2 2551 Magmeter

Wetted Materials:

• Sensor body and Electrodes and Grounding ring:

• -P0, -P1, -P2: Polypropylene and 316L SS

• -T0, -T1, -T2: PVDF and Titanium

• -V0, -V1,-V2: PVDF and Hastelloy-C

• -W0, -W1, -W2: PVDF and 316L SS

• O-rings: FPM (standard)

EPDM, Kalrez® (optional)

The user is responsible for determining the chemical

suitability of these materials for a specific application.

• Case: PBT

• Display window: Polyamide

Power Requirements

• 4 to 20 mA: 21.6 to 26.4 VDC, 22.1 mA max.

400 mV p-p maximum ripple voltage

• Frequency: 5 to 26.4 VDC, 15 mA max.

• Digital: 5 to 6.5 VDC, 15 mA max.

• Auxiliary (only required for units with relays):

9 to 24 VDC, 0.4A max

• Reverse polarity and short circuit protected

Performance

• Pipe size range: DN15 to DN300 (½ to 12 in.)

• Flow Range Minimum: 0.05 m/s (0.15 ft/s)

(Bi-directional) Maximum: 10 m/s (33 ft/s)

• Linearity: ±1% of reading +0.01m/s (0.033 ft/s)

• Repeatability ±0.5% of reading @ 25°C (77°F)

• Minimum Conductivity: 20 μS/cm

Output Specifications

Current output (4 to 20 mA)

• Max Loop Resistance: 300Ω

• Loop Accuracy: 32 μA max. error (25°C @ 24 VDC)

• Temp. drift: ±1 μA per °C max.

• Power supply rejection: ±1 μA per V

• Isolation: Low voltage <48 VAC/DC

from electrodes and aux power

• Maximum cable: 300 m (1000 ft.)

• Error condition: 22.1 mA

Frequency output:

• Output modes: Freq, Freq÷10, or Mirror Relay 1

• Max. Pullup Voltage: 30 VDC

• Reverse Polarity Protected to -40 V

• Max. Current Sink: 50 mA, current limited

• Maximum cable: 300 m (1000 ft.)

Digital (S3L) Output:

• Serial ASCII, TTL level 9600 bps

• Compatible with Signet 8900

Standards and Approvals

• CE

• UL, CUL (for display versions with relays)

• NEMA 4X / IP65 Enclosure (with cap installed)

• EMC: EN55011: 1998 +A1:99+A2:02

Class B Emissions

EN61326: 1997 +A1:98+A2:01

EN61000-6-2:2001

• Safety: EN61010-1:2001

• U.S. Patent No. 7,055,396 B1

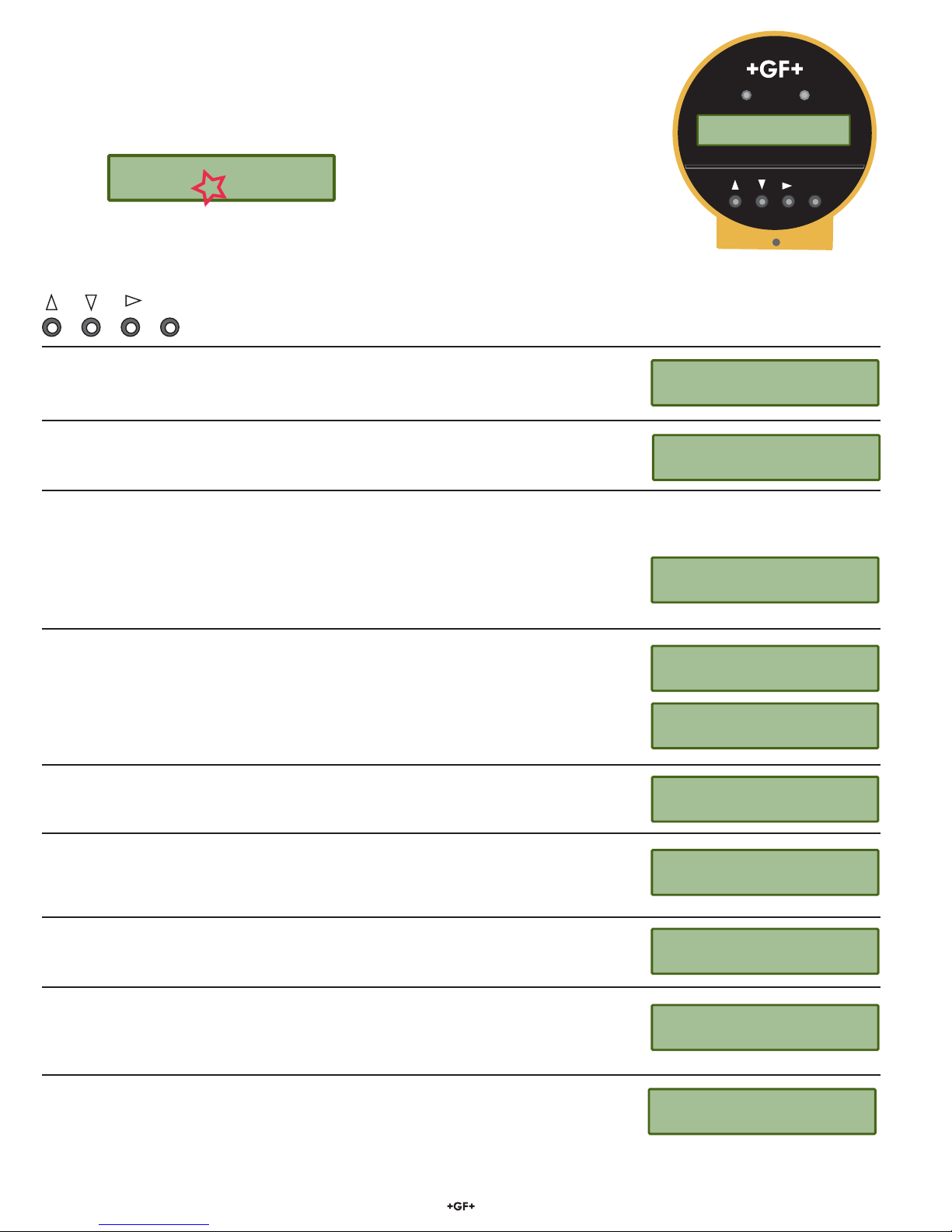

2.0 Specifications

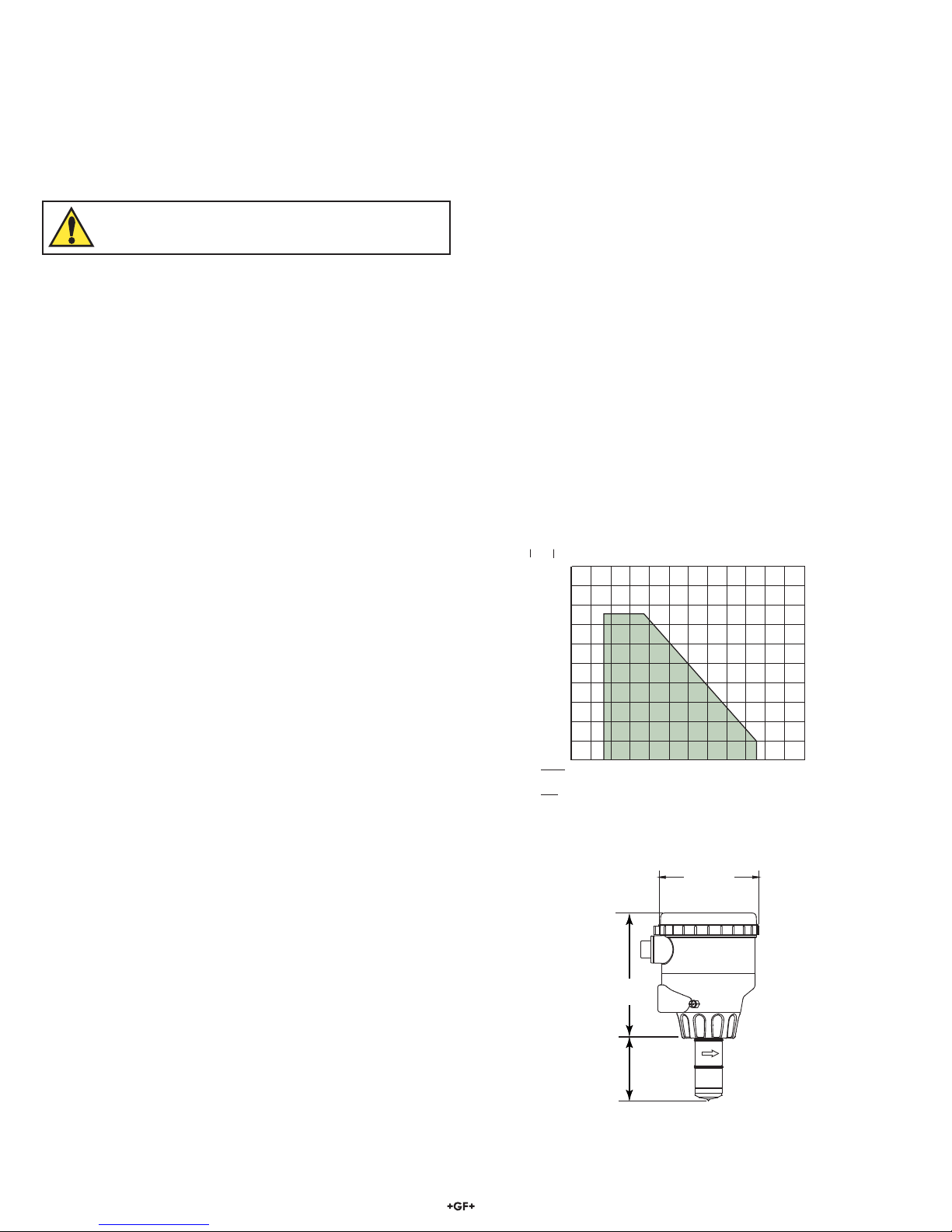

40

80

120

160

200

3

6

8

11

14

0 40 80 120 160 200

-18 4 27 49 71 93

°F

°C

psi

bar

240

115

2551

Pressure vs. Temperature

Media Temperature

Operating Pressure

2551

Acceptable

Media Range

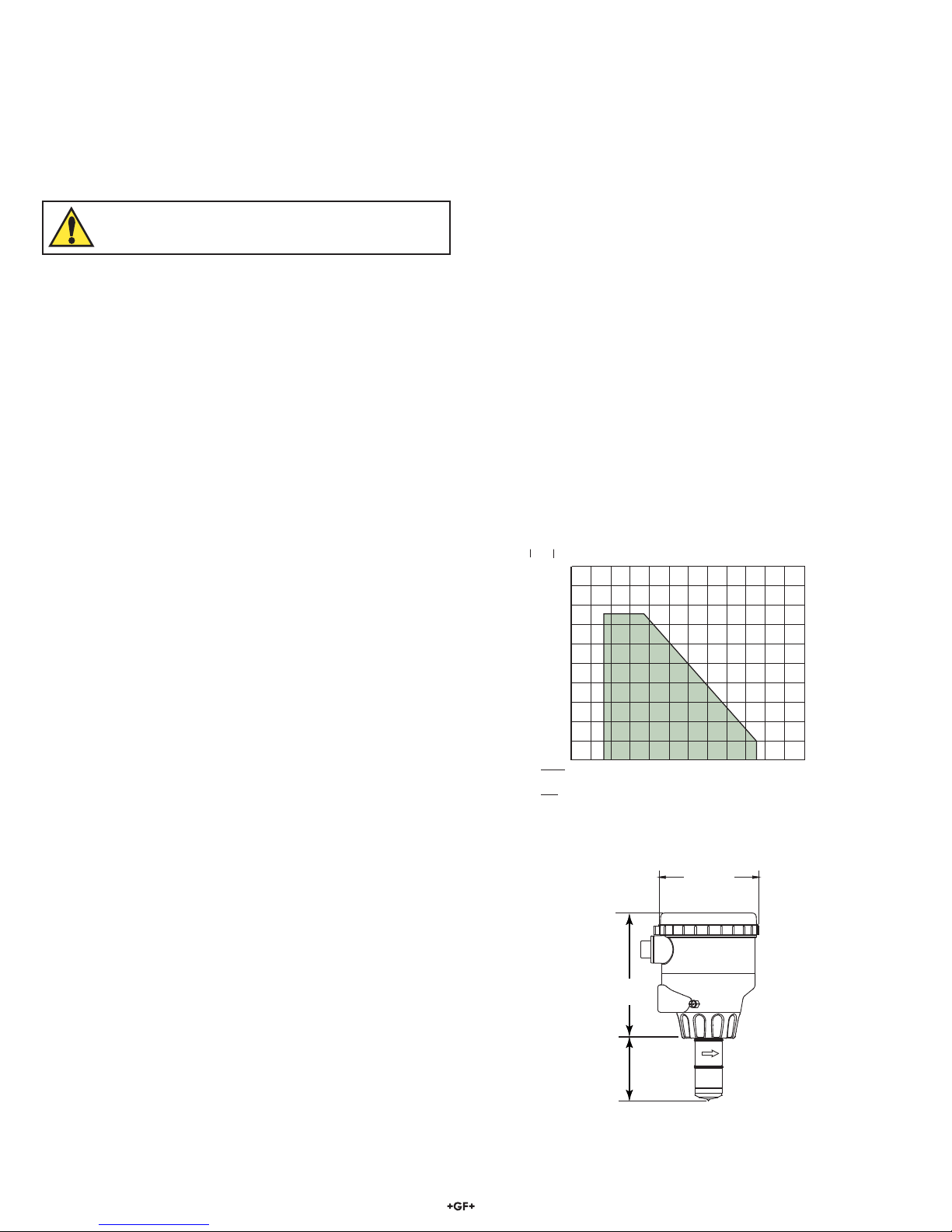

Dimensions

116.8 mm

(4.6 in.)

-XO

-X1

-X2

95.3 mm

(3.75 in.)

Pipe Range

1/2 to 4 in. -XO = 58 mm (2.3 in.)

5 to 8 in. -X1 = 91 mm (3.6 in.)

10 to 12 in. -X2 = 167 mm (6.6 in.)

X = Sensor Body P, T, V, or W

Relay Specifications

• Relay 1 and 2 Type: Mechanical SPDT

Rating: 5 A @ 30 VDC max., 5 A @ 250 VAC max.

• Relay 3 Type: Solid State

Rating: 50 mA @ 30 VDC, 50 mA @ 42 VAC

Hysteresis: Adjustable, plus timer delay

Trigger Delay: Adjustable (0 to 9999.9 sec.)

Relay Modes: Off, Low, High, Window, and Proportional Pulse

Relay Source: Flow Rate, Resettable Totalizer

Error Condition: Selectable; Fail Open or Fail Closed

Display

Characters: 2 x 16

Contrast: User-set in four levels

Backlighting (only on relay versions):

Requires external 9-24 VDC, 0.4 mA max.

Environmental Requirements

Storage Temperature:

-20° to 70°C (-4° to 158°F)

Relative Humidity :

0 to 95% (non-condensing)

Operating Temperature

• Ambient: -10° to 70°C (14° to 158°F)

• Media: 0° to 85°C (32° to 185°F)

Max. operating pressure:

10.3 bar @ 25°C (150 psi @ 77°F)

1.4 bar @ 85°C (20 psi @ 185°F)