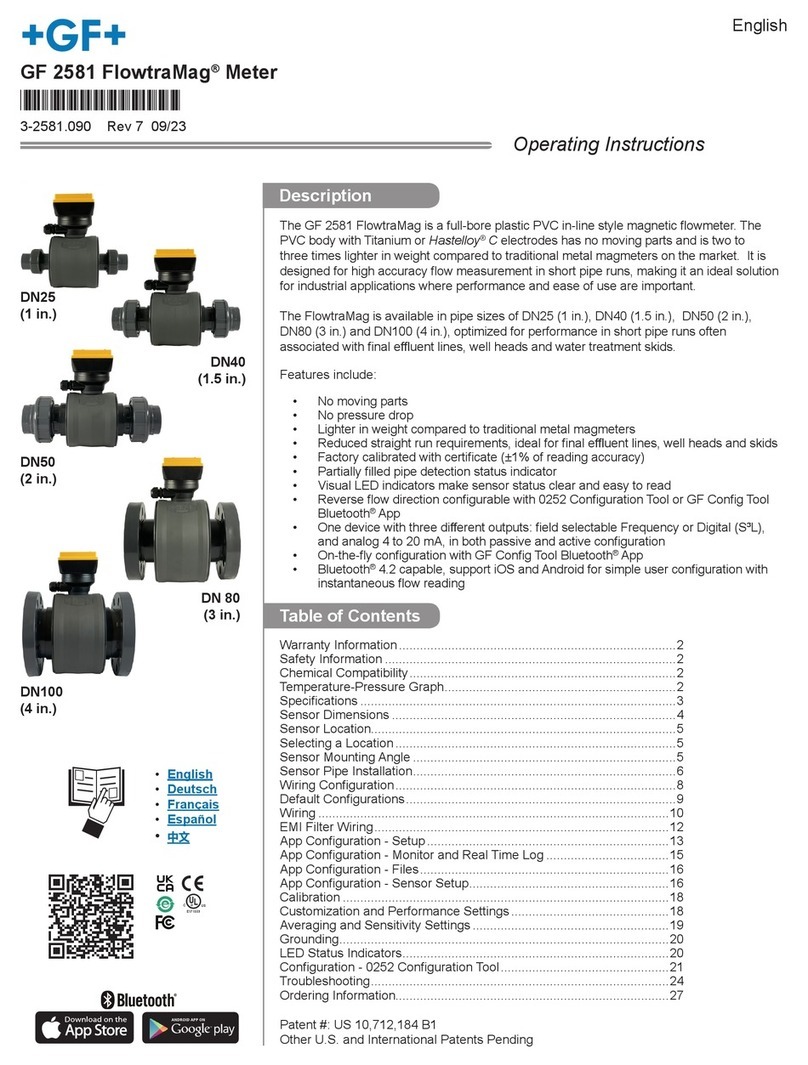

2Signet 8150 Flow Totalizer

Caution / Warning / Danger

Indicatesapotentialhazard.Failuretofollowallwarnings

mayleadtoequipmentdamage,injury,ordeath

Electrostatic Discharge (ESD) / Electrocution Danger

AlertsusertoriskofpotentialdamagetoproductbyESD,

and/orriskofpotentialofinjuryordeathviaelectrocution.

Hand Tighten Only

Overtighteningmaypermanentlydamageproductthreads

andleadtofailureoftheretainingnut.

Do Not Use Tools

Useoftool(s)maydamageproductbeyondrepairand

potentiallyvoidproductwarranty.

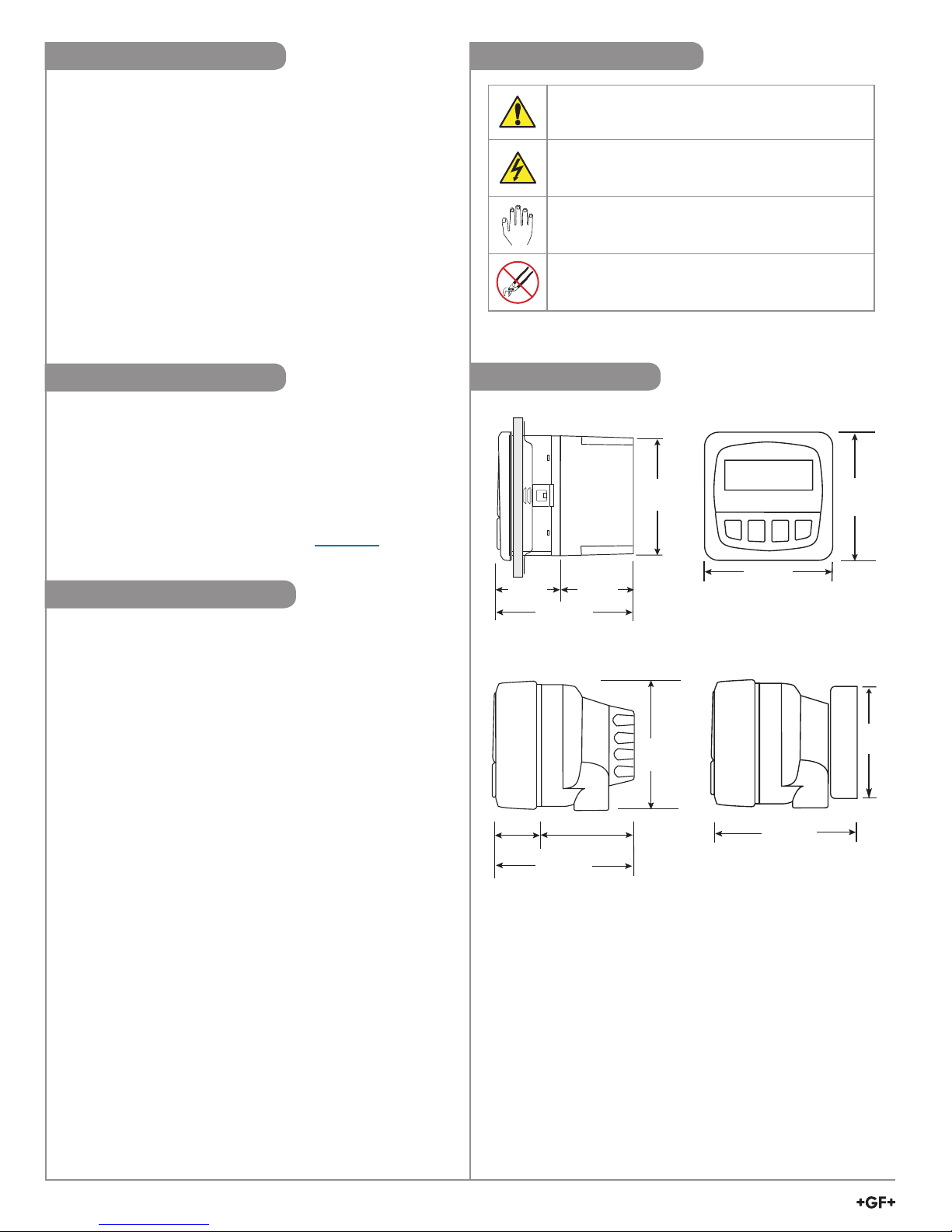

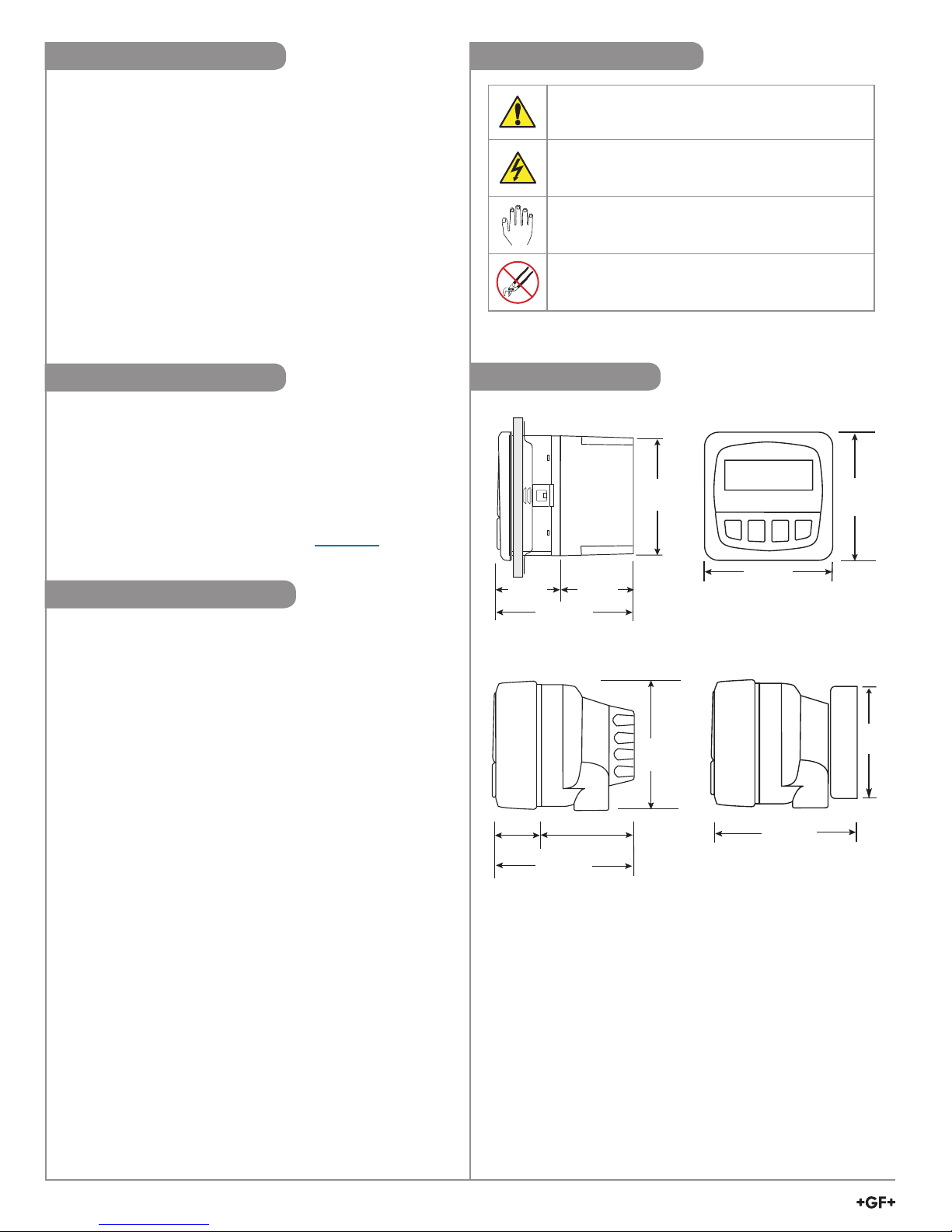

Dimensions

RefertoyourlocalGeorgFischerSalesofceforthemost

currentwarrantystatement.

Allwarrantyandnon-warrantyrepairsbeingreturnedmust

includeafullycompletedServiceFormandgoodsmustbe

returnedtoyourlocalGFSalesofceordistributor.

ProductreturnedwithoutaServiceFormmaynotbe

warrantyreplacedorrepaired.

Signetproductswithlimitedshelf-life(e.g.pH,ORP,chlorine

electrodes,calibrationsolutions;e.g.pHbuffers,turbidity

standardsorothersolutions)arewarrantedoutofboxbutnot

warrantedagainstanydamage,duetoprocessorapplication

failures(e.g.hightemperature,

chemicalpoisoning,dry-out)or

mishandling(e.g.brokenglass,

damagedmembrane,freezing

and/orextremetemperatures).

ThankyouforpurchasingtheSignetlineofGeorgFischer

measurementproducts.

Ifyouwouldliketoregisteryourproduct(s),youcannow

registeronlineinoneofthefollowingways:

• Visitourwebsitewww.gfsignet.com.

UnderService and Supportclickon

Product Registration Form

• Ifthisisapdfmanual(digitalcopy),click here

Chemical Compatibility

Warranty Information

Product Registration

Safety Information

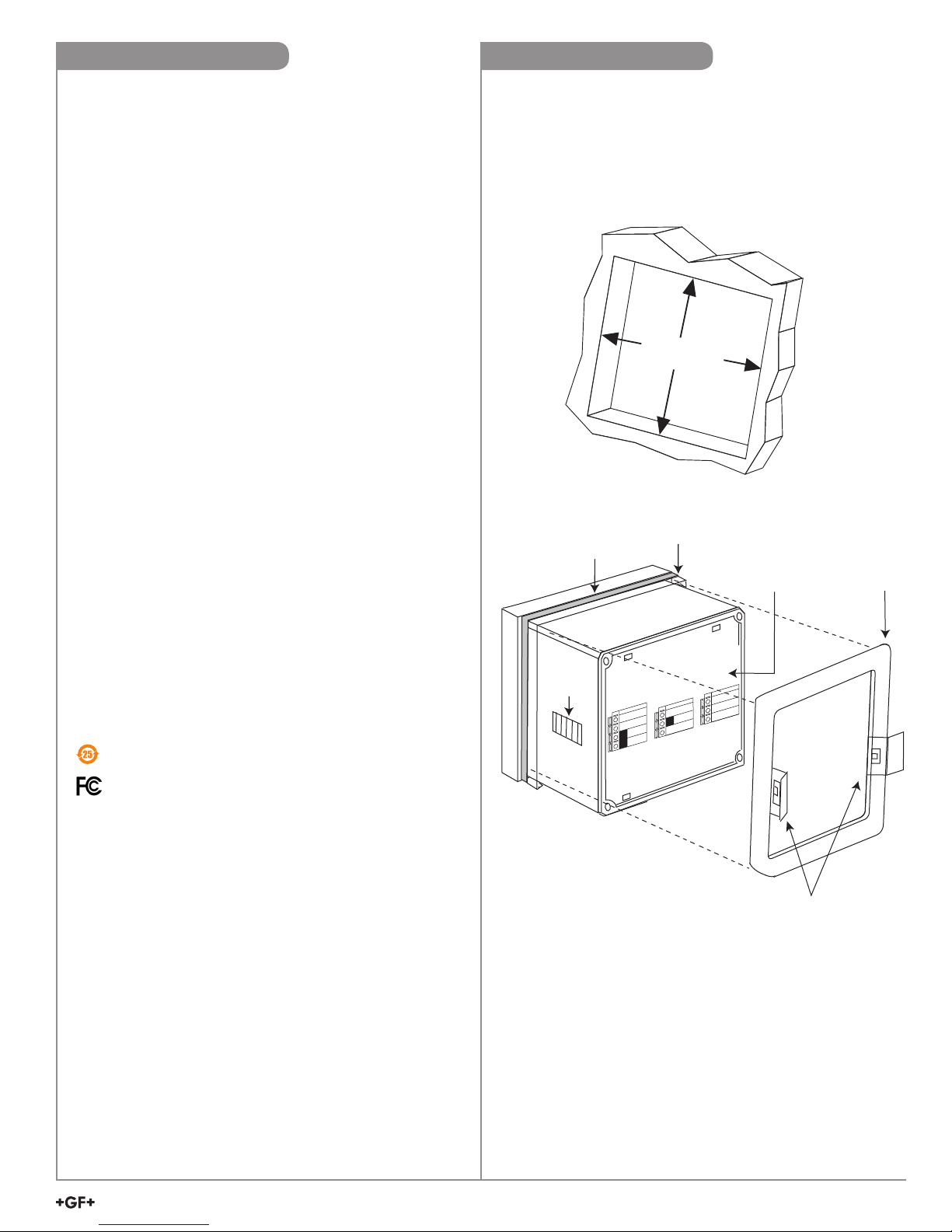

96 mm

(3.8 in.)

96 mm

(3.8 in.)

FRONT VIEW

106 mm

(4.2 in.)

82 mm

(3.2 in.)

Universal Mount

92 mm

(3.6 in.)

97 mm

(3.8 in.)

56 mm

(2.2 in.)

41 mm

(1.6 in.)

Optional

Rear

Cover

Panel Mount

SIDE VIEW

102 mm

(4.0 in.)

42 mm

(1.7 in.)

60 mm

(2.3 in.)

96 mm

(3.8 in.)

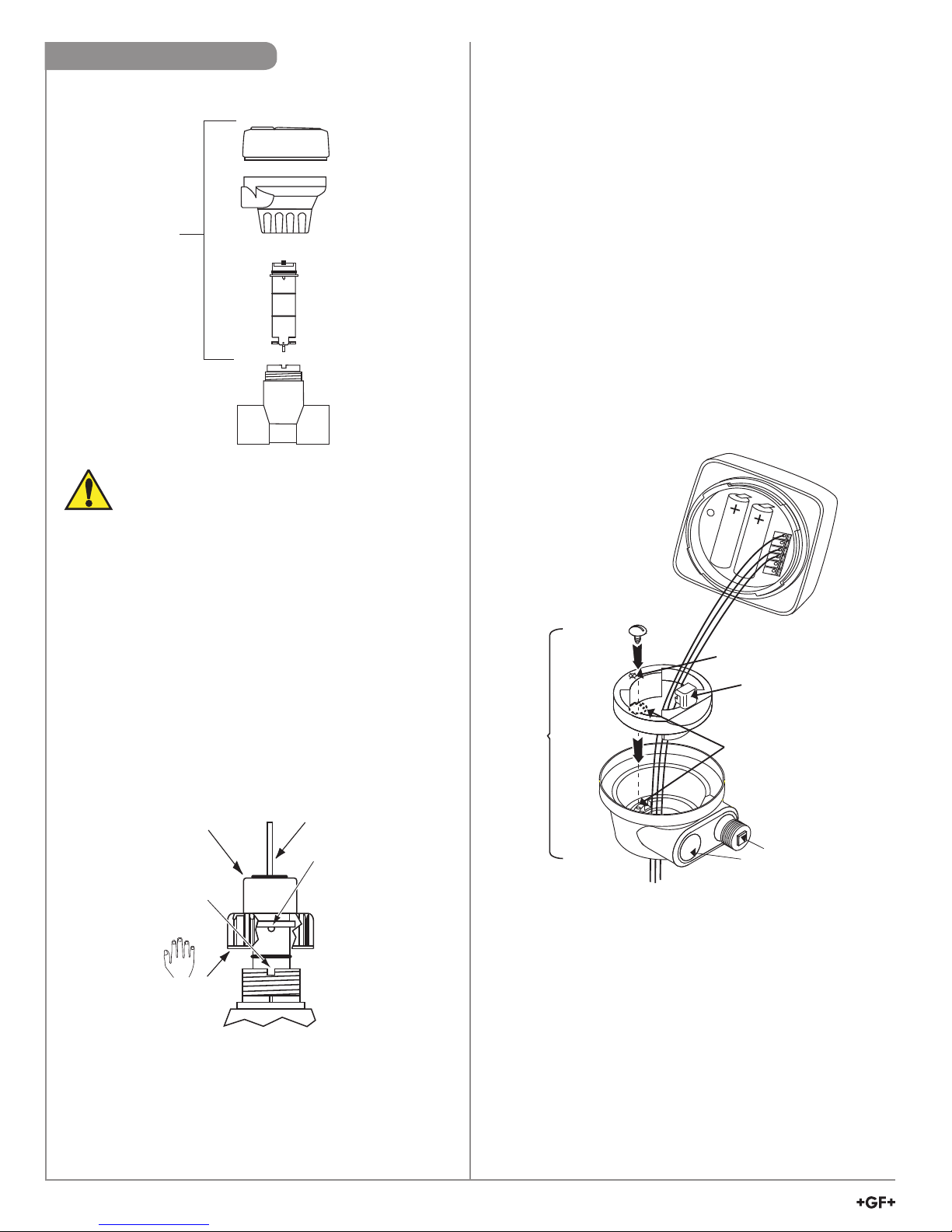

Theretainingnutsofpaddlewheelsensorsarenotdesigned

forprolongedcontactwithaggressivesubstances.Strong

acids,causticsubstancesandsolventsortheirvapormay

leadtofailureoftheretainingnut,ejectionofthesensorand

lossoftheprocessuidwithpossiblyseriousconsequences,

suchasdamagetoequipmentandseriouspersonalinjury.

Retainingnutsthatmayhavebeenincontactwithsuch

substances,e.g.,duetoleakageorspilling,mustbereplaced.

Integral Mount

96 mm

(3.8 in.)

96 mm

(3.8 in.)

FRONT VIEW

106 mm

(4.2 in.)

82 mm

Universal Mount

92 mm

(3.6 in.)

97 mm

(3.8 in.)

56 mm

(2.2 in.)

41 mm

(1.6 in.)

Optional

Rear

Cover

Panel Mount

SIDE VIEW

102 mm

(4.0 in.)

42 mm

(1.7 in.)

60 mm

(2.3 in.)

96 mm

(3.8 in.)