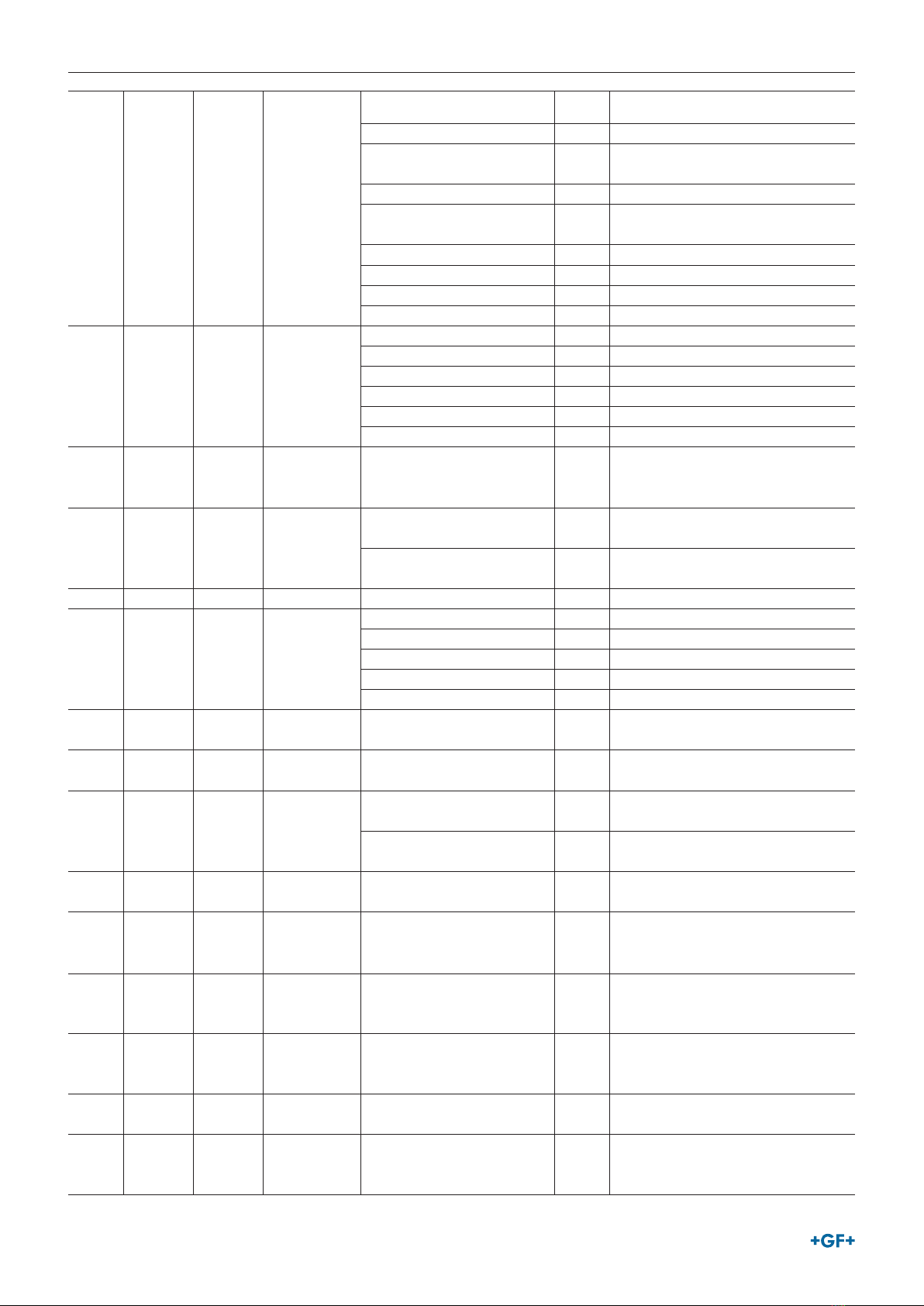

8

GF U3000 V2 Ultrasonic FlowmeterModbus Supplement to the operating instructions

8 7

Instru-

ment

Status

Flags

uint16

Online:1 R Device is reading flow

Urgent Error:1 An urgent error has been reported

Remote Total Changes

Disabled:1

Instrument has barred updates of all

totals. 1=MBM changes disabled

Current Loop Alarm:1 1=active (current loop alarm active)

Digital Device 0 Alarm:1 1=active (Digital device 0 is currently

unimplemented, so always 0)

Digital Device 1 Alarm:1 1=active (Digital Output 1)

Digital Device 2 Alarm:1 1=active (Digital Output 2)

Digital Device 3 Alarm:1 1=active (Digital Output 3)

Reserved:8

9,10 8,9 Date /

Time

uint32

Sec:6 R 0 to 59

Min:6 0 to 59

Hour:5 0 to 23

Day:5 1 to 31; 1st = 1

Month:4 1 to 12; Jan = 1

Year:6 (base 2000) Add 2000 for full year.

11 10 Reserved uint16

Reserved: 1

Outputs Available:3

Reserved:12

R

Not available at the time of writing, but

may be used to allow Management

system to control digital output(s)

12 11 Reserved uint16

Reserved:1 W Not available at the time of writing but

may be used to allow the

Output Values:3

Reserved:12

MBM to control digital output(s) on a

unit

12-100 Reserved uint16 Sec:6 RZ 0 to 59

101,

102 100-101

Date /

Time uint32

Min:6 R 0 to 59

Hour:5 0 to 23

Day:5 1 to 31; 1st = 1

Month:4 1 to 12; Jan = 1

Year:6 (base 2000) Add 2000 for full year.

103,

104

102-103 Reserved uint16× 2 RZ Reads Zero. Not used. Future Expansion

105,

106

104,105 Measured

Velocity

IEEE 754 SP m/s, ft/s, ft/s, m/s R Metric1, Imperial, US Imperial, Metric2

Reads zero when not measuring flow.

107,

108

106,107 Measured

Flow

IEEE 754 SP

l/s, Imp gallon/s, US gallon/s,

m3/hr

R Metric1, Imperial, US

s, US gallon/s, m3/hr Imperial, Metric2

Reads zero when not measuring flow.

109,

110

108,109 Forward

Total

IEEE 754 SP litres, Imp gallons, US

gallons,m3

RW Metric1, Imperial, US Imperial, Metric2

111,

112 110,111

Reverse

Total IEEE 754 SP

litres, Imp gallons, US

gallons,m3 RW Metric1, Imperial, US Imperial, Metric 2

113,

114 112,113

Fwd

Energy

Total

IEEE 754 SP kWH, BTU, BTU, kWH RW Metric1, Imperial, US Imperial, Metric2

115,

116 114,115

Rev

Energy

Total

IEEE 754 SP kWH, BTU, BTU, kWH RW Metric1, Imperial, US Imperial, Metric2

117-132 116-131 Reserved uint16× 16 RZ Reads Zero. Not used. Future Expansi-

on.

133,

134 132, 133

Instanta-

neous

Power

IEEE 754 SP kW, BTU/s, BTU/s, kW R

Metric1, Imperial, US Imperial, Metric2

Reads zero when not measuring flow.