Instruction Manual

2

Original instruction manual

Follow the instruction manual

The instruction manual is part of the product and is an important element of the safety concept.

• Read and follow the instruction manual.

• Always keep the instruction manual available at the product.

• Pass on the instruction manual to all subsequent users of the product.

Contents

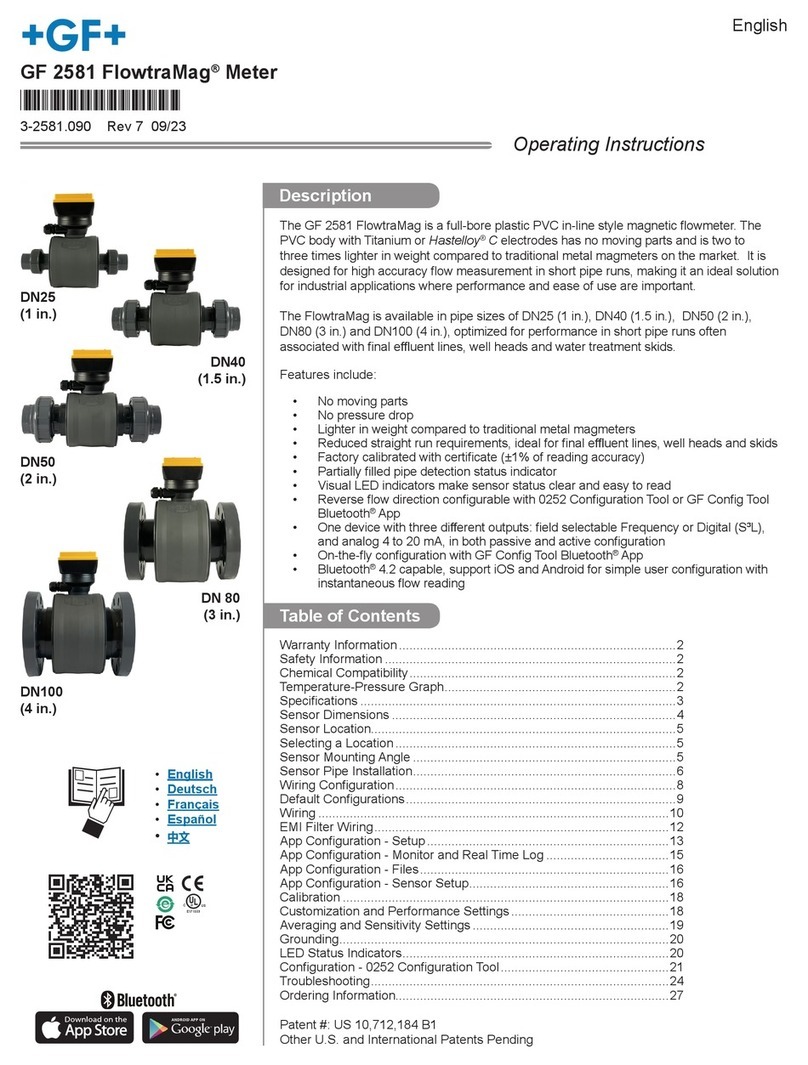

1 Intended use....................................................................................................................................................4

2 About this document......................................................................................................................................4

2.1 Warnings .................................................................................................................................................4

2.2 Other related documents.....................................................................................................................4

2.3 Abbreviations.........................................................................................................................................5

3 Safety and responsibility ..............................................................................................................................5

4 Transport and storage...................................................................................................................................5

5 Design and function .......................................................................................................................................6

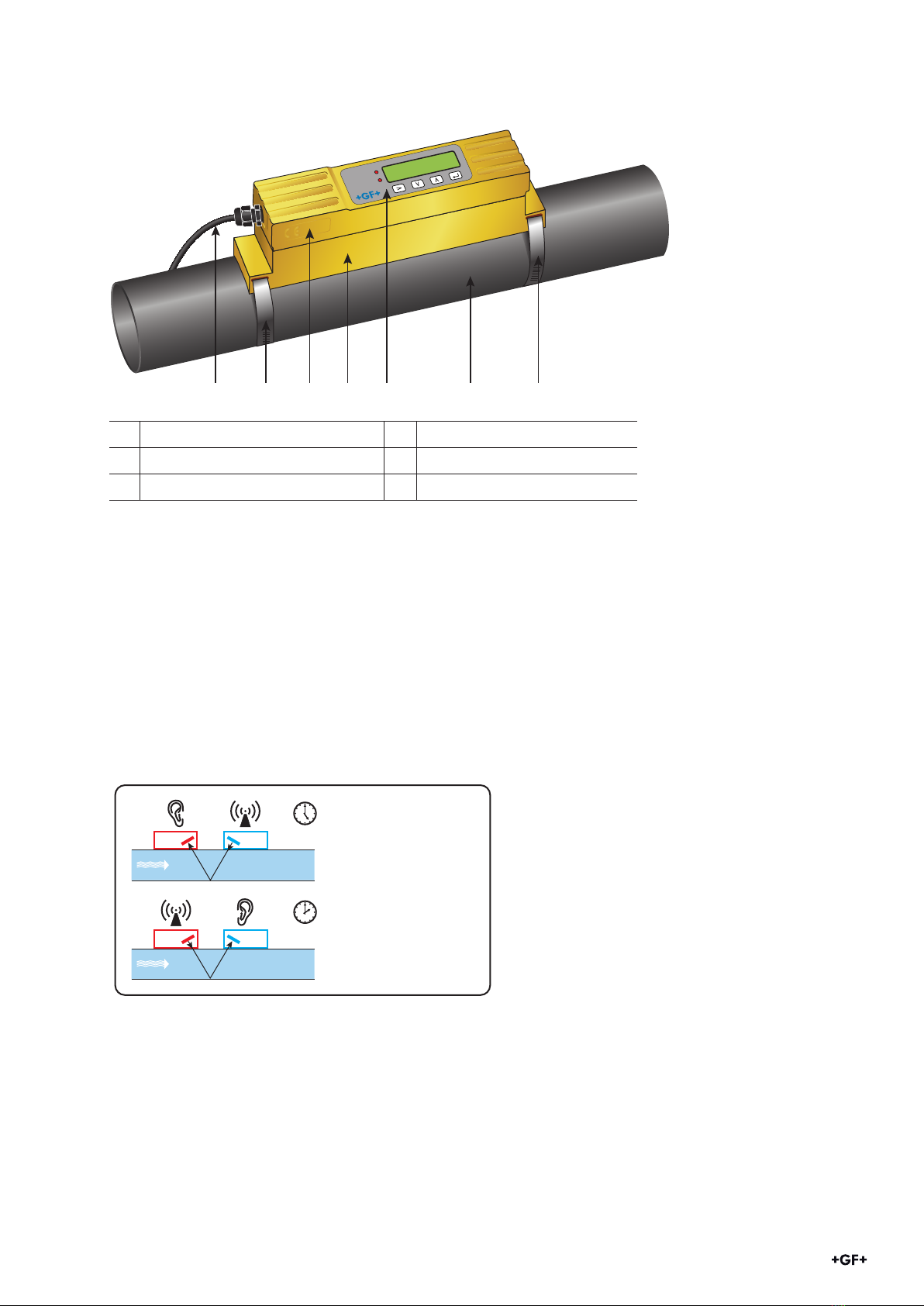

5.1 Design......................................................................................................................................................6

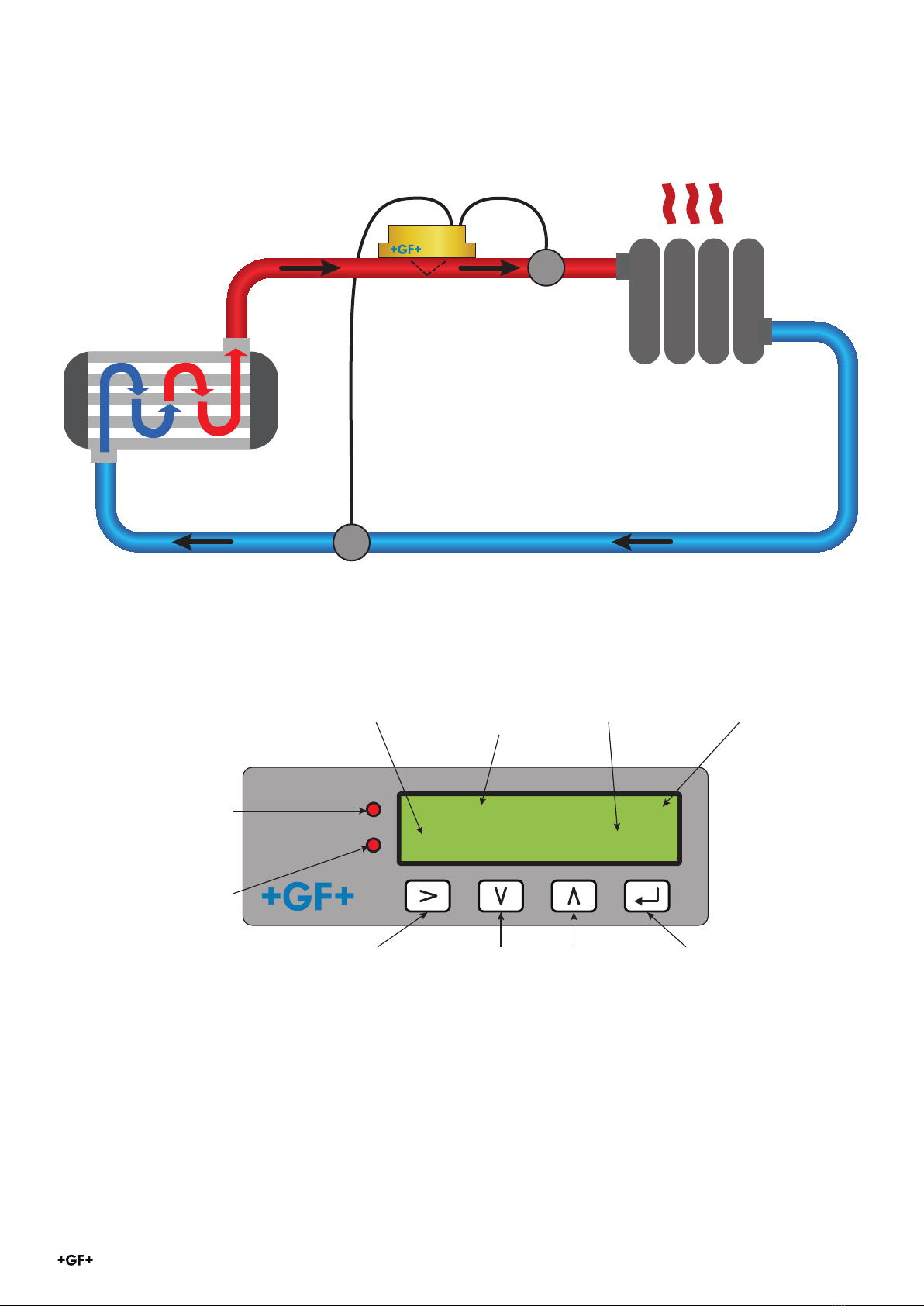

5.2 Principle of operation ...........................................................................................................................6

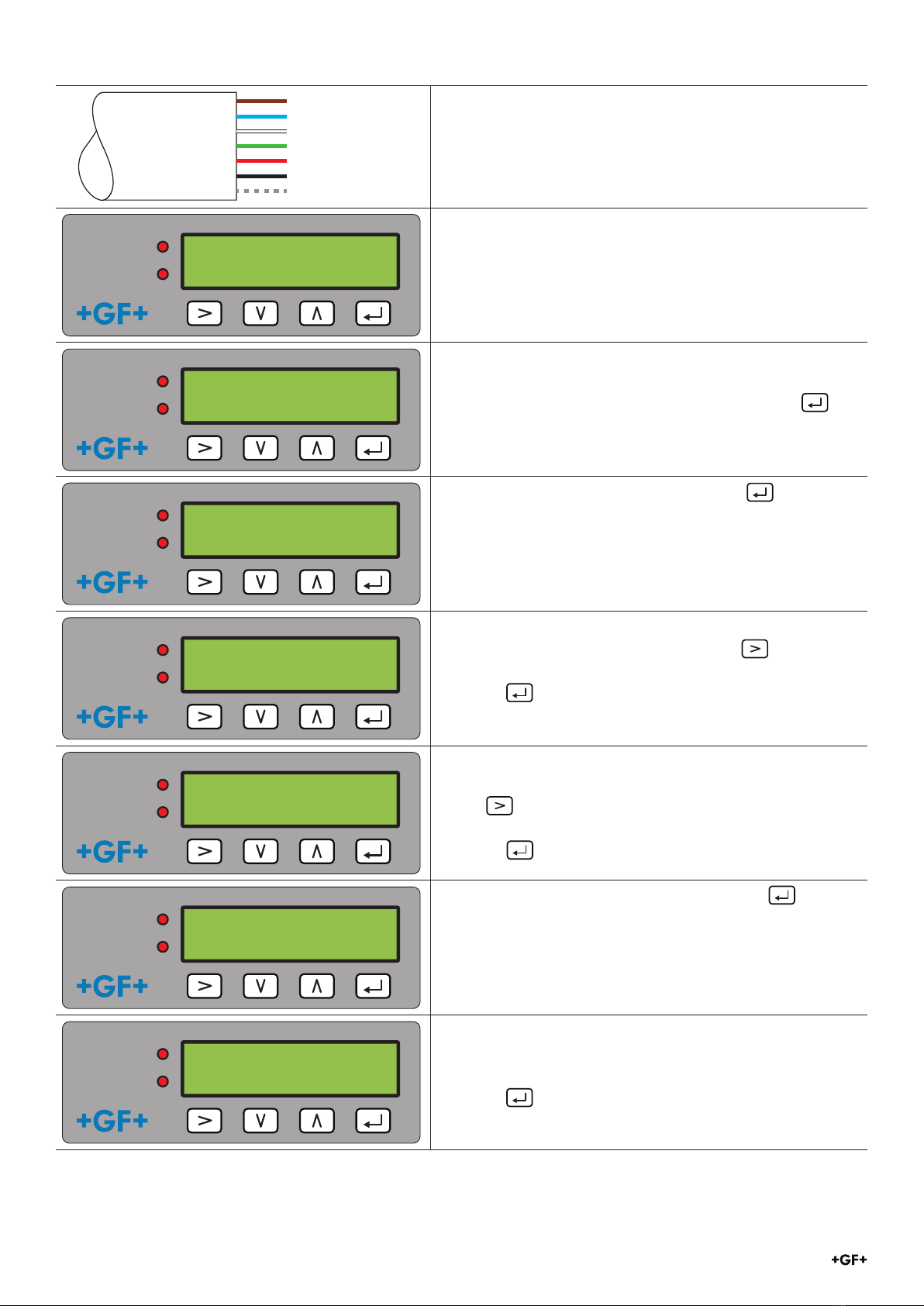

5.3 User Interface ........................................................................................................................................7

6 Scope of delivery ............................................................................................................................................8

7 Installation ......................................................................................................................................................8

7.1 Identify suitable location for flow measurement............................................................................8

7.2 Identify suitable location for temperature measurement (HM versions only) ..........................9

7.3 Pipe mounting surface preparation...................................................................................................9

7.4 Start-Up...................................................................................................................................................10

7.5 Adjusting the sensor distance ............................................................................................................11

7.6 Mounting the GF U1000 V2 on the pipe.............................................................................................12

7.6.1 Selecting the pipe adapter........................................................................................................12

7.6.2 Applying gel pads.......................................................................................................................13

7.6.3 Mounting the guide rail..............................................................................................................13

7.6.4 Removing sensor-holding screws ..........................................................................................14

7.6.5 Connecting the electronics module ........................................................................................14

7.7 Moving the guide rail ............................................................................................................................15

7.8 Attach the temperature sensors (HM versions only)......................................................................15

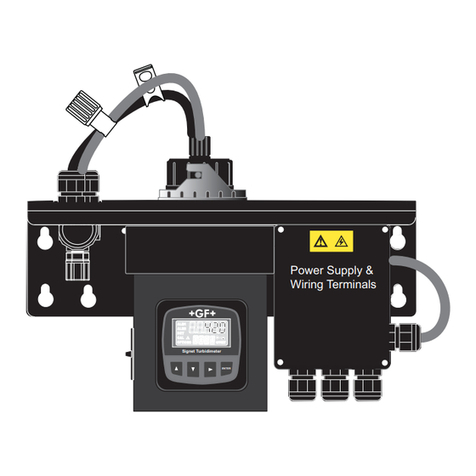

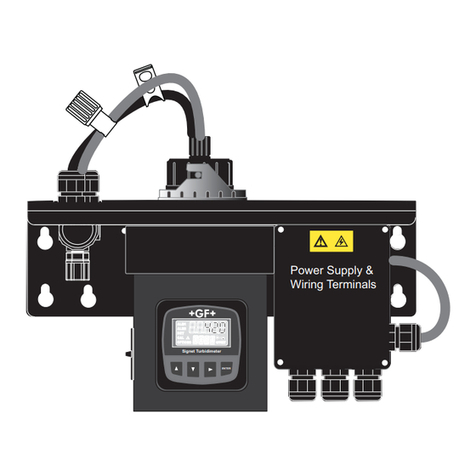

8 Electrical connection & outputs...................................................................................................................16

8.1 4-20 mA, Pulse option (not for HM versions)...................................................................................16

8.1.1 Interface cable ............................................................................................................................16

8.2 Pulse output ...........................................................................................................................................17

8.2.1 Volumetric pulses.......................................................................................................................17

8.2.2 Frequency mode.........................................................................................................................18

8.2.3 Energy pulse (HM versions only).............................................................................................18

8.2.4 Flow alarm – low flow...............................................................................................................18

8.2.5 Flow alarm – signal loss...........................................................................................................18

8.3 Current / 4-20 mA Output....................................................................................................................18

8.4 Modbus option........................................................................................................................................19

8.4.1 Interface cable ............................................................................................................................19

8.4.2 Modbus connections at device.................................................................................................20

8.4.3 Modbus wiring diagramm.........................................................................................................20

8.4.4 Modbus registers........................................................................................................................22

8.5 Temperature probes (HM versions only)..........................................................................................24