F4

2

IT

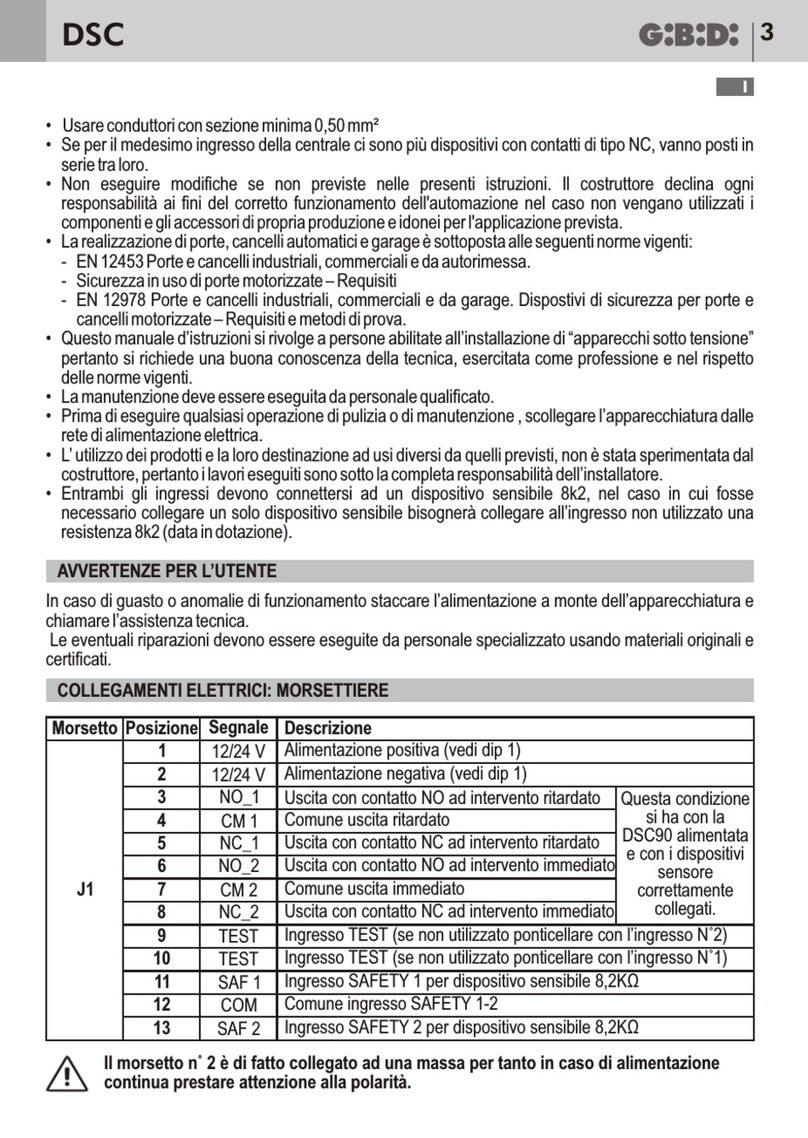

2 - CARATTERISTICHE TECNICHE / FUNZIONI

1 - CARATTERISTICHE TECNICHE

F4

115 Vac monofase 50/60 Hz

1 o 2

115 Vac

115 Vac 40W max

24 Vac 3W max

Ad innesto

-20°C +60°C

24 Vac 8W max

Apparecchiatura

Alimentazione

N° motori

Alimentazione motore

Lampeggiante

Lampada spia

Ricevitore radio

Temperatura di utilizzo

Alimentazione accessori

Tipo

AS06321

Codice

12 Vac 15W max

Elettroserratura

IP55

Grado di protezione

Apparecchiatura elettronica per l’automazione di

un cancello a battente, scorrevole, porta basculante o barriera

con uno o due motori a 115Vac

• LED rossi di segnalazione dei contatti N.C. (FCAM1-FCCM1-FCAM2-FCCM2-PHOTO-STOP).

• LED verdi di segnalazione dei contatti N.A. (START-PED).

• Gestione di 1 elettroserratura 12Vac.

• Gestione del colpo d’ariete per sganciare l’elettroserratura e del colpo finale per agganciare l’elettroserratura.

Attivando il colpo d’ariete si attiva anche il colpo finale in chiusura (1s di moto extra).

• Apprendimento del tempo di lavoro tramite procedura o impostato con trimmer.

• Rallentamenti in apertura e chiusura, solo tramite procedura di apprendimento tempi.

• Regolazione del tempo di pausa e sfasamento.

• Gestione del lampeggiatore fisso o intermittente.

• Gestione della luce di cortesia.

• Programmazione della chiusura automatica.

• Fotocellula attiva in chiusura (il funzionamento in apertura è selezionabile con un dip switch).

• Regolazione della forza del motore con opportuno trimmer.

• Gamma di funzionamento: Automatica - Passo Passo con stop, Pedonale.

• Gestione dell’ingresso STOP con funzionamento come stop (blocco) o costa (liberazione ostacolo).

• Mantenimento oleodinamico per motori oleodinamici (DIP1_10 ON).

• Dip switch di esclusione degli ingressi FINECORSA e FOTOCELLULA, se non utilizzati.

AVVERTENZE:

Questo prodotto è stato collaudato in GI.BI.DI. verificando la perfetta corrispondenza delle caratteristiche alle direttive vigenti.

GI.BI.DI. S.r.l. si riserva la facoltà di modificare i dati tecnici senza avviso, in funzione dell’evoluzione del prodotto.

LEGGERE ATTENTAMENTE QUESTO MANUALE PRIMA DI PROCEDERE ALL’INSTALLAZIONE.

Grazie per avere scelto GIBIDI.

SMALTIMENTO: GI.BI.DI. consiglia di riciclare i componenti in plastica e di smaltire in appositi centri abilitati

I componenti elettronici evitando di contaminare l'ambiente con sostanze inquinanti.

F4 3

IT

3 - AVVERTENZE PER L’INSTALLAZIONE

4 - AVVERTENZE PER L’UTENTE

In caso di guasto o anomalie di funzionamento staccare l’alimentazione a monte dell’apparecchiatura e chiamare

l’assistenza tecnica. Verificare periodicamente il funzionamento delle sicurezze. Le eventuali riparazioni devono

essere eseguite da personale specializzato usando materiali originali e certificati.

Il prodotto non deve essere usato da bambini o persone con ridotte capacità fisiche, sensoriali o mentali, oppure

mancanti di esperienza e conoscenza, a meno che non siano stati correttamente istruiti. Non accedere alla

scheda per regolazioni e/o manutenzioni.

• Prima di procedere con l’installazione bisogna predisporre a monte dell’impianto un interruttore magneto

termico e differenziale con portata massima 10A. L’interruttore deve garantire una separazione omnipolare dei

contatti, con distanza di apertura di almeno 3 mm.

• Per evitare possibili interferenze, differenziare e tenere sempre separati i cavi di potenza (sezione minima

1,5mm²) dai cavi di segnale (sezione minima 0,5mm²).

• Eseguire i collegamenti facendo riferimento alle tabelle seguenti e alla serigrafia sulla scheda. Fare molta

attenzione a collegare in serie tutti i dispositivi che vanno collegati allo stesso ingresso N.C. (normalmente

chiuso) e in parallelo tutti i dispositivi che condividono lo stesso ingresso N.O. (normalmente aperto).

• Una errata installazione o un uso errato del prodotto può compromettere la sicurezza dell’impianto.

• Tutti i materiali presenti nell’imballo non devono essere lasciati alla portata dei bambini in quanto potenziali

fonti di pericolo.

• Il costruttore declina ogni responsabilità ai fini del corretto funzionamento dell'automazione nel caso non

vengano utilizzati i componenti e gli accessori di propria produzione e idonei per l'applicazione prevista.

• Al termine dell’istallazione verificare sempre con attenzione il corretto funzionamento dell’impianto e dei

dispositivi utilizzati.

• Questo manuale d’istruzioni si rivolge a persone abilitate all’installazione di “apparecchi sotto tensione” pertan-

to si richiede una buona conoscenza della tecnica, esercitata come professione e nel rispetto delle norme vigenti.

• La manutenzione deve essere eseguita da personale qualificato.

• Prima di eseguire qualsiasi operazione di pulizia o di manutenzione, scollegare l’apparecchiatura dalle rete di

alimentazione elettrica.

• L’apparecchiatura qui descritta deve essere utilizzata solo all’uso per il quale è stata concepita.

• Verificare lo scopo dell'utilizzo finale e assicurarsi di prendere tutte le sicurezze necessarie.

• L’utilizzo dei prodotti e la loro destinazione ad usi diversi da quelli previsti, non è stata sperimentata dal

costruttore, pertanto i lavori eseguiti sono sotto la completa responsabilità dell’installatore.

• Segnalare l’automazione con targhe di avvertenza che devono essere visibili.

• Avvisare l’utente che bambini o animali non devono giocare o sostare nei pressi del cancello.

• Proteggere adeguatamente i punti di pericolo (per esempio mediante l’uso di una costa sensibile).

• Non installare in ambiente esplosivo.

ATTENZIONE: IMPORTANTI ISTRUZIONI DI SICUREZZA.

E' importante per la sicurezza delle persone seguire queste istruzioni.

Conservare il presente libretto di istruzioni.