17

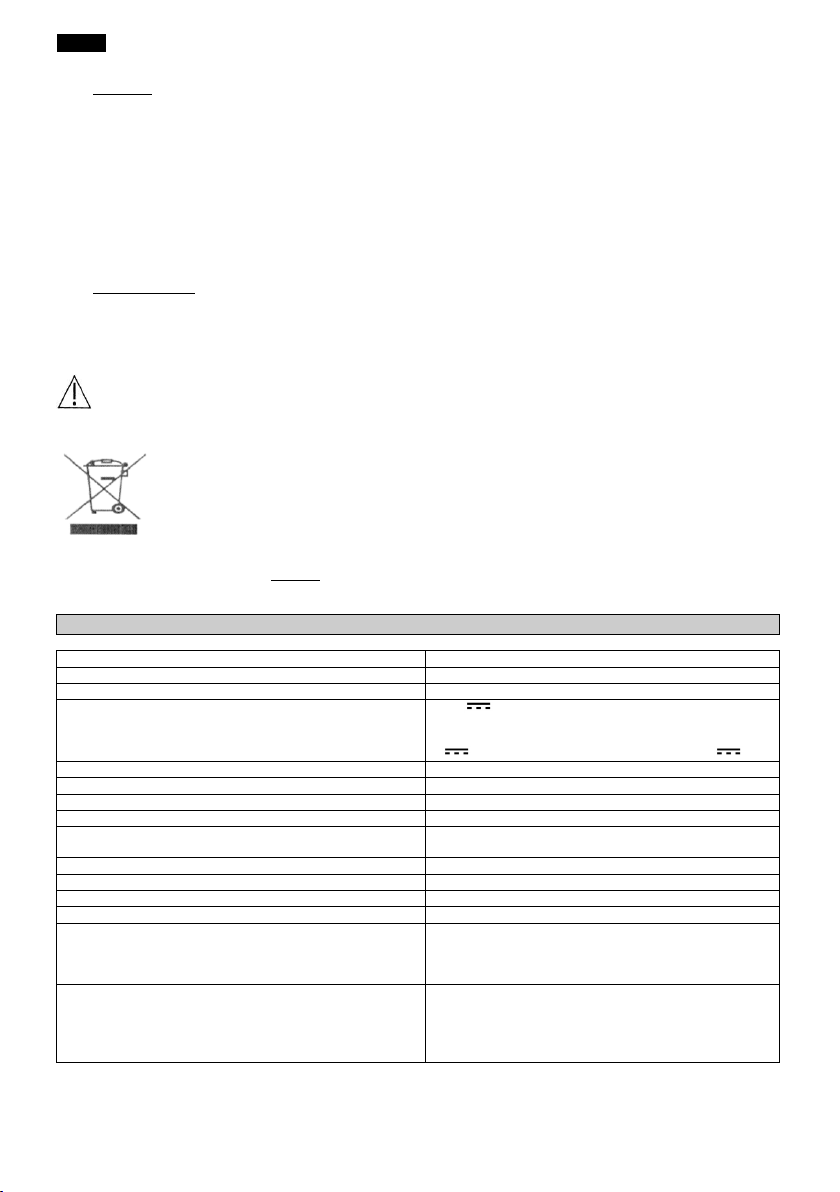

SUPERVEGA EVO BATTERY ASPIRATOR is a surgical aspirator with the following electrica features : 14V 4A with AC/DC

adapter mod. UE60-140429SPA1 of FUHUA (input: 100-240V~ - 50/60Hz - 100VA) or Internally powered equipment (Li-Ion

Battery 14.8V 5.2A) or with cigarette lighter adapter (12V 4A). SUPERVEGA EVO BATTERY ASPIRATOR is a desk-

type electric suction unit for the aspiration of body liquids, oral, nasal and tracheal aspiration in adults or children. This device has

been designed to offer ease of transport and continuous use, thanks to an electronic system that manages the power supply. The

large LCD display facilitates the use of the device and increases suction by adjusting the control buttons.

The signal on the LCD screen, placed on the front panel, allows you to monitor the charge status of the Lithium battery. The lithium

battery and the innovative Feedback system, which guarantees a smart use by automatically controlling and adjusting the suction

power, allow the battery to increase its autonomy and decrease the noise produced.

The "PROXIMITY" function allows the device to be activated/deactivated via an infra-red proximity sensor (detecting the presence

of the hand from a distance of tenths of centimetres without touching the suction unit) and it prevents and avoids possible cross-

contamination between patients as they are treated in turns.

Made of highly heat resistant, electrically insulated plastic material in conformity with the latest European safety standard, the

product is supplied with a complete polycarbonate autoclavable jar with overflow valve.

READ INSTRUCTION MANUAL CAREFULLY BEFORE USE.

THE DEVICE IS FOR USE BY QUALIFIED PERSONNEL (SURGEON / PROFESSIONAL NURSE / ASSISTANT)

THE USE OF THE DEVICE AT HOME IS RESTRICTED TO AN ADULT IN FULL POSSESSION OF MENTAL FACULTIES AND / OR

HOME CARERS

THE INSTRUMENT MUST NOT DISASSEMBLED. FOR TECHNICAL SERVICE ALWAYS CONTACT GIMA S.p.A.

1. Check the condition of the unit before each use. The surface of the unit should carefully inspected for visual damage.

Check the mains cable and do not connect to power if damage is apparent;

2. Before connecting the appliance always check that the electric data indicated on the data label and the type of plug used,

correspond to those of the mains electricity to witch it’s to be connected;

3. Respect the safety regulations indicated for electrical appliances and particularly:

Use original components and accessories provided by the manufacturer to guarantee the highest efficiency and safety

of the device;

The device can be used only with the bacteriological filter;

Never immerge the appliance into water;

Do not place or store the aspirator in places where it may fall or be pulled into the bathtub or washbasin. In the event

it is accidentally dropped, do not attempt to remove the device from the water whilst the plug is still connected:

disconnect the mains switch, remove the plug from the power supply and contact the GIMA technical service

department. Do not attempt to make the device work before it has been thoroughly checked by qualified personnel

and/or the GIMA technical service department.

Position the device on stable and flat surfaces in a way that the air inlets on the back aren’t obstructed;

To avoid incidents, do not place the aspirator on unstable surfaces, which may cause it to accidentally fall and lead to a

malfunction and/or breakage. Should there be signs of damage to the plastic parts, which may expose inner parts of

the energised device, do not connect the plug to the electrical socket. Do not attempt to make the device work

before it has been thoroughly checked by qualified personnel and/or the GIMA technical service department.

Don’t use in the presence of inflammable substances such as anaesthetic, oxygen or nitrous oxide;

Don’t touch the device with wet hands and always prevent the appliance coming into contact with liquids;

Don’t leave the appliance connected to the power supply socket when not in use;

Don’t pull the power supply cable to disconnect the plug remove the plug from the mains socket correctly;

Store and use the device in places protected against the weather and far from any sources of heat. After each use, it is

recommended to store the device in its own box away from dust and sunlight.

Don’t use the device thoracic drainage.

In general, it is inadvisable to use single or multiple adapters and/or extensions. Should their use be necessary, you

must use ones that are in compliance with safety regulations, however, taking care not to exceed the maximum power

supply tolerated, which is indicated on the adapters and extensions.

4. For repairs, exclusively contact technical service and request the use of original spare parts.

Failure to comply with the above can jeopardise the safety of the device;

5. Use only for the purpose intended. Don’t use for anything other than the use defined by the manufacturer.

The manufacturer will not be responsible for damage due to improper use or connection to an electrical system not

complying with current regulation.

6. The medical device requires special precautions regarding electromagnetic compatibility and must be installed and used in

accordance with the information provided with the accompanying documents: the SUPERVEGA EVO device must be installed

and used away from mobile and portable RF communication devices (mobile phones, transceivers, etc.) that may

interference with the said device.