5

Important safety information

• Our products in compliance with EN 179 and EN 1125 guarantee a very high quality and safety

standard. In order to ensure that this high standard is maintained, the doors must remain in faultless

condition during and after assembly. The door must be tested for correct, smooth, and unimpeded

opening and may not show any signs of warpage.

• With the use of profile seals and door seals, it must be ensured that they do not impair the use of the

door as intended and/or the proper function of the panic door lock.

• Before the panic door lock is installed on a fire-proof or smoke protection door, it should be

determined whether the panic door lock is suitable for this special door.

• Fasteners differing from those included in the scope of supply may be necessary for fastening a panic

lock on various types of doors. In the process, a permanent and solid fixing means should be chosen by

the installer according to the requirements.

• Panic door locks are not suitable for use on swing doors unless they have been specially designed by the

manufacturer for this purpose.

• Panic door locks should normally be installed at a height of 900 mm to 1100 mm above the surface of

the finished floor with the door closed. If the majority of the door users are small children, a lowering

of the actuation bar height should be taken into consideration.

• If a door closer is installed, it should be ensured that the actuation of the door is not rendered

unnecessarily difficult for children or physically impaired and elderly persons.

• The lock with striking plate should be fastened such that secure engagement is assured. It should be

ensured that protrusion in the engaged position of the latch and bolt does not prevent the door from

moving freely.

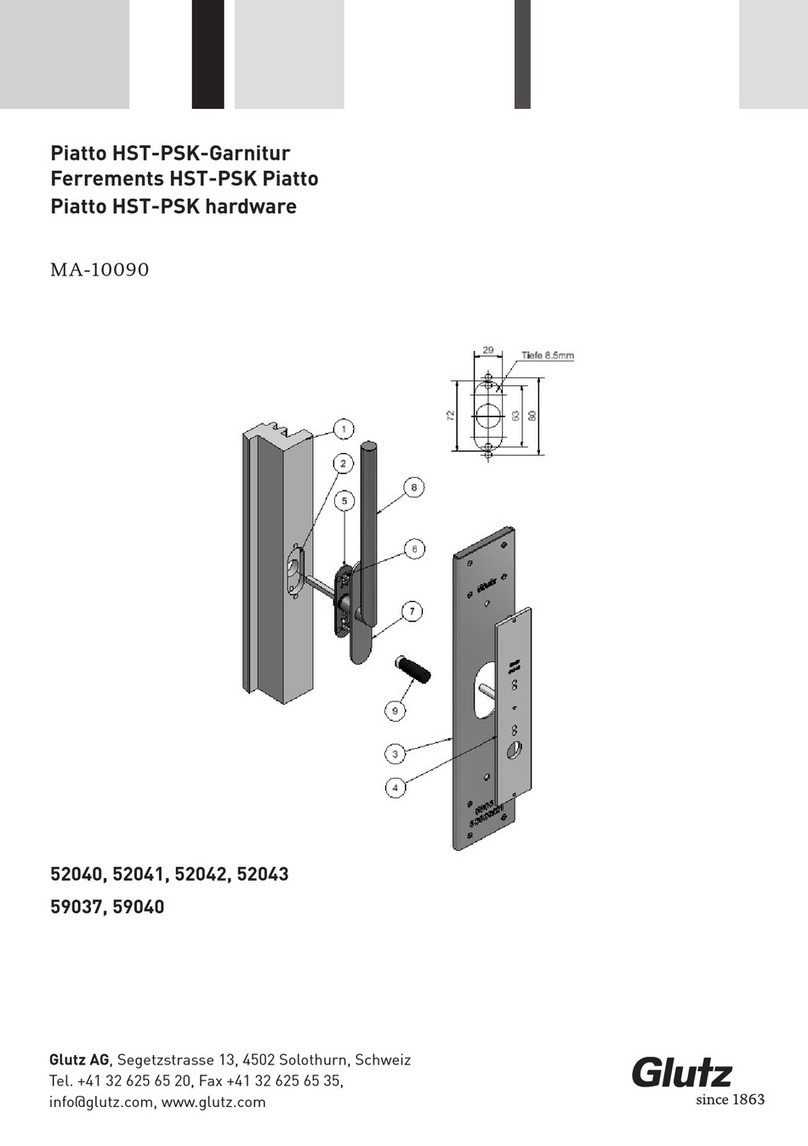

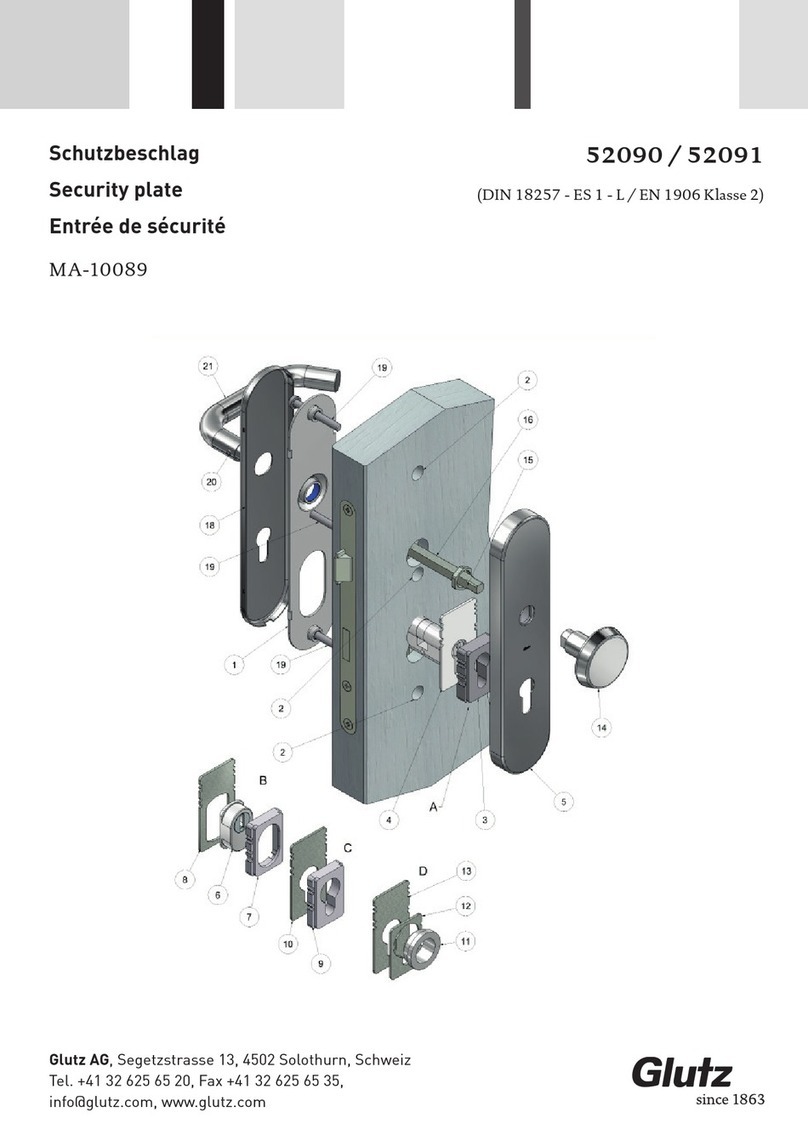

• The provided striking plates should be installed as indicated in the manual such that conformity with

the tested standard element is assured.

A plate with the inscription ‚Turn the handle to open‘ (EN 179), or a

pictogram should be affixed on the inside of the door, directly above the

fitting or on the fitting itself, if it has a sufficiently large and level surface for

the necessary inscription.

The bolt of the lock must always be able to engage in the striking plate fre-

ely and without friction, even if pressure is exerted on the door. Fasten the

striking plate (if available) in the frame. The contour of the striking plate

must be adapted to the door situation as necessary. (see the contour for the

striking plate recess)