2Signet 4150 Turbidimeter

Refer to your local Georg Fischer Sales office for the most

current warranty statement.

All warranty and non-warranty repairs being returned must

include a fully completed Service Form and goods must be

returned to your local GF Sales office or distributor.

Product returned without a Service Form may not be

warranty replaced or repaired.

Signet products with limited shelf-life (e.g. pH, ORP, chlorine

electrodes, calibration solutions; e.g. pH buffers, turbidity

standards or other solutions) are warranted out of box but not

warranted against any damage, due to process or application

failures (e.g. high temperature,

chemical poisoning, dry-out) or

mishandling (e.g. broken glass,

damaged membrane, freezing

and/or extreme temperatures).

Thank you for purchasing the Signet line of Georg Fischer

measurement products.

If you would like to register your product(s), you can now

register online in one of the following ways:

• Visit our website www.gfsignet.com.

Under Service and Support click on

Product Registration Form

• If this is a pdf manual (digital copy), click here

Warranty Information Disclaimer

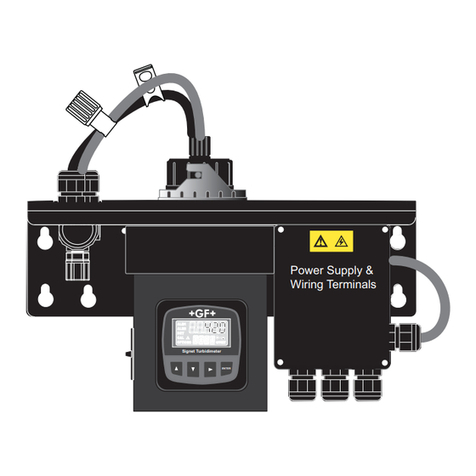

4150 Turbidimeter Parts

Product Registration

Safety Information

This manual contains basic instructions that must be followed

during the commissioning, operation, care and maintenance

of the instrument. The safety protection provided by this

equipment may be impaired if it is commissioned and/or used

in a manner not described in this manual. Consequently, all

responsible personnel must read this manual prior to working

with this instrument.

Georg Fischer Signet LLC accepts no responsibility for damage

caused by the introduction of vapors, fluids or other materials

into the instrument process stream which is not compatible with

the wetted materials. A list of the wetted materials can be found

in the specifications on page 3 of this manual.

Material Safety Data Sheets (MSDS) are available online at

www.gfsignet.com

It is the responsibility of the Distributor, Dealer, or Agent to

provide a current copy of the MSDS to the Consumers of

Georg Fischer Piping Systems products. The information

contained herein is presented in good faith and has been

compiled from sources believed to be reliable. It represents the

best information currently available to us. No warranty express

or implied, or merchantability, fitness or otherwise is made and

we assume no liability resulting from its use. This information is

offered for your consideration and users should make their own

investigation and verification to determine the suitability of the

information for their particular purposes. In no event shall

Georg Fischer Piping Systems, the parent company or its

subsidiaries be liable for any claims, losses, or damages of any

third party or for lost profits or any special, indirect, incidental,

consequential or exemplary damages, howsoever arising,

even if Georg Fischer Piping Systems has been advised of the

possibility of such damages. This information relates to the

material designated and may not be valid for such material

used in combination with any other materials nor in any process.

Caution / Warning / Danger

Indicates a potential hazard. Failure to follow all warnings

may lead to equipment damage, injury, or death

Electrostatic Discharge (ESD) / Electrocution Danger

Alerts user to risk of potential damage to product by ESD,

and/or risk of potential injury or death via electrocution.

Do Not Use Tools

Use of tool(s) may damage product beyond repair and

potentially void product warranty.

DO NOT

FREEZE

Do Not Freeze (Calibration Standards)

Products are temperature sensitive and may contain

freezable liquids. Freezing damage voids accuracy.

Unpacking and Inspecting the Instrument and Accessories

The table below indicates the items in the Turbidimeter shipment.

Qty Item

1 3-4150- ( __ ) Turbidimeter

1 3-4150.090 Instruction Manual

1 3-4150.380 Desiccant Pack (Do not open until ready to install)

1 4150-0009 or 4150-0004 Measurement Cuvette

1 4150-0005 Tubing Kit:

1

1

2

2

1

shutoff clamp

backpressure valve

connectors and inserts [customer-supplied 8 mm (5/16 in.) tubing]

connecting tubing with fittings for flow-through assembly

drain vent screw (used in pressurized systems)

1 Mounting Hardware Kit

Remove the instrument from the packing carton.

Carefully inspect all items to ensure that no visible damage has

occurred during shipment.

If the items received do not match the order, please immediately

contact the local distributor or the Georg Fischer Signet Customer

Service department.