page 10 of 12 ‡ SIGNET 2550 InsertionMagmeter

5.7 Calibration data

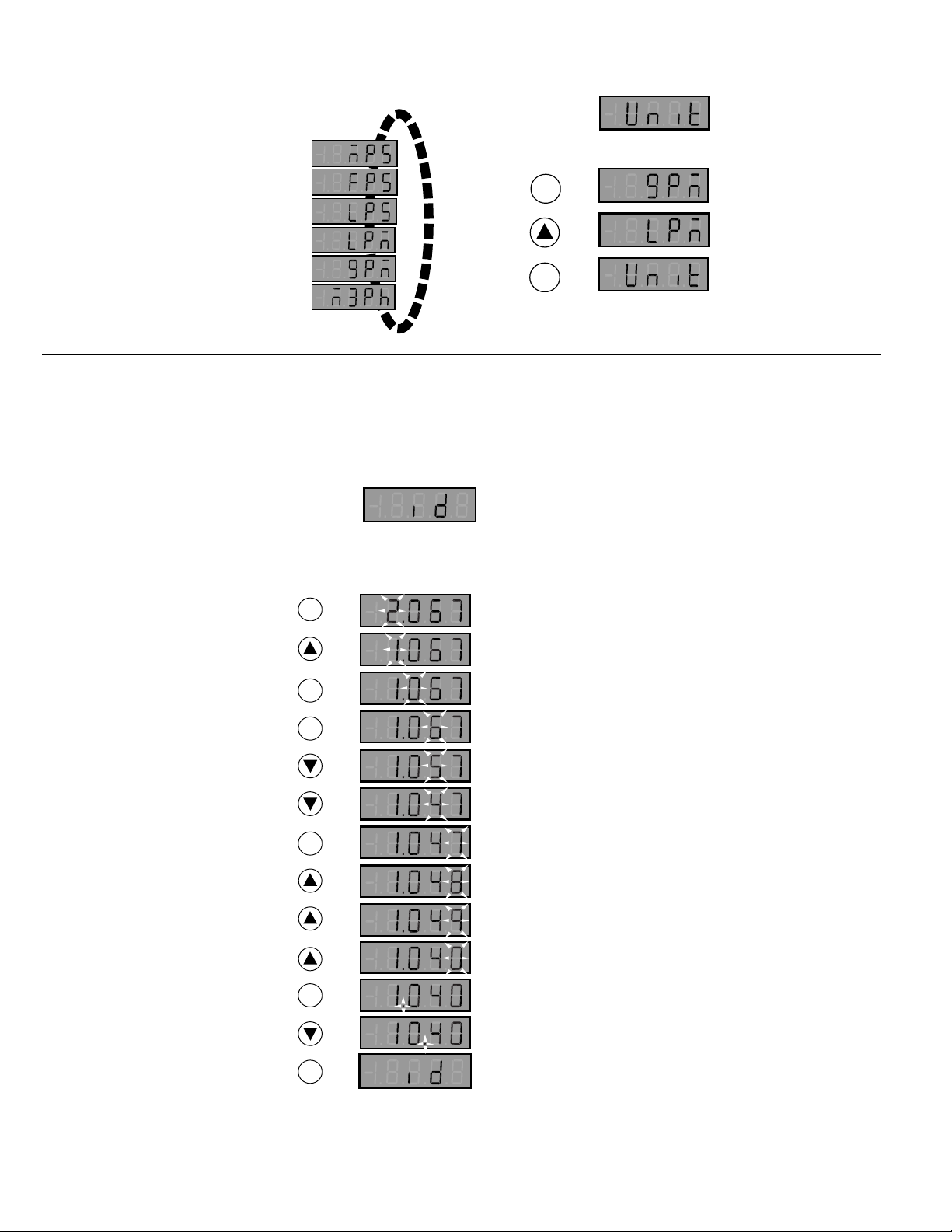

Pipe type pipe pipe gpm/fps lpm/fps K A K A

size id pls/gal gpm/Hz pls/l lpm/Hz

PVC sched 80 3.5 in. 3.33 27.0803 102.51 55.39 1.08 14.63 4.10

PVC sched 40 3.5 in. 3.52 30.3488 114.88 49.43 1.21 13.06 4.60

steel sch 5S 3.5 in. 3.83 35.9843 136.22 41.68 1.44 11.01 5.45

steel sch 10S 3.5 in. 3.76 34.6087 131.01 43.34 1.38 11.45 5.24

steel sch 40S 3.5 in. 3.55 30.816 116.65 48.68 1.23 12.86 4.67

steel sch 80S 3.5 in. 3.36 27.7026 104.87 54.15 1.11 14.30 4.19

PVC sched 80 4 in. 3.79 35.089 132.83 42.75 1.40 11.29 5.31

PVC sched 40 4 in. 4.00 39.1289 148.12 38.33 1.57 10.13 5.92

steel sch 5S 4 in. 4.33 45.9819 174.06 32.62 1.84 8.62 6.96

steel sch 10S 4 in. 4.26 44.4251 168.17 33.76 1.78 8.92 6.73

steel sch 40S 4 in. 4.03 39.6786 150.2 37.80 1.59 9.99 6.01

steel sch 80S 4 in. 3.83 35.8343 135.65 41.86 1.43 11.06 5.43

PVC sched 80 5 in. 4.77 55.6521 210.67 26.95 2.23 7.12 8.43

PVC sched 40 5 in. 5.02 61.592 233.15 24.35 2.46 6.43 9.33

steel sch 5S 5 in. 5.35 69.9366 264.74 21.45 2.80 5.67 10.59

steel sch 10S 5 in. 5.30 68.6343 259.81 21.85 2.75 5.77 10.39

steel sch 40S 5 in. 5.05 62.3557 236.04 24.06 2.49 6.35 9.44

steel sch 80S 5 in. 4.81 56.7076 214.66 26.45 2.27 6.99 8.59

PVC sched 80 6 in. 5.71 79.7865 302.03 18.80 3.19 4.97 12.08

PVC sched 40 6 in. 6.03 89.0406 337.06 16.85 3.56 4.45 13.48

steel sch 5S 6 in. 6.41 100.489 380.4 14.93 4.02 3.94 15.22

steel sch 10S 6 in. 6.36 98.9267 374.48 15.16 3.96 4.01 14.98

steel sch 40S 6 in. 6.07 90.0473 340.87 16.66 3.60 4.40 13.63

steel sch 80S 6 in. 5.76 81.2466 307.55 18.46 3.25 4.88 12.30

PVC sched 80 8 in. 7.57 140.096 530.33 10.71 5.60 2.83 21.21

PVC sched 40 8 in. 7.94 154.408 584.5 9.71 6.18 2.57 23.38

steel sch 5S 8 in. 8.41 173.018 654.95 8.67 6.92 2.29 26.20

steel sch 10S 8 in. 8.33 169.822 642.85 8.83 6.79 2.33 25.71

steel sch 40S 8 in. 7.98 155.928 590.26 9.62 6.24 2.54 23.61

steel sch 80S 8 in. 7.63 142.328 538.77 10.54 5.69 2.78 21.55

PVC sched 80 10 in. 9.49 220.605 835.09 6.80 8.82 1.80 33.40

PVC sched 40 10 in. 9.98 243.625 922.23 6.16 9.75 1.63 36.89

steel sch 5S 10 in. 10.48 268.966 1018.2 5.58 10.76 1.47 40.73

steel sch 10S 10 in. 10.42 265.794 1006.1 5.64 10.63 1.49 40.24

steel sch 40S 10 in. 10.02 245.779 930.38 6.10 9.83 1.61 37.22

steel sch 80S 10 in. 9.75 232.712 880.92 6.45 9.31 1.70 35.24

PVC sched 80 12 in. 11.29 312.252 1182 4.80 12.49 1.27 47.28

PVC sched 40 12 in. 11.89 346.019 1309.8 4.34 13.84 1.15 52.39

steel sch 5S 12 in. 12.44 378.713 1433.6 3.96 15.15 1.05 57.34

steel sch 10S 12 in. 12.39 375.796 1422.6 3.99 15.03 1.05 56.90

steel sch 40S 12 in. 12.00 352.51 1334.4 4.26 14.10 1.12 53.38

steel sch 80S 12 in. 11.75 337.975 1279.4 4.44 13.52 1.17 51.18

Pipe type pipe pipe gpm/fps lpm/fps K A K A

size id pls/gal gpm/Hz pls/l lpm/Hz

U.S. pipe data

PVC sched 80 2 in. 1.91 8.95858 33.912 167.44 0.36 44.23 1.36

PVC sched 40 2 in. 2.05 10.2576 38.829 146.23 0.41 38.63 1.55

steel sch 5S 2 in. 2.25 12.3379 46.704 121.58 0.49 32.12 1.87

steel sch 10S 2 in. 2.16 11.3896 43.115 131.70 0.46 34.79 1.72

steel sch 40S 2 in. 2.07 10.459 39.592 143.42 0.42 37.89 1.58

steel sch 80S 2 in. 1.94 9.20375 34.84 162.98 0.37 43.05 1.39

PVC sched 80 2.5 in. 2.29 12.8375 48.596 116.85 0.51 30.87 1.94

PVC sched 40 2.5 in. 2.45 14.6341 55.397 102.50 0.59 27.08 2.22

steel sch 5S 2.5 in. 2.71 17.965 68.005 83.50 0.72 22.06 2.72

steel sch 10S 2.5 in. 2.64 16.9969 64.341 88.25 0.68 23.31 2.57

steel sch 40S 2.5 in. 2.47 14.8228 56.49 101.20 0.59 26.55 2.26

steel sch 80S 2.5 in. 2.32 13.2101 50.006 113.55 0.53 30.00 2.00

PVC sched 80 3 in. 2.86 20.0796 76.01 74.70 0.80 19.73 3.04

PVC sched 40 3 in. 3.04 22.6531 85.752 66.22 0.91 17.49 3.43

steel sch 5S 3 in. 3.33 27.2107 103 55.13 1.09 14.56 4.12

steel sch 10S 3 in. 3.26 26.0162 98.483 57.66 1.04 15.23 3.94

steel sch 40S 3 in. 3.07 23.042 87.224 65.10 0.92 17.20 3.49

steel sch 80S 3 in. 2.90 20.5876 77.933 72.86 0.82 19.25 3.12