 100 ms

Max loop

impedance: 350 max with a 12 V instrument supply

voltage, 950 max with a 24 V instrument

supply voltage

Accuracy: ±0.1% of max range

Sensor (PLS) Auxiliary (AUX) pulse outputs:

• Open-collector transistor, optically isolated, 5 mA max. sink,

28 VDC max. pull-up voltage, programmable (AUX) pulse width

Totalizer reset: Front keypad or external contact closure,

30 m (100 ft) max cable length

• External contact closure overrides security feature (sec. 5)

General

Sensor

compatibility: All Signet flow sensors

Accuracy: ±0.5% of reading

Input: Optically isolated

Enclosure:

• Rating: NEMA 4X/IP65 front

• Dimensions: 1/4 DIN, 96 x 96 x 88 mm (3.8 x 3.8 x 3.5 in.)

• Case material: ABS plastic

• Keypad: Sealed 4-key silicone rubber

• Weight: Approximately 500 g (18 oz.)

Display:

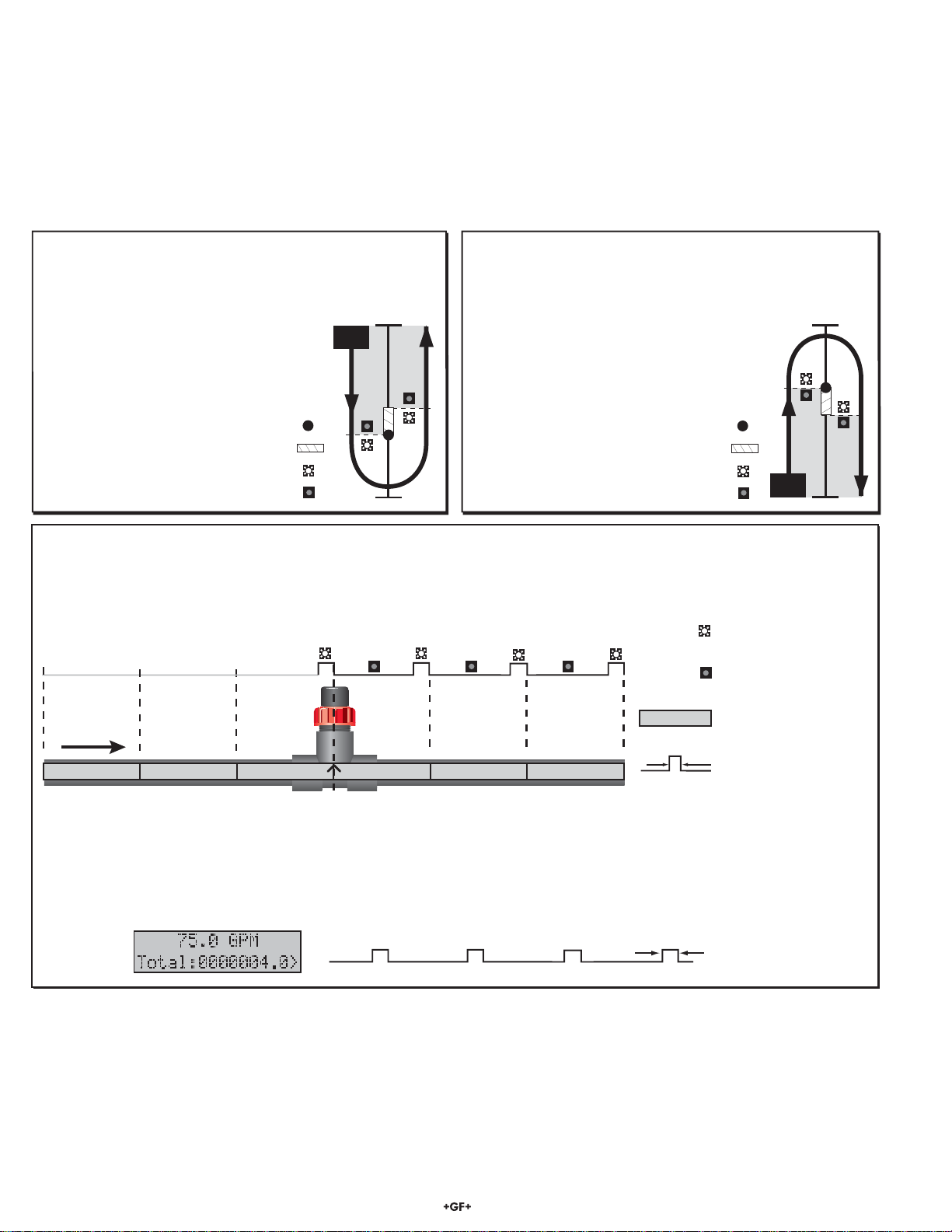

• Type: Microprocessor controlled air-core meter

movement and backlit alphanumeric 2 x 16 LCD

• Update rate: Flow = 1s, totalizer = < 200 ms

• Contrast: User selected, 5 levels

• Annunciators: 2 LEDs

Totalizers:

• 8-digit resettable with security option

• 8-digit non-resettable

Environmental

Operating temp.: -10 to 55 °C (14 to 131 °F),

50 °C (122 °F) max. with optional rear cover

Storage temp.: -15 to 80 °C (5 to 176°F)

Rel. humidity: 0 to 95%, non-condensing

Altitude: 4000 m max.

Pollution degree: 2

Noise immunity: EN50082-2

Noise emissions: EN55011

Safety: EN61010-1

Agency Approvals

• CE, UL, CUL

• Manufactured under ISO 9001 for Quality and

ISO 14001 for Environmental Management.

• Power supply, 115 VAC - 24 VAC, #3-5000.075

• Front snap-on bezel, #3-5000.525 (code 198 840 226)

• Assorted flow unit/multiplier decals, #3-5500.611 (code 198 840 230)

• 5500 instruction sheet #3-5500.090-1 (code 198 869 914)

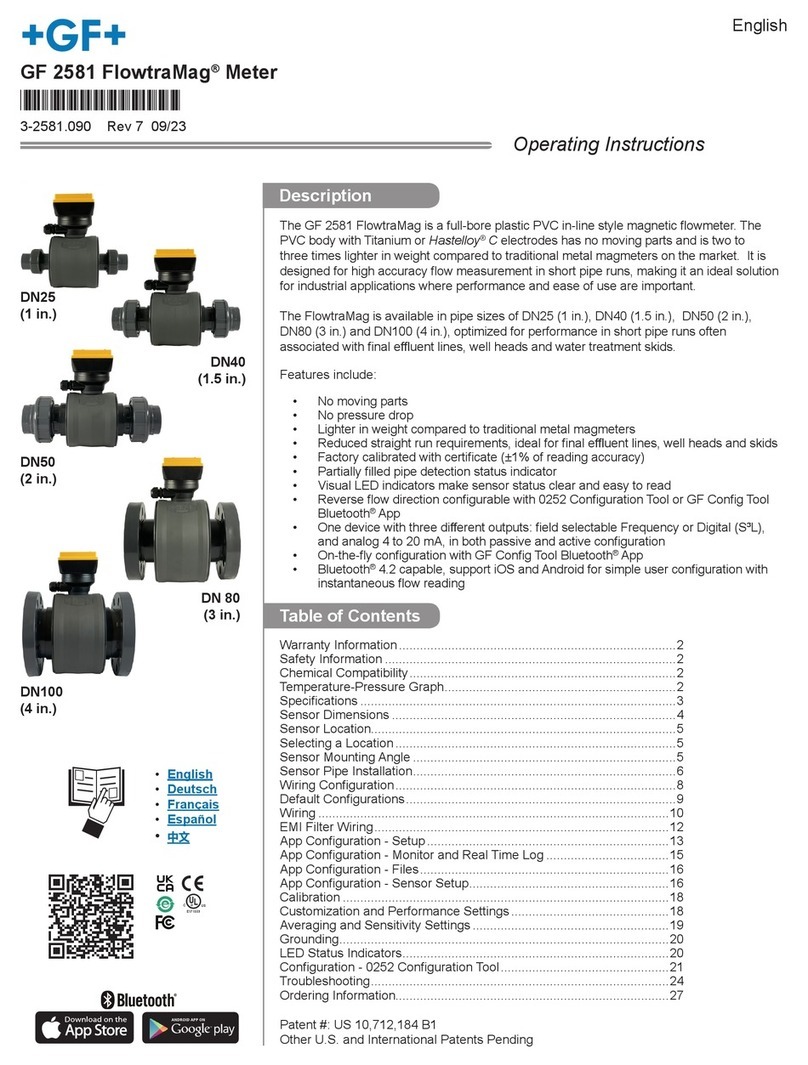

10. Parts and Accessories

Optional surface mount bracket

#3-5000.598 (code 198 840 225)

Splashproof rear cover

#3-5000.395 (code 198 840 227)

5 x 5 inch adapter plate for Signet retrofit

#3-5000.399 (code 198 840 224)

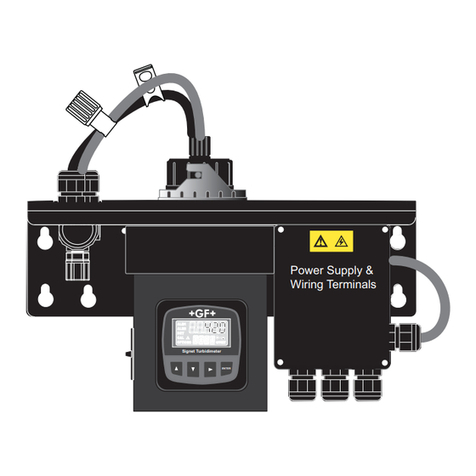

Internal

PLS/AUX

circuits

+

GND

5500 rear PLS/AUX

output terminals

100Ω

11. Specifications

China RoHS (Go to www.gfsignet.com for details)