2GF 2751-7 pH Electronics

Caution / Warning / Danger

Indicates a potential hazard. Failure to follow all warnings

may lead to equipment damage, injury, or death

Electrocution Danger

Alerts user to risk of

potential of injury or death via

electrocution.

Electrostatic Discharge (ESD)

Alerts user to risk of potential damage to product by ESD

Personal Protective Equipment (PPE)

Always utilize the most appropriate PPE during

installation and service of GF products.

Note / Technical Notes

Highlights additional information or detailed procedure.

Refer to your local Georg Fischer Sales oce for the most

current warranty statement.

All warranty and non-warranty repairs being returned must

include a fully completed Service Form and goods must be

returned to your local GF Sales oce or distributor.

Product returned without a Service Form may not be

warranty replaced or repaired.

GF products with limited shelf-life (e.g. pH, ORP, chlorine

electrodes, calibration solutions; e.g. pH buers, or other

solutions) are warranted out of box but not warranted against

any damage, due to process or application failures (e.g. high

temperature, chemical poisoning, dry-out) or mishandling (e.g.

broken glass, damaged membrane, freezing and/or extreme

temperatures).

• Remove electrical power from the transmitter before wiring

input connections.

• Follow instructions carefully to avoid personal injury or

damage to the electronics.

Warranty Information

Safety Information

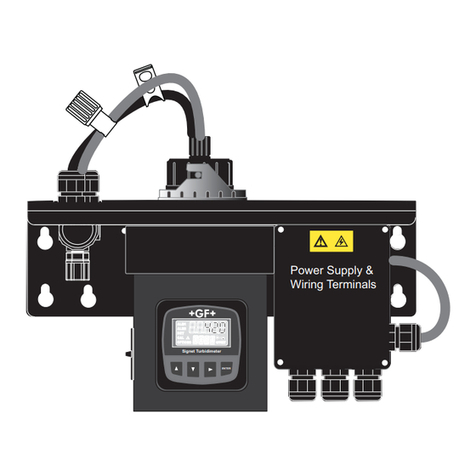

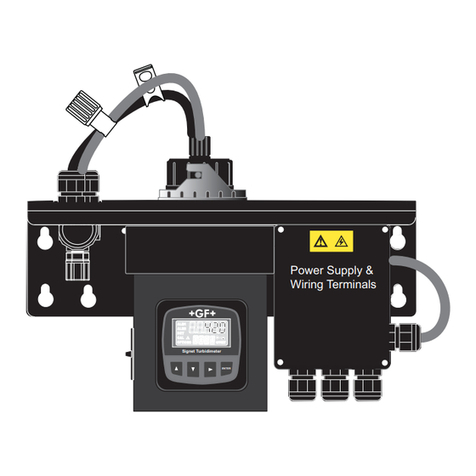

Dimensions

Specications

61.0 mm

(2.40 in.)

94 mm

(3.69 in.)

General

Compatible Electrode ..........2724-00 Flat pH Electrode

Compatible Instrument ........9950-X Chlorine Controller

Mounting ..............................DryLoc

®

connection

Materials ..............................PC+PBT

Cable ...................................4.6 m (15 ft) 3 conductor shielded,

22 AWG

Shipping Weight ..................0.64 kg (1.41 lb)

Performance

Electronics Accuracy ...........± 0.02 pH @ 25 °C

pH........................................ ≤ 0.01 pH

Response Time....................< 6 s for 95% of change

(includes electrode response)

Operational Range ..............-1.0 to 15.00 pH

Electrical

Input Specications

Input Impedance ..................> 10

11

Ω

Temperature Drift .................± 0.002 pH per ºC

Input Resolution...................0.02 pH, 0.3 ºC

Output Specications

Digital (S³L)..........................Serial ASCII, TTL level 9600 bps

Max. Cable Length ..............30 m (100 ft)

Environmental

Storage Temperature ...........–20 °C to 85 °C (–4 °F to 185 °F)

Operating Temperature ........0 °C to 85 °C (32 °F to 185 °F)

(electronics only)

Relative Humidity................. 0 to 95%, non-condensing

Enclosure Requirements .......NEMA 4X/IP65 with electrode

connected

Standards and Approvals

• CE, WEEE

• RoHS Compliant

• Manufactured under ISO 9001, ISO 14001 and ISO 45001

China RoHS (Go to gfsignet.com for details)

Declaration of Conformity according to FCC Part 15

This device complies with Part 15 of the FCC rules.

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) This device must accept any interference received,

including interference that may cause undesired operation.